The global temperature calibration equipment market is experiencing steady growth, driven by increasing demand for precision measurement across industries such as pharmaceuticals, food and beverage, and energy. According to Mordor Intelligence, the global temperature sensor market—which closely aligns with calibration technologies—is projected to grow at a CAGR of over 5.5% from 2023 to 2028. This expansion underscores the rising need for reliable and accurate temperature calibration tools, including dry block temperature calibrators. These devices offer portability, speed, and ease of use, making them a preferred choice for field and laboratory applications. As regulatory standards tighten and quality assurance becomes more critical, manufacturers are investing in advanced calibration solutions to ensure compliance and operational efficiency. In this context, leading dry block temperature calibrator manufacturers are leveraging innovation, traceable standards, and global distribution networks to capture a growing share of this expanding market. The following list highlights the top nine companies shaping the industry through performance, reliability, and technological advancement.

Top 9 Dry Block Temperature Calibrator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Handheld and dry block calibrators

Domain Est. 1986

Website: fluke.com

Key Highlights: Fluke Calibration offers handheld and dry block calibrators for industrial temperature calibration. Wide temperature range, high accuracy….

#2 Dry Block Solutions

Domain Est. 1996

Website: ellab.com

Key Highlights: All Dry Block calibrators feature portability, accuracy, speed and advanced documenting functions via the calibration software….

#3 Accurate and portable temperature dry block calibrators

Domain Est. 1996

Website: beamex.com

Key Highlights: Beamex offers various dry block calibrators for temperature calibration for field and laboratory use in process industry….

#4 Dry Block and Liquid Bath Temperature Calibrators

Domain Est. 2001

Website: kayeinstruments.com

Key Highlights: High-accuracy dry block calibrators and liquid bath calibrators engineered for consistent, compliant temperature calibration across critical applications….

#5 ETC Series Easy Temperature Calibrators

Domain Est. 2002

Website: ametekcalibration.com

Key Highlights: The ETC Series is the ideal dry block temperature calibrator when time is the critical factor and the highest accuracy is not a requirement….

#6 Isotech

Domain Est. 2002

Website: isotechna.com

Key Highlights: Isotech makes temperature calibration equipment, including thermometers, fixed point cells, block calibrators, and more. Get accurate readings with Isotech!…

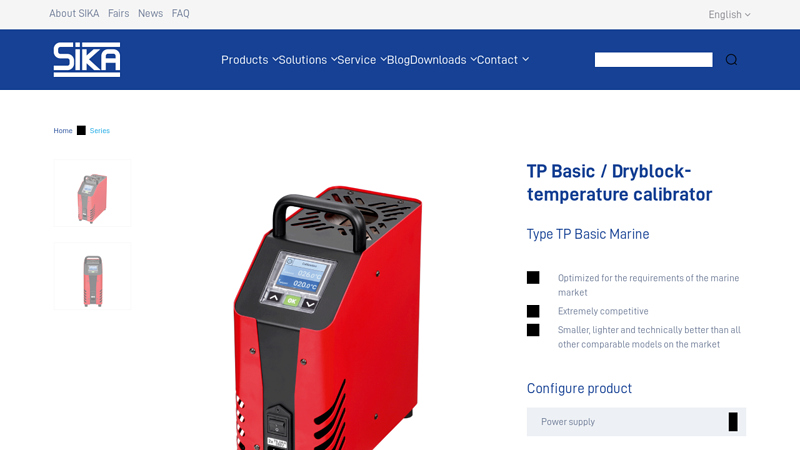

#7 TP Basic/Dryblock

Domain Est. 2003

Website: sika-usa.com

Key Highlights: The easy operation, the integrated internal reference temperature sensor and the dry block calibration function ensure an extremely easy calibration process….

#8 Advanced Dry Block Temperature Calibrator

Domain Est. 2005

Website: tempsens.com

Key Highlights: Improve calibration accuracy with Tempsens’ dry block calibrators. Ideal for industries requiring precise temperature measurement and reliable results….

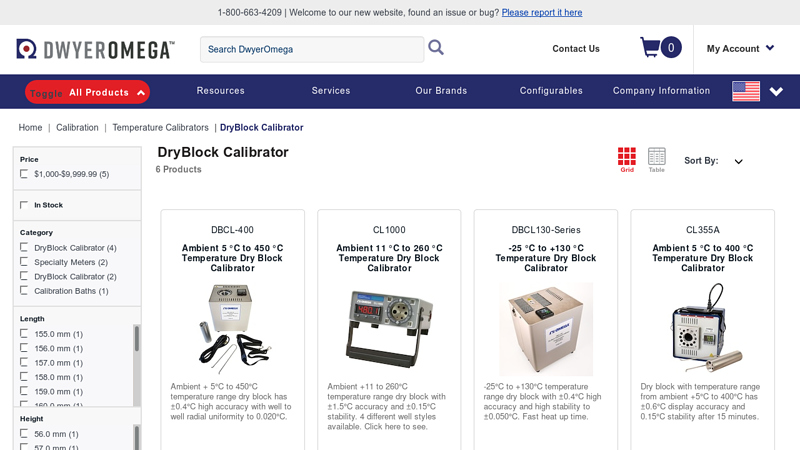

#9 Dry Block Calibrators

Domain Est. 2022

Expert Sourcing Insights for Dry Block Temperature Calibrator

H2: 2026 Market Trends for Dry Block Temperature Calibrators

The global market for dry block temperature calibrators is expected to experience steady growth through 2026, driven by increasing demand for precision, efficiency, and compliance across regulated industries. Key trends shaping the market include technological advancements, growing emphasis on automation, expansion in emerging economies, and stricter regulatory standards.

