The global door locking mechanism market is undergoing significant transformation, driven by rising demand for enhanced security, smart home integration, and commercial infrastructure development. According to a 2023 report by Mordor Intelligence, the market was valued at USD 13.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.5% from 2023 to 2028, reaching an estimated USD 21.3 billion by the end of the forecast period. This growth is fueled by increasing adoption of electronic and biometric locking systems, particularly in residential and commercial sectors across North America, Europe, and Asia-Pacific. Additionally, urbanization, stricter building regulations, and the proliferation of IoT-enabled devices are accelerating innovation among leading manufacturers. As competition intensifies, companies are investing in R&D to offer more secure, convenient, and connected locking solutions. In this evolving landscape, identifying the top players shaping the industry becomes crucial for stakeholders, from property developers to security solution providers. Here’s a data-driven look at the top 10 door locking mechanism manufacturers leading the charge in technology, market share, and global reach.

Top 10 Door Locking Mechanism Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

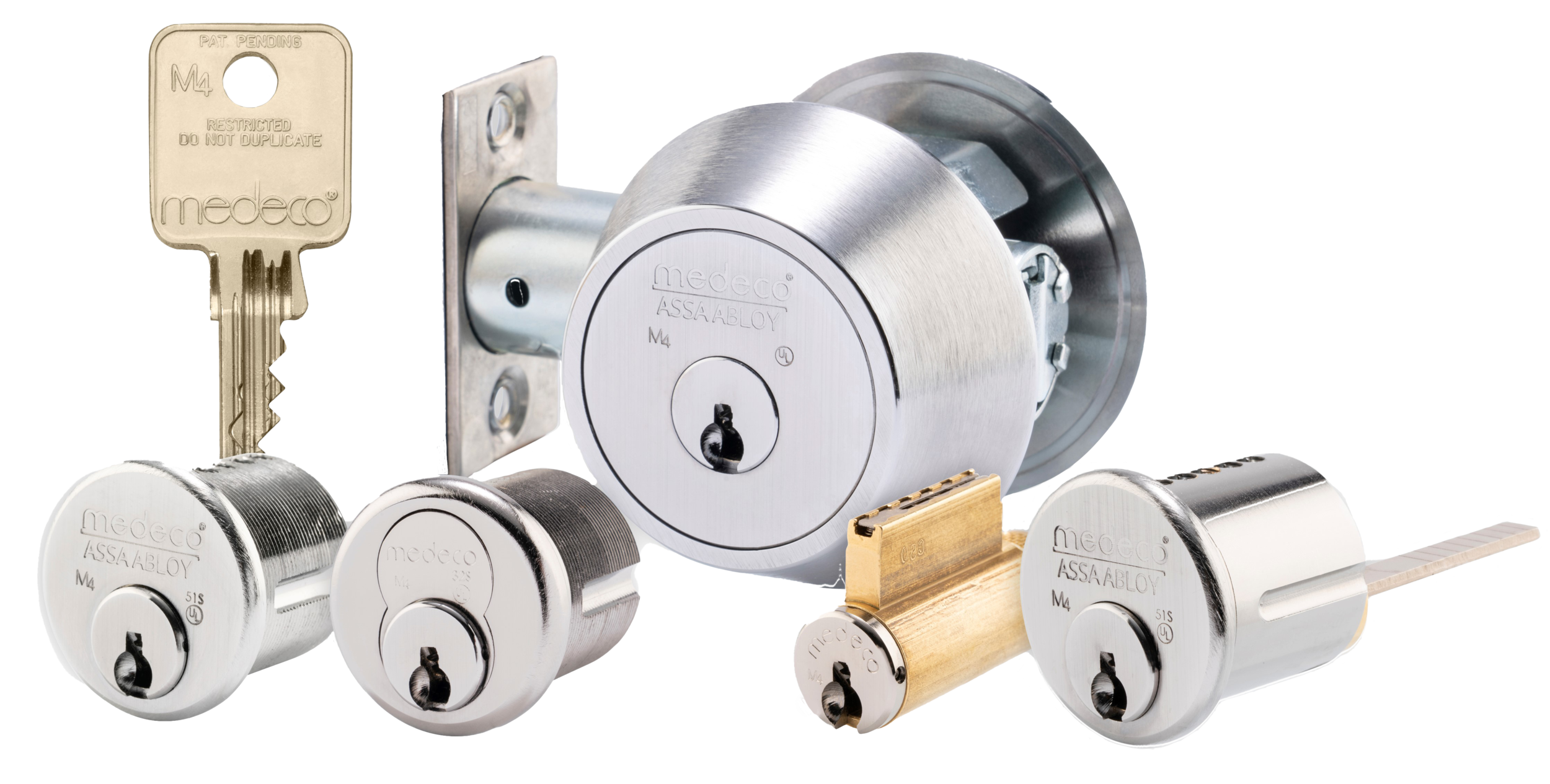

#1 Medeco

Domain Est. 1996

Website: medeco.com

Key Highlights: Medeco offers a wide range of key system technology. Our technology includes options for high security locks, prevention against illegal key duplication, and ……

#2 Camden Door Controls is the industry leading manufacturer of door …

Domain Est. 1997

Website: camdencontrols.com

Key Highlights: Camden Door Controls is the industry leading manufacturer of door activation and locking products. We support our customers with a network of more than 50 ……

#3 OMNIA Industries

Domain Est. 1999 | Founded: 1964

Website: omniaindustries.com

Key Highlights: Manufacturers of Locksets & Architectural Hardware of Fine Quality Since 1964 … Pocket Door Hardware · Outlet Store. New Products. EOMNIA · OMNIA+ Level ……

#4 Master Lock®

Domain Est. 1995

Website: masterlock.com

Key Highlights: Master Lock is recognized around the world as the authentic, enduring name in locks, combination padlocks and security products….

#5 Adams Rite

Domain Est. 1996

Website: adamsrite.com

Key Highlights: Adams Rite is the Aluminum Hardware Authority specializing in electromechanical deadlocks and deadlatches, electric strikes, exit devices and trim for narrow ……

