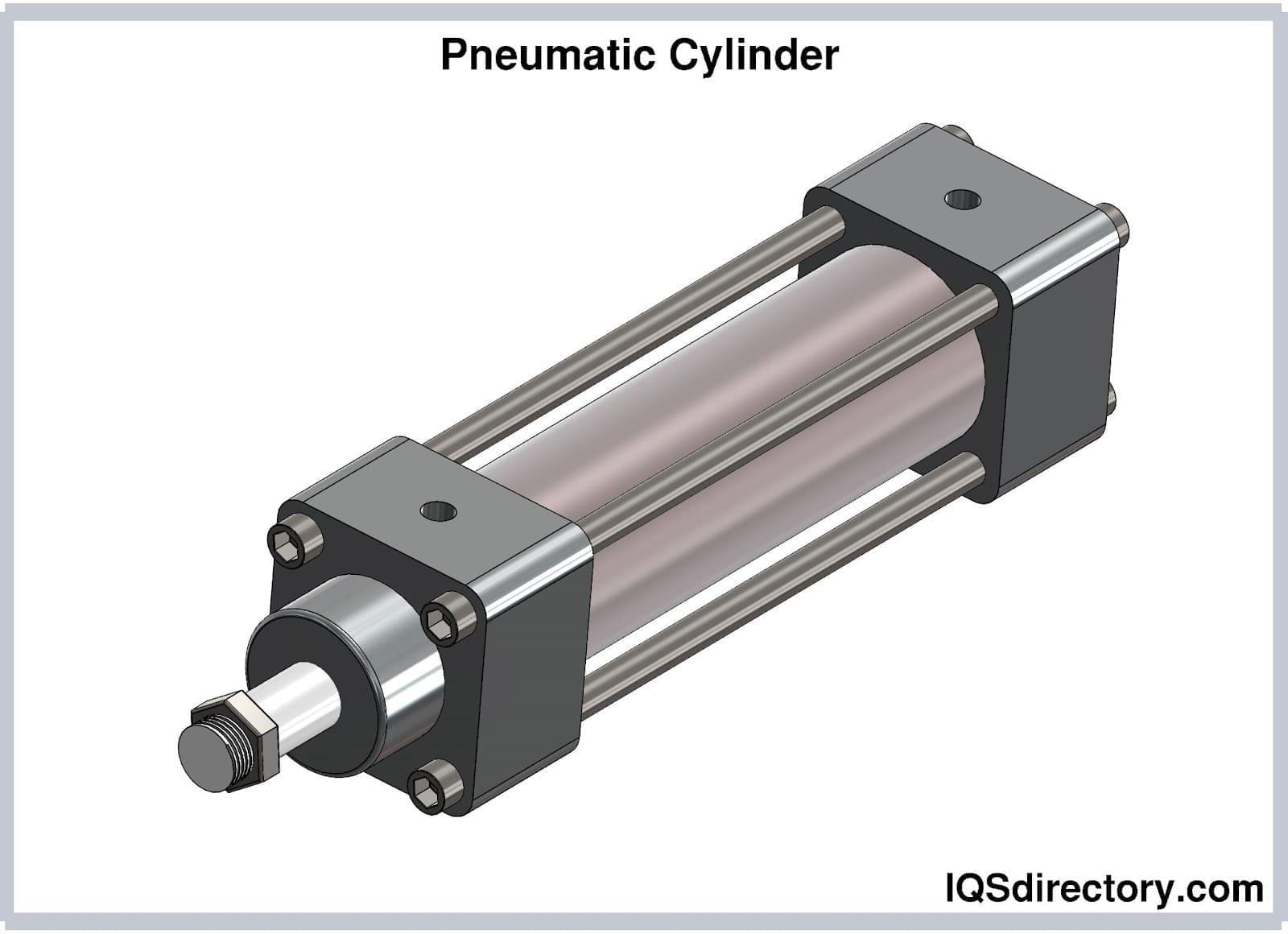

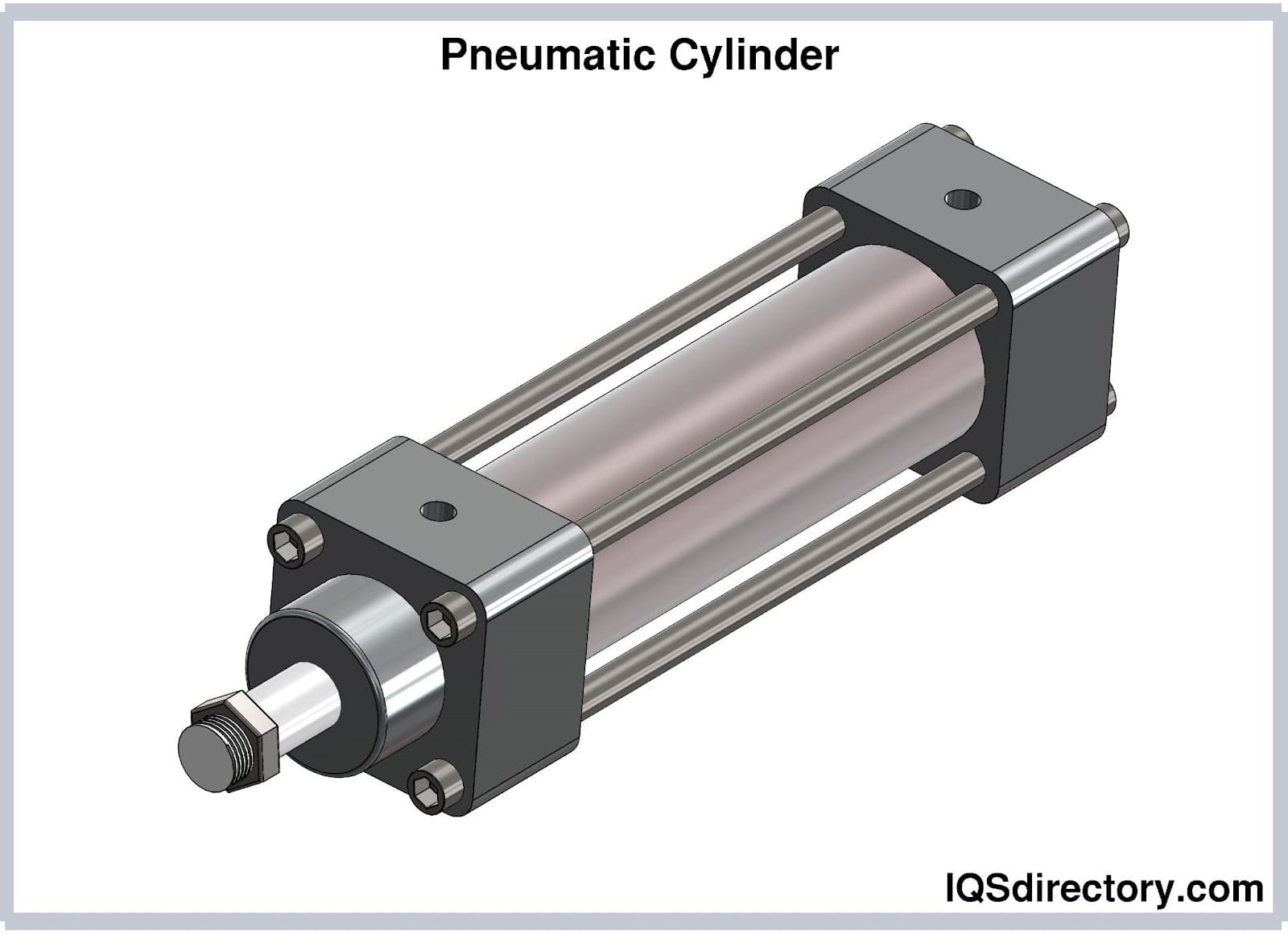

The global pneumatic cylinders market is experiencing steady growth, driven by rising automation across industries such as automotive, manufacturing, and material handling. According to Grand View Research, the global pneumatic cylinders market size was valued at USD 4.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2030. This growth is fueled by the increasing demand for energy-efficient automation solutions and the superior reliability of pneumatic systems in harsh operating environments. Double acting pneumatic air cylinders, in particular, are gaining traction due to their ability to deliver consistent force in both extension and retraction strokes, making them ideal for precision control applications. As industries continue to modernize production lines, the demand for high-performance components has elevated the prominence of leading manufacturers who combine innovation, durability, and global reach. In this context, the following list highlights the top 10 double acting pneumatic air cylinder manufacturers shaping the future of industrial automation.

