The global lip seal market is experiencing steady growth, driven by rising demand across automotive, industrial machinery, and manufacturing sectors. According to Mordor Intelligence, the seal market is projected to grow at a CAGR of approximately 5.2% from 2023 to 2028, fueled by expanding industrial automation and the need for efficient fluid containment in rotating equipment. A key segment within this market, double lip seals offer enhanced protection against contaminants and lubricant leakage, making them critical components in high-performance applications. With increasing production in automotive and heavy machinery industries—particularly in Asia-Pacific regions—the demand for reliable, high-quality double lip seals has intensified. This growing need has elevated the prominence of leading manufacturers who combine technical innovation, material science, and precision engineering. Based on market presence, product range, and technological advancement, here are the top 9 double lip seal manufacturers shaping the industry’s future.

Top 9 Double Lip Seal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Seal Manufacturer

Domain Est. 1996

Website: clarkseals.com

Key Highlights: Clark Seals designs and manufacturers custom shaft seals that are perfectly matched to each application, ensuring maximum reliability and performance….

#2 Double Lip Oil Seal Supplier & Distributor

Domain Est. 1998

Website: rocketseals.com

Key Highlights: Double lip oil seals feature two lips for better fluid separation or contamination exclusion. Many oil seals are spring loaded to provide constant, a uniform ……

#3 Standard & Custom Oil Seals for Industrial Applications

Domain Est. 1999

Website: sspseals.com

Key Highlights: SSP Manufacturing, Inc manufactures oil seals in a wide variety of materials and sizes. Get industrial oil seals for different industrial application….

#4 Bi

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker DB, DC, and DA rotary shaft oil seal profiles feature two opposite facing spring loaded elastomer lips with varying metal case designs for ……

#5 Tenute seals

Domain Est. 1996

Website: skf.com

Key Highlights: The E11 seals family are TENUTE rotary shaft seals with the sealing lips working at the outer diameter featuring a rubber-fabric reinforcement in the seal back….

#6 Oil Seals

Domain Est. 1996

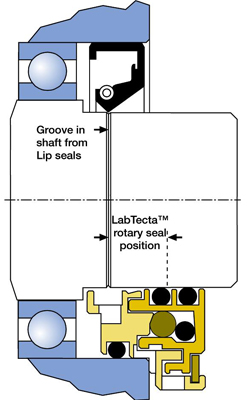

Website: trelleborg.com

Key Highlights: Oil Seals, also known as radial oil seals, radial shaft seals or rotary shaft lip seals, are round sealing devices used to seal between two machine parts….

#7 John Crane

Domain Est. 1996

Website: johncrane.com

Key Highlights: For more than 100 years, John Crane mechanical seals have helped energy and process industries work more effectively, safely, and reliably….

#8 Inch and Metric Oil Seal Types

Domain Est. 1996

Website: gbsa.com

Key Highlights: Dual Lip Seals. Dual lip seals are typically used for difficult sealing applications requiring the separation of two fluids. The chart below shows different ……

#9 Simrit/CFW Oil/Grease Double Lip Seals

Domain Est. 2007

Website: espint.com

Key Highlights: This radial shaft seal has a secondary lip or double lip to assist in keeping dust, debris, and other contaminates out from an outside environment….

Expert Sourcing Insights for Double Lip Seal

H2: 2026 Market Trends for Double Lip Seals

The global double lip seal market is projected to experience steady growth and notable transformation by 2026, driven by increasing demand across industrial and automotive sectors, technological advancements, and a heightened focus on energy efficiency and equipment longevity. The following analysis outlines key trends expected to shape the market during this period.

-

Growing Demand in Automotive and Industrial Applications

The automotive industry remains a primary driver for double lip seals, especially with the continued production of internal combustion engine (ICE) vehicles and hybrid models. These seals are critical for protecting transmission systems, axles, and engine components from contaminants and lubricant leakage. Additionally, expanding industrial automation and manufacturing activities—particularly in emerging economies—are boosting demand for reliable sealing solutions in gearboxes, pumps, and motors. -

Shift Toward High-Performance Materials

By 2026, there is an increasing preference for advanced elastomeric materials such as fluorocarbon rubber (FKM), hydrogenated nitrile butadiene rubber (HNBR), and thermoplastic polyurethane (TPU). These materials offer superior resistance to heat, oils, chemicals, and abrasion, enhancing seal performance and lifespan. Manufacturers are investing in R&D to develop proprietary compounds that maintain sealing integrity under extreme operating conditions. -

Expansion in Aftermarket and Replacement Demand

As industrial machinery and vehicles age, the replacement and maintenance cycle for seals is accelerating. The aftermarket segment is expected to grow significantly by 2026, supported by extended equipment lifespans and cost-conscious maintenance strategies. Double lip seals, known for their dual protection and extended service life, are becoming preferred choices for preventive maintenance programs. -