#6 DOOR Smarter Access and Building Intelligence for Multifamily

Domain Est. 1997

Website: door.com

Key Highlights: Simplify property operations with DOOR. Our full-stack platform powers smart access, automation, and Building Intelligence for multifamily, student housing, ……

#7 SDC Security Door Controls

Domain Est. 1997

Website: sdcsecurity.com

Key Highlights: SDC Security Door Controls manufactures premium access control systems, electronic locks, magnetic locks, electric strikes, delayed egress systems, ……

#8

Domain Est. 1998

Website: sargentlock.com

Key Highlights: SARGENT Manufacturing delivers trusted, high-performance door hardware built for today’s commercial and architectural demands….

#9 CompX Security Products

Domain Est. 1998

Website: compx.com

Key Highlights: Electronic. CompX designs and manufactures industry leading keyless, electronic locking systems like CompX eLock, RegulatoR, StealthLock and Pearl….

#10 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

Expert Sourcing Insights for Door Locking Mechanism

H2: 2026 Market Trends for Door Locking Mechanisms

The global door locking mechanism market is poised for significant transformation by 2026, driven by advancements in smart home technology, heightened security concerns, and the increasing adoption of IoT-enabled devices. This analysis explores key trends shaping the industry in the coming years.

1. Surge in Smart Lock Adoption

Smart door locks are expected to dominate the market by 2026, with compound annual growth rates (CAGR) exceeding 15% in major regions like North America, Europe, and Asia-Pacific. Integration with virtual assistants (e.g., Amazon Alexa, Google Assistant) and mobile applications allows users to remotely control access, monitor entry logs, and receive real-time alerts. Biometric authentication (fingerprint, facial recognition) and voice-activated locks are becoming standard features, enhancing both convenience and security.

2. Integration with Smart Home Ecosystems

Door locking mechanisms are increasingly becoming a core component of broader smart home platforms. By 2026, interoperability with home automation systems (such as Apple HomeKit, Samsung SmartThings, and Google Home) will be a critical selling point. Consumers seek seamless experiences—locking doors automatically when the security system is armed or unlocking upon geofencing detection of a homeowner’s smartphone.

