The global drain pipe sock market is experiencing steady growth, driven by rising infrastructure development, increased focus on erosion control, and expanding applications in civil engineering and drainage systems. According to Mordor Intelligence, the global geotextiles market—of which drain pipe socks are a key component—is projected to grow at a CAGR of over 6.5% from 2023 to 2028. Drain pipe socks, primarily used to wrap perforated pipes in subsurface drainage, play a critical role in preventing soil infiltration while allowing water flow, making them essential in construction, agriculture, and landscaping projects.

This growing demand has led to a competitive landscape with manufacturers enhancing product durability, filtration efficiency, and compatibility with various soil types. Advancements in nonwoven polypropylene and polyethylene materials have further improved performance and cost-effectiveness. As infrastructure investment rises—particularly in emerging economies—the need for reliable drainage solutions continues to fuel innovation and expansion among leading suppliers.

Based on market presence, product quality, and technical capabilities, the following seven manufacturers have emerged as key players in the drain pipe sock industry, serving diverse sectors with scalable and compliant drainage solutions.

Top 7 Drain Pipe Sock Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Drain

Domain Est. 2000

Website: tchristy.com

Key Highlights: 6 inch diameter … T. Christy Enterprises is one of North America’s largest manufacturers of adhesives, solvents and sealants, with over 40 years of experience….

#2 Pipe Sock

Domain Est. 2004

Website: drainagesolutionsinc.com

Key Highlights: DRAIN-SLEEVE filter sock prevents sand and silt from entering and clogging perforated drainage pipes. DRAIN-SLEEVE is recommended for the protection of all ……

#3 Ultra

Domain Est. 1997

Website: spillcontainment.com

Key Highlights: The 9-foot-long filter socks are placed in front of storm drains. The woven geotextile material allows stormwater to flow through into the storm drain….

#4 Infrastructure Drainage Filter Sock™

Domain Est. 1998

Website: carriff.com

Key Highlights: The Super Sock™ (Type H) from Carriff is a field-tested, industry-leading solution for underground drainage systems in highway infrastructure….

#5 AdvanEdge Site Drain Pipe

Domain Est. 2000

Website: adspipe.com

Key Highlights: ADS AdvanEdge® Highway and Site Drain Pipe provides the proper drainage to increases the playability of turf surfaces & reduce maintenance and repair costs….

#6 The Drainage Products Store

Domain Est. 2009

Website: drainageproducts.us

Key Highlights: 2–5 day delivery 30-day returnsDrainage Products Store provides top quality products for your drainage, sediment control, septic, residential and commercial projects….

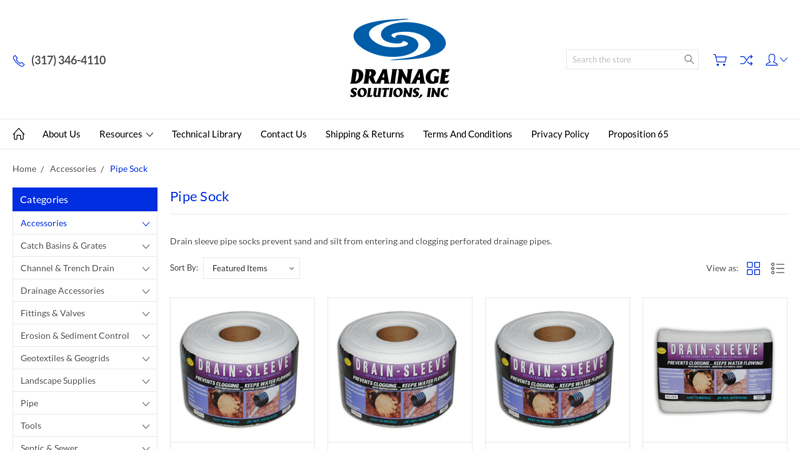

#7 Pipe Socks

Domain Est. 2013

Website: thedrainagesource.com

Key Highlights: 3-day delivery 30-day returnsDrain sleeve pipe socks prevent sand and silt from entering and clogging perforated drainage pipes. Extend the life of your pipes with Drainage Solutio…

Expert Sourcing Insights for Drain Pipe Sock

H2: 2026 Market Trends for Drain Pipe Sock

The global market for drain pipe socks is projected to experience steady growth by 2026, driven by increasing demand in construction, civil engineering, and environmental protection sectors. These geotextile-based filtration sleeves are essential components in drainage systems, used to prevent soil intrusion while allowing water to flow freely through perforated pipes. As urbanization accelerates and infrastructure development expands—particularly in emerging economies—the need for reliable subsurface drainage solutions is expected to rise.

