The global bedroom furniture market, driven by rising disposable incomes, urbanization, and growing demand for modern home furnishings, is projected to expand at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030, according to Grand View Research. With dressers representing a key segment due to their functional appeal in storage and aesthetics, manufacturers are scaling innovation in design, material sustainability, and supply chain efficiency. As demand surges—particularly in North America and Asia-Pacific—consolidated players and regional artisans alike are positioning themselves to capture value in a competitive landscape. Based on production scale, brand reputation, and market reach, the following six dresser manufacturers stand out as leaders shaping the industry’s trajectory.

Top 6 Dresser Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dresser

Domain Est. 1986

Website: siemens.com

Key Highlights: Siemens revives critical roll-threader machine after lightning strike, using advanced motion control technology to improve quality, speed, and reliability….

#2 Dresser Utility Solutions

Domain Est. 2020

Website: dresserutility.com

Key Highlights: Dresser Utility Solutions is a leading provider of Global Infrastructure technology for the energy transition including measurement instrumentation, coupling ……

#3 Bernhardt

Domain Est. 1995

Website: bernhardt.com

Key Highlights: Explore Bernhardt’s collection of designer furniture crafted with uniquely beautiful materials and an elevated aesthetic….

#4 Desmond

Domain Est. 1996

Website: desmond-stephan.com

Key Highlights: The Desmond Stephan Mfg. Company has over 100 years experience – more than any other company in the United States – manufacturing Grinding Wheel Dressers. ……

#5 Changer & Dresser Corp.

Domain Est. 2001

Website: changer-dresser.com

Key Highlights: Changer & Dresser Corp, the North American Division of Kyokutoh, is a leader in the spot welding automation industry and supplies automotive and welding ……

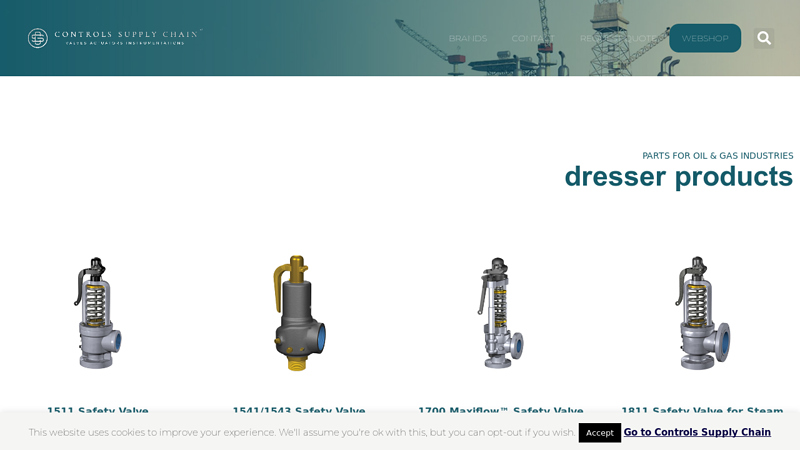

#6 Dresser Valves

Domain Est. 2012

Website: dresser-valves.nl

Key Highlights: The range includes a complete line of safety valves, including spring-loaded and pilot operated designs. Dresser Valves also delivers reciprocating and rotary ……

Expert Sourcing Insights for Dresser

H2 2026 Market Trends Analysis for Dresser

As we look toward the second half of 2026, Dresser—a key player in industrial and energy infrastructure solutions, particularly within oil & gas, water, and power sectors—will face a dynamic market landscape shaped by technological advancement, regulatory shifts, and evolving energy demands. Here’s a detailed analysis of the key H2 2026 market trends impacting Dresser:

1. Accelerated Energy Transition & Diversification

- Shift to Low-Carbon Infrastructure: Global decarbonization goals will drive increased investment in hydrogen-ready infrastructure, carbon capture utilization and storage (CCUS), and biogas handling systems. Dresser is likely expanding its product lines to include valves, regulators, and compression solutions compatible with hydrogen blends and supercritical CO₂.

- Natural Gas as a Transitional Fuel: Despite long-term decarbonization, natural gas remains critical for grid stability. Dresser benefits from demand for high-efficiency, low-emission gas compression and distribution systems, particularly in Asia and emerging markets.

- Growth in Renewable Integration: Dresser’s expertise in pressure control and flow management may extend to geothermal and green hydrogen production facilities, positioning the company at the nexus of traditional and renewable energy systems.

2. Digitalization and Smart Infrastructure

- IIoT Integration: By H2 2026, Dresser’s industrial solutions will increasingly incorporate Industrial Internet of Things (IIoT) sensors and predictive maintenance capabilities. Smart valves and actuators with real-time performance monitoring will enhance operational efficiency and reduce downtime for clients.

- Digital Twins & Asset Management: Adoption of digital twin technology for pipeline networks and processing facilities will grow. Dresser can leverage this trend by offering integrated digital services that complement its physical products, creating recurring revenue streams.

- Cybersecurity Focus: As infrastructure becomes more connected, demand for secure, resilient systems will rise. Dresser must ensure its digital offerings meet stringent cybersecurity standards, especially for critical energy infrastructure.

