The global industrial fan market is experiencing robust growth, driven by rising demand for efficient ventilation and cooling systems across heavy industries such as manufacturing, power generation, and mining. According to Grand View Research, the global industrial fans market size was valued at USD 5.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increasing industrial automation, stricter environmental regulations, and the need for energy-efficient air movement solutions. Within this expanding landscape, drum fans—known for their high-volume, low-speed (HVLS) operation and superior airflow distribution—have emerged as critical components in large-scale industrial applications. As demand intensifies, a select group of manufacturers have distinguished themselves through innovation, durability, and technical expertise. Based on market presence, production capacity, and technological advancement, here are the top 9 drum fans industrial manufacturers shaping the future of industrial air solutions.

Top 9 Drum Fans Industrial Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Order A Large Industrial Portable Drum Fan

Domain Est. 1995

Website: industrialfans.hunterfan.com

Key Highlights: In stock Rating 5.0 (1) Our portable Drum Fan is available in 36″ or 42″ and is the ideal solution for warehouses, manufacturing plants, automotive facilities and any space where…

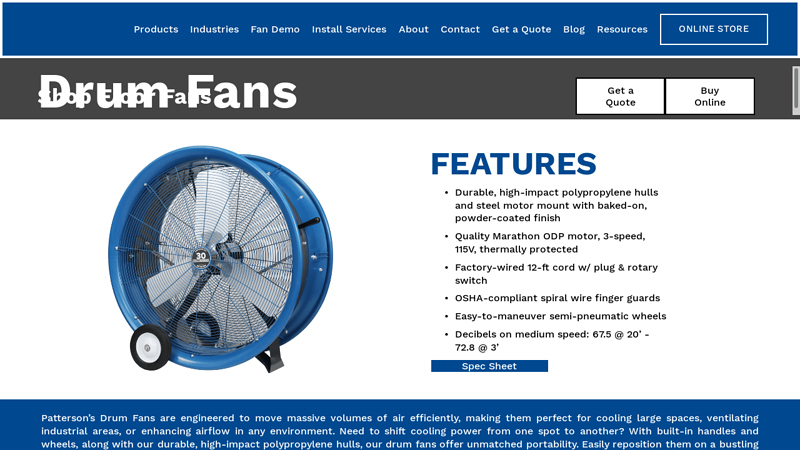

#2 Industrial Drum Fans

Domain Est. 1997

Website: pattersonfan.com

Key Highlights: Patterson’s Drum Fans are engineered to move massive volumes of air efficiently, making them perfect for cooling large spaces, ventilating industrial areas….

#3 Drum & Floor Fans

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: 30-day returnsShop for Drum & Floor Fans in Cooling Fans. Global Industrial is a Leading Distributor of HVAC & Fans supplies….

#4 Drum Fans

Domain Est. 1998

Website: pennfan.com

Key Highlights: Penn Fan’s industrial drum fans offer industry leading value. Cool people or products efficently and effectively with a Type-D Fan….

#5 High-Performance Industrial Fans & Ventilation

Domain Est. 1999

Website: trianglefans.com

Key Highlights: For over 70 years, Triangle Engineering has delivered durable, high-performance industrial fans. Explore our ventilation solutions for manufacturing, warehouses…

#6 Industrial Fans Direct

Domain Est. 2005

Website: industrialfansdirect.com

Key Highlights: Patterson fans stand up to the rigors of industrial use while retaining low maintenance. Whether you’re managing a large warehouse, a manufacturing facility, ……

#7 Portable Circulation Fans

Domain Est. 2009

Website: masterindustrialproducts.com

Key Highlights: Master Industrial 36″ Heavy-Duty Barrel Fan · Master Industrial 36″ Direct-Drive High Velocity Barrel Fan · Master 48″ High Capacity Belt Drive Drum Fan · Master ……

#8 Airmaster Fan Company

Domain Est. 1997

Website: airmasterfan.com

Key Highlights: We build fans for heavy-duty environments where lesser fans burn out- with real specifications that no competitor can match- to stand the test of time….

#9 Drum Fans

Domain Est. 2020

Expert Sourcing Insights for Drum Fans Industrial

H2: 2026 Market Trends for Industrial Drum Fans

The industrial drum fan market is poised for significant transformation and growth by 2026, driven by technological advancements, increasing industrial automation, and a global focus on energy efficiency and sustainability. This analysis explores key trends expected to shape the industrial drum fan sector over the coming years.

