The global double drop trailer market is experiencing robust growth, driven by increasing demand for heavy-haul and oversized freight transportation across industries such as construction, energy, and manufacturing. According to a report by Mordor Intelligence, the global trailer market—encompassing flatbed, drop deck, and specialized trailers—is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028, with double drop trailers representing a critical segment due to their ability to transport tall and heavy cargo while complying with road height regulations. This surge is further fueled by infrastructure development initiatives and the expansion of renewable energy projects, particularly in North America and Asia-Pacific. As logistics operators prioritize efficiency, payload capacity, and regulatory compliance, the need for high-performance double drop trailers has intensified. This growing demand has positioned key manufacturers at the forefront of innovation in materials, design, and durability. Based on market presence, product range, customer reviews, and technical capabilities, the following list highlights the top 10 double drop trailer manufacturers leading the industry today.

Top 10 Double Drop Trailer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Towmaster

Domain Est. 1997

Website: towmaster.com

Key Highlights: Towmaster is an industry-leading truck and trailer equipment manufacturer, upfitter, and distributor. Find a dealer near you to invest in a Towmaster ……

#2 Double

Domain Est. 1998

Website: faymonville.com

Key Highlights: The extra low double-drop trailer is the ideal solution for extremely high and bulky goods, such as industrial components, machinery or oversized containers ……

#3 Detachable Double Drop Extendable

Domain Est. 1996

Website: trailking.com

Key Highlights: Trail King’s Commercial Detachable Gooseneck Double Drop Extendable trailer comes with the most standard equipment of any trailer of its kind on the market….

#4 Everything You Need to Know About Double

Domain Est. 1996

Website: mercer-trans.com

Key Highlights: Double drop trailers are a smart solution for shippers who need to move freight that simply won’t fit on a standard flatbed or step deck….

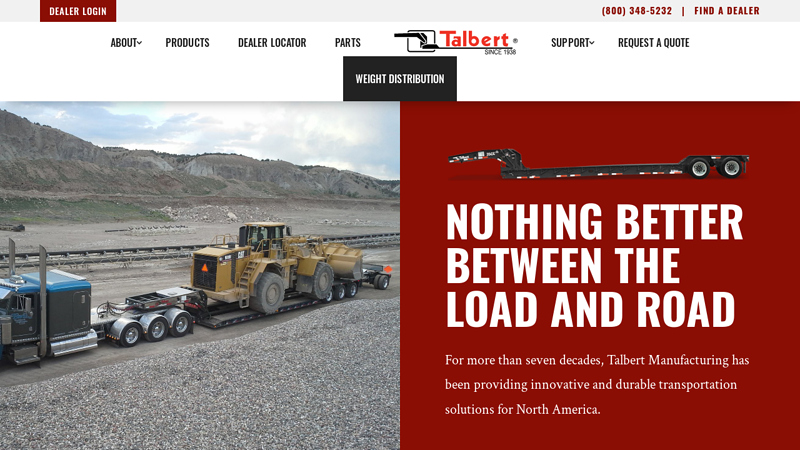

#5 Talbert Manufacturing

Domain Est. 1997

Website: talbertmfg.com

Key Highlights: Heavy haul equipment trailers serving a variety of commercial, military, government, aerospace, & energy applications….

#6 Wilson Trailer

Domain Est. 1997

Website: wilsontrailer.com

Key Highlights: The Premier flatbed and drop deck trailers are true all-aluminum trailers offering corrosion free hauling with maximum hauling capacity ratings at 80,000 lbs….

#7 It’s the Doonan Double Drop.