3. Focus on Cybersecurity and Data Privacy

As connectivity increases, so do concerns about cyber threats. Manufacturers are investing heavily in end-to-end encryption, two-factor authentication, and secure firmware updates to protect user data. Regulatory standards and consumer awareness will push companies to adopt transparent privacy practices, with certifications becoming a competitive advantage.

4. Growth in Commercial and Multifamily Applications

Beyond residential use, commercial buildings, hotels, and multifamily housing units are adopting digital locking systems. Keyless entry solutions streamline access management for property managers and enhance tenant experience. Technologies like Bluetooth and NFC-based access cards or mobile credentials are replacing traditional keys in corporate offices and apartment complexes.

5. Sustainability and Energy Efficiency

Eco-conscious design is gaining traction. By 2026, many smart locks will feature low-energy Bluetooth (BLE), solar-assisted charging, or energy-harvesting mechanisms. Long-lasting battery life and recyclable materials will appeal to environmentally aware consumers and support green building certifications.

6. Expansion in Emerging Markets

Rapid urbanization and rising disposable incomes in regions like Southeast Asia, Latin America, and the Middle East are fueling demand for advanced locking solutions. Localized manufacturing and partnerships with regional tech firms will help global brands penetrate these markets effectively.

7. AI and Predictive Analytics Integration

Artificial intelligence is beginning to play a role in access behavior analysis. By 2026, advanced locking systems may use AI to detect unusual entry patterns, predict maintenance needs, or adapt access permissions based on user routines—further enhancing security and usability.

In conclusion, the 2026 door locking mechanism market will be defined by intelligence, connectivity, and user-centric design. Companies that prioritize innovation, security, and ecosystem integration will lead the next phase of growth in this evolving industry.

Common Pitfalls Sourcing Door Locking Mechanisms (Quality, IP)

When sourcing door locking mechanisms—especially for industrial, commercial, or security-critical applications—overlooking key quality and IP (Intellectual Property) considerations can lead to product failure, liability, and reputational damage. Below are common pitfalls to avoid:

Inadequate Quality Assurance Standards

Many suppliers, particularly low-cost manufacturers, may lack robust quality control processes. This results in inconsistent product performance, premature wear, or mechanical failure. Always verify that suppliers adhere to recognized standards such as ISO 9001, and request third-party testing reports for durability, cycle testing, and environmental resistance.

Misunderstanding IP (Ingress Protection) Ratings

A frequent error is assuming that a locking mechanism is suitable for outdoor or harsh environments without verifying its IP rating. For example, a lock with an IP54 rating offers limited dust and splash protection but is insufficient for submersion or high-pressure washdowns. Ensure the IP rating matches the intended usage environment—such as IP65 for outdoor or industrial settings where dust and water jets are present.

Overlooking Material and Finish Quality

Low-grade materials (e.g., zinc alloys instead of stainless steel) or poor plating can lead to corrosion, reduced strength, and aesthetic degradation. This is especially critical in coastal or chemically aggressive environments. Always specify material composition and surface treatments (e.g., electroplating, powder coating) and validate them through sample testing.

Ignoring Certification and Compliance Requirements

Locking mechanisms used in safety-critical applications (e.g., fire doors, access control in public buildings) may require certifications like CE, UL, or EN standards. Sourcing non-compliant products can result in legal liability or project rejection. Confirm that the product meets regional and application-specific regulatory requirements.

Supply Chain Transparency and IP Infringement Risks

Many generic locking mechanisms replicate patented designs without authorization. Sourcing such components exposes your company to legal risk, including cease-and-desist orders or product recalls. Conduct due diligence to ensure the supplier has legitimate rights to the design or offers licensed alternatives. Request proof of design ownership or freedom-to-operate documentation.

Insufficient Testing for Real-World Conditions

Suppliers may provide data sheets based on ideal lab conditions, not real-world use. Mechanisms should be tested under expected loads, temperatures, and usage cycles. Request performance data from independent labs or conduct in-house validation testing before full-scale procurement.