Regional Market Growth in Asia-Pacific

The Asia-Pacific region, led by China, India, and Southeast Asia, is anticipated to dominate market growth. Rapid industrialization, rising automotive production, and infrastructure development are fueling demand. Local manufacturing hubs are also attracting global seal producers, leading to increased competition and innovation within the region. -

Sustainability and Environmental Regulations

Environmental standards are influencing seal design and material selection. Regulations aimed at reducing oil leakage and improving energy efficiency are pushing manufacturers to develop eco-friendly, low-friction sealing solutions. Recyclability and reduced material waste in production processes are also becoming key considerations for suppliers aiming to meet corporate sustainability goals. -

Integration of Smart Monitoring and Predictive Maintenance

A notable trend emerging by 2026 is the integration of double lip seals with condition-monitoring technologies. While the seals themselves are passive components, they are increasingly being used in systems equipped with sensors that detect early signs of wear or failure. This synergy supports predictive maintenance strategies, minimizing downtime and optimizing performance in critical applications. -

Consolidation and Strategic Partnerships

The competitive landscape is evolving, with major players engaging in mergers, acquisitions, and joint ventures to expand their product portfolios and geographic reach. Companies like SKF, Freudenberg Sealing Technologies, and Trelleborg are strengthening their positions through innovation and customer-specific solutions, particularly in high-growth sectors such as electric vehicles and renewable energy.

In conclusion, the 2026 outlook for the double lip seal market is positive, characterized by technological innovation, material advancements, and expanding applications. As industries prioritize reliability and efficiency, double lip seals will continue to play a vital role in protecting rotating equipment and reducing operational costs globally.

Common Pitfalls When Sourcing Double Lip Seals (Quality, IP)

Sourcing double lip seals—critical components for preventing contamination and retaining lubricants—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to premature failure, equipment downtime, and safety risks. Below are common pitfalls to avoid:

Poor Material Selection

Choosing substandard elastomers or reinforcement materials compromises seal performance. Using materials incompatible with operating temperatures, chemicals, or pressure conditions leads to swelling, cracking, or hardening. Always verify the material specification (e.g., NBR, FKM, EPDM) matches the application environment.

Inadequate IP Rating Compliance

Assuming a double lip seal automatically ensures dust or water resistance is a mistake. IP ratings must be validated through independent testing. Seals labeled with misleading or unverified IP ratings (e.g., IP67) may fail under real-world conditions, exposing sensitive components to contaminants.

Lack of Dimensional Accuracy

Poor manufacturing tolerances result in improper fit, causing leaks or excessive friction. Always request dimensional drawings and verify critical parameters such as inner/outer diameter and lip interference. Inconsistent production batches often stem from unqualified suppliers.

Insufficient Quality Control and Certification

Sourcing from suppliers without ISO 9001 certification or traceable quality processes increases risk. Absence of documented inspections, material test reports, or batch traceability makes it difficult to ensure reliability and resolve field failures.

Overlooking Dynamic Performance Testing

Not all double lip seals perform equally under motion, pressure, or thermal cycling. Seals that haven’t undergone dynamic testing (e.g., run-out, wear, temperature cycling) may fail prematurely in service. Request test data relevant to your application.

Ignoring OEM Specifications and Approvals

Using non-approved or counterfeit seals can void equipment warranties and lead to liability. Always confirm the seal meets OEM specifications and, if required, carries official approvals (e.g., SKF, NSK, or manufacturer-specific certifications).

Inadequate Supplier Due Diligence

Relying on low-cost suppliers without auditing manufacturing capabilities or quality systems increases the risk of receiving inferior products. Conduct supplier assessments, request samples, and perform on-site audits when sourcing in high volumes.

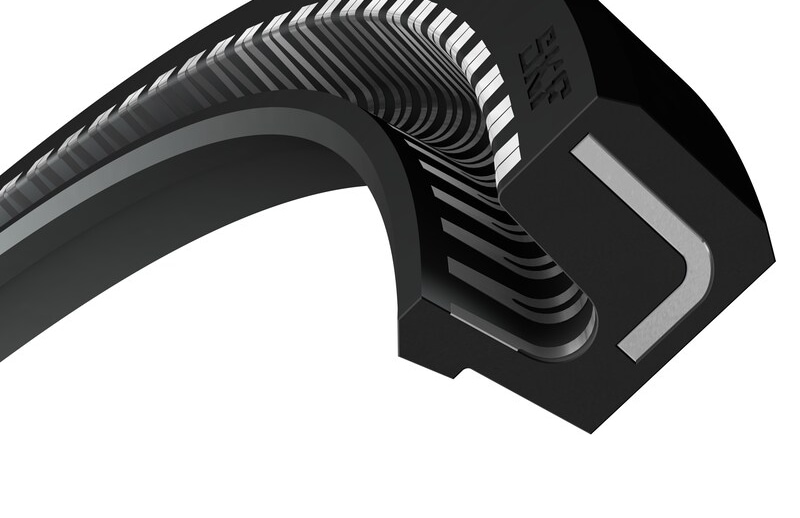

Misunderstanding Lip Design and Function

Not all double lip seals serve the same purpose—one lip may exclude contaminants while the other retains lubricant. Confusing the orientation or function leads to incorrect installation and rapid failure. Ensure technical documentation clearly defines lip roles and installation direction.

