The global drill bit market is experiencing robust growth, driven by increasing demand from construction, manufacturing, and woodworking industries. According to Mordor Intelligence, the global drill bit market was valued at USD 3.97 billion in 2023 and is projected to reach USD 5.13 billion by 2029, growing at a CAGR of 4.4% during the forecast period. This expansion is fueled by advancements in cutting materials, rising infrastructure development, and the need for precision tools in industrial applications. Mortise bits, a specialized category within drill bits, are particularly critical in cabinetry, furniture making, and door hardware installation, where clean, square-edged holes are essential. As demand for high-performance and durable mortise bits rises, a select group of manufacturers has emerged as leaders in innovation, material quality, and precision engineering. The following analysis highlights the top 9 drill press mortise bit manufacturers shaping this growing segment.

Top 9 Drill Press Mortise Bit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powermatic Premium Mortise Chisel and Bit Set of 4

Domain Est. 1995

Website: jettools.com

Key Highlights: In stock 10-day returnsThese premium hollow chisel and bit sets are machined from solid bars of the finest carbon steel. They have one cutting edge, one spur and a brad point for ….

#2 Mortising Bits

Domain Est. 1996

Website: carbideprocessors.com

Key Highlights: Free delivery over $150Tons of mortising bits includes Hollow Mortising Chisels, Screw-On Mortise Bits, Carbide Tipped Mortise Bits, and bits for vibrating mortise machines….

#3 Drill Press Mortising Attachment with 4 pc. Chisel and Bit Set

Domain Est. 1996

#4 King Canada 4pc Mortising Attachment

Domain Est. 1996

Website: kmstools.com

Key Highlights: Convert your drill press into a mortising machine for all your square hole drilling needs. Fits King Canada drill press models KC-116C(FC), KC-117C(FC), KC-118 ……

#5 Mortises on a Drill Press

Domain Est. 1996

Website: info.lagunatools.com

Key Highlights: Need to make mortises for an upcoming project? One of the easiest ways to make them is by using a drill press equipped with a Forstner bit….

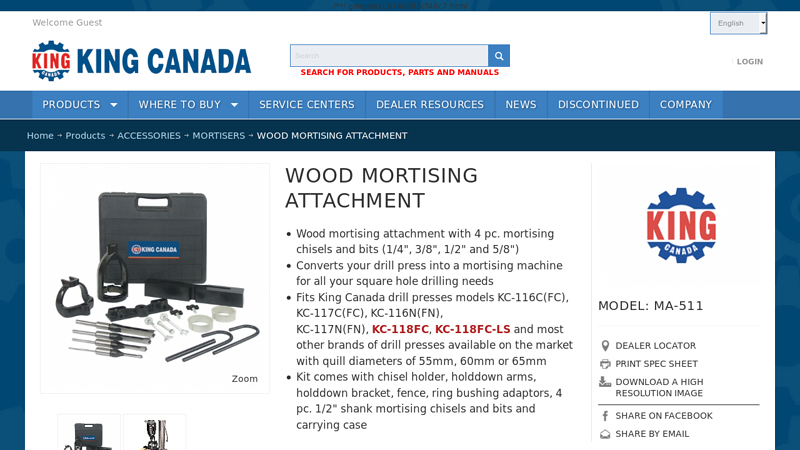

#6 Wood mortising attachment KING Canada

Domain Est. 1997

Website: kingcanada.com

Key Highlights: Converts your drill press into a mortising machine for all your square hole drilling needs; Fits King Canada drill presses models KC-116C(FC), KC-117C(FC) ……

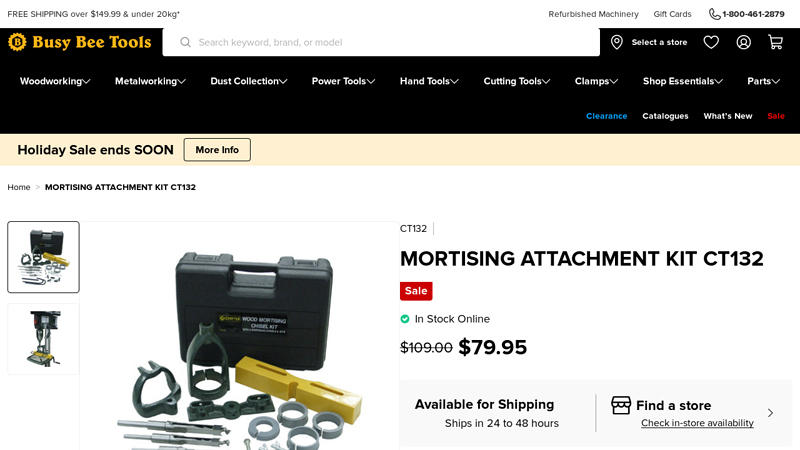

#7 mortising attachment kit ct132

Domain Est. 1998

#8 Drilling

Domain Est. 1999

Website: fisch-tools.com

Key Highlights: The FISCH® brand has been synonymous with superior quality woodworking tools for 70 years. The wonderful reputation which our products enjoy worldwide is……