One key trend shaping the 2026 outlook is the growing emphasis on sustainable construction practices. Drain pipe socks made from recycled or eco-friendly synthetic fibers are gaining traction, aligning with green building standards and government regulations promoting environmental stewardship. Manufacturers are investing in R&D to improve the durability, permeability, and biodegradability of materials, which will enhance long-term performance while reducing ecological footprints.

Another significant trend is the integration of smart technologies in infrastructure. While still in early stages, some advanced drainage systems are beginning to incorporate sensor-equipped pipe socks that monitor soil moisture, sediment accumulation, and flow rates. This data can be used for predictive maintenance and optimized water management, particularly in flood-prone or drought-affected regions.

Regionally, Asia-Pacific is expected to dominate market growth due to rapid industrialization, expanding transportation networks, and large-scale urban development projects in countries like India, China, and Southeast Asian nations. North America and Europe will maintain stable demand, supported by aging infrastructure rehabilitation efforts and stringent stormwater management regulations.

Additionally, the competitive landscape is evolving, with key players focusing on product differentiation, cost efficiency, and strategic partnerships with civil engineering firms and government agencies. Customizable sizing, material options, and installation-friendly designs are becoming critical selling points.

In conclusion, the drain pipe sock market in 2026 will be characterized by innovation, sustainability, and geographic expansion, positioning it as a vital component in modern drainage infrastructure worldwide.

Common Pitfalls Sourcing Drain Pipe Sock (Quality, IP)

When sourcing drain pipe socks—used for sediment control and filtration in drainage systems—several critical pitfalls related to quality and Ingress Protection (IP) ratings can compromise performance and lead to costly failures. Being aware of these issues helps in making informed procurement decisions.

Poor Material Quality

One of the most frequent issues is substandard fabric or geotextile material. Low-quality drain pipe socks may use thin, non-durable polypropylene or polyester that degrades quickly under UV exposure, mechanical stress, or prolonged moisture. This results in reduced filtration efficiency, premature tearing, and ineffective sediment retention. Always verify material specifications, including weight (e.g., grams per square meter), UV stabilization, and tensile strength.

Inconsistent Pore Size and Filtration Efficiency

Inferior socks often have inconsistent or oversized pore ratings, allowing fine sediments to pass through and clog the drainage system. This undermines their primary function. Ensure the sock meets required filtration standards (e.g., ASTM D4491) and is matched to the soil and drainage pipe specifications. A mismatch can lead to blocked pipes and reduced system lifespan.

Lack of Valid IP (Ingress Protection) Certification

Many suppliers claim “waterproof” or “high protection” without providing certified IP ratings. Drain pipe socks are not typically assigned formal IP codes like electrical enclosures (IP67, etc.), but the concept applies to their ability to prevent sediment and debris ingress. Be cautious of vague claims—always request test data or third-party validation showing filtration efficiency and durability under real-world conditions.

Inadequate Seam Strength and Construction

Weak stitching or poorly sealed seams can cause the sock to split open during installation or under backfill pressure. Look for socks with reinforced, ultrasonically welded or heat-sealed seams. Poor construction reduces effective lifespan and increases maintenance costs.

Misrepresentation of Dimensional Accuracy

Sizing inaccuracies—such as incorrect diameter or length—lead to poor fit around drainage pipes, creating gaps that allow unfiltered soil entry. Verify that the sock dimensions match the pipe size precisely, and consider tolerance ranges provided by the manufacturer.

Insufficient UV and Chemical Resistance

Drain pipe socks exposed during installation or in chemically aggressive soils may degrade rapidly if not properly treated. Ensure the product is rated for UV resistance (e.g., 500+ hours UV exposure testing) and compatible with expected soil chemistry, especially in industrial or contaminated sites.

Overlooking Installation and Handling Requirements

Even high-quality socks fail if not installed correctly. Some suppliers fail to provide clear installation guidelines or training, leading to improper placement, stretching, or damage. Choose suppliers that offer technical support and detailed specifications for handling, overlap, and securing methods.

Conclusion

To avoid these pitfalls, prioritize suppliers with proven track records, third-party testing reports, and transparent specifications. Always request samples, verify material certifications, and ensure compatibility with your project’s environmental and engineering requirements.