Top 10 Double Acting Pneumatic Air Cylinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hydraulic Cylinder Manufacturer

Domain Est. 1999

Website: cylval.com

Key Highlights: Cylinders & Valves, Inc. offers a wide variety of standard and custom hydraulic cylinders, pneumatic cylinders, replacement parts, and cylinder repair….

#2 Pneumatic Cylinders

Domain Est. 1995

Website: smcusa.com

Key Highlights: Pneumatic cylinders are devices that use compressed air to generate linear motion. They are commonly used in various industrial and commercial applications….

#3 Industrial Hydraulic and Pneumatic Cylinders

Domain Est. 1997

Website: alkoncorp.com

Key Highlights: Alkon is your single source for dependable, high-quality hydraulic and pneumatic cylinders for industrial applications….

#4 Air Cylinders

Domain Est. 1998

Website: smcworld.com

Key Highlights: A leading manufacturer of pneumatic control devices that use compressed air as a power source for automation … Double Power Cylinder; Platform Cylinder ……

#5 Double Acting Pneumatic Cylinders

Domain Est. 1999

Website: yatesind.com

Key Highlights: For nearly five decades, Yates Cylinders has persevered as a leading manufacturer of quality, affordable double acting pneumatic cylinders….

#6 Pneumatic Cylinders

Domain Est. 1995

Website: discreteautomation.emerson.com

Key Highlights: AVENTICS offers an expansive portfolio of air-actuated cylinders, many of which are designed to operate in tight spaces and harsh environments….

#7 Original Line® Air Cylinder

Domain Est. 1996

Website: bimba.com

Key Highlights: This product has versatile options including three-position air cylinders, MRS air cylinders, non-rotating air cylinders, and PC air cylinders….

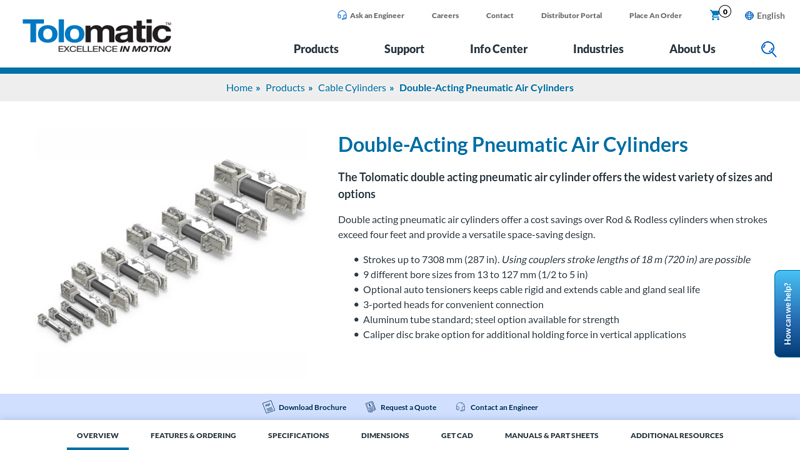

#8 Double Acting Pneumatic Air Cylinders

Domain Est. 1996

Website: tolomatic.com

Key Highlights: The Tolomatic double acting pneumatic air cylinder offers the widest variety of sizes and options · Strokes up to 7308 mm (287 in). · 9 different bore sizes from ……

#9 Pneumatic Cylinders & Actuators

Domain Est. 2000

Website: arozone.com

Key Highlights: Our cylinders range from small bore, repairable double-acting cylinders and medium bore, disposable single-acting cylinders for light duty applications to NFPA ……

