The global drip irrigation market is experiencing robust growth, driven by rising water scarcity, increasing demand for water-efficient agricultural practices, and government initiatives promoting precision farming. According to a report by Mordor Intelligence, the drip irrigation market was valued at USD 6.65 billion in 2023 and is projected to grow at a CAGR of 11.3% from 2024 to 2029. Similarly, Grand View Research estimates that the market size reached USD 7.08 billion in 2022 and is expected to expand at a CAGR of 12.1% over the forecast period (2023–2030). This accelerating demand is fueling innovation and competition among manufacturers of drip irrigation components, particularly pipe fittings—critical elements that ensure system durability, leakage control, and optimal water distribution. As adoption spreads across smallholder farms and large-scale agribusinesses alike, the need for high-quality, reliable fittings has never been greater. Here, we spotlight the top 10 manufacturers leading the way in engineering, scalability, and market reach in the global drip irrigation pipe fittings landscape.

Top 10 Drip Irrigation Pipe Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Drip Irrigation System & Technology

Domain Est. 2000

Website: netafimusa.com

Key Highlights: Netafim North America’s Mining Division provides a full spectrum of drip irrigation supplies including leach lines, fittings, filters, valves, air vents, as ……

#2 Drip Fittings – DIG Corp

Domain Est. 1996

Website: digcorp.com

Key Highlights: DIG’s drip irrigation fittings are available in a variety of sizes and configurations for both home gardeners and professionals….

#3 Irrigation Pipe Fittings & Drip System Connectors for Tubing

Domain Est. 1996

Website: ndspro.com

Key Highlights: Fittings connect sections of tubing together and are used to set up the layout of the drip system. Connection types include barbed or insert, compression, ……

#4 Drip Irrigation Connectors & Accessories

Domain Est. 1996

Website: netafim.com

Key Highlights: Do you need irrigation connectors? Find the connectors you need to run a world-class precision irrigation system and protect your crops. Enter Now!…

#5 Jain Irrigation Systems Ltd.

Domain Est. 1997

Website: jains.com

Key Highlights: Products We Offer · Drip Irrigation Systems · Micro & Mini Sprinklers · Sprinkler Irrigation · Filters, Dosing Pump & Injectors · PVC Pipes & Fittings · PE Pipes & ……

