The global washing machine accessories market is experiencing steady expansion, driven by rising consumer demand for efficient, leak-proof, and adaptable laundry solutions. According to Grand View Research, the global washing machine market size was valued at USD 61.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth trajectory indirectly fuels the demand for essential components like drain hose adapters, which ensure compatibility across diverse plumbing setups and enhance appliance performance. As urbanization increases and homeowners prioritize appliance longevity and efficiency, the need for reliable, high-quality drain hose adapters has become more pronounced. Leading manufacturers are responding with innovative, durable designs that cater to a wide range of washing machine models and regional plumbing standards. In this competitive landscape, the top five drain hose adapter manufacturers distinguish themselves through engineering precision, material quality, and widespread compatibility—critical factors supported by rising market demand and the proliferation of connected, high-efficiency laundry systems.

Top 5 Drain Hose Adapter For Washing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

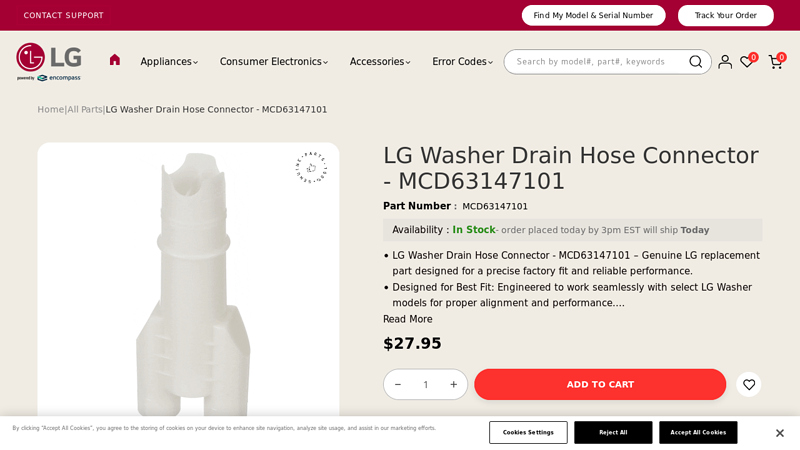

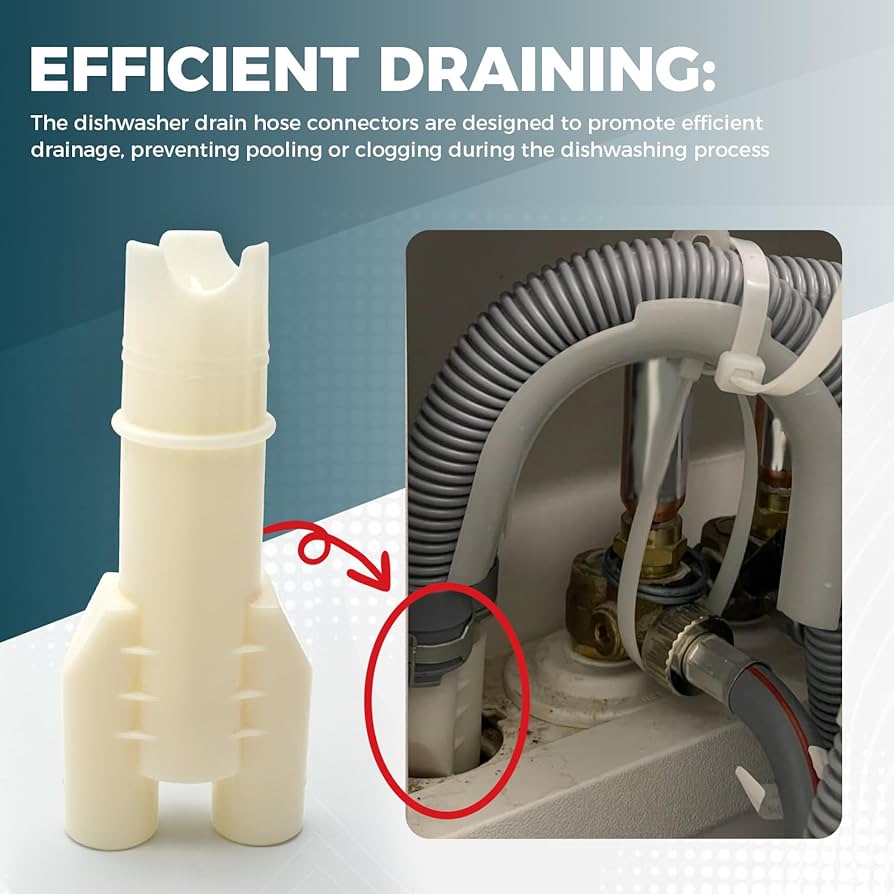

#1 LG Washer Drain Hose Connector

Domain Est. 2004

Website: lgparts.com

Key Highlights: In stock $11.45 deliveryLG Washer Drain Hose Connector – MCD63147101 – Genuine LG replacement part designed for a precise factory fit and reliable performance….