#10 AirTAC International Group

Domain Est. 2001

Website: airtac.com

Key Highlights: Airtac International Group with its headquater located in Ningbo and established in Taiwan in 1988, is a well-known supplier/manufacture of pneumatic equipments ……

Expert Sourcing Insights for Double Acting Pneumatic Air Cylinder

H2: 2026 Market Trends for Double Acting Pneumatic Air Cylinders

The global market for double acting pneumatic air cylinders is poised for steady growth through 2026, driven by technological advancements, increasing automation across industries, and rising demand for energy-efficient and reliable motion control systems. Key trends shaping the market include:

-

Growth in Industrial Automation: The continued expansion of Industry 4.0 and smart manufacturing is accelerating the adoption of pneumatic components, including double acting cylinders. These cylinders are favored for their precise control, durability, and ability to deliver consistent bidirectional force. Sectors such as automotive, packaging, food and beverage, and pharmaceuticals are investing heavily in automated production lines, boosting demand.

-

Demand for Compact and Lightweight Designs: Manufacturers are focusing on miniaturization and lightweight construction to meet space constraints in modern machinery. Innovations in materials—such as high-strength aluminum alloys and composite seals—are enabling the development of cylinders that maintain performance while reducing weight and energy consumption.

-

Integration with Smart Systems: A notable trend is the integration of double acting cylinders with sensors and IoT-enabled monitoring systems. Smart pneumatic cylinders allow for real-time diagnostics, predictive maintenance, and improved process control, enhancing operational efficiency and reducing downtime.

-

Energy Efficiency and Sustainability: With growing emphasis on energy conservation, manufacturers are optimizing cylinder designs to reduce air consumption. Features such as improved sealing technologies, low-friction coatings, and regenerative circuits are being adopted to enhance energy efficiency and support sustainability goals.

-

Regional Market Shifts: Asia-Pacific, particularly China, India, and Southeast Asia, is expected to dominate market growth due to rapid industrialization, government initiatives promoting manufacturing (e.g., “Make in India,” “Made in China 2025”), and expanding infrastructure. Meanwhile, North America and Europe are focusing on retrofitting existing systems with advanced pneumatic solutions to improve productivity.

-

Customization and Application-Specific Solutions: End-users are increasingly demanding tailored solutions for specialized applications. Manufacturers are responding with configurable cylinders that support different stroke lengths, mounting options, and environmental ratings (e.g., washdown, explosion-proof).

-

Competitive Landscape and Innovation: Leading players such as SMC Corporation, Festo, Parker Hannifin, and Airtac are intensifying R&D efforts to differentiate products through enhanced durability, longer service life, and digital integration. Strategic partnerships and expansions into emerging markets are also key growth strategies.

In conclusion, the double acting pneumatic air cylinder market in 2026 will be characterized by innovation, integration, and responsiveness to industrial automation needs. Companies that invest in smart technologies, sustainable design, and global market expansion are likely to capture significant market share.

Common Pitfalls When Sourcing Double-Acting Pneumatic Air Cylinders: Quality and IP Protection

Sourcing double-acting pneumatic air cylinders involves more than just matching bore size and stroke length. Overlooking critical quality and Ingress Protection (IP) factors can lead to premature failure, downtime, and safety hazards. Below are common pitfalls to avoid:

1. Prioritizing Low Cost Over Build Quality

One of the most frequent mistakes is selecting cylinders based solely on price. Low-cost cylinders often use inferior materials (e.g., low-grade aluminum, substandard seals), poor machining tolerances, and lack proper surface treatments. This results in:

- Rapid wear of seals and piston rods

- Increased friction and reduced efficiency

- Shorter service life and higher total cost of ownership

- Inconsistent performance under load

Solution: Evaluate total cost of ownership—consider durability, maintenance frequency, and downtime costs.

2. Ignoring IP Rating Requirements

The Ingress Protection (IP) rating indicates a cylinder’s resistance to dust and moisture. Selecting a cylinder with an inadequate IP rating for the operating environment can cause serious issues.