-

Rising Demand in Manufacturing and Processing Industries

Industrial drum fans are critical components in ventilation, cooling, and material handling across sectors such as chemical processing, food and beverage, pharmaceuticals, and mining. As global manufacturing output expands—particularly in emerging economies like India, Southeast Asia, and parts of Africa—the demand for reliable and efficient air movement systems is expected to rise. Drum fans, known for their robust construction and high airflow capacity, will see increased adoption in large-scale industrial facilities. -

Integration of Smart Technologies and IoT

By 2026, the integration of Internet of Things (IoT) sensors and smart monitoring systems into industrial drum fans will become more widespread. Smart drum fans will offer real-time performance tracking, predictive maintenance alerts, and remote control capabilities via centralized building or plant management systems. This shift toward Industry 4.0 practices will enhance operational efficiency, reduce downtime, and lower maintenance costs, making smart drum fans a preferred choice for modern industrial setups. -

Emphasis on Energy Efficiency and Regulatory Compliance

With tightening global energy regulations and growing pressure to reduce carbon emissions, manufacturers are prioritizing energy-efficient equipment. Industrial drum fans designed with aerodynamically optimized blades, variable frequency drives (VFDs), and high-efficiency motors will dominate the market. Regulatory standards such as the EU’s Ecodesign Directive and U.S. DOE efficiency requirements will drive innovation and adoption of low-energy-consumption models. -

Shift Toward Customization and Application-Specific Designs

As industries face unique environmental and operational challenges, the demand for customized drum fans tailored to specific applications—such as corrosion-resistant models for chemical plants or explosion-proof fans for hazardous environments—will grow. Manufacturers will increasingly offer modular designs and configurable options to meet precise customer requirements, supporting better integration and performance in diverse industrial settings. -

Growth in Aftermarket Services and Retrofitting

With many existing industrial facilities seeking to modernize without full system overhauls, the aftermarket for drum fan upgrades and retrofits will expand. Retrofitting older fans with energy-efficient motors, digital controls, and improved housings will provide cost-effective solutions for improving airflow and reducing power consumption. Service contracts, performance audits, and lifecycle management will become key differentiators among suppliers. -

Regional Market Expansion and Competitive Dynamics

Asia-Pacific is expected to lead market growth due to rapid industrialization and infrastructure development. China, India, and Vietnam will be key markets, supported by government initiatives promoting manufacturing and clean energy. Meanwhile, North America and Europe will focus on replacing aging infrastructure and adopting high-efficiency systems. Competitive pressures will push manufacturers to innovate in materials (e.g., lightweight composites), noise reduction, and sustainability.

Conclusion

By 2026, the industrial drum fan market will be characterized by smarter, more efficient, and highly adaptable solutions. Companies that invest in digital integration, energy optimization, and customer-centric design will be best positioned to capture market share. As industries continue to prioritize operational resilience and environmental responsibility, industrial drum fans will play an increasingly vital role in sustainable industrial airflow management.

Common Pitfalls When Sourcing Industrial Drum Fans (Quality and IP)

Sourcing industrial drum fans involves careful evaluation to ensure performance, durability, and compliance. However, buyers often encounter several recurring challenges related to quality assurance and intellectual property (IP). Avoiding these pitfalls is crucial for maintaining operational efficiency and protecting business interests.

Poor Quality Control and Substandard Materials

One of the most frequent issues when sourcing drum fans—especially from low-cost manufacturers—is receiving units made with inferior materials or lacking proper quality control. Subpar steel, inadequate motor insulation, or improper balancing can lead to premature failure, safety hazards, and increased maintenance costs.

Key risks:

– Use of non-compliant or off-spec materials

– Inconsistent manufacturing processes

– Lack of performance testing (e.g., airflow, pressure, noise)

Solution: Require third-party certifications (such as ISO 9001), request test reports, and conduct factory audits or product sampling before bulk orders.

Misrepresentation of IP and Design Infringement

Industrial drum fans often incorporate patented designs, especially in blade geometry, motor integration, or housing configurations. Sourcing from suppliers who copy branded or patented models can expose your company to intellectual property (IP) infringement claims.

Common scenarios:

– Suppliers offering “compatible” or “equivalent” models that mimic patented designs

– Unauthorized use of OEM trademarks or part numbers

– Lack of transparency about original equipment design ownership

Solution: Verify that suppliers have legitimate rights to the designs they offer. Request IP documentation or design registration proof, and consider legal review for high-volume or custom procurement.

Inadequate IP Protection in Supply Agreements

Even when sourcing original designs, failure to secure proper IP clauses in contracts can result in loss of proprietary modifications or reverse engineering by the manufacturer.

Risk areas:

– No clear ownership of custom fan designs or tooling

– Supplier reproduces your design for competitors

– Lack of non-disclosure agreements (NDAs) or confidentiality terms

Solution: Include robust IP clauses in procurement contracts specifying ownership, usage rights, and restrictions on replication or resale.

Overlooking Ingress Protection (IP) Ratings

The term “IP” can also refer to Ingress Protection ratings (e.g., IP55, IP68), which define protection against dust and water. Misunderstanding or misrepresenting these ratings can lead to equipment failure in harsh environments.

Pitfalls:

– Suppliers claim high IP ratings without certification

– Testing not performed under standardized conditions (IEC 60529)

– Inadequate sealing in humid or outdoor applications

Solution: Require certified test reports for claimed IP ratings and validate with independent labs if necessary.

