The global hydroponics market is experiencing robust expansion, driven by increasing demand for sustainable agriculture, vertical farming, and climate-resilient food production systems. According to a 2023 report by Mordor Intelligence, the hydroponics market was valued at USD 33.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 11.6% from 2024 to 2029. This surge is largely fueled by urbanization, limited arable land, and advancements in controlled environment agriculture—making efficient irrigation solutions like drip systems a critical component in modern hydroponic setups.

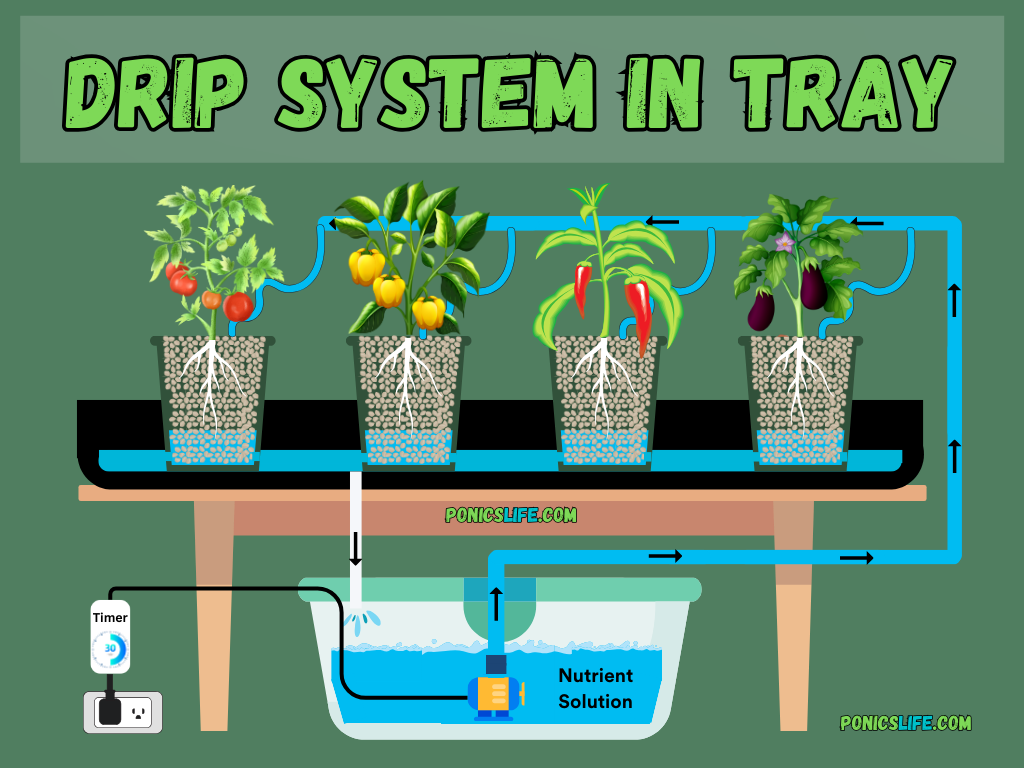

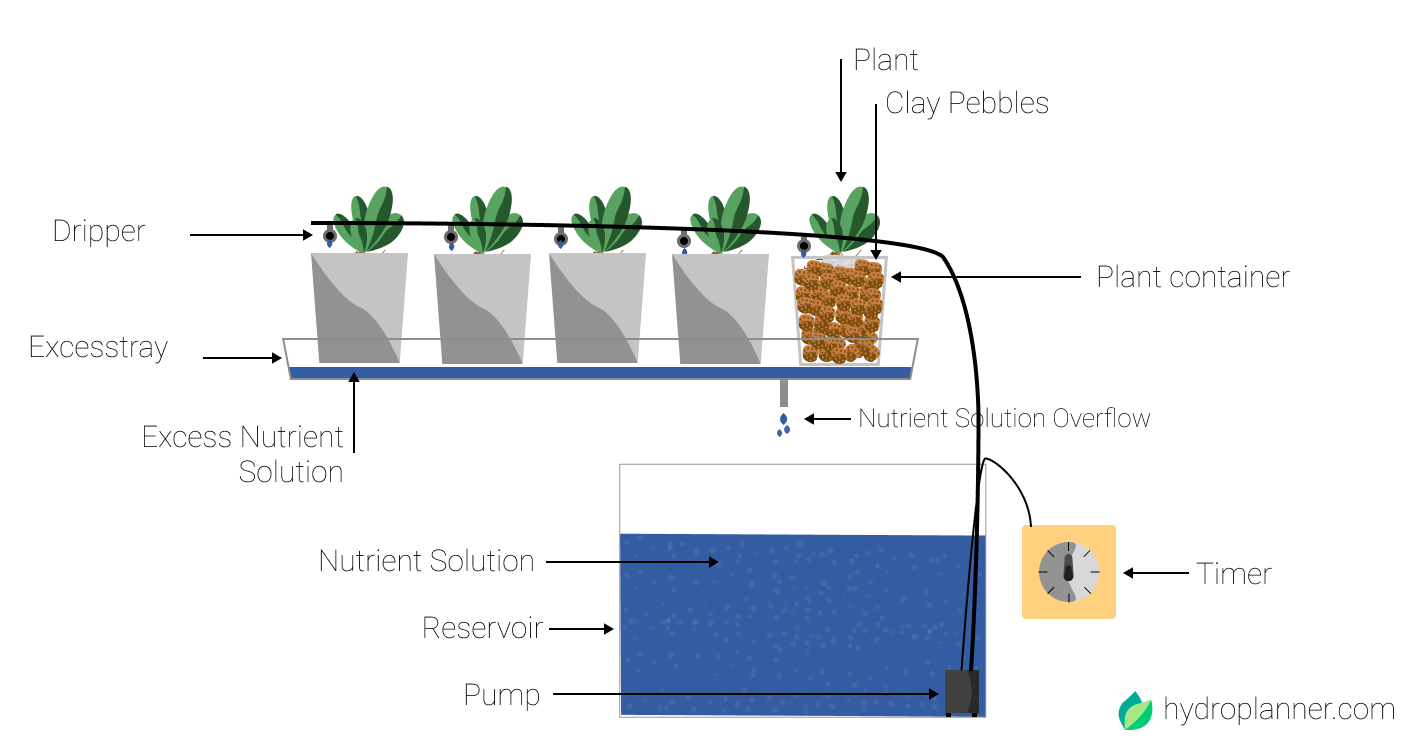

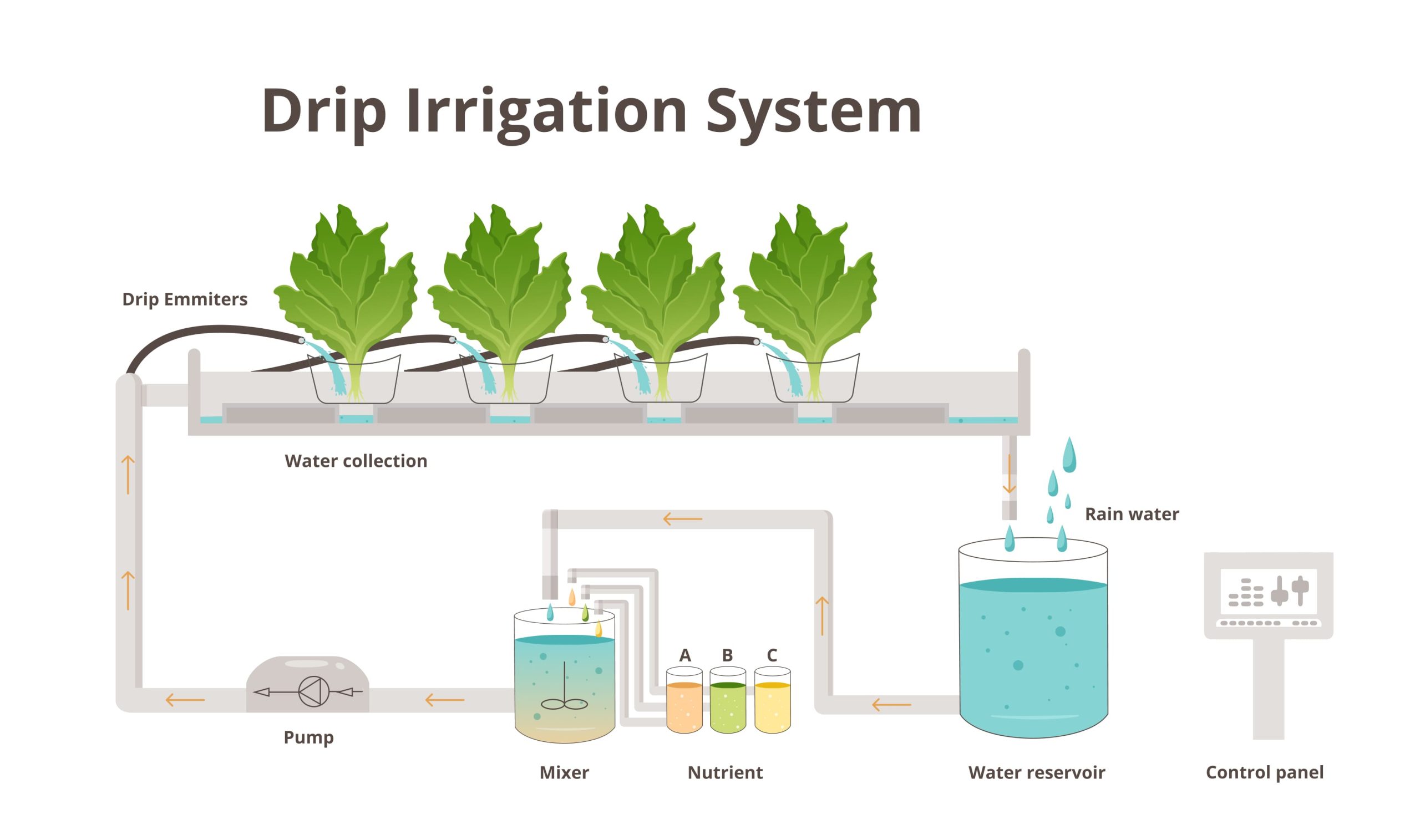

Drip systems, known for their precision in delivering nutrient solutions directly to plant roots, minimize water waste and optimize crop yields. As hydroponic farming scales across commercial greenhouses and indoor farms, manufacturers specializing in reliable, automated, and scalable drip irrigation