Domain Est. 1997

Website: doonan.com

Key Highlights: With its robust frame, powerful hydraulics, and innovative extendable box beams, the Doonan Double Drop effortlessly lifts and secures the engine. As this ……

#8 Fixed

Domain Est. 2001

Website: xlspecializedtrailer.com

Key Highlights: XL’s Double Drops are sure to meet your needs with a fixed, non-removable gooseneck and capacity options ranging from 30,000 pounds to 120,000 pounds in 16 feet ……

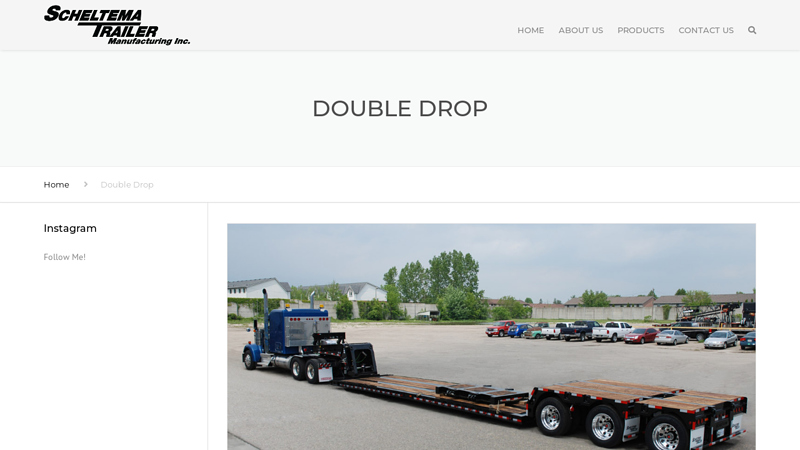

#9 Double Drop

Domain Est. 2001

Website: scheltematrailer.com

Key Highlights: Scheltema Trailer offers a variety of double drop deck trailers; fixed gooseneck, removable gooseneck, and extendable decks, are a few options available….

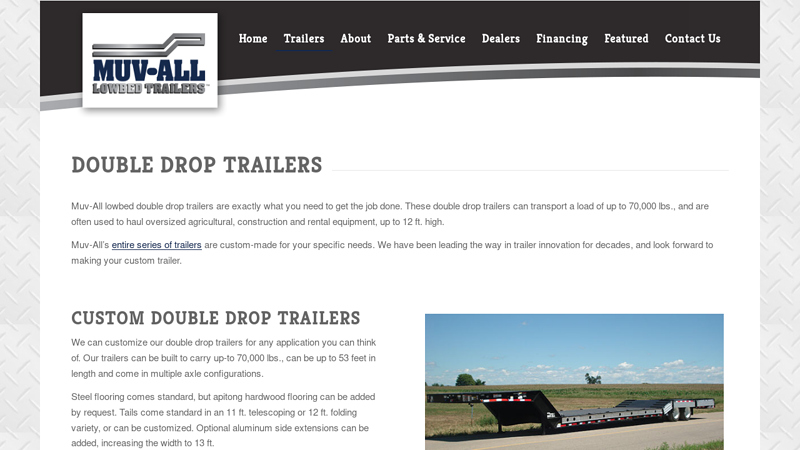

#10 Double Drop Trailers

Domain Est. 2015

Website: muvalltrailer.com

Key Highlights: Custom double drop trailers are one of our top sellers. If you need an extremely strong, trusted, high-quality trailer to get the job done count on Muv-All….

Expert Sourcing Insights for Double Drop Trailer

H2: 2026 Market Trends for Double Drop Trailers

The double drop deck trailer market in 2026 is poised for moderate growth, driven by infrastructure investment and shifting freight dynamics, but constrained by regulatory pressures and evolving transportation alternatives. Key trends shaping the sector include:

1. Infrastructure-Led Demand Surge:

The most significant driver in 2026 will be the continued rollout of major public infrastructure projects, particularly in North America and parts of Asia. Government funding for bridge replacements, renewable energy installations (wind turbine transport), and highway expansions is increasing demand for heavy-haul and specialized trailers. Double drop decks, with their low deck height and high weight capacity, are critical for transporting oversized components like steel beams, transformers, and construction machinery. This demand is expected to peak in late 2025–2026 as multi-year programs reach active construction phases.