Final Recommendation

To mitigate risks in sourcing industrial drum fans:

– Prioritize suppliers with verifiable quality management systems

– Conduct due diligence on IP legitimacy and contractual safeguards

– Confirm environmental protection ratings with documented evidence

Proactive vetting helps ensure reliable performance and legal compliance while protecting your business from hidden liabilities.

Logistics & Compliance Guide for Drum Fans Industrial

Overview

This guide outlines the essential logistics and compliance procedures for Drum Fans Industrial, ensuring safe, efficient, and legally compliant transportation, storage, and handling of industrial fan products and components. Adherence to these standards supports operational excellence and regulatory compliance across all supply chain activities.

Product Classification and Handling

Drum fans and related industrial equipment are classified as heavy machinery with specific handling requirements. Components may include steel casings, motors, impellers, and control panels. All items must be properly labeled, secured, and handled using appropriate lifting and transport equipment to prevent damage or injury.

Packaging and Palletization Standards

All drum fans must be packaged according to internal specifications and international shipping standards (e.g., ISTA, ISO). Use of wooden or recyclable composite pallets, moisture barriers, corner protectors, and stretch-wrapping is mandatory. Crated units should include internal bracing to prevent movement during transit.

Domestic and International Shipping

Drum Fans Industrial utilizes certified freight carriers experienced in heavy industrial equipment transport. For international shipments, compliance with Incoterms (typically FOB or EXW) must be clearly defined in contracts. Required documentation includes commercial invoices, packing lists, bills of lading, and export declarations.

Export Compliance

All exports must comply with applicable regulations, including:

– U.S. Department of Commerce Export Administration Regulations (EAR)

– International Traffic in Arms Regulations (ITAR), if applicable

– Sanctions lists (OFAC) screening for restricted parties and destinations

Ensure proper Export Control Classification Numbers (ECCNs) are assigned and validated for all products prior to shipment.

Import Regulations and Duties

Importers must provide accurate Harmonized System (HS) codes for drum fans (typically under 8414.59 or country-specific classifications). Duties, taxes, and import permits vary by destination. Work with local customs brokers to ensure timely clearance and compliance with destination country safety and environmental standards.

Hazardous Materials Considerations

While drum fans themselves are not hazardous, associated components such as lubricants, cleaning solvents, or packaging materials may be classified as hazardous. If applicable, shipments must comply with DOT (49 CFR), IATA, or IMDG regulations, including proper labeling, documentation, and training.

Storage and Warehousing

Store drum fans in covered, dry, and secure facilities with adequate ventilation. Implement a first-in, first-out (FIFO) inventory system. Stack only as high as structurally safe and clearly mark storage areas with load limits and handling instructions.

Safety and Regulatory Compliance

Adhere to OSHA standards for material handling, including forklift operation, personal protective equipment (PPE), and workplace safety signage. Ensure compliance with local environmental regulations regarding waste disposal, noise emissions during testing, and energy efficiency standards (e.g., DOE, EU Ecodesign).

Documentation and Recordkeeping

Maintain accurate records for a minimum of five years, including:

– Shipping manifests

– Export license applications (if required)

– Certificates of origin

– Compliance audits

– Safety data sheets (SDS) for any associated chemicals

Training and Accountability

All logistics and operations personnel must complete annual training in safety protocols, hazardous materials handling (if applicable), export control awareness, and proper equipment operation. Assign compliance officers to oversee adherence and conduct periodic internal audits.

Continuous Improvement

Regularly review logistics performance and compliance metrics. Implement corrective actions for non-conformances and stay updated on changes in trade regulations, environmental standards, and transportation best practices to maintain operational efficiency and legal compliance.

Conclusion for Sourcing Industrial Drum Fans

Sourcing industrial drum fans requires a strategic approach that balances performance requirements, cost-efficiency, durability, and supplier reliability. These critical components play a vital role in ventilation, cooling, and material handling across various industrial applications, making the selection of high-quality fans essential for operational efficiency and safety.

Key considerations in the sourcing process include understanding the specific operational demands—such as airflow volume, pressure requirements, temperature resistance, and environmental conditions—ensuring compatibility with existing systems, and evaluating energy efficiency to reduce long-term operational costs. Additionally, adherence to industry standards and certifications (e.g., AMCA, CE, ISO) is crucial to guarantee safety, performance, and regulatory compliance.

Partnering with reputable suppliers who offer technical expertise, proven product quality, warranty support, and timely delivery helps mitigate risks and ensures supply chain resilience. Conducting thorough market research, comparing OEMs and aftermarket options, and leveraging bulk purchasing or long-term agreements can further optimize costs without compromising reliability.

In conclusion, successful sourcing of industrial drum fans hinges on a comprehensive evaluation of technical specifications, supplier credibility, and total cost of ownership. By adopting a diligent and informed procurement strategy, organizations can enhance system performance, improve operational uptime, and achieve sustainable industrial efficiency.