systems are emerging as key enablers of this agricultural transformation. With North America and Europe leading adoption and Asia-Pacific witnessing the fastest growth, competition among manufacturers is intensifying—spurring innovation in system design, IoT integration, and energy efficiency.

In this landscape, identifying leading drip system manufacturers requires evaluating performance metrics, system compatibility, durability, and customer support. Based on market presence, product innovation, and customer feedback, the following nine manufacturers have distinguished themselves as top providers of drip irrigation solutions for hydroponic applications.

Top 9 Drip System For Hydroponics Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Drip Irrigation System & Technology

Domain Est. 2000

Website: netafimusa.com

Key Highlights: Drip Irrigation Systems | Boost yields with Netafim’s drip irrigation system and fight food and water scarcity with our drip watering system….

#2 Reinfa

Domain Est. 2022

Website: reinfa.com

Key Highlights: Discover Reinfa’s diverse vertical farming system categories, including hydroponic, aeroponic, and drip solutions. Tailored for commercial growers to ……

#3 Drip Irrigation for Hydroponic Tomatoes

Domain Est. 1997

Website: irritec.com

Key Highlights: The most suitable irrigation system for hydroponic tomatoes is drip irrigation. The system consists of one drip lateral per row, made up of a white LDPE pipe….

#4 Wilma grow systems – Hydroponic drip irrigation kits

Domain Est. 1998

Website: atami.com

Key Highlights: The Wilma Grow System offers a reliable, electrically powered drip-irrigation solution for optimal plant growth. Its automatic watering ensures a perfect ……

#5 Irrigation

Domain Est. 2010

#6 Drip Irrigation Systems

Domain Est. 2010

Website: rivulis.com

Key Highlights: Drip irrigation delivers water, nutrients, and chemicals to individual plants with extreme precision in an open field, orchard, and protected crop environment….