3. Regulatory and ESG Pressures

- Stricter Emissions Standards: Regulations such as methane leakage controls (e.g., U.S. EPA Methane Rules, EU Methane Regulation) will require advanced leak detection and repair (LDAR) technologies. Dresser is likely focusing on low-bleed valves, zero-emission actuators, and compliance-ready monitoring systems.

- ESG Investment Scrutiny: Investors and clients will demand transparent ESG reporting. Dresser must demonstrate sustainability in its supply chain, product lifecycle, and operational footprint to maintain competitiveness and access capital.

- Circular Economy Initiatives: Re-manufacturing and lifecycle extension of industrial components will gain importance. Dresser may expand its service offerings in refurbishment, retrofitting, and sustainable product design.

4. Geopolitical and Supply Chain Resilience

- Regionalization of Supply Chains: Ongoing supply chain volatility and trade tensions will push Dresser to localize production and sourcing, particularly in North America, Europe, and key Asian markets like India and Vietnam.

- Critical Materials Management: Dependence on rare metals and specialized alloys may drive investment in alternative materials or recycling programs to mitigate risk and cost volatility.

- Infrastructure Modernization in Emerging Markets: Countries in Southeast Asia, Africa, and Latin America will continue upgrading energy and water infrastructure, offering growth opportunities for Dresser’s reliable, scalable solutions.

5. Competitive Landscape and M&A Activity

- Consolidation in Industrial Sector: H2 2026 may see increased M&A as companies like Dresser seek to broaden digital capabilities, enter new energy markets (e.g., hydrogen), or enhance service portfolios.

- Competition from Tech-Enabled Startups: Agile entrants offering AI-driven predictive analytics or modular, plug-and-play systems could challenge traditional OEMs. Dresser’s response will likely involve partnerships or internal innovation hubs.

Strategic Implications for Dresser

- Product Portfolio Evolution: Continued expansion into low-carbon and digital-ready solutions will be essential.

- Service-Led Growth: Transition from product-centric to service-oriented business models (e.g., performance-based contracts) will enhance customer retention.

- R&D Focus: Investment in hydrogen compatibility, AI-driven diagnostics, and automation will differentiate Dresser in a crowded market.

Conclusion:

In H2 2026, Dresser operates at a pivotal juncture where traditional strengths in industrial infrastructure intersect with transformative energy and digital trends. Success will depend on agility in product innovation, commitment to sustainability, and strategic digital integration. Companies that proactively align with decarbonization, digitalization, and resilience will lead the next era of industrial solutions—positioning Dresser to thrive if it continues its trajectory of strategic adaptation.

Common Pitfalls When Sourcing Dressers: Quality and Intellectual Property Issues

Sourcing dressers—especially from overseas manufacturers—can present significant challenges related to both product quality and intellectual property (IP) protection. Avoiding these pitfalls is crucial for maintaining brand reputation, ensuring customer satisfaction, and safeguarding your business legally.

Quality-Related Pitfalls

1. Inconsistent Material Standards

One of the most common issues is the variation in material quality. Suppliers may use lower-grade wood, particleboard instead of solid wood, or substandard finishes to cut costs. This leads to dressers that are less durable, prone to warping, or have an unattractive appearance.

2. Poor Craftsmanship and Construction

Inadequate joinery, misaligned drawers, weak hardware (e.g., flimsy drawer slides), and uneven finishes are signs of poor craftsmanship. These issues often stem from insufficient quality control processes at the manufacturing facility.

3. Lack of Pre-Shipment Inspections

Skipping third-party quality inspections before shipment increases the risk of receiving defective products. Without proper checks, issues like structural flaws, color mismatches, or damaged components may go unnoticed until the goods arrive.

4. Inadequate Testing for Durability

Many sourced dressers fail to undergo standard durability tests (e.g., drawer cycle tests, load-bearing capacity). This can result in products that break or wear out quickly under normal use, leading to returns and negative reviews.

Intellectual Property-Related Pitfalls

1. Design Infringement and Copying

Suppliers may unknowingly or deliberately produce dressers that copy patented or copyrighted designs from well-known brands. Sourcing such products exposes your business to legal action, product seizures, and reputational damage.

2. Lack of Design Protection in Manufacturing Contracts

Failing to include IP ownership clauses in contracts with manufacturers can result in losing rights to custom designs. Some suppliers may replicate and sell your unique dresser designs to competitors if not legally restricted.

3. Unauthorized Subcontracting

Suppliers might outsource production to unauthorized subcontractors without your knowledge. These third parties are harder to monitor and may have weaker IP safeguards, increasing the risk of design leaks or counterfeiting.

4. Weak Enforcement in Sourcing Regions

In some countries, IP laws are either poorly enforced or difficult to navigate. Even if your design is protected, taking legal action against infringement can be costly and ineffective, leaving your IP vulnerable.

Mitigation Strategies

To avoid these pitfalls:

– Conduct thorough due diligence on suppliers, including factory audits.

