The global drawstring cord lock market is experiencing steady growth, driven by rising demand across apparel, sportswear, outdoor gear, and medical textile sectors. According to Grand View Research, the global technical textiles market—of which drawstring components are a critical enabler—is projected to expand at a CAGR of 5.2% from 2023 to 2030, fueled by innovation in functional fastening solutions and increasing consumer preference for adjustable, secure closures. Similarly, Mordor Intelligence forecasts sustained growth in the sportswear and outdoor accessories markets, with a CAGR of approximately 6.3% through 2028, further accelerating the need for reliable cord management systems. As brands prioritize durability, ergonomics, and manufacturability, selecting the right drawstring cord lock supplier has become a strategic decision impacting product performance and compliance. In this landscape, manufacturers that combine precision engineering, scalable production, and material innovation are gaining competitive advantage. Here are the top 9 drawstring cord lock manufacturers leading the industry with proven track records in quality, R&D, and global supply chain integration.

Top 9 Drawstring Cord Lock Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Cord Lock Manufacturer

Domain Est. 2009

Website: wysecn.com

Key Highlights: WYSE provides bulk Cord End, Cord Lock, Eyelets, Drawstring, etc., produced by China factory. Contact us now….

#2 Oregon Cord Lock – Cord Locks and Handi

Domain Est. 1996

Website: cordlock.com

Key Highlights: Oregon Cord Lock is a manufacturer and seller of Cord Lock Drawstring Toggles in 2 sizes and many color, we also sell Handi-bobs….

#3 MH Manufacturer Plastic Cord Lock Stopper for Drawstrings

Domain Est. 2001

Website: mh-chine.com

Key Highlights: Crafted from high-quality plastic, this cord lock ensures a strong grip, keeping cords and drawstrings in place without slipping….

#4 Plastic Cord Locks in Bulk

Domain Est. 1997

#5 Plastic Cord Locks, Cord Stoppers & Drawstring Cord Locks

Domain Est. 2002

#6 Top Cord Lock Stopper Suppliers Worldwide

Domain Est. 2006

Website: shinfang.com

Key Highlights: As a leader in the production of plastic rope buckles, Shin Fang Plastic provides high-quality and reliable custom cord locks to meet various needs….

#7 CORD LOCK & STOP

Domain Est. 2007

Website: pacifictrimming.com

Key Highlights: Free delivery over $129 30-day returns…

#8 Cord Lock

Domain Est. 2009

Website: pinlilabel.com

Key Highlights: Our custom cord locks are available in a variety of shapes, colors, and sizes. They allow you to quickly close the opening and add design to the garment. Our ……

#9 Cord Lock

Domain Est. 2019

Website: ji-horng.com

Key Highlights: Over 30 years specialized in manufacturing plastic cord end lock. Offering multiple designs and sizes of cord adjuster, cord loop, and cord stopper….

Expert Sourcing Insights for Drawstring Cord Lock

H2: 2026 Market Trends for Drawstring Cord Locks

The global drawstring cord lock market is poised for steady growth through 2026, driven by increasing demand across fashion, outdoor gear, sportswear, and functional apparel sectors. As sustainability, versatility, and user convenience become central to product design, drawstring cord locks are evolving both functionally and aesthetically to meet modern consumer expectations.

-

Rising Demand in Activewear and Streetwear

The surge in athleisure and casual fashion continues to fuel demand for functional closures like drawstring cord locks. Brands are integrating ergonomic and lightweight cord locks into hoodies, sweatpants, backpacks, and gym bags. With the global activewear market expanding, particularly in North America and Asia-Pacific, manufacturers of cord locks are seeing increased B2B partnerships with apparel and accessories brands. -

Material Innovation and Sustainability

Environmental concerns are reshaping material choices. By 2026, a significant shift toward eco-friendly materials—such as recycled plastics (rPET), bio-based polymers, and biodegradable composites—is expected in cord lock production. Brands aiming for circular economy goals are prioritizing recyclable or compostable cord lock solutions, especially in Europe, where regulatory pressures on plastic usage are strong. -

Customization and Brand Differentiation

Drawstring cord locks are becoming branding tools. Companies are investing in custom-molded locks with logos, unique colors, and textures to enhance product identity. This trend is especially prominent in premium outdoor and lifestyle brands, where aesthetics and functionality intersect. Injection molding technologies are enabling cost-effective small-batch customization, supporting niche and DTC (direct-to-consumer) brands. -

Technological Enhancements

Innovations such as anti-slip mechanisms, one-pull tightening systems, and low-profile designs are gaining traction. These improvements enhance usability, particularly in performance wear and outdoor equipment. Smart textiles and wearable integration may also open new avenues—though still nascent—such as cord locks with embedded tracking or tension sensors in high-end gear. -

Regional Growth Dynamics

Asia-Pacific remains the dominant manufacturing and consumption hub for drawstring cord locks, supported by strong textile industries in China, India, and Vietnam. However, North America and Western Europe are witnessing growth in demand due to rising outdoor recreation participation and the popularity of functional urban wear. Localized supply chains and nearshoring trends may also boost regional production in these markets. -

E-commerce and Fast Fashion Influence

The rise of online apparel retail and fast fashion continues to impact cord lock demand. Fast fashion cycles require quick turnaround and cost-effective components, favoring high-volume, low-cost plastic cord locks. However, this is balanced by a counter-trend toward durability and repairability, especially in markets with growing secondhand and rental fashion ecosystems.