#2 LG Washing Machine Hose & Hose Connector

Domain Est. 1995

Website: lg.com

Key Highlights: 6–19 day delivery · 15-day returnsExplore the LG washing machine hose & hose connector today and maximise the performance of your LG washing machine hose & hose connector….

#3 WH41X26961

Domain Est. 1999

Website: geapplianceparts.com

Key Highlights: In stock $7.95 deliveryWashing Machine Drain Hose Extension Kit. WH49X301. 1.3 star rating (4). $35.00. Add to Cart; XWFE3PK. GE® XWFE™ REFRIGERATOR WATER FILTER 3-PACK. XWFE3PK. 4…

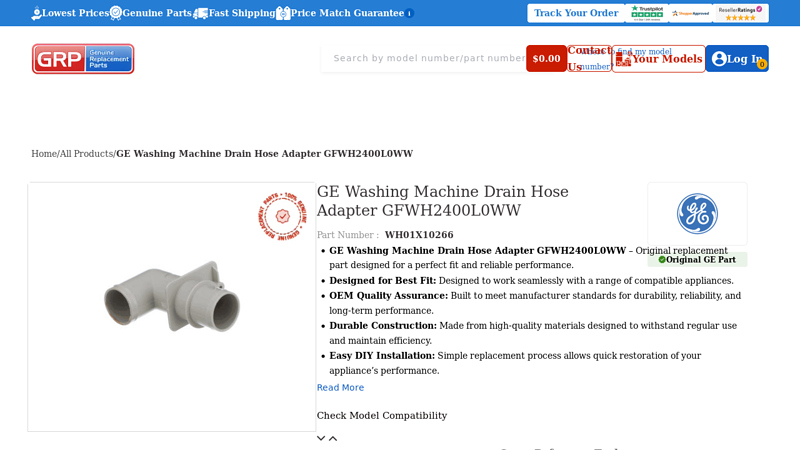

#4 GE Washing Machine Drain Hose Adapter GFWH2400L0WW

Domain Est. 2018

Website: genuinereplacementparts.com

Key Highlights: Drain hose adapter connects the external drain hose to the washer’s internal drain hose.Shut off the water supply and unplug the washer before installing this ……

#5 Washing Machine Hoses & Connectors

Domain Est. 1996

Expert Sourcing Insights for Drain Hose Adapter For Washing Machine

2026 Market Trends for Drain Hose Adapter for Washing Machine

As the home appliance and plumbing accessories market continues to evolve, the demand for specialized components such as the drain hose adapter for washing machines is expected to experience notable shifts by 2026. Driven by technological advancements, changing consumer behaviors, and global sustainability initiatives, this niche product segment is poised for growth and transformation. Below is an in-depth analysis of the key market trends shaping the future of drain hose adapters.