- Pitfall: Using an IP54-rated cylinder in a washdown environment (requiring at least IP65/IP67)

- Consequence: Water or contaminants enter the cylinder, damaging internal components and seals

Solution: Match the IP rating to the environment:

– IP65: Protected against dust and low-pressure water jets

– IP67: Dust-tight and resistant to temporary immersion

– IP69K: High-pressure, high-temperature washdown (common in food & pharma)

3. Overlooking Seal Material Compatibility

Seals are critical to cylinder longevity and performance. Using incompatible seal materials can lead to swelling, hardening, or premature failure.

- Pitfall: Using NBR (nitrile) seals with certain lubricants or in high-temperature environments

- Consequence: Seal degradation, air leakage, and loss of actuation force

Solution: Select seals based on:

– Operating temperature range

– Air quality (presence of oil, moisture)

– Chemical exposure (e.g., cleaning agents)

Consider alternatives like Viton® for high temps or FDA-compliant seals in food processing.

4. Assuming All ISO Standards Are Equal

While many cylinders claim to meet ISO 6431 or ISO 15552 standards, actual compliance varies. Some manufacturers cut corners on dimensions, mounting interfaces, or material specs.

- Pitfall: Purchasing non-compliant cylinders that don’t interchange with existing equipment

- Consequence: Difficult installation, misalignment, mechanical stress

Solution: Source from reputable suppliers with third-party certifications and request compliance documentation.

5. Neglecting Air Quality and Filtration Needs

Pneumatic cylinders require clean, dry, and properly lubricated air. Overlooking air preparation leads to internal contamination and premature wear.

- Pitfall: Installing cylinders without inline filters, regulators, or lubricators (FRL units)

- Consequence: Abrasive particles damage cylinder bores; moisture corrodes rods

Solution: Ensure proper air treatment upstream, especially in harsh environments.

6. Failing to Verify Manufacturer Reputation and IP (Intellectual Property)

Counterfeit or reverse-engineered cylinders are common in the market. These may infringe on intellectual property and lack performance guarantees.

- Pitfall: Sourcing from unknown brands copying design features of established OEMs

- Consequence: Poor reliability, no technical support, warranty issues

Solution: Choose suppliers with strong IP protection, transparent manufacturing, and proven track records.

7. Underestimating Environmental and Operating Conditions

Ambient temperature, humidity, vibration, and load dynamics significantly affect cylinder performance.

- Pitfall: Using standard cylinders in extreme cold (< -10°C) without low-temp seals

- Consequence: Seal brittleness, rod jamming, failure to actuate

Solution: Specify environmental adaptations:

– Low-temperature seals (e.g., silicone or special NBR)

– Corrosion-resistant coatings (e.g., stainless steel, hard anodized)

– Cushioning for high-speed or heavy loads

By addressing these pitfalls early in the sourcing process, you ensure reliable, long-lasting performance of double-acting pneumatic cylinders in your application.

Logistics & Compliance Guide for Double Acting Pneumatic Air Cylinders

Product Overview

Double Acting Pneumatic Air Cylinders are mechanical devices that use compressed air to generate force and motion in both the extension and retraction strokes. They are widely used in industrial automation, manufacturing, packaging, and material handling systems. Understanding logistics and regulatory compliance is essential for safe international shipping, customs clearance, and operational use.

Packaging and Handling Requirements

Proper packaging ensures product integrity during transit.

- Protective Packaging: Cylinders should be packed in sturdy corrugated cardboard boxes with internal foam or molded plastic inserts to prevent movement.

- Corrosion Protection: Apply corrosion-inhibiting oil or VCI (Volatile Corrosion Inhibitor) paper, especially for long-distance or maritime shipping. Seal ports with protective caps.

- Labeling: Clearly label packages with:

- Product name and model number

- Net weight and gross weight

- “Fragile” and “This Side Up” orientation indicators

- Handling instructions (e.g., “Do Not Stack”)

Shipping and Transportation

Adherence to shipping standards ensures safe and compliant transit.

- Mode of Transport: Suitable for air, sea, and ground freight. Pressurized components must be fully depressurized before shipping.

- Hazard Classification: Not classified as hazardous under IATA, IMDG, or ADR when empty and depressurized.