2. Emphasis on Lightweight and Fuel-Efficient Designs:

With rising fuel costs and stricter emissions regulations (e.g., EPA Phase 3 in the U.S.), manufacturers are investing heavily in lightweight composite materials (e.g., high-strength steel, aluminum components) and aerodynamic enhancements. Trailers with reduced tare weight allow operators to carry heavier payloads without exceeding legal gross vehicle weight limits, improving profitability. Integration with telematics for route optimization and load monitoring is becoming standard, enhancing operational efficiency.

3. Regulatory and Permitting Challenges:

While demand grows, operators face increasing complexity in permitting for oversize loads. Tighter bridge formula regulations and urban access restrictions are prompting regional operators to adopt modular or detachable gooseneck solutions that simplify permitting for double drops. Cross-border transport faces added scrutiny, especially in the EU and between U.S. and Canada, influencing trailer configurations and logistics planning.

4. Shift Toward Rental and Fleet Flexibility:

Fleet operators are showing a growing preference for rental and leasing models to manage capital expenditure and respond to project-based demand spikes. This trend benefits large trailer leasing companies and encourages manufacturers to design more durable, easily maintainable double drop trailers suitable for shared fleets. Customization options for specific industries (e.g., wind energy, oil & gas) are also in higher demand.

5. Sustainability and Lifecycle Management:

Environmental concerns are pushing manufacturers and fleets to focus on trailer longevity and recyclability. Enhanced corrosion protection, modular replaceable components, and end-of-life recycling programs are becoming selling points. Some operators are exploring hybrid or electric-powered dolly units to reduce the carbon footprint of double drop configurations.

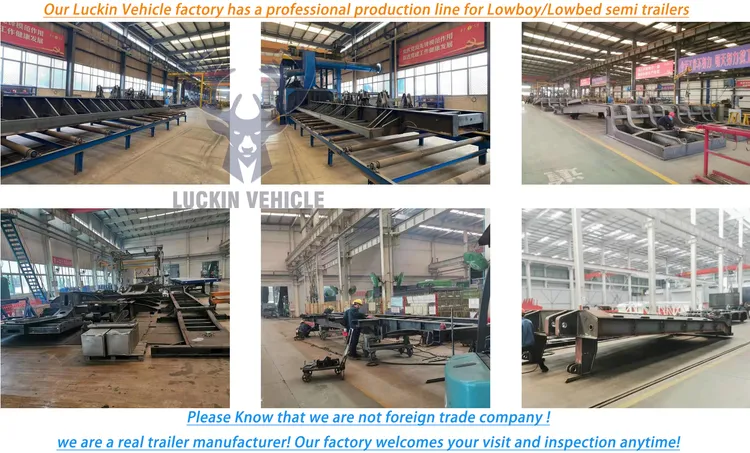

6. Competitive Landscape and Regional Divergence:

North America remains the largest market due to expansive freight networks and infrastructure spending. Europe sees steady but slower growth, limited by stricter regulations and smaller average load sizes. Asia-Pacific, especially India and Southeast Asia, is emerging as a high-growth region, driven by urbanization and industrial expansion, though quality standards and road conditions remain challenges.

Conclusion:

By 2026, the double drop trailer market will remain a niche but vital segment within the heavy-haul transportation ecosystem. Success will depend on manufacturers’ ability to balance payload efficiency, regulatory compliance, and sustainability, while operators leverage technology and flexible fleet strategies to navigate a complex logistical environment.

Common Pitfalls When Sourcing Double Drop Trailers: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Double Drop Trailer

Double drop trailers, also known as step deck or lowboy trailers, are essential for transporting tall, heavy, or oversized freight that cannot be carried on standard flatbed trailers. This guide outlines key logistical considerations and compliance requirements to ensure safe and legal operation.

Understanding the Double Drop Trailer Configuration

A double drop trailer features three distinct deck levels: a raised front section (often called the “neck”), a significantly lower middle section (the “well” or “pit”), and a slightly raised rear section. This design provides a lower center of gravity and increased vertical clearance for cargo, making it ideal for machinery, construction equipment, and other tall loads.