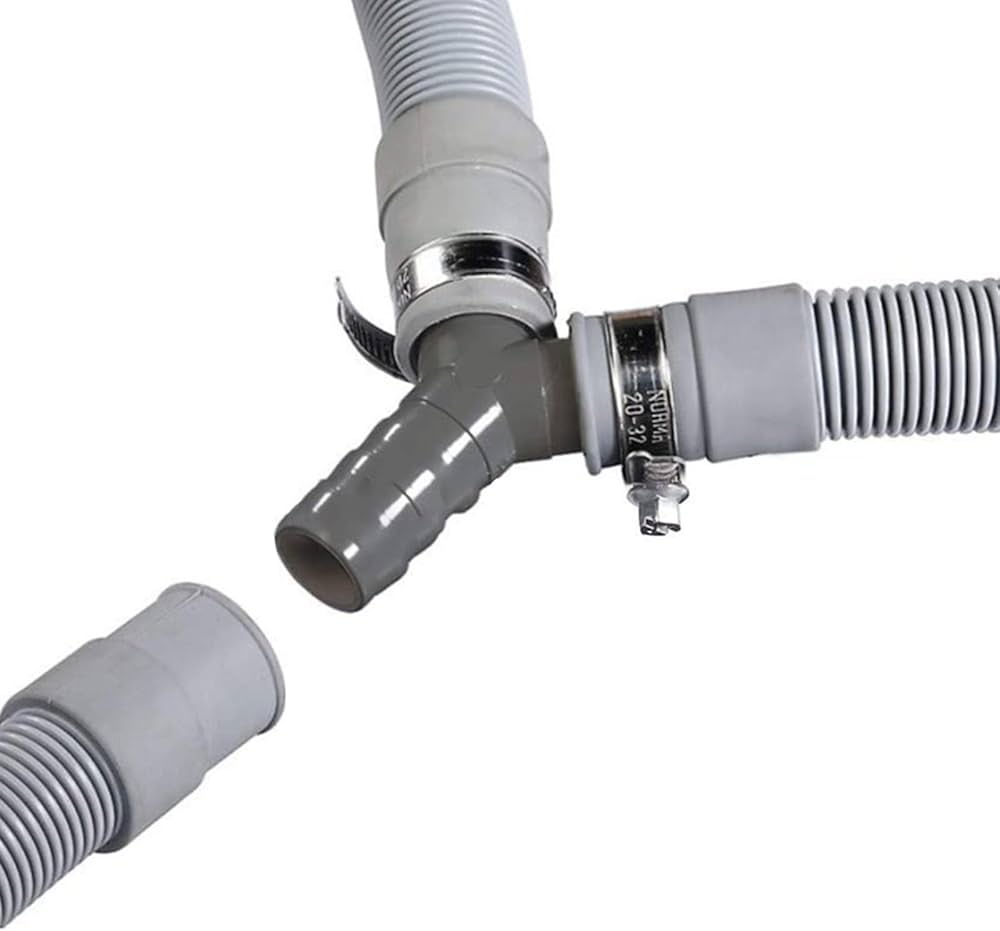

Increasing Demand for Universal and Multi-Compatible Adapters

A major trend driving the 2026 market is the rising consumer preference for universal-fit drain hose adapters. With a wide variety of washing machine brands and drain configurations across regions, homeowners and installers are seeking adapters that offer compatibility with multiple models and international plumbing standards. Manufacturers are responding by designing versatile adapters with adjustable diameters, twist-lock mechanisms, and standardized threading (e.g., 3/4″ NPT and 19/32″ BSP), enhancing ease of installation and reducing the need for multiple SKUs.

Growth in E-Commerce and DIY Appliance Installation

The proliferation of online retail platforms such as Amazon, Home Depot, and Alibaba is making drain hose adapters more accessible to end consumers. Coupled with the growing trend of DIY home repairs and appliance installations, this shift is increasing demand for user-friendly, plug-and-play adapters. Product listings with detailed compatibility charts, video tutorials, and customer reviews are influencing purchasing decisions, pushing manufacturers to invest in digital marketing and customer education.