- Packing Group: Non-hazardous; typically shipped as general cargo.

- Temperature Control: Avoid extreme temperatures during storage and transport to prevent seal degradation.

Import and Export Compliance

Ensure all international trade requirements are met.

- HS Code (Harmonized System Code): Typically classified under 8412.21.00 – Pneumatic cylinders. Confirm with local customs authority.

- Export Controls: Generally not subject to ITAR or EAR restrictions unless integrated into controlled equipment. Verify for dual-use applications.

- Documentation: Required documents include:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (if required by trade agreement)

- Duties and Tariffs: Vary by destination country. Use HS code to determine applicable rates.

Regulatory and Safety Standards

Compliance with international standards ensures safe operation and market access.

- ISO Standards:

- ISO 6432: Cylinders with bore sizes from 16 to 40 mm

- ISO 15552: Compact cylinders (replaces ISO 6431)

- ISO 6953: Pneumatic fluid power – Cylinders – Mounting dimensions

- CE Marking: Required for sale in the European Economic Area (EEA). Compliance with:

- Machinery Directive 2006/42/EC

- Pressure Equipment Directive (PED) 2014/68/EU – if applicable (depends on pressure/volume)

- ATEX Directive 2014/34/EU – only if used in explosive atmospheres

- REACH & RoHS: Compliant with EU regulations on chemical substances (REACH) and hazardous substances (RoHS) for electrical components.

- UL/cUL Certification: Required for sale in North America if integrated into machinery under UL 508A or similar. Optional for standalone cylinders.

Environmental and Disposal Compliance

Environmental responsibility is critical at end-of-life.

- Materials: Constructed mainly from aluminum, steel, and elastomeric seals. Recyclable through standard metal reclamation processes.

- End-of-Life Disposal: Follow local WEEE (Waste Electrical and Electronic Equipment) guidelines if the cylinder includes sensors. Otherwise, dispose of as industrial scrap metal.

- No Hazardous Fluids: Air cylinders do not contain oils or toxic hydraulic fluids under normal conditions.

Regional Compliance Considerations

Be aware of region-specific requirements.

- North America:

- Comply with OSHA standards for workplace safety.

- Follow CSA standards in Canada (e.g., CSA Z462 for electrical safety if solenoid valves are attached).

- European Union:

- Ensure CE marking with technical file and Declaration of Conformity.

- Comply with the EU Supply of Machinery (Safety) Regulations.

- China:

- May require CCC (China Compulsory Certification) if part of a larger machine.

- Australia/New Zealand:

- Comply with AS/NZS 4262:2016 for pneumatic fluid power systems.

Best Practices for Compliance Management

Maintain ongoing regulatory adherence.

- Technical Documentation: Maintain up-to-date technical files, test reports, and declarations of conformity.

- Supplier Verification: Source materials from REACH-compliant suppliers.

- Labeling Accuracy: Ensure all product labels include manufacturer details, model, pressure ratings, and safety warnings.

- Training: Train logistics staff on proper handling, storage, and documentation procedures.

By following this guide, businesses can ensure smooth logistics operations and full compliance when distributing Double Acting Pneumatic Air Cylinders globally.

Conclusion:

The sourcing of double-acting pneumatic air cylinders has been successfully evaluated based on key criteria including performance requirements, quality, cost, delivery timelines, and supplier reliability. Double-acting cylinders offer superior control in both extension and retraction strokes, making them ideal for applications requiring precise and powerful bidirectional movement. After assessing various suppliers and product specifications, it is evident that selecting a reputable manufacturer with ISO certification, robust material construction (such as anodized aluminum or stainless steel), and strong after-sales support ensures long-term operational efficiency and reduced maintenance costs.

Furthermore, considering factors like bore size, stroke length, pressure ratings, and mounting options tailored to the specific application enhances system compatibility and performance. Strategic sourcing, including volume pricing and local distributor partnerships, contributes to cost savings and supply chain resilience. In conclusion, procuring double-acting pneumatic cylinders from qualified suppliers not only meets current operational demands but also supports scalability, reliability, and safety in industrial automation and machinery systems.