The global door lock market is experiencing robust growth, driven by rising urbanization, increasing demand for smart home technologies, and growing security concerns across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the global door lock market was valued at USD 19.3 billion in 2023 and is projected to reach USD 28.7 billion by 2029, growing at a CAGR of approximately 6.8% during the forecast period. Similarly, Grand View Research highlights the expanding adoption of electronic and biometric locks, noting that the smart locks segment alone is expected to grow at a CAGR of over 13% from 2023 to 2030. In this evolving landscape, door lock latch manufacturers play a critical role in ensuring mechanical reliability and compatibility with next-generation locking systems. As innovation accelerates and security standards rise, identifying the top manufacturers becomes essential for OEMs, builders, and technology integrators seeking high-performance, durable components. The following list highlights the top 10 door lock latch manufacturers leading the industry through technological advancement, global reach, and consistent product quality.

Top 10 Door Lock Latch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cal

Domain Est. 1997

Website: cal-royal.com

Key Highlights: For over 40 years Cal-Royal Products, Inc. has been a leading manufacturer of security door hardware, locksets, door closers, exit devices for residential, ……

#2 CompX Security Products

Domain Est. 1998

Website: compx.com

Key Highlights: CompX is a domestic cabinet lock manufacturer with facilities in South Carolina, Illinois and California. As industry leading producers of cabinet locks….

#3 OMNIA Industries

Domain Est. 1999 | Founded: 1964

Website: omniaindustries.com

Key Highlights: Manufacturers of Locksets & Architectural Hardware of Fine Quality Since 1964 … Pocket Door Hardware · Outlet Store. New Products. EOMNIA · OMNIA+ Level ……

#4 Latch Manufacturers

Domain Est. 2015

Website: latchmanufacturers.com

Key Highlights: Easily locate latch manufacturers that are able to provide many options of latches, including: locking or non-locking, stainless steel or carbon steel, ……

#5 Adams Rite Products

Domain Est. 1996

Website: adamsrite.com

Key Highlights: Our product lines include deadlocks, deadlatches, flushlocks, exit devices, electric strikes, trim, power locks, cylinders and door hardware accessories….

#6 Eberhard

Domain Est. 1996

Website: eberhard.com

Key Highlights: Eberhard innovates products that improve security and performance. Visit our New Products page to see the latest in electronic and bluetooth enabled latches….

#7 DOOR Smarter Access and Building Intelligence for Multifamily

Domain Est. 1997

Website: door.com

Key Highlights: Accessing door using smart lock. Residential Doors. High-quality, connected door hardware built for multifamily properties. Smart lock. Mortise Smart Lock (M3)….

#8

Domain Est. 1998

Website: sargentlock.com

Key Highlights: SARGENT Manufacturing delivers trusted, high-performance door hardware built for today’s commercial and architectural demands….

#9 Baldwin Hardware

Domain Est. 1998

Website: baldwinhardware.com

Key Highlights: Baldwin Hardware is a leading provider of high-quality, stylish and durable door and cabinet hardware for both residential and commercial applications….

#10 page

Domain Est. 2001

Website: allegiscorp.com

Key Highlights: Rotary Latches; Cab Latches; Latch Strikers. Bar Lock Latches; Bolt Latches; Clamps; Latch Cams; Latch Rods & Cables; Paddle Latches; Recessed T-Handle Latches ……

Expert Sourcing Insights for Door Lock Latch

2026 Market Trends for Door Lock Latch

The door lock latch market in 2026 is being reshaped by converging technological advancements, evolving consumer demands, and shifting regulatory landscapes. Key trends indicate a strong move towards smarter, more secure, and user-centric solutions across residential, commercial, and automotive sectors.

Smart Integration and IoT Dominance

By 2026, IoT-enabled door lock latches are becoming mainstream. Consumers and businesses increasingly demand systems that integrate with smart home platforms (e.g., Apple HomeKit, Google Home, Amazon Alexa) and building management systems. Features such as remote access, real-time alerts, and usage tracking are now expected rather than premium add-ons. This trend is accelerating due to falling sensor costs and improved wireless connectivity (e.g., Wi-Fi 6, Matter protocol adoption).

Enhanced Security and Biometric Authentication

Security remains paramount, driving adoption of advanced biometric latches—especially fingerprint and facial recognition—in both residential and commercial applications. In high-security sectors like healthcare and data centers, multi-factor authentication (e.g., PIN + biometrics) is becoming standard. Additionally, anti-tampering mechanisms and encryption protocols are being embedded directly into latch systems to combat digital and physical breaches.

Sustainability and Material Innovation

Environmental regulations and consumer preferences are pushing manufacturers toward sustainable materials and energy-efficient designs. Recycled metals, low-VOC finishes, and longer product lifecycles are key selling points. In commercial construction, green building certifications (e.g., LEED, BREEAM) are influencing procurement decisions, favoring latches with lower environmental impact.