Emphasis on Durable and Eco-Friendly Materials

By 2026, sustainability will play a pivotal role in product development. Consumers and regulatory bodies alike are demanding plumbing accessories made from recyclable, lead-free, and BPA-free materials. Silicone-reinforced rubber and recycled PVC are emerging as preferred materials for drain hose adapters due to their durability, flexibility, and reduced environmental impact. Additionally, longer product lifespans are being prioritized to minimize waste and support circular economy models.

Smart Laundry Systems and Integration Needs

While still in early adoption, smart washing machines with IoT connectivity are beginning to influence ancillary components. Although drain hose adapters themselves are not “smart,” future designs may need to accommodate sensors or flow-monitoring systems integrated into the drainage process. This could drive innovation in adapter design, such as built-in leak detection ports or standardized connection points for modular smart laundry systems.

Regional Market Variations and Regulatory Compliance

Market dynamics will differ significantly by region. In North America and Europe, stringent plumbing codes (e.g., UPC and CE marking) will require adapters to meet strict leak-proof and pressure-resistance standards. In contrast, fast-growing markets in Southeast Asia, Africa, and Latin America are seeing increased urbanization and appliance ownership, creating new demand for affordable and reliable adapters. Manufacturers will need to tailor product offerings to local standards, water pressure conditions, and drain pipe configurations.

Competitive Landscape and Brand Differentiation

The drain hose adapter market remains fragmented, with a mix of OEM suppliers, third-party accessory brands, and generic manufacturers. By 2026, successful brands will differentiate through quality assurance, patented designs, and bundled kits (e.g., adapter + clamp + extension hose). Private-label partnerships with major appliance retailers are also expected to grow, offering customized solutions under retailer branding.

Conclusion

The 2026 market for drain hose adapters for washing machines will be shaped by a combination of consumer convenience, sustainability, and globalization. As households seek reliable, easy-to-install, and eco-conscious solutions, manufacturers that innovate in design, materials, and distribution will capture greater market share. While a small component in the broader appliance ecosystem, the drain hose adapter is becoming increasingly strategic in ensuring efficient, leak-free laundry operations worldwide.

Common Pitfalls When Sourcing a Drain Hose Adapter for a Washing Machine (Quality & IP Considerations)

When sourcing a drain hose adapter for a washing machine, overlooking key quality and compatibility factors can lead to leaks, poor performance, or even appliance damage. Here are common pitfalls to avoid:

Poor Material Quality Leading to Premature Failure

Many low-cost adapters are made from brittle plastics or low-grade rubber that degrade quickly when exposed to water, heat, or detergents. This can result in cracking, splitting, or warping after only a few months of use. Always verify that the adapter is constructed from durable, water-resistant materials like reinforced PVC, EPDM rubber, or high-impact plastic designed for continuous water exposure.

Inadequate Sealing Mechanism Causing Leaks

A common issue with generic or poorly designed adapters is the lack of effective sealing features such as integrated rubber gaskets, secure clamping mechanisms, or proper taper fits. Without a watertight seal, water can leak at the connection points—especially under pump pressure—leading to water damage or mold growth. Ensure the adapter includes reliable sealing components compatible with both the washing machine hose and the drain pipe.

Incorrect or Inconsistent Thread Size and IP (Ingress Protection) Compatibility

Adapters must match the specific thread standards (e.g., 19mm or 3/4-inch BSP/NPT) used by the washing machine outlet and the household drain system. Mismatched threading prevents a secure fit and causes leaks. While IP ratings are less commonly specified for simple hose adapters, ensure the design prevents water ingress into electrical compartments if near control areas. Always verify dimensional compatibility and nominal pipe size (NPS) rather than relying solely on generic descriptions.