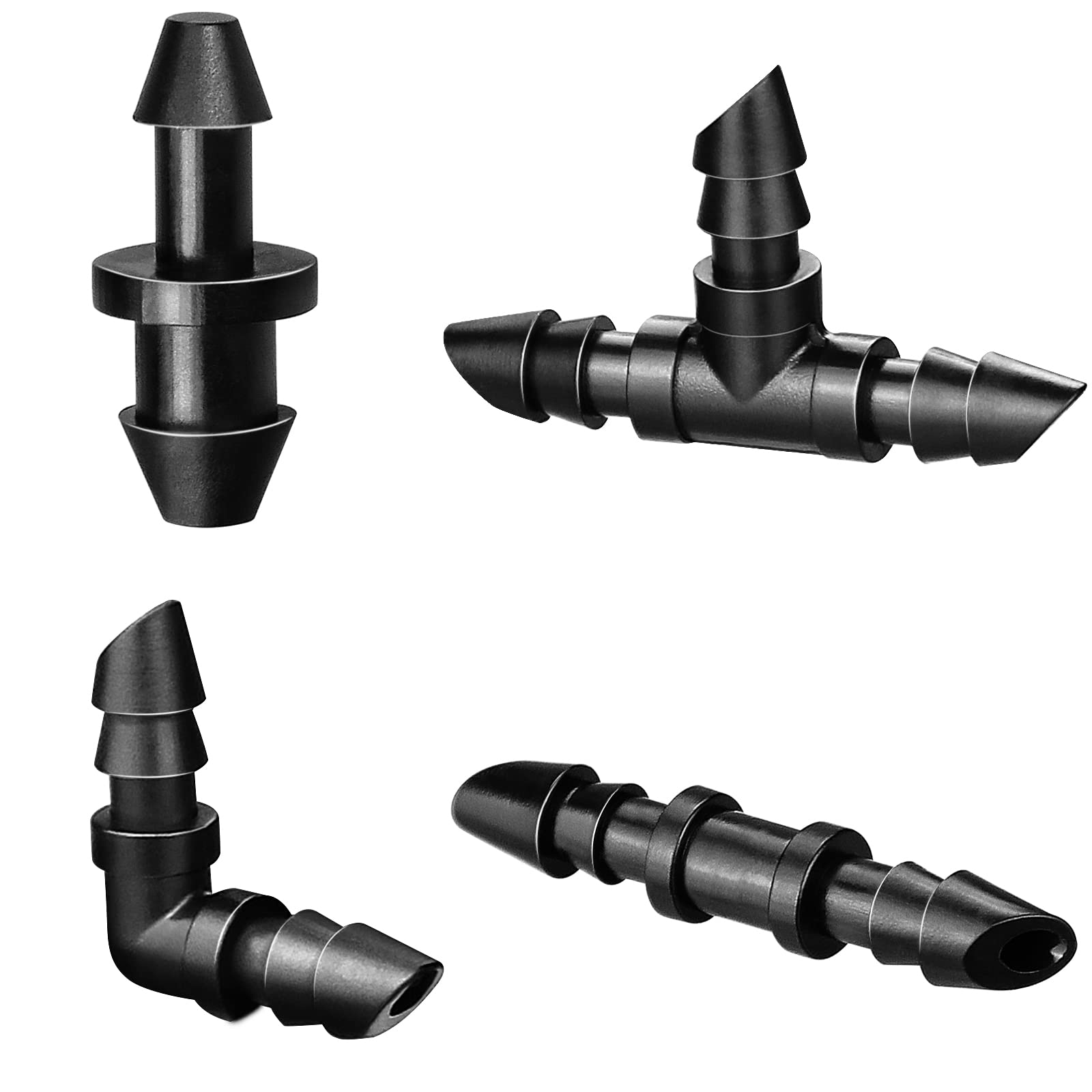

#6 Drip Irrigation Fittings

Domain Est. 1997

Website: dripirrigation.com

Key Highlights: Free delivery 30-day returnsTees, elbows, adapters, couplers, 1/4″ to 3/4″, compression, barbed, and spin-loc styles….

#7 Drip Irrigation System,Chinadrip Irrigation Equipment Co.,Ltd.

Domain Est. 2006

Website: chinadrip.com

Key Highlights: Chinadrip manufactures drip tape,tape and tubing fittings,emitter,filter,air valve,micro sprinkler and accessories for irrigation system….

#8 Drip irrigation

Domain Est. 2007

Website: irritec.us

Key Highlights: Our high quality drip irrigation products include thin wall driplines, light driplines, heavy wall driplines and on-line drippers….

#9 Drip Irrigation Systems

Domain Est. 2011 | Founded: 2001

Website: ksnmdrip.com

Key Highlights: Since 2001, KSNM has led the way in manufacturing Drip Irrigation Systems, focused on enhancing productivity for small farmers….

#10 Fittings Water and Gas, Fittings for Irrigation, Drip Tape

Domain Est. 2013

Website: sabspa.com

Key Highlights: SAB SpA is a company of the System Group specialising in the production of pipe fittings and accessories for irrigation, water and gas conduction and water ……

Expert Sourcing Insights for Drip Irrigation Pipe Fittings

H2: 2026 Market Trends for Drip Irrigation Pipe Fittings

The global market for drip irrigation pipe fittings is poised for significant transformation by 2026, driven by increasing demand for water-efficient agricultural practices, technological advancements, and supportive government policies. As climate change intensifies water scarcity and arable land diminishes, drip irrigation systems—known for their precision and efficiency—are becoming essential tools in sustainable farming. Pipe fittings, which are critical components ensuring seamless connectivity and durability within these systems, are expected to witness robust growth and innovation.

One key trend shaping the 2026 landscape is the rising adoption of smart irrigation technologies. Integration with IoT (Internet of Things) sensors and automated control systems is enhancing the functionality of drip irrigation networks. As a result, manufacturers are developing smart-compatible fittings equipped with features such as pressure regulation, clog resistance, and real-time monitoring capabilities. These intelligent fittings not only improve system performance but also reduce maintenance costs and water wastage, making them increasingly attractive to commercial and large-scale agricultural users.