#7 Responsive Drip Irrigation

Domain Est. 2013

Website: responsivedrip.com

Key Highlights: GrowStream™ tube is the world’s first and only plant-responsive irrigation and fertigation system which allows the plant to self-regulate its own water delivery ……

#8 Hydroponic Growing Systems

Domain Est. 2016

#9 Drip Irrigation System

Domain Est. 2019

Expert Sourcing Insights for Drip System For Hydroponics

H2: 2026 Market Trends for Drip Systems in Hydroponics

The global market for drip systems in hydroponics is poised for significant transformation by 2026, driven by technological innovation, rising demand for sustainable agriculture, and increasing adoption of controlled environment farming. Below are the key trends shaping this sector:

1. Increased Adoption of Smart Irrigation Technology

By 2026, drip systems in hydroponics are expected to integrate advanced automation and IoT (Internet of Things) capabilities. Smart sensors, real-time monitoring, and AI-driven analytics will enable precise control over nutrient delivery, pH levels, and water flow. These innovations enhance operational efficiency and crop yields, making smart drip systems a preferred choice for commercial growers and urban farming ventures.

2. Rising Demand for Sustainable Agriculture Solutions

With growing concerns over water scarcity and environmental degradation, drip-based hydroponic systems are gaining traction due to their water efficiency. These systems deliver water and nutrients directly to plant roots, reducing wastage by up to 60% compared to traditional methods. By 2026, governments and agribusinesses will increasingly promote such technologies as part of climate-smart agriculture initiatives.

3. Expansion of Urban and Vertical Farming

Urbanization and limited arable land are fueling the growth of vertical and indoor farming. Drip irrigation systems, known for their scalability and low maintenance, are ideal for these setups. The market will see a surge in compact, modular drip systems tailored for small-scale urban farms, rooftop gardens, and home growers, particularly in North America, Europe, and parts of Asia-Pacific.

4. Advancements in Drip Component Durability and Design

Manufacturers are focusing on developing more durable, clog-resistant emitters and tubing materials to improve system longevity and reduce maintenance. Innovations in anti-algae and self-cleaning drip lines are expected to become standard by 2026, especially in warm and humid climates where biofilm buildup is common.

5. Growth in Emerging Markets

While North America and Europe currently dominate the hydroponic drip system market, regions such as Southeast Asia, the Middle East, and Africa are projected to witness rapid growth. Increasing government support for food security, coupled with investments in agritech startups, will drive adoption in countries like India, UAE, and South Africa.

6. Competitive Landscape and Market Consolidation

By 2026, the market is expected to see increased consolidation as major players acquire niche hydroponic tech firms to expand their product portfolios. Companies such as Netafim, Rain for Rent, and General Hydroponics are likely to lead through R&D investments and strategic partnerships with agritech platforms.

7. Focus on Organic and Pesticide-Free Produce

Consumer demand for clean, organic food is pushing growers to adopt hydroponic drip systems that minimize chemical runoff and support integrated pest management. This trend will encourage the development of eco-friendly drip kits compatible with organic nutrient solutions.

In conclusion, the 2026 market for drip systems in hydroponics will be defined by intelligence, sustainability, and scalability. As the global food system evolves, drip-based hydroponics will play a pivotal role in ensuring resilient and efficient food production.

Common Pitfalls When Sourcing Drip Systems for Hydroponics

Sourcing a drip system for hydroponics can significantly impact the efficiency and success of your operation. However, several common pitfalls—particularly related to quality and intellectual property (IP)—can lead to performance issues, increased costs, or legal complications. Being aware of these risks helps ensure you select a reliable, compliant system.

Quality-Related Pitfalls

1. Substandard Materials and Construction

Many low-cost drip systems are made from inferior plastics or components that degrade quickly under UV light, nutrient exposure, or continuous water pressure. This can lead to leaks, clogs, or system failure. Always verify that tubing, emitters, and connectors are made from UV-stabilized, food-grade, and chemically resistant materials.

2. Inconsistent Flow Rates and Clogging

Poorly designed emitters often deliver inconsistent nutrient flow, resulting in uneven plant growth. Additionally, systems without proper filtration or self-flushing mechanisms are prone to clogging from mineral buildup or organic debris, increasing maintenance demands.