Conclusion

By 2026, the drawstring cord lock market will reflect broader industry shifts: sustainability, customization, and functional design. While plastic-based locks will remain dominant, innovation in materials and smart features will differentiate premium offerings. Manufacturers who align with eco-conscious practices and partner closely with fashion and outdoor brands are likely to lead the evolving market landscape.

Common Pitfalls Sourcing Drawstring Cord Locks (Quality, IP)

When sourcing drawstring cord locks—commonly used in apparel, bags, outdoor gear, and medical wear—overlooking critical quality and intellectual property (IP) considerations can lead to product failures, legal issues, and reputational damage. Below are key pitfalls to avoid:

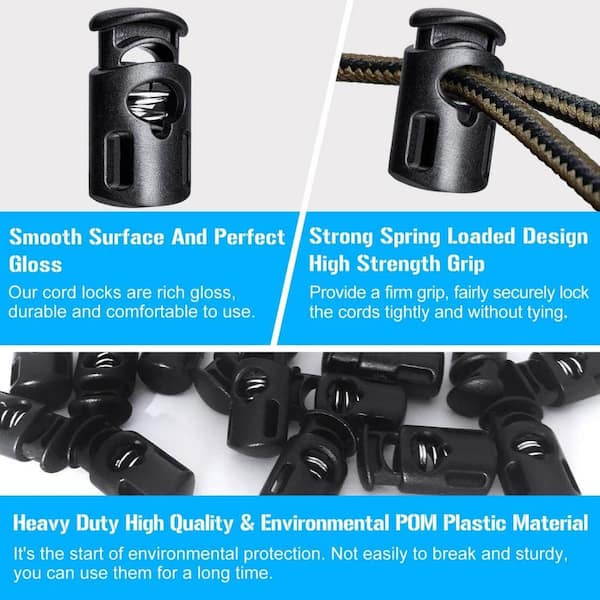

Poor Material Quality and Durability

Many low-cost suppliers use substandard plastics (e.g., brittle polypropylene or recycled content) that degrade under UV exposure, extreme temperatures, or repeated use. This leads to cracking, jamming, or failure to hold tension—especially problematic in outdoor or safety-critical applications.

Inconsistent Dimensional Tolerances

Low-quality molds or poor manufacturing control result in inconsistent lock dimensions. This affects compatibility with cords, leading to slippage or excessive friction. Inconsistent release mechanisms can frustrate users and reduce product reliability.

Lack of Environmental and Safety Compliance

Some suppliers fail to meet regulatory standards such as REACH, RoHS, or CPSIA. This is especially critical if products are sold in the EU or US. Non-compliant materials may contain harmful phthalates or heavy metals, risking recalls and legal liability.

Ignoring IP and Patent Infringement Risks

Many popular cord lock designs (e.g., YKK, Duraflex) are protected by patents or design rights. Sourcing generic copies that mimic patented mechanisms can expose buyers to legal action, shipment seizures, or forced product redesigns. Always verify freedom-to-operate (FTO) before mass production.

Inadequate Testing and Certification

Reputable cord locks undergo load, cycle, and weather resistance testing. Suppliers who cannot provide test reports (e.g., tensile strength, cycle life) may deliver components unsuitable for intended use—especially in high-performance or safety applications like medical gowns or tactical gear.

Misrepresentation of “Waterproof” or “IP-Rated” Claims

Some suppliers falsely advertise cord locks as “IP67” or “waterproof.” Unless the lock design and integration are properly engineered and tested, such claims are misleading. IP ratings apply to complete enclosures, not individual components, and improper use can compromise product integrity.

Overlooking Supplier Verification

Sourcing from uncertified or unverified manufacturers increases the risk of inconsistent quality, delayed shipments, and counterfeit parts. Always conduct factory audits, request samples, and verify certifications like ISO 9001.

Avoiding these pitfalls requires due diligence in material selection, supplier vetting, compliance verification, and IP clearance—ensuring reliable performance and legal safety in the final product.

Logistics & Compliance Guide for Drawstring Cord Lock

This guide provides essential information for the safe, legal, and efficient handling, transportation, and use of drawstring cord locks across product supply chains and retail environments. Adherence to these guidelines helps ensure product safety, regulatory compliance, and operational efficiency.