#9 Mortise chisel & bit sets 543

Domain Est. 2010

Website: cmtorangetools.com

Key Highlights: A new selection of chisel and bit sets in all the popular sizes 6,35mm (1/4”) to 19mm (3/4”) diameter. These sets are for use on any standard drill press ……

Expert Sourcing Insights for Drill Press Mortise Bit

2026 Market Trends for Drill Press Mortise Bits

The demand for drill press mortise bits is poised for steady growth in 2026, driven by advancements in woodworking technology, the expanding DIY movement, and increasing precision requirements in both industrial and hobbyist applications. Several key trends are expected to shape the market landscape:

Rising Demand in the DIY and Home Workshop Sector

The continued surge in home improvement and hobbyist woodworking projects will significantly influence the 2026 market. Platforms like YouTube and social media have empowered more individuals to take on complex joinery tasks, increasing the need for reliable, easy-to-use mortise bits. Affordable, high-quality sets designed specifically for home drill presses will see heightened demand, with manufacturers focusing on user-friendly packaging, clear instructions, and compatibility guides.

Advancements in Bit Materials and Coatings

Innovation in cutting materials will be a major trend, with increased adoption of carbide-tipped and solid carbide mortise bits. These materials offer superior durability, heat resistance, and longer tool life—especially critical for hardwood joinery. Additionally, nano-coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) will become more common, enhancing chip evacuation, reducing friction, and minimizing wear, thus improving performance in high-speed drilling applications.

Integration with CNC and Hybrid Systems

While traditionally used in manual drill presses, there will be a growing niche for mortise bits compatible with hybrid CNC-routers or CNC add-ons for benchtop drill presses. As small-scale manufacturers and makerspaces adopt semi-automated solutions, demand will rise for precision-ground mortise bits that ensure repeatable, accurate cuts. This trend reflects the broader industry shift toward smart tools and digital fabrication integration.

Focus on Precision and Interchangeable Systems

Woodworkers will increasingly seek modular mortise bit systems with interchangeable cutters and adjustable spindles, allowing for variable mortise widths and depths. Brands offering metric and imperial sizing options with tight tolerances will gain market share, particularly among custom furniture makers and cabinet shops where accuracy is paramount.

Sustainability and Ethical Manufacturing

By 2026, environmentally conscious consumers and B2B buyers will prioritize brands that emphasize sustainable manufacturing practices, recyclable packaging, and ethical sourcing of raw materials (such as cobalt and tungsten). Companies transparent about their supply chain and carbon footprint may gain a competitive edge in both retail and industrial segments.

Regional Market Expansion

Emerging markets in Southeast Asia, Eastern Europe, and Latin America are expected to show increased demand for mid-tier drill press mortise bits as local woodworking industries grow. Simultaneously, North American and Western European markets will continue to drive innovation, with premium products emphasizing performance, safety, and compatibility with digital design software (e.g., CAD-to-cut workflows).

In summary, the 2026 market for drill press mortise bits will be shaped by technological innovation, evolving user needs, and a blend of craftsmanship and automation. Manufacturers that adapt to these trends—offering durable, precise, and user-accessible solutions—will be well-positioned for growth.

Common Pitfalls When Sourcing Drill Press Mortise Bits (Quality & Intellectual Property)

Sourcing Drill Press Mortise Bits can present several challenges, particularly concerning product quality and intellectual property (IP) issues. Avoiding these pitfalls is essential for ensuring performance, durability, and legal compliance.

Poor Material Quality and Construction

One of the most frequent issues is receiving bits made from substandard materials. Low-grade high-speed steel (HSS) or improper heat treatment leads to rapid dulling, chipping, or breakage during use. Inferior brazing techniques can cause the cutting edges to detach from the shank, especially under heavy load. Always verify the type of steel used—industrial-grade HSS or, better yet, carbide-tipped bits offer longer life and better performance.

Inaccurate Dimensional Tolerances

Low-cost or counterfeit bits often fail to maintain precise dimensions. Slight deviations in the width, thickness, or alignment of the chisel and auger can result in poorly fitting mortises, requiring excessive handwork to correct. This undermines the efficiency of using a drill press and compromises joint strength. Reliable suppliers provide tight tolerances and consistent geometry across multiple bits in a set.

Inadequate Heat Treatment

Proper heat treatment is critical for hardness and toughness balance. Poorly heat-treated bits may be too brittle (prone to chipping) or too soft (quickly losing their edge). Reputable manufacturers follow strict metallurgical processes; sourcing from unknown or unverified suppliers increases the risk of receiving poorly treated tools that fail prematurely.

Misrepresentation of Branding and Performance Claims

Some suppliers falsely market generic or imitation bits as equivalents to premium brands (e.g., replicating the design or name of well-known models without authorization). These copies often underperform and may infringe on trademarks or patented designs. Be cautious of exaggerated claims like “professional-grade” or “industrial strength” without verifiable certifications or manufacturer backing.