Lack of Pressure Resistance and Structural Integrity

Washing machine pumps generate significant water pressure during drain cycles. Adapters not rated for such conditions may bulge, detach, or burst. Avoid flimsy or thin-walled designs; instead, choose adapters tested for typical household pump pressures (usually up to 10–15 psi). Reinforced joints and molded一体 construction enhance durability.

Ignoring Compliance with Regional Plumbing Standards

Plumbing components must often comply with local regulations (e.g., UPC in the U.S., WRAS in the UK). Non-compliant adapters may not pass inspection or could void appliance warranties. Check for certifications or manufacturer claims indicating adherence to relevant plumbing and water safety standards.

By addressing these pitfalls—prioritizing material quality, proper fit, sealing, pressure resistance, and regulatory compliance—you can ensure reliable, leak-free performance from your washing machine drain hose adapter.

Logistics & Compliance Guide for Drain Hose Adapter For Washing Machine

Product Classification & Tariff Codes

Identify the correct Harmonized System (HS) code for the drain hose adapter to ensure accurate customs classification. Common classifications may fall under Chapter 84 (Nuclear reactors, boilers, machinery) or Chapter 39 (Plastics and articles thereof), depending on material composition and design. Typical HS codes could include 8481.80 (other taps, cocks, valves) or 3917.33 (plastic tubes, pipes, and hoses fittings), but final determination should be made based on product specifics and destination country regulations. Accurate classification is essential for duty calculation and import compliance.

Packaging & Labeling Requirements

Package the drain hose adapter in moisture-resistant, durable materials to prevent damage during transit. Each unit should include clear labeling with product name, model number, material composition (e.g., “Polypropylene”), country of origin, and any relevant safety or compliance markings. Retail packaging must comply with destination market requirements (e.g., CE marking for the EU, UPC barcode for North America). Ensure multilingual labeling if distributing across multiple regions.

Import/Export Regulations

Verify import restrictions, permitted materials, and conformity assessment procedures in the destination country. For example, the European Union requires compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. In the U.S., ensure compliance with EPA and CPSC guidelines if applicable. Provide commercial invoices, packing lists, and certificates of origin with shipments. Consider using an experienced freight forwarder to manage customs documentation and avoid delays.

Transportation & Handling

Ship adapters in standard cartons stacked on pallets for stability. Use appropriate cushioning to prevent movement during transit. The product is non-hazardous and does not require special handling under IATA, IMDG, or ADR regulations. Maintain storage in dry, temperature-controlled environments to prevent material degradation. Follow first-in, first-out (FIFO) inventory practices to ensure product quality.

Regulatory Compliance & Certifications

Ensure the drain hose adapter meets plumbing and safety standards in target markets. In the U.S., compliance with UPC (Uniform Plumbing Code) or IPC (International Plumbing Code) may be required. In the EU, adherence to EN standards for plumbing fittings is recommended. Obtain necessary third-party testing and certification if mandated. Retain technical documentation (e.g., test reports, material safety data sheets) for audit purposes.

Sustainability & Environmental Compliance

Manufacture and package the adapter using recyclable materials where possible. Comply with Extended Producer Responsibility (EPR) regulations in applicable regions, such as packaging waste schemes in the EU. Avoid the use of restricted substances as defined by environmental regulations. Communicate environmental attributes (e.g., recyclability) in product literature to support green procurement initiatives.

In conclusion, sourcing a drain hose adapter for a washing machine requires careful consideration of compatibility, material quality, and local availability. It is essential to identify the specific make and model of the washing machine, as well as the dimensions and thread type of the existing hose and drainage system, to ensure a proper fit. Opting for durable materials such as reinforced rubber or high-quality plastic with corrosion-resistant fittings can enhance longevity and prevent leaks. Whether purchasing from hardware stores, appliance retailers, or online marketplaces, comparing prices, reading customer reviews, and verifying return policies can lead to a cost-effective and reliable solution. Ultimately, selecting the right drain hose adapter ensures efficient water drainage, prevents potential water damage, and maintains the optimal performance of the washing machine.