Product Overview

Drawstring cord locks (also known as cord toggles, cord stoppers, or cord adjusters) are small plastic or metal components used to secure and adjust drawstrings on garments, bags, backpacks, hooded apparel, and other textile products. They function by pinching or clamping the cord to prevent slipping, allowing users to tighten or loosen the fit.

Regulatory Compliance

Consumer Product Safety Standards (CPSIA – USA)

- Drawstring cord locks used in children’s apparel must comply with U.S. Consumer Product Safety Commission (CPSC) regulations under 16 CFR Part 1199 and 16 CFR Part 1550.

- Apparel for children aged 2T to 12 years must not have drawstrings in hoods or neck areas due to strangulation hazards.

- Drawstrings in waist or bottom areas must be ≤ 3 inches in length when fully extended.

- All components, including cord locks, must be tested for small parts (if detachable), lead content (<100 ppm), and phthalates (<0.1%).

EU General Product Safety Directive (GPSD) & REACH

- Products sold in the European Union must meet the GPSD, ensuring general safety for consumers.

- REACH regulations require disclosure and restriction of Substances of Very High Concern (SVHCs).

- Ensure cord locks do not contain restricted substances such as certain phthalates, cadmium, or PAHs.

- Labeling must include CE marking when applicable and traceability information.

Other International Requirements

- Canada: Comply with the Children’s Clothing Regulations under the Canada Consumer Product Safety Act (CCPSA). Drawstrings in hoods and necks of children’s clothing are restricted.

- Australia/New Zealand: Follow AS/NZS 1906.2:2017 for children’s sleepwear and general product safety standards.

- UK: Post-Brexit, adhere to UKCA marking requirements and the UK GPSR (General Product Safety Regulations 2005).

Packaging & Labeling

- Clearly label packaging with product specifications, lot numbers, and compliance markings (e.g., CE, UKCA, CPSIA).

- Include age grading and warnings where applicable (e.g., “Not intended for children under 3 years due to small parts”).

- Use tamper-evident packaging if required by retailer or region.

Storage & Handling

- Store in a dry, temperature-controlled environment to prevent deformation or brittleness.

- Keep away from direct sunlight and UV exposure to avoid material degradation.

- Handle with clean hands or gloves to avoid contamination, especially in sterile or sensitive production environments.

- Segregate by lot number to support traceability in case of recalls.

Transportation & Logistics

- Use appropriate inner packaging (e.g., polybags, clamshells) to prevent loss or damage during transit.

- Palletize securely using stretch wrap and corner boards; avoid overstacking.

- Follow Incoterms clearly in shipping documentation (e.g., FOB, EXW, DDP).

- Maintain a cold chain or climate control if transporting in extreme environments.

- Ensure carriers are compliant with IATA or IMDG regulations if shipping internationally (though cord locks are generally non-hazardous).

Quality Assurance & Testing

- Conduct regular batch testing for:

- Dimensional accuracy

- Tensile strength of locking mechanism

- Material composition (RoHS, REACH, CPSIA)

- Durability under repeated use (cycle testing)

- Maintain a documented quality management system (e.g., ISO 9001).

- Retain samples and test reports for minimum of 5 years.

Risk Mitigation & Recall Preparedness

- Implement a product traceability system (batch/lot tracking).

- Develop a recall plan that includes communication protocols, return logistics, and regulatory reporting.

- Monitor CPSC, RAPEX, and Health Canada alerts for emerging safety issues related to drawstrings.

Responsible Sourcing & Sustainability

- Source materials from suppliers with ethical labor practices and environmental management systems.

- Consider recyclable or bio-based materials for cord locks (e.g., recycled nylon, bioplastics).

- Provide documentation for corporate social responsibility (CSR) or ESG reporting upon request.

Conclusion

Compliance with logistics and regulatory requirements for drawstring cord locks is critical to ensuring consumer safety and avoiding legal or financial penalties. By following this guide, manufacturers, importers, and retailers can mitigate risks, maintain market access, and support sustainable business practices. Always consult local regulations and update compliance protocols as standards evolve.

Conclusion:

Sourcing drawstring cord locks requires a strategic approach that balances quality, cost, and reliability. After evaluating various suppliers, materials, and manufacturing processes, it is evident that selecting the right cord lock involves considering factors such as durability, ease of use, compatibility with different cord types, and compliance with safety and environmental standards. Suppliers from regions like China, India, and Southeast Asia offer competitive pricing and scalability, while closer regional suppliers may provide faster lead times and better communication.

Ultimately, establishing long-term partnerships with reputable manufacturers, conducting thorough sample testing, and ensuring consistent quality control are key to securing a reliable supply chain. By prioritizing these elements, businesses can effectively source drawstring cord locks that meet product requirements, enhance end-user satisfaction, and support efficient production processes.