Weight Distribution and Load Securement

Proper weight distribution is critical to maintaining trailer stability and complying with axle weight limits. Cargo should be positioned to keep the center of mass centered over the axles, with weight evenly distributed side-to-side. Use tiedowns, chains, binders, and blocking/bracing in accordance with the FMCSA’s Cargo Securement Rules (49 CFR Part 393, Subpart I). The number and strength of tiedowns must correspond to the weight and dimensions of the load.

Height, Width, and Length Restrictions

While double drop trailers provide increased vertical clearance, overall dimensions must still comply with federal and state regulations. Standard limits are:

- Height: Typically 13’6″ maximum (varies by state)

- Width: 8’6″ maximum

- Length: Varies by state and trailer type; generally up to 53′ for the trailer alone

Measure cargo from the ground to the highest point, including packaging and securing equipment. Exceeding these dimensions requires an oversize/overweight permit.

Oversize/Overweight Permits

Transporting loads that exceed standard dimensions or weight limits requires permits from the appropriate state transportation departments. Permit applications typically require:

- Detailed load dimensions and weight

- Shipping route (including roads, bridges, and overpasses)

- Travel times and dates

- Emergency contact information

Permits are often route-specific and time-sensitive. Some states participate in reciprocity agreements, but individual approval is required for each jurisdiction.

Route Planning and Bridge Clearances

Careful route planning is essential to avoid low bridges, restricted roads, and weight-limited infrastructure. Use GPS systems designed for commercial vehicles and consult state DOT resources. Pay close attention to bridge formulas and posted weight restrictions, especially on the trailer’s well section, which may be closer to the road surface and more susceptible to under-clearance issues.

State and Local Regulations

Regulations vary significantly between states. Some states restrict double drop trailer use on certain highways, require escort vehicles for oversize loads, or impose additional lighting and signage requirements (e.g., “OVERSIZE LOAD” banners, strobe lights). Always verify requirements with each state along the planned route.

Safety and Inspection Compliance

Double drop trailers must meet Federal Motor Carrier Safety Regulations (FMCSR), including regular inspections (pre-trip, post-trip, and periodic). Key inspection points include:

- Structural integrity of the deck and gooseneck

- Condition of suspension, axles, tires, and brakes

- Functionality of lights and reflectors

- Securement device condition (chains, binders, etc.)

Ensure the trailer is registered, inspected, and marked according to USDOT and state requirements.

Training and Driver Responsibilities

Drivers must be trained in the unique handling characteristics of double drop trailers, including reduced ground clearance on the well deck and increased risk of trailer “belly scraping” on inclines or uneven terrain. They are responsible for verifying load security, compliance with permits, and adherence to routing and timing restrictions.

Conclusion

Operating a double drop trailer demands meticulous planning, strict compliance with regulations, and skilled execution. By understanding the trailer’s capabilities, securing loads properly, obtaining necessary permits, and following state-specific rules, carriers can ensure safe, efficient, and legal transport of oversized cargo.

Conclusion for Sourcing Double Drop Trailers

Sourcing double drop trailers requires a strategic approach that balances cost, quality, durability, and compliance with transportation regulations. After evaluating various suppliers, material specifications, customization options, and after-sales support, it is evident that selecting the right trailer involves more than just the initial purchase price. Factors such as payload capacity, axle configuration, deck length, and weight distribution play a crucial role in ensuring operational efficiency and safety.

Partnering with reputable manufacturers who adhere to industry standards (such as DOT and CVSA compliance) and who offer robust warranties and maintenance support enhances long-term value. Additionally, considering total cost of ownership—factoring in fuel efficiency, maintenance frequency, and resale value—can lead to smarter investment decisions.

In conclusion, successful sourcing of double drop trailers hinges on thorough due diligence, clear understanding of operational needs, and building strong relationships with reliable suppliers. By prioritizing quality, compliance, and serviceability, businesses can secure trailers that maximize freight capability, ensure safety, and support growth in demanding transport environments.