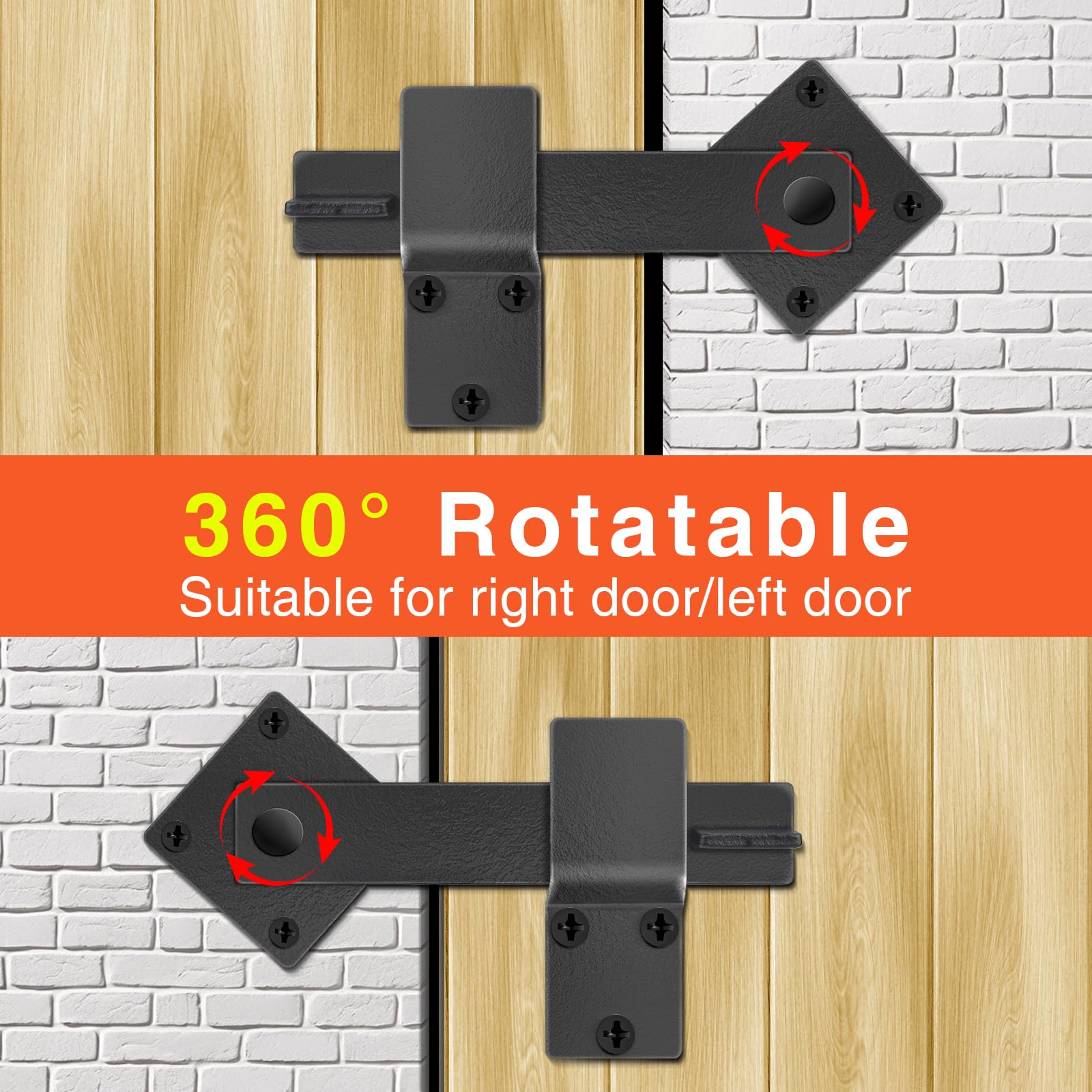

Growth in Retrofit and DIY Solutions

The residential market is seeing a surge in demand for retrofit smart latches that can be easily installed on existing doors. This trend is fueled by the desire for modernization without full door replacement. DIY-friendly designs with clear instructions and mobile app support are gaining traction, particularly in mature markets like North America and Western Europe.

Automotive Sector Electrification and Lightweighting

In the automotive industry, the shift to electric vehicles (EVs) is influencing latch design. 2026 sees increased demand for lightweight, energy-efficient latches that support vehicle range optimization. Additionally, integration with vehicle access apps and keyless entry systems is now standard, with growing interest in gesture-based and proximity-sensing latches.

Regional Diversification and Supply Chain Resilience

Geopolitical factors and post-pandemic supply chain lessons have led manufacturers to diversify production. Asia-Pacific remains a manufacturing hub, but nearshoring is rising in North America and Eastern Europe. Companies are investing in localized supply chains to reduce lead times and mitigate disruption risks, influencing global pricing and availability.

Cybersecurity and Data Privacy Regulations

As smart latches collect more user data, compliance with data protection laws (e.g., GDPR, CCPA) is critical. By 2026, manufacturers are prioritizing end-to-end encryption, secure firmware updates, and transparent data policies. Products with third-party cybersecurity certifications are gaining competitive advantage.

In summary, the 2026 door lock latch market is defined by intelligence, security, sustainability, and seamless integration. Companies that innovate across these dimensions while ensuring reliability and compliance will lead the evolving access control landscape.

Common Pitfalls Sourcing Door Lock Latch (Quality, IP)

Sourcing door lock latches—especially with specific quality and Ingress Protection (IP) requirements—can present several challenges. Overlooking these pitfalls can lead to product failures, safety issues, or non-compliance. Below are key areas to watch for:

Poor Material Quality and Durability

One of the most common issues is selecting latches made from substandard materials. Low-grade metals or plastics may corrode, warp, or break prematurely, especially in harsh environments. This compromises both security and longevity. Always verify material specifications such as stainless steel grade (e.g., 304 or 316 for corrosion resistance) and ensure components are tested for cycle life (e.g., 100,000+ operations).

Inaccurate or Misleading IP Ratings

Suppliers may claim a certain IP rating (e.g., IP65, IP67) without proper third-party certification. An IP67 latch should be dust-tight and withstand immersion in water, but some products fail under real-world conditions. Always request test reports or certifications from recognized bodies (e.g., IEC 60529) and avoid relying solely on supplier claims.

Inadequate Environmental Sealing

Even if a latch has an IP rating, poor design can lead to gaps or weak points in sealing. O-rings, gaskets, or housing seams may degrade over time or fail to maintain a tight seal after repeated use. Inspect the sealing mechanism and consider real-world installation factors