Another major trend is the expansion of drip irrigation in emerging economies, particularly in Asia-Pacific, Africa, and Latin America. Countries like India, China, and Brazil are investing heavily in agricultural modernization to boost food security and improve crop yields. Government subsidies and initiatives promoting micro-irrigation are accelerating the uptake of drip systems, directly stimulating demand for high-quality pipe fittings. Localized manufacturing and distribution networks are also emerging to meet regional needs, reducing logistics costs and improving accessibility.

Environmental sustainability is further influencing product development. By 2026, there is a growing emphasis on eco-friendly materials, with manufacturers exploring biodegradable polymers and recyclable plastics for pipe fittings. This shift aligns with global sustainability goals and appeals to environmentally conscious farmers and agribusinesses. Additionally, the push for long-lasting, UV-resistant fittings capable of withstanding extreme weather conditions is driving innovation in material science and engineering design.

Lastly, market consolidation and strategic partnerships are expected to intensify as leading players seek to expand their global footprint. Mergers, acquisitions, and collaborations between irrigation technology firms and agricultural equipment providers will likely enhance product offerings and accelerate R&D in drip irrigation components.

In summary, the 2026 market for drip irrigation pipe fittings will be characterized by technological integration, geographic expansion, sustainability-driven innovation, and increasing industry consolidation—positioning the sector as a cornerstone of the future of precision agriculture.

Common Pitfalls When Sourcing Drip Irrigation Pipe Fittings (Quality, IP)

Sourcing drip irrigation pipe fittings involves more than just finding the lowest price—overlooking key quality and intellectual property (IP) factors can lead to system failures, costly repairs, and legal issues. Here are common pitfalls to avoid:

Poor Material Quality and Durability

Low-cost fittings made from substandard plastics (e.g., recycled or non-UV-stabilized polypropylene or polyethylene) degrade quickly under sunlight and temperature fluctuations. This leads to cracking, leaks, and reduced system lifespan, especially in outdoor agricultural environments.

Inconsistent Dimensional Accuracy

Fittings with poor manufacturing tolerances may not seal properly with pipes or other components. This results in leaks, pressure loss, and inefficient water distribution—undermining the core purpose of drip irrigation.

Lack of Pressure and Flow Specifications

Many generic fittings don’t clearly state pressure ratings (e.g., operating vs. burst pressure) or flow compatibility. Using mismatched fittings can cause blowouts or uneven water delivery, particularly in high-pressure or large-scale systems.

Absence of Certifications and Standards Compliance

Reputable systems comply with international standards (e.g., ISO 9261, ASTM F877). Sourcing fittings without these certifications increases the risk of poor performance and may void warranties on connected equipment.

Counterfeit or IP-Infringing Products

Unscrupulous suppliers may copy patented designs from leading brands (e.g., Netafim, Rain Bird). These counterfeit fittings may look similar but fail prematurely. Purchasing them can also expose buyers to IP infringement risks, especially in regulated markets.

Inadequate UV and Chemical Resistance

Irrigation systems are exposed to sunlight and fertilizers. Fittings not designed to resist UV radiation or chemical degradation will become brittle and fail, leading to unplanned maintenance and crop stress.

Limited Technical Support and Traceability

Generic suppliers often lack technical documentation, installation guides, or batch traceability. This makes troubleshooting difficult and increases liability if system-wide failures occur.

Ignoring Compatibility with Existing Systems

Mixing fittings from different manufacturers—even if they appear to fit—can cause long-term compatibility issues due to variations in materials, sealing mechanisms, or barb designs.

Avoiding these pitfalls requires due diligence: verify material specs, demand compliance documentation, source from reputable suppliers, and ensure IP legitimacy—protecting both system performance and legal compliance.

Logistics & Compliance Guide for Drip Irrigation Pipe Fittings

This guide outlines the essential logistics and compliance considerations for the import, export, distribution, and use of drip irrigation pipe fittings. Adhering to these requirements ensures smooth operations, reduces legal risks, and supports sustainable agricultural practices.

Product Classification & HS Codes

Accurate classification of drip irrigation pipe fittings is critical for customs clearance and determining applicable tariffs. Most fittings fall under the following Harmonized System (HS) codes:

- 3917.32: Plastic tubes, pipes, and hose fittings (for polyethylene or PVC fittings).