-

Technological Innovation and Smart Features

By 2026, dry block calibrators are anticipated to integrate more advanced digital features such as wireless connectivity (Bluetooth and Wi-Fi), cloud-based data logging, and compatibility with calibration management software. These enhancements enable real-time monitoring, remote operation, and improved traceability—critical for industries like pharmaceuticals, food safety, and aerospace. -

Demand for Portability and Field Calibration

There is a rising preference for compact, lightweight, and battery-operated dry block calibrators, especially in field service applications. The trend supports on-site maintenance and reduces equipment downtime. In 2026, manufacturers are likely to focus on ruggedized, portable models designed for harsh environments. -

Expansion in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are expected to see increased adoption of dry block calibrators due to industrialization, infrastructure development, and growth in pharmaceutical and manufacturing sectors. Local regulatory bodies are also tightening compliance requirements, boosting investment in calibration equipment. -

Regulatory Compliance and Quality Standards

Industries such as healthcare, energy, and manufacturing are under growing pressure to meet ISO/IEC 17025, FDA, and other international standards. This drives demand for high-accuracy, traceable calibration tools. Dry block calibrators offering NIST-traceable certifications and integrated documentation will be in higher demand. -

Shift Toward Multi-Function and Modular Systems

Manufacturers are responding to customer needs by offering modular inserts and multi-temperature block systems capable of calibrating various probe types and sizes. This versatility improves cost-efficiency and reduces the need for multiple dedicated calibrators. -

Sustainability and Energy Efficiency

Environmental considerations are beginning to influence product design. By 2026, energy-efficient heating and cooling mechanisms, longer operational cycles on battery power, and reduced material waste in production may become selling points. -

Competitive Landscape and Market Consolidation

The market is expected to see continued innovation from key players such as Fluke, Beamex, AMETEK, and WIKA. Increased competition may lead to strategic partnerships, mergers, or expanded service offerings, including calibration-as-a-service (CaaS) models.

In conclusion, the 2026 dry block temperature calibrator market will be defined by smarter, more connected, and user-centric devices tailored to meet evolving industrial and regulatory demands. Companies investing in R&D, digital integration, and global distribution networks are likely to capture significant market share.

Common Pitfalls When Sourcing a Dry Block Temperature Calibrator (Quality and IP Considerations)

Sourcing a Dry Block Temperature Calibrator (DBTC) requires careful evaluation to ensure long-term reliability, accuracy, and suitability for your application. Overlooking critical quality and Ingress Protection (IP) factors can lead to inaccurate calibrations, safety hazards, and costly downtime. Below are key pitfalls to avoid.

Poor Build Quality and Material Selection

Choosing a DBTC based solely on price often leads to units constructed with substandard materials. Low-quality aluminum blocks may warp or corrode over time, reducing thermal uniformity and lifespan. Similarly, poorly finished heating elements can result in hotspots and inconsistent temperature distribution. Always verify the manufacturer uses high-grade, anodized aluminum for inserts and stainless steel for housings where appropriate. Check for robust construction, smooth bore alignment, and precise machining tolerances to ensure repeatability and durability.

Inadequate Ingress Protection (IP) Rating for the Environment

One of the most overlooked factors is the IP rating in relation to the operating environment. A DBTC with a low IP rating (e.g., IP20) is only protected against large solid objects and offers no liquid protection—making it unsuitable for industrial or laboratory settings where spills, dust, or moisture are present. Using such a unit in harsh environments risks internal contamination, electrical failure, or measurement drift. Always match the IP rating to your environment: IP54 or higher is recommended for workshops or field use, offering protection against dust and water splashes.

Lack of Traceable Calibration and Certification

Purchasing a DBTC without proper traceable calibration documentation undermines its purpose. Some suppliers offer “as calibrated” units without accredited certificates (e.g., ISO/IEC 17025), leading to non-compliance with quality standards like ISO 9001 or ISO/IEC 17025. Ensure the unit comes with a valid, accredited calibration certificate from a recognized body, including measurement uncertainty and traceability to national standards.

Insufficient Temperature Uniformity and Stability Specifications

Not all dry blocks perform equally across their range. Some lower-quality models claim wide temperature ranges but fail to maintain adequate uniformity (< ±0.5°C) or stability (< ±0.1°C) across the block and over time. This leads to inconsistent calibration results, especially when verifying multiple sensors simultaneously. Review published performance data under real-world conditions and verify claims with independent test reports if available.