– Request material specifications and prototypes before mass production.

– Implement third-party quality inspections at various production stages.

– Secure IP rights through patents, trademarks, and design registrations.

– Include strong IP protection clauses in supplier agreements.

– Monitor for unauthorized sales or listings of your designs online.

By proactively addressing quality and IP concerns, businesses can ensure reliable, legally compliant dresser sourcing that supports long-term success.

Logistics & Compliance Guide for Dresser

This guide outlines the essential logistics and compliance procedures for Dresser to ensure efficient operations, regulatory adherence, and supply chain integrity. All employees, partners, and third-party vendors must follow these protocols to maintain operational excellence and legal compliance.

Scope and Applicability

This guide applies to all Dresser facilities, distribution centers, transportation partners, and personnel involved in the movement, storage, handling, or documentation of products and materials. It covers international and domestic operations, including import/export activities.

Regulatory Compliance Requirements

Dresser must comply with all applicable local, national, and international regulations, including but not limited to:

– International Maritime Organization (IMO) standards

– International Air Transport Association (IATA) regulations

– U.S. Department of Transportation (DOT) regulations

– European Union’s REACH and RoHS directives

– Customs-Trade Partnership Against Terrorism (C-TPAT) guidelines

– Export Administration Regulations (EAR) and International Traffic in Arms Regulations (ITAR), where applicable

Ensure all shipments are screened against denied party lists and export control classifications.

Packaging and Labeling Standards

All products must be packaged to prevent damage during transit and in compliance with:

– Hazardous materials (if applicable) per UN recommendations

– Proper use of barcodes, RFID tags, and standardized shipping labels

– Clear labeling of product contents, weight, handling instructions, and safety warnings

– Compliance with destination country labeling requirements (e.g., language, CE marking)

Transportation and Carrier Management

- Use only pre-qualified carriers who meet Dresser’s safety, security, and sustainability standards.

- Maintain contracts with service level agreements (SLAs) covering on-time delivery, damage rates, and incident reporting.

- Optimize routing to reduce emissions and transit time.

- Monitor real-time shipment tracking and proactively manage delays.

Customs Clearance and Documentation

- Ensure accurate and complete documentation for all cross-border shipments, including:

- Commercial invoices

- Packing lists

- Certificates of origin

- Export declarations (e.g., EEI via AES)

- Assign responsibility to trained trade compliance personnel for classification (HTS codes), valuation, and duty management.

- Maintain records for a minimum of five years per U.S. CBP and EU requirements.

Inventory and Warehouse Compliance

- Implement a documented inventory management system with cycle counting and audit trails.

- Store hazardous materials in designated, ventilated areas with proper spill containment.

- Ensure warehouse facilities comply with OSHA, fire safety, and environmental standards.

- Enforce access controls and security monitoring to prevent theft or tampering.

Sustainability and Environmental Responsibility

- Minimize packaging waste through reusable or recyclable materials.

- Measure and report logistics-related carbon emissions annually.

- Partner with carriers committed to fuel efficiency and low-emission technologies.

- Comply with WEEE and other end-of-life product return regulations.

Incident Reporting and Corrective Actions

- Report all logistics incidents (delays, damages, compliance violations) within 24 hours using the internal incident reporting system.

- Conduct root cause analysis and implement corrective and preventive actions (CAPA).

- Escalate regulatory violations to the Compliance Officer immediately.

Training and Accountability

- All logistics and supply chain personnel must complete annual training on:

- Regulatory updates

- Security protocols

- Hazardous materials handling

- Ethical sourcing and anti-bribery policies

- Assign compliance responsibilities to designated officers at each regional hub.

Audits and Continuous Improvement

- Conduct internal and third-party audits annually to assess compliance and performance.

- Use audit findings to update procedures and enhance logistics efficiency.

- Benchmark against industry best practices and pursue certifications such as ISO 9001, ISO 14001, or TAPA.

By adhering to this Logistics & Compliance Guide, Dresser ensures safe, reliable, and legally compliant delivery of products worldwide while upholding its commitment to operational integrity and sustainability.

Conclusion on Sourcing Dresser Suppliers

Sourcing the right dresser suppliers is a critical step in ensuring product quality, cost-efficiency, and supply chain reliability. After evaluating various suppliers based on criteria such as manufacturing capabilities, material sourcing, pricing, lead times, quality control, and ethical practices, it is clear that a balanced approach—combining both domestic and international suppliers—offers the best long-term value.

Key takeaways include the importance of conducting thorough due diligence, prioritizing suppliers with certifications (e.g., FSC, ISO), and establishing strong communication channels to manage expectations and resolve issues promptly. Suppliers from regions like Southeast Asia and Eastern Europe often provide competitive pricing and craftsmanship, while local or regional suppliers offer faster delivery and easier oversight.

Ultimately, building strategic partnerships with a select group of reliable suppliers—rather than relying on a single source—can enhance flexibility, reduce risks, and support scalability. Continuous performance monitoring and regular re-evaluation will ensure that supplier relationships remain aligned with business goals and evolving market demands.