Logistics & Compliance Guide for Drain Pipe Sock

Product Overview

A drain pipe sock is a filter sleeve designed to fit over drainage pipes, stormwater outlets, or construction site dewatering points. It helps prevent sediment, debris, and pollutants from entering waterways by filtering runoff. These are commonly used in construction, landscaping, and environmental remediation projects.

Shipping & Handling

- Packaging: Drain pipe socks are typically shipped in polyethylene bags or shrink-wrapped bundles. Ensure packaging is intact to prevent contamination or moisture damage.

- Storage: Store in a dry, shaded area away from direct sunlight and extreme temperatures. UV exposure can degrade fabric integrity.

- Weight & Dimensions: Light in weight but bulky due to volume. Optimize pallet stacking and container loading to maximize space utilization.

- Handling: Use gloves when handling to avoid transferring oils or contaminants. Avoid dragging to prevent abrasion or tearing.

Transportation Requirements

- Mode of Transport: Suitable for road, rail, air, and sea freight. For air freight, confirm weight and size restrictions with carriers.

- Hazard Classification: Non-hazardous material. No special handling or documentation required under IATA, IMDG, or DOT regulations.

- Temperature Control: Not required. However, prolonged exposure to temperatures above 60°C (140°F) may affect material performance.

- Documentation: Include commercial invoice, packing list, and bill of lading. For international shipments, provide a certificate of origin if requested.

Import & Export Compliance

- HS Code: Typically classified under 6307.90 (Other made-up articles, including filter fabrics). Confirm with local customs authority as classifications may vary by country.

- Import Duties & Taxes: Vary by destination country. Check with local customs for applicable tariffs, especially under environmental or construction product categories.

- Restricted Countries: No known global restrictions, but verify local environmental regulations—some jurisdictions may require performance certifications.

- Export Controls: Not subject to ITAR or EAR regulations. No license required for most destinations.

Regulatory & Environmental Compliance

- EPA & Stormwater Regulations (USA): Compliant with EPA NPDES (National Pollutant Discharge Elimination System) requirements when used as part of a sediment control plan. Must meet site-specific erosion and sediment control (ESC) BMPs.

- ISO Standards: Look for products tested to ISO 10538 (geotextile filtration) or ASTM D4491 (hydraulic conductivity).

- REACH & RoHS (EU): Ensure materials are free from SVHCs (Substances of Very High Concern). Most polypropylene-based socks comply if no toxic additives are used.

- Local Environmental Laws: In Australia (EPA Victoria), Canada (provincial environmental acts), and the UK (EA regulations), drain socks must be part of an approved erosion control strategy.

Product Certification & Testing

- ASTM Standards: Confirm compliance with ASTM D5101 (geotextile installation) and D5084 (hydraulic conductivity).

- SED-1 Certification (USA): Some states require SED-1 certification for sediment control products used in public works projects.

- Third-Party Testing: Request test reports for permittivity, tensile strength, and soil retention efficiency.

- Labeling: Product labels should include material type (e.g., 100% polypropylene), pore size, dimensions, and compliance statements.

Disposal & End-of-Life

- Reusability: Some drain pipe socks are reusable if cleaned and undamaged. Inspect for tears or clogging before reuse.

- Disposal: Non-hazardous waste. Dispose of in accordance with local solid waste regulations. If contaminated with hazardous materials (e.g., oil, chemicals), treat as hazardous waste.

- Recycling: Polypropylene socks may be recyclable. Check with local recyclers for acceptance of geotextile materials.

- Landfill: Acceptable in non-hazardous landfills if recycling is not available.

Best Practices for Compliance & Logistics

- Maintain documentation of material safety data sheets (MSDS/SDS), test reports, and compliance certificates.

- Train field personnel on proper installation and handling to maintain product performance and regulatory compliance.

- Audit supply chain partners for adherence to environmental and shipping standards.

- Regularly review regulatory updates in target markets to ensure continued compliance.

For additional support, consult your supplier or a compliance specialist familiar with environmental construction products.

Conclusion for Sourcing Drain Pipe Sock

Sourcing drain pipe socks requires careful consideration of material quality, compatibility with drainage systems, cost-effectiveness, and supplier reliability. After evaluating various suppliers and product options, it is clear that selecting a durable, permeable geotextile sock—typically made from polypropylene or polyester—ensures effective filtration, prevents soil migration, and enhances the longevity of drainage installations. Prioritizing suppliers with proven track records, consistent product standards, and timely delivery capabilities will support project efficiency and performance. Ultimately, a strategic sourcing approach that balances quality, cost, and sustainability will optimize both short-term application success and long-term infrastructure durability.