3. Lack of Durability and Environmental Resistance

Some drip systems are not built for long-term agricultural use. They may crack in cold temperatures, warp under heat, or degrade when exposed to common hydroponic solutions. Ensure components are rated for greenhouse or outdoor conditions, depending on your setup.

4. Inadequate Pressure Regulation

Without proper pressure-compensating emitters or regulators, systems can deliver too much or too little water to plants, especially in uneven terrain or larger installations. This undermines the precision hydroponics requires.

5. Poor Compatibility and Scalability

Cheap or generic systems may not integrate well with existing pumps, timers, or controllers. They also often lack modularity, making it difficult to expand or reconfigure as your operation grows.

Intellectual Property (IP)-Related Pitfalls

1. Infringement of Patented Designs

Some suppliers offer drip components that mimic patented technologies (e.g., pressure-compensating emitters or anti-siphon mechanisms) without licensing them. Using such products can expose your business to legal liability, especially in commercial operations.

2. Counterfeit or Knockoff Products

Markets, particularly online, are flooded with counterfeit versions of well-known hydroponic brands. These may appear identical but lack performance guarantees and IP rights compliance. Always purchase from authorized distributors or reputable manufacturers.

3. Lack of Technical Support and Documentation

IP-protected systems often come with detailed installation guides, warranties, and technical support. When sourcing unbranded or infringing products, you may receive no documentation or support, increasing the risk of improper installation and system failure.

4. Risk to Brand Reputation and Certification

For commercial growers, using non-compliant or infringing equipment can jeopardize organic certifications or sustainability claims. It may also affect partnerships or supply agreements that require adherence to IP and quality standards.

How to Avoid These Pitfalls

- Verify certifications: Look for ISO, NSF, or food-safe material certifications.

- Source from reputable suppliers: Choose established brands with transparent manufacturing and distribution practices.

- Check patent status: Research whether key components are patented and confirm the supplier has the right to use them.

- Request samples and test performance: Evaluate flow consistency, durability, and resistance to clogging before bulk orders.

- Review warranty and support terms: Ensure the supplier offers technical assistance and product guarantees.

By addressing both quality and IP concerns during sourcing, you can invest in a drip system that delivers reliable performance, legal compliance, and long-term value for your hydroponic operation.

Logistics & Compliance Guide for Drip System for Hydroponics

Product Classification & HS Code

The Drip System for Hydroponics is classified under the Harmonized System (HS) Code 8424.89.90 – “Mechanical appliances for projecting, dispersing or spraying liquids or powders, other than sprays; other: other: other.” This classification covers irrigation and agricultural spraying equipment, including hydroponic drip systems. Confirm with local customs authorities, as some countries may apply sub-classifications based on specific components or usage.

Import/Export Regulations

- Export Controls: Drip systems are generally not subject to export restrictions under dual-use or strategic trade controls. However, if the system includes smart controllers with embedded software or IoT capabilities, verify compliance with relevant export control regulations (e.g., EAR in the U.S.).

- Import Requirements: Most countries do not impose strict import bans on hydroponic drip systems. However, agricultural equipment may require documentation proving compliance with local irrigation or water efficiency standards.

- Restricted Countries: Monitor sanctions lists (e.g., OFAC, EU) to ensure no shipments are made to embargoed regions.

Packaging & Labeling

- Packaging: Use durable, moisture-resistant packaging (e.g., corrugated cardboard with plastic lining) to prevent damage during transit. Include cushioning materials for fragile components like emitters and timers.

- Labeling Requirements:

- Product name and model number

- Manufacturer name and address

- Country of origin

- HS code (recommended)

- Voltage and power specifications (for systems with electronic timers/pumps)

- Language: Labels must be in the official language(s) of the destination country

- Barcodes: Include UPC (U.S.) or EAN (international) for retail distribution

- Warning labels (if applicable): E.g., “For agricultural use only,” “Keep away from children”

Shipping & Freight Considerations

- Freight Mode:

- Air freight: Suitable for small, high-value orders or urgent deliveries

- Ocean freight (FCL/LCL): Cost-effective for bulk shipments; use moisture-barrier wrapping for containerized cargo

- Dimensions & Weight: Optimize packaging to reduce dimensional weight for cost efficiency. Provide accurate carton dimensions and gross weight for freight quotes.