Avoiding these pitfalls ensures reliable sealing performance, extends equipment life, and maintains the intended IP protection level in demanding environments.

Logistics & Compliance Guide for Double Lip Seal

Product Overview

The Double Lip Seal is a mechanical sealing component designed to prevent leakage of fluids and contaminants in rotating shaft applications. It features two sealing lips that provide enhanced protection against dust, dirt, and moisture ingress, commonly used in automotive, industrial machinery, and hydraulic systems.

Material Composition

Double Lip Seals are typically manufactured from elastomeric materials such as Nitrile Rubber (NBR), Fluorocarbon Rubber (FKM/Viton®), or Silicone (VMQ), with a metal reinforcement ring (often carbon steel or stainless steel). Confirm material specifications per product variant to ensure compliance with regional and industry standards.

Packaging Requirements

- Seal components must be individually wrapped in anti-corrosive paper or vacuum-sealed plastic to prevent moisture damage.

- Outer packaging should be sturdy corrugated cardboard or reusable plastic containers with cushioning material to avoid deformation during transit.

- Label each package with part number, batch/lot number, quantity, and handling symbols (e.g., “Do Not Stack,” “Keep Dry”).

Storage Conditions

- Store in a cool, dry, and well-ventilated area with temperatures between 15°C and 25°C (59°F–77°F).

- Avoid direct sunlight, ozone sources (e.g., electric motors), and exposure to solvents or aggressive chemicals.

- Maximum recommended storage duration: 5 years for NBR, 10 years for FKM, when stored under ideal conditions.

Transportation Guidelines

- Use enclosed, climate-controlled vehicles for long-distance or international shipments to prevent thermal and humidity damage.

- Avoid exposure to extreme temperatures (below -10°C or above 40°C) during transit.

- Ensure packages are securely stacked and braced to prevent crushing or shifting.

- For air freight, comply with IATA regulations; for sea freight, follow IMDG Code where applicable (note: seals are generally non-hazardous).

Regulatory Compliance

- REACH (EU): Confirm that all constituent materials are registered under REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). Provide SVHC (Substances of Very High Concern) declarations if applicable.

- RoHS (EU): Ensure compliance with RoHS 2 (2011/65/EU) for restriction of hazardous substances, particularly lead, cadmium, and certain brominated flame retardants.

- Conflict Minerals (US): If applicable, comply with SEC Rule 13p-1 requiring disclosure of tantalum, tin, tungsten, and gold (3TG) sourcing from conflict-affected regions.

- Customs Classification: Classify under HS Code 8484.10 (Mechanical seals, of graphite or other carbon) or 8484.90 (Other mechanical seals), depending on material composition. Confirm locally for accuracy.

Import/Export Documentation

- Commercial Invoice

- Packing List

- Certificate of Origin

- Material Safety Data Sheet (MSDS/SDS) – though non-hazardous, may be requested

- REACH/RoHS Compliance Certificate

- Export License (if required by destination country)

Quality & Certification

- Ensure seals meet relevant international standards such as ISO 6194 (rubber seals for rotating shafts) or SAE AS5710.

- Maintain traceability via batch/lot numbers and provide inspection certificates (e.g., ISO 9001 certified production).

- Conduct periodic audits of manufacturing and packaging processes to ensure ongoing compliance.

Handling & Safety

- No special personal protective equipment (PPE) required under normal handling conditions.

- Avoid sharp tools during installation to prevent seal damage.

- Discard damaged or deformed seals; do not attempt repair.

Disposal & Environmental Considerations

- Dispose of defective or used seals in accordance with local waste regulations.

- Elastomeric seals are generally non-hazardous waste but should not be incinerated without proper emission controls.

- Recycle metal reinforcement rings where feasible through certified metal recycling programs.

Contact & Support

For compliance inquiries, logistics support, or documentation requests, contact:

[Your Company Name] Compliance & Logistics Team

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Double Lip Seal:

After a comprehensive evaluation of technical requirements, supplier capabilities, quality standards, and cost considerations, sourcing double lip seals requires a strategic approach that balances performance, durability, and total cost of ownership. Double lip seals offer superior protection against contaminants and improved lubricant retention, making them essential in demanding applications across industries such as automotive, industrial machinery, and manufacturing.

The final decision should prioritize suppliers with certified quality management systems (e.g., ISO 9001), proven experience in seal manufacturing, and the ability to customize solutions to meet specific operational conditions (e.g., temperature, pressure, and media compatibility). Engaging in long-term partnerships with reliable suppliers ensures consistent quality, timely delivery, and technical support.

In conclusion, successful sourcing of double lip seals involves not only competitive pricing but also a focus on material quality, engineering expertise, and after-sales service. By selecting the right supplier and seal configuration, organizations can enhance equipment reliability, reduce maintenance costs, and extend service life—ultimately improving overall operational efficiency.