The global automotive brake fluid market is experiencing robust growth, driven by increasing vehicle production, rising aftermarket demand, and stringent safety regulations. According to a report by Mordor Intelligence, the brake fluid market was valued at USD 1.85 billion in 2023 and is projected to grow at a CAGR of over 4.2% from 2024 to 2029. A key segment within this market is Dot 3 brake fluid, which remains the most widely used glycol-based fluid due to its balanced performance, compatibility, and cost-effectiveness—especially in hydraulic clutch systems. With the surge in light and heavy-duty vehicle manufacturing, particularly in emerging economies, demand for high-performance Dot 3 formulations that ensure reliable clutch operation under varied thermal conditions has intensified. As original equipment manufacturers (OEMs) and aftermarket suppliers prioritize fluid stability and moisture resistance, selecting the right Dot 3 brake fluid is critical for maintaining clutch system integrity and longevity. This analysis highlights the top five Dot 3 brake fluid manufacturers leading in innovation, performance metrics, and market adoption within the clutch application segment.

Top 5 Dot 3 Brake Fluid For Clutch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 [PDF] Havoline® Brake and Clutch Fluid DOT 3

Domain Est. 1990

Website: cglapps.chevron.com

Key Highlights: Havoline® Brake and Clutch Fluid DOT 3 is compatible with other brands of DOT 3 brake fluid, and may be used as make-up or service refill wherever DOT 3 ……

#2 Mobil Brake Fluid DOT 3

Domain Est. 1991

Website: mobil.com

Key Highlights: Mobil Brake Fluid DOT 3 is a high performance hydraulic brake fluid for use in automotive disc, drum and anti-skid brake systems and clutch systems….

#3 Brake Fluid DOT 3

Domain Est. 1997

Website: kleenflo.com

Key Highlights: For drum, disc, ABS braking systems and clutch systems requiring a Department of Transportation 3 type fluid (DOT 3). Conforms to CMVSS 116 and DMVSS 116….

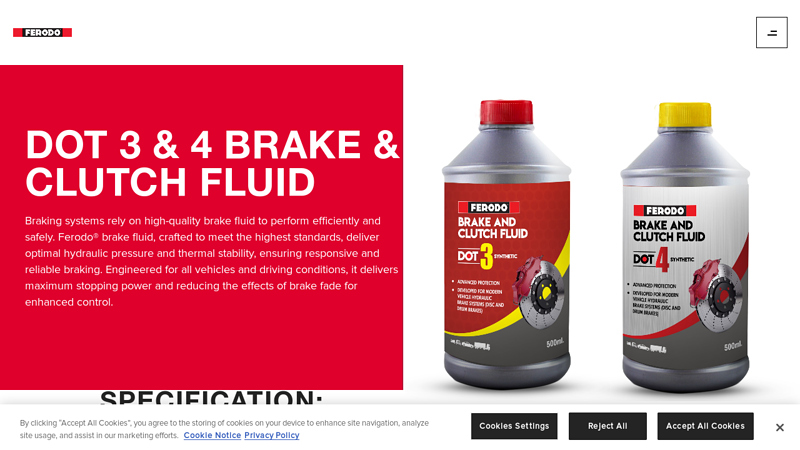

#4 Dot 3 & 4 Brake & Clutch Fluid

Domain Est. 2001

Website: ferodo.com

Key Highlights: Ferodo ® Brake & Clutch Fluid Dot 3 is a synthetic fluid formulated with high performance additives and is suitable for vehicle’s hydraulic disc or drum brake ……

#5 Brake & Clutch Fluid DOT 3

Domain Est. 2022

Website: valvolineglobal.com

Key Highlights: Valvoline Brake & Clutch Fluid DOT 3 is a high-performance, non-mineral brake fluid. Its chemical composition is based on glycol ethers….

Expert Sourcing Insights for Dot 3 Brake Fluid For Clutch

H2: 2026 Market Trends for DOT 3 Brake Fluid for Clutch Systems

As the global automotive industry evolves toward enhanced safety, performance, and sustainability, the demand for high-quality brake fluids—particularly DOT 3 brake fluid used in clutch systems—is expected to reflect significant shifts by 2026. DOT 3 brake fluid, a glycol-based fluid known for its balanced performance in standard operating conditions, remains a staple in conventional internal combustion engine (ICE) vehicles and many light-duty applications. The following analysis outlines key market trends expected to influence the DOT 3 brake fluid for clutch systems segment through 2026.