- Incoterms: Recommended terms include:

- FOB (Free On Board): Seller delivers goods to the port; risk transfers upon loading.

- DDP (Delivered Duty Paid): Seller handles all logistics and import clearance (ideal for B2C or simplified client experience).

- Temperature Sensitivity: While drip components are generally non-hazardous, prolonged exposure to extreme temperatures may affect plastic integrity. Avoid storage in direct sunlight or freezing conditions.

Regulatory Compliance

- Electrical Components: If the system includes a pump or timer with electrical input:

- CE Marking (EU): Required for safety, EMC, and RoHS compliance

- FCC Certification (U.S.): For electronic controllers emitting radio frequency energy

- UL/ETL Listing: Recommended for North American markets

- Material Safety:

- Ensure all wetted parts (tubing, emitters, reservoirs) are made from food-grade, BPA-free plastics compliant with FDA 21 CFR or EU Regulation (EC) No 1935/2004

- Comply with REACH (EU) and Proposition 65 (California) for restricted substances

- Water Efficiency Standards: Some regions (e.g., California, Australia) require irrigation equipment to meet water-saving certifications. Verify local requirements.

Documentation Requirements

- Commercial Invoice: Must include detailed product description, HS code, value, currency, and Incoterms

- Packing List: Itemize contents per package, including weights and dimensions

- Bill of Lading / Air Waybill: Issued by carrier; ensure accuracy for customs clearance

- Certificate of Origin: May be required for preferential tariff treatment under trade agreements (e.g., USMCA, ASEAN)

- Compliance Certificates: Include copies of CE, FCC, or RoHS declarations if applicable

Environmental & Sustainability Compliance

- WEEE Directive (EU): If electronic components are included, ensure registration with national WEEE authorities and provide take-back information

- Plastic Packaging Taxes: Some countries (e.g., UK) impose taxes on non-recycled plastic packaging. Use recyclable materials where possible

- Carbon Footprint Reporting: Larger importers may require emissions data for logistics (Scope 3). Consider carbon-neutral shipping options

After-Sales & Warranty Logistics

- Spare Parts Availability: Maintain inventory of common replacement parts (emitters, filters, tubing connectors) for regional distribution centers

- Warranty Claims: Establish a process for handling returns, including pre-paid labels (for DDP shipments) and inspection protocols

- Local Support: Partner with regional distributors for technical support and compliance with local consumer protection laws (e.g., 2-year warranty under EU Consumer Rights Directive)

Risk Mitigation

- Insurance: Obtain cargo insurance covering loss, damage, and delay in transit

- Customs Delays: Provide complete documentation and use licensed customs brokers in target markets

- Product Recalls: Implement a traceability system (batch/lot numbering) to support rapid recall if compliance issues arise

By adhering to this guide, businesses can ensure smooth global distribution of hydroponic drip systems while maintaining compliance with international trade, safety, and environmental regulations.

Conclusion: Sourcing a Drip System for Hydroponics

In conclusion, sourcing a drip irrigation system for hydroponics requires careful consideration of several key factors, including system reliability, component quality, scalability, cost-efficiency, and ease of maintenance. Drip systems offer precise nutrient delivery, improved water conservation, and enhanced plant growth, making them a highly effective choice for both small-scale and commercial hydroponic operations.

When sourcing, it is essential to evaluate suppliers based on product durability, availability of replacement parts, technical support, and compatibility with your specific crop types and growing environment. Opting for a well-designed, customizable system from a reputable supplier ensures long-term performance and reduces downtime due to clogs or malfunctions—common concerns with drip emitters.

Additionally, integrating timers, filters, and pressure regulators enhances automation and system efficiency, contributing to sustainable and low-labor cultivation. As the hydroponics industry continues to grow, investing in a high-quality drip system not only boosts productivity but also supports consistent yields and resource optimization.

Ultimately, a strategic sourcing approach—balancing upfront costs with long-term benefits—will enable growers to maximize the advantages of drip-based hydroponics and achieve a successful, scalable, and sustainable growing operation.