Missing Safety Features and Compliance

Low-cost units may lack essential safety certifications (e.g., CE, UKCA, UL) or critical protection mechanisms like over-temperature shutdown, thermal fuses, or ground fault protection. Using non-compliant equipment poses risks to personnel and equipment. Always confirm the DBTC meets relevant electrical safety standards and includes fail-safe design features.

Incompatible or Poor-Quality Inserts

Interchangeable inserts are vital for versatility, but poorly manufactured inserts can create air gaps, leading to inaccurate heat transfer and longer stabilization times. Ensure inserts are precisely machined, clearly labeled, and made from compatible materials. Avoid kits with thin-walled or poorly finished bores that degrade quickly with repeated use.

Neglecting Long-Term Support and Spare Parts Availability

Even high-quality units require maintenance. Sourcing from suppliers with poor after-sales support or limited spare parts (e.g., replacement inserts, sensors, or heating elements) can render the calibrator unusable prematurely. Evaluate the manufacturer’s service network, warranty terms, and availability of consumables before purchase.

By addressing these quality and IP-related pitfalls during procurement, you ensure the DBTC delivers accurate, reliable, and safe performance throughout its service life.

Logistics & Compliance Guide for Dry Block Temperature Calibrator

Regulatory Compliance

Ensure all Dry Block Temperature Calibrators comply with relevant international and local standards, including but not limited to ISO/IEC 17025 for calibration laboratories, IEC 61326-1 for electromagnetic compatibility, and applicable national electrical safety standards (e.g., UL, CE, or UKCA marking). Devices must be supplied with a valid calibration certificate traceable to national or international standards (e.g., NIST, PTB). Verify that calibration documentation includes measurement uncertainty, environmental conditions during calibration, and accreditation body details where applicable. Maintain records of all compliance documentation for audit purposes.

Transportation & Handling

Package Dry Block Temperature Calibrators securely using manufacturer-recommended packaging to prevent physical damage during transit. Use shock-absorbing materials and rigid outer containers. Label packages with “Fragile,” “This Side Up,” and “Temperature-Sensitive” indicators as appropriate. Avoid exposure to extreme temperatures, moisture, and vibration during shipping. For international shipments, comply with IATA/ICAO regulations if transporting lithium batteries (if applicable). Ensure handlers are trained in proper lifting techniques to prevent injury and equipment damage.

Import/Export Documentation

Prepare complete import/export documentation including commercial invoice, packing list, certificate of origin, and equipment-specific conformity declarations. For controlled goods or dual-use items, verify if export licenses are required under regulations such as the EU Dual-Use Regulation or U.S. Export Administration Regulations (EAR). Include technical specifications (e.g., temperature range, power requirements) to support accurate customs classification. Retain digital and physical copies of all documentation for a minimum of five years.

Storage Conditions

Store Dry Block Temperature Calibrators in a clean, dry, temperature-controlled environment (typically 15–30°C, 30–70% RH unless otherwise specified by the manufacturer). Avoid direct sunlight, corrosive atmospheres, and magnetic fields. Keep devices in protective cases or original packaging when not in use. Implement a first-in, first-out (FIFO) inventory system to minimize prolonged storage. Perform periodic visual inspections and functional checks to ensure readiness for deployment.

Installation & Commissioning

Install and commission units according to manufacturer guidelines and local electrical codes. Verify power supply compatibility (voltage, frequency, grounding). Conduct initial performance verification using a reference thermometer traceable to national standards. Document installation details, including location, environmental conditions, and verification results. Update asset management records and assign unique identification numbers. Train designated personnel on safe operation and basic troubleshooting procedures.

Maintenance & Recalibration

Schedule routine maintenance and recalibration at intervals specified by the manufacturer or quality management system (typically annually). Use accredited calibration laboratories that adhere to ISO/IEC 17025. Maintain a log of all maintenance, repairs, and calibration events, including dates, technicians, findings, and corrective actions. Store calibration certificates with device records. Remove from service any unit failing calibration until repaired and successfully recalibrated.

Disposal & End-of-Life

Dispose of end-of-life Dry Block Temperature Calibrators in compliance with local electronic waste (WEEE) regulations. Remove batteries (if present) and recycle separately according to hazardous waste guidelines. Document disposal through certified waste management providers. Retain disposal records to support environmental compliance and audit requirements.

Conclusion:

After evaluating various suppliers and models, sourcing a dry block temperature calibrator is a strategic decision that enhances the accuracy, efficiency, and portability of temperature calibration processes. These devices offer rapid heating and cooling, excellent temperature stability, and ease of use across a wide range of industrial, laboratory, and field applications. Key factors such as temperature range, accuracy, interchangeability of inserts, calibration traceability, and technical support significantly influence the selection process.

Choosing a reputable supplier with certified calibration standards (e.g., ISO 17025 accreditation), reliable customer service, and cost-effectiveness ensures long-term reliability and compliance with quality standards. Ultimately, investing in a high-quality dry block temperature calibrator not only improves measurement consistency but also supports regulatory compliance and operational efficiency. Therefore, sourcing from a trusted manufacturer with proven performance and after-sales support is recommended to meet current and future calibration needs effectively.