- 7307.23: Steel or iron pipe fittings (if metal components are included).

- 8424.89: Agricultural spraying machinery and mechanical appliances (may apply to integrated emitters or connectors).

Always verify the specific HS code with your customs authority or a licensed customs broker, as classification depends on material composition, design, and intended use.

Regulatory Compliance

Drip irrigation components must meet regulatory standards in both the country of origin and the destination market:

- United States (EPA & State Regulations): Fittings used in potable water systems must comply with NSF/ANSI Standard 61 for health effects. California also requires compliance with AB 1953 for low-lead content.

- European Union (REACH & RoHS): Fittings must conform to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) regulations, particularly regarding phthalates and heavy metals.

- Israel & Australia: Must meet local water efficiency and material safety standards (e.g., Israel Standards Institution – SI 5495, Australian Standards AS/NZS 4020).

- Other Regions: Check for national irrigation or water conservation standards (e.g., India BIS certification, South Africa SABS).

Packaging & Labeling Requirements

Proper packaging and labeling support logistics efficiency and regulatory compliance:

- Packaging: Use moisture-resistant, durable packaging suitable for stacking and long-distance transport. Clearly label packages with product type, quantity, batch number, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Labeling: Include essential product information on packaging or tags: manufacturer name, material type, size/dimensions, pressure rating (e.g., 10 psi), compliance marks (e.g., NSF, CE), and traceability codes.

- Multilingual Labels: For export markets, provide labels in the local language(s), especially safety and usage instructions.

Transportation & Storage

Optimize logistics to maintain product integrity:

- Mode of Transport: Choose based on volume and urgency—containerized sea freight for bulk shipments, air freight for urgent or low-volume needs. Ensure secure palletization and use of stretch wrap.

- Climate Considerations: Avoid prolonged exposure to extreme heat or UV radiation, which can degrade plastic fittings. Store in shaded, dry areas with ventilation.

- Stacking & Handling: Do not exceed recommended stacking heights to prevent deformation. Use forklifts with smooth tines and avoid dragging packages.

Import/Export Documentation

Ensure all required documentation is accurate and complete:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Test Reports or Certifications (e.g., NSF, CE, ISO)

- Import Permits (if required by destination country)

- Phytosanitary Certificate (rare, but may apply if packaging includes wood)

Environmental & Sustainability Compliance

Drip irrigation supports water conservation, but fittings themselves must meet environmental standards:

- Recyclability: Design and source fittings made from recyclable materials (e.g., HDPE, LDPE). Provide disposal guidelines.

- Waste Management: Comply with local e-waste or plastic waste regulations, especially for fittings with electronic components (e.g., smart connectors).

- Carbon Footprint: Optimize supply chain routes and use sustainable packaging materials to reduce environmental impact.

Quality Assurance & Traceability

Implement systems to ensure product consistency and accountability:

- Conduct regular quality checks during manufacturing and before shipment.

- Maintain batch tracking records for at least 5 years to support recalls or compliance audits.

- Adhere to ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) if applicable.

Conclusion

Managing the logistics and compliance of drip irrigation pipe fittings requires attention to classification, regulations, packaging, and documentation. Proactive planning and adherence to international standards ensure timely delivery, legal compliance, and customer satisfaction in the growing precision agriculture market.

In conclusion, sourcing drip irrigation pipe fittings requires a careful balance between quality, cost-effectiveness, reliability, and compatibility with existing irrigation systems. It is essential to prioritize durable, UV-resistant materials such as high-density polyethylene (HDPE) or polypropylene to ensure longevity and performance under varying environmental conditions. Evaluating suppliers based on reputation, compliance with industry standards, and availability of technical support can significantly impact the success of an irrigation project.

Additionally, considering factors such as local availability, lead times, and after-sales service contributes to operational efficiency and reduces downtime. Bulk purchasing and long-term partnerships with trusted manufacturers or distributors can lead to favorable pricing and consistent supply. Ultimately, making informed sourcing decisions for drip irrigation fittings supports water conservation, enhances crop yields, and promotes sustainable agricultural practices.