-

Stable Demand in ICE and Aftermarket Segments

Despite the rise of electric vehicles (EVs), internal combustion engine vehicles will continue to dominate global fleets through 2026, especially in developing regions. This sustained presence supports consistent demand for DOT 3 brake fluid, which is commonly used in clutch hydraulic systems due to its affordability, availability, and compatibility with older and mid-tier vehicle models. The aftermarket sector—driven by routine maintenance, fluid replacement cycles (typically every 2 years), and DIY consumer behavior—will remain a key growth driver. -

Pressure from Higher-Performance Alternatives

DOT 4 and, to a lesser extent, DOT 5.1 brake fluids offer higher boiling points and improved moisture resistance, making them increasingly preferred in performance and modern vehicles. As automakers push for longer service intervals and improved thermal stability, the market share of DOT 3 may gradually erode in new vehicle specifications. However, its use in clutch systems—where extreme temperatures are less common compared to brake systems—will help preserve its relevance. -

Regional Market Disparities

In emerging markets such as India, Southeast Asia, Africa, and Latin America, cost sensitivity and the prevalence of older vehicle fleets will sustain strong demand for DOT 3 brake fluid. These regions prioritize affordability and availability, making DOT 3 a practical choice for clutch applications. In contrast, North America and Western Europe may see a slower decline in DOT 3 usage, supported by legacy vehicles and consumer familiarity. -

Regulatory and Environmental Considerations

Environmental regulations are increasingly targeting the lifecycle impact of automotive chemicals. DOT 3 brake fluid is non-biodegradable and requires proper disposal. By 2026, stricter environmental compliance standards may encourage the development of more eco-friendly formulations or recycling initiatives, potentially affecting production costs and supply chain logistics. -

Impact of EV and ADAS Adoption

While electric vehicles typically use brake-by-wire systems and may reduce reliance on traditional hydraulic clutches (especially in automatic/EV drivetrains), many EVs still incorporate hydraulic components in service brakes. Manual transmission EVs are rare, but hybrid and performance ICE models using clutch systems will continue to require DOT 3 fluid. The gradual integration of advanced driver assistance systems (ADAS) does not directly impact clutch fluid demand but emphasizes the need for reliable, consistent hydraulic performance—reinforcing quality control in fluid specifications. -

Consolidation and Brand Competition

The brake fluid market is seeing increased consolidation among lubricant and fluid manufacturers. By 2026, major players like Valvoline, Castrol, ACDelco, and Pentosin are expected to dominate through brand trust, distribution networks, and bundled automotive service offerings. Competition will focus on product differentiation via additive packages that enhance corrosion protection and moisture resistance—even within the DOT 3 category.

Conclusion

By 2026, the DOT 3 brake fluid market for clutch systems will occupy a mature but resilient niche. While technological advancements and the EV transition may limit growth, ongoing demand from legacy vehicles, cost-driven markets, and the aftermarket will sustain its role. Manufacturers who emphasize quality, environmental compliance, and regional customization will be best positioned to maintain relevance in this evolving segment.

Common Pitfalls When Sourcing DOT 3 Brake Fluid for Clutch Systems

When maintaining or repairing a vehicle’s clutch system, using the correct DOT 3 brake fluid is essential for reliable performance and component longevity. However, several pitfalls can compromise quality, safety, and system integrity. Being aware of these issues helps ensure proper sourcing and application.

Poor Fluid Quality and Contamination

One of the most significant risks is purchasing low-quality or contaminated DOT 3 brake fluid. Substandard products may not meet the Department of Transportation (DOT) FMVSS No. 116 specifications, leading to reduced boiling points and increased moisture absorption. Contaminated fluid—often from improper storage or unsealed containers—can introduce water, dirt, or incompatible chemicals into the clutch hydraulic system, potentially causing corrosion, seal degradation, or brake fade.

Non-Compliance with OEM Specifications (IP Issues)

Using brake fluid that doesn’t conform to the vehicle manufacturer’s specifications is a common mistake. While DOT 3 is widely used, some manufacturers require specific performance characteristics beyond the basic DOT standard. Ignoring Intellectual Property (IP) guidance in service manuals or technical bulletins—such as recommending only OEM-approved fluids—can void warranties or lead to premature system failure. Always verify compatibility with the vehicle’s service documentation.

Mislabeling and Counterfeit Products

The automotive fluid market is prone to counterfeit or mislabeled products, especially when sourcing from non-authorized or online discount retailers. Fake DOT 3 fluid may resemble genuine products but lack proper formulation, resulting in poor performance and system damage. Always purchase from reputable suppliers and verify batch numbers, expiration dates, and packaging integrity.

Improper Storage and Shelf Life Neglect

DOT 3 brake fluid is hygroscopic, meaning it absorbs moisture from the air. Fluid stored in unsealed or previously opened containers can degrade rapidly, lowering its dry and wet boiling points. Using expired fluid or that exposed to humidity compromises the clutch system’s ability to withstand high temperatures, increasing the risk of vapor lock and clutch failure.

Mixing with Incompatible Fluid Types

Although DOT 3 is glycol-based, mixing it with other fluid types—such as DOT 5 (silicone-based) or incompatible aftermarket additives—can cause chemical reactions that damage seals and reduce performance. Always confirm that the fluid is 100% DOT 3 and avoid mixing unless explicitly permitted by the manufacturer.

Conclusion

Sourcing DOT 3 brake fluid for clutch systems requires careful attention to quality, compliance, and handling. Avoiding these common pitfalls ensures optimal clutch performance, prolongs system life, and maintains safety. Always prioritize OEM recommendations, purchase from trusted suppliers, and handle the fluid properly from storage to application.