Intellectual Property Infringement

Many high-quality mortise bit designs are protected by patents or trademarks. Sourcing from manufacturers or suppliers that copy patented geometries—such as specific auger flute designs, chisel configurations, or shank innovations—can expose your business to legal risks, especially if used commercially. Always confirm that the product is legitimately licensed or from a brand that respects IP rights.

Lack of Traceability and Support

Reputable suppliers provide clear product traceability, including batch numbers, material certifications, and contact information for technical support. Generic or off-brand bits often lack documentation, making it difficult to address quality issues or recalls. This absence of support can be costly if bits fail during critical operations.

Inconsistent Quality Control

When sourcing from low-cost manufacturers, especially in bulk, there can be significant variance between individual bits in a set. One bit may cut cleanly while another vibrates excessively or produces rough walls. This inconsistency stems from lax quality control processes and undermines reliability in production environments.

To avoid these pitfalls, prioritize suppliers with proven track records, transparent manufacturing practices, and respect for intellectual property. Investing in genuine, high-quality mortise bits ultimately saves time, reduces waste, and ensures better results.

Logistics & Compliance Guide for Drill Press Mortise Bit

Product Classification and HS Code

Drill press mortise bits are typically classified under the Harmonized System (HS) code 8207.50, which covers interchangeable tools for hand tools, whether or not power-operated, or for machine-tools (for example, for pressing, stamping, punching, drilling, boring, broaching, milling, turning, or screw driving), of base metal. Specific country-level classifications may vary, so verification with local customs authorities is recommended.

Import/Export Documentation

Ensure the following documents are prepared for international shipments:

– Commercial Invoice (including product description, quantity, value, and HS code)

– Packing List (detailing weight, dimensions, and packaging type)

– Bill of Lading or Air Waybill

– Certificate of Origin (if required by trade agreements)

– Import/Export Licenses (if applicable based on destination)

Regulatory Compliance

Drill press mortise bits must comply with relevant safety and material regulations in the target market:

– United States: Complies with OSHA standards for tool safety; no special licensing needed for general hardware.

– European Union: Must meet CE marking requirements under the Machinery Directive (2006/42/EC) if sold as part of a machine system; individual bits may fall under general product safety directives.

– United Kingdom: UKCA marking may be required; adherence to the Provision and Use of Work Equipment Regulations (PUWER) is advised.

– Canada: Must meet CSA Group standards for tool safety; check with the Canadian Border Services Agency (CBSA) for import requirements.

Packaging and Labeling Requirements

- Packaging must be durable to prevent damage during transit, especially for bits with sharp cutting edges.

- Labels should include:

- Product name and model number

- Material composition (e.g., HSS, carbide-tipped)

- Dimensions (diameter, shank size, cutting length)

- Manufacturer or brand name

- Safety warnings (e.g., “Use with appropriate safety gear”)

- Country of origin

Safety and Handling Instructions

- Ship in protective packaging (e.g., blister packs or foam inserts) to prevent injury and damage.

- Include safety data sheet (SDS) if the product contains regulated materials (e.g., cobalt in carbide tips).

- Recommend handling with gloves and proper storage away from moisture to prevent corrosion.

Transportation Considerations

- Classified as non-hazardous goods for air, sea, and ground freight.

- Can be shipped via standard courier or freight services.

- Avoid exposure to extreme temperatures and humidity during transit.

Environmental and Disposal Compliance

- Comply with local waste disposal regulations (e.g., WEEE in the EU) if the bit contains regulated metals.

- Encourage recycling of worn-out bits through metal recycling programs.

- Manufacturers should follow ISO 14001 standards for environmental management if applicable.

Quality Assurance and Standards

- Products should meet recognized industry standards such as:

- ANSI B94.3 for cutting tool nomenclature (USA)

- ISO 5415 for tool shank dimensions

- Maintain quality control documentation to support compliance claims and facilitate audits.

Record Keeping and Traceability

- Retain shipping, compliance, and certification records for a minimum of 5 years.

- Implement batch or serial traceability to support recalls or customer inquiries.

- Ensure supplier documentation (e.g., material certifications) is verifiable and up to date.

Conclusion

Proper logistics and compliance management for drill press mortise bits ensures smooth international trade, regulatory adherence, and customer safety. Always verify specific requirements with local authorities and stay updated on regulatory changes in target markets.

Conclusion for Sourcing a Drill Press Mortise Bit

After evaluating various factors such as performance, durability, compatibility, and cost, sourcing a high-quality drill press mortise bit is essential for achieving precision and efficiency in woodworking tasks. Premium options, such as hollow chisel mortisers with sharpenable chisels and robust steel auger bits, offer superior results and longer tool life, especially for frequent or professional use. While budget alternatives may suffice for occasional projects, investing in a reputable brand ensures better accuracy, reduced wear, and greater ease of maintenance. Compatibility with your specific drill press or mortising machine is critical, and purchasing from trusted suppliers with good customer support adds value and reliability. Ultimately, selecting the right mortise bit involves balancing quality, application needs, and long-term usability—making informed sourcing decisions key to successful and consistent mortise joint creation.