Poor Documentation and Technical Support

Lack of detailed installation guides, CAD models, or responsive technical support can delay integration and increase engineering costs. Choose suppliers who provide comprehensive documentation and post-sale support to ensure smooth deployment and troubleshooting.

Avoiding these pitfalls requires due diligence, clear specifications, and ongoing supplier evaluation. Prioritizing quality and IP integrity from the outset protects your product’s reliability and your organization’s legal standing.

Logistics & Compliance Guide for Door Locking Mechanism

Product Classification and HS Code

Identify the appropriate Harmonized System (HS) code for door locking mechanisms, typically falling under Chapter 83 (Miscellaneous Articles of Base Metal). Common classifications include HS 8301.20 (Locks for doors, windows, etc., of base metal) or 8301.40 (Bolts, other than spring bolts, for locks). Accurate classification ensures correct duty assessment and compliance with import/export regulations.

Regulatory Compliance Requirements

Ensure door locking mechanisms meet relevant safety, security, and quality standards in the destination market. In the EU, compliance with the Construction Products Regulation (CPR) and CE marking under EN 12209 (Building hardware – Mechanical door locks, latches and exit devices) is mandatory. In the U.S., adherence to ANSI/BHMA standards (e.g., A156.13 for cylindrical locks) is required. Fire-rated models must also comply with local fire safety codes (e.g., NFPA 80 in the U.S.).

Packaging and Labeling Standards

Package products to prevent damage during transit, using protective materials such as foam inserts or corrugated boxes. Labeling must include product specifications, model number, safety certifications (e.g., CE, UL), country of origin, and handling instructions. For international shipments, include multilingual labels where required and ensure barcode compliance for inventory tracking.

Import/Export Documentation

Prepare complete documentation including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. For regulated markets, provide test reports, compliance certificates (e.g., CE, FCC if electronic), and declarations of conformity. Export controls may apply if the product includes encryption or military-grade components.

Transportation and Handling

Use secure freight methods appropriate for weight and volume. Secure units to prevent shifting during transit. Avoid exposure to moisture and extreme temperatures. Clearly mark packages as “Fragile” and “This Side Up” when applicable. For large shipments, consider container load optimization and use of pallets for warehouse efficiency.

Customs Clearance and Duties

Work with licensed customs brokers to facilitate clearance in destination countries. Declare accurate product value, quantity, and classification to avoid delays or penalties. Be aware of duty rates, import taxes, and potential anti-dumping measures. Maintain records for audit purposes under customs regulations such as the U.S. Customs-Trade Partnership Against Terrorism (C-TPAT) or Authorized Economic Operator (AEO) programs.

Environmental and RoHS Compliance

Ensure materials used in door locking mechanisms comply with environmental regulations such as the EU’s Restriction of Hazardous Substances (RoHS) Directive. Avoid restricted substances like lead, mercury, and hexavalent chromium. Provide Environmental Product Declarations (EPD) or Material Declarations upon request, especially for green building projects.

End-of-Life and Recycling Considerations

Design for disassembly and recyclability where possible. Inform customers of proper disposal methods in accordance with WEEE (Waste Electrical and Electronic Equipment) directives if applicable. Offer take-back programs or partner with certified e-waste recyclers to support compliance with sustainability obligations.

Conclusion for Sourcing Door Locking Mechanism:

After a comprehensive evaluation of available options, suppliers, and technical requirements, it is concluded that sourcing the door locking mechanism should prioritize reliability, security, durability, and compatibility with existing door systems. Based on performance specifications, cost-efficiency, and supplier reputation, a balanced approach combining high-quality materials, proven design, and favorable after-sales support is recommended.

Sourcing from established suppliers with certifications (such as ISO 9001, CE, or ANSI/BHMA) ensures compliance with industry standards and consistent product quality. Additionally, considerations such as ease of installation, scalability for future projects, and availability of spare parts further support long-term operational efficiency.

In summary, the optimal sourcing strategy involves selecting a locking mechanism that meets security and functional requirements while maintaining cost-effectiveness and supply chain reliability. This will ensure enhanced safety, user satisfaction, and reduced lifecycle costs across applications—whether for residential, commercial, or industrial use.