Logistics & Compliance Guide for DOT 3 Brake Fluid for Clutch Systems

DOT 3 brake fluid is widely used in both brake and clutch hydraulic systems due to its compatibility, performance, and availability. Ensuring proper logistics handling and regulatory compliance is essential for safety, environmental protection, and legal adherence. This guide outlines key considerations for the storage, transportation, handling, and regulatory compliance of DOT 3 brake fluid when used in clutch applications.

1. Product Overview

DOT 3 brake fluid is a glycol-ether-based hydraulic fluid meeting the U.S. Department of Transportation (DOT) Federal Motor Vehicle Safety Standard (FMVSS) No. 116. It is suitable for use in clutch systems of vehicles with hydraulic clutches due to its high boiling point (minimum dry boiling point of 205°C / 401°F) and compatibility with rubber seals and metal components.

2. Storage Requirements

- Container Integrity: Store in original, tightly sealed containers to prevent moisture absorption, which degrades fluid performance.

- Environment: Keep in a cool, dry, well-ventilated area away from direct sunlight and heat sources (ideally 15–25°C / 59–77°F).

- Segregation: Store separately from oxidizing agents, acids, and incompatible materials. Avoid contact with aluminum, zinc, and copper alloys.

- Shelf Life: Typically 2 years from manufacture date if unopened; once opened, use within 6–12 months due to hygroscopic nature.

3. Transportation & Shipping

- Classification: DOT 3 brake fluid is generally classified as a flammable liquid (UN 1993, Class 3, PG III) under the UN Model Regulations.

- Packaging: Use UN-certified packaging with proper closure and labeling. Small quantities (<1 L) may be shipped as limited quantity (LQ) under 49 CFR or ADR regulations.

- Labeling: Include GHS-compliant hazard labels:

- Pictogram: Flame

- Signal Word: Warning

- Hazard Statements: H226 (Flammable liquid and vapor), H315 (Causes skin irritation), H319 (Causes serious eye irritation)

- Precautionary Statements: P210, P305+P351+P338, etc.

- Documentation: Prepare Safety Data Sheet (SDS), transport documents, and, if required, a Dangerous Goods Declaration.

4. Handling & Worker Safety

- PPE (Personal Protective Equipment): Use chemical-resistant gloves, safety goggles, and protective clothing when handling.

- Ventilation: Ensure adequate ventilation in work areas to prevent vapor buildup.

- Spill Response: In case of spill, absorb with inert material (e.g., sand or absorbent pads), place in a sealed container, and dispose of as hazardous waste. Do not flush into drains.

- First Aid:

- Skin contact: Wash with soap and water.

- Eye contact: Rinse thoroughly with water for at least 15 minutes; seek medical attention.

- Inhalation: Move to fresh air.

- Ingestion: Do not induce vomiting; seek immediate medical help.

5. Environmental & Regulatory Compliance

- Regulations: Comply with local, national, and international regulations such as:

- OSHA (U.S.): Hazard Communication Standard (29 CFR 1910.1200)

- EPA: Resource Conservation and Recovery Act (RCRA) for waste disposal

- REACH & CLP (EU): Registration, Evaluation, Authorization of Chemicals

- Transport: ADR (road), IMDG (sea), IATA (air)

- Waste Disposal: Used or contaminated DOT 3 fluid is considered hazardous waste. Dispose of through licensed waste management facilities in accordance with local regulations.

- Spill Reporting: Report significant spills to environmental authorities if required by local laws (e.g., spills >5 gallons in the U.S. may require reporting under CERCLA).

6. Compatibility & Application Notes

- Clutch Systems: DOT 3 is compatible with most hydraulic clutch systems. Confirm vehicle manufacturer specifications before use.

- Mixing: Do not mix with DOT 5 (silicone-based) fluids. DOT 3 is miscible with DOT 4 and DOT 5.1, but manufacturer recommendations should be followed.

- Moisture Sensitivity: Regularly inspect and replace fluid per maintenance schedules to maintain performance and prevent corrosion.

7. Recordkeeping & Training

- Maintain SDS access for all personnel.

- Train staff on safe handling, emergency procedures, and regulatory compliance.

- Keep logs of inventory, inspections, spills, and disposal activities.

By following this logistics and compliance guide, businesses and technicians can safely and legally manage DOT 3 brake fluid used in clutch systems, ensuring operational efficiency and environmental responsibility.

In conclusion, when sourcing DOT 3 brake fluid for a clutch system, it is essential to ensure compatibility with your vehicle’s specifications, as most hydraulic clutch systems use the same fluid as the brake system. DOT 3 brake fluid is widely available, cost-effective, and suitable for standard operating conditions due to its adequate boiling point and hygroscopic nature. However, it must be stored properly and used from a sealed container to prevent moisture contamination, which can degrade performance. Always consult your vehicle’s owner manual and follow the manufacturer’s recommendations to ensure optimal safety, reliability, and longevity of the clutch and braking systems. Using the correct fluid and maintaining it properly will help ensure smooth clutch operation and overall vehicle safety.

![[PDF] Havoline® Brake and Clutch Fluid DOT 3](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-havoline-brake-and-clutch-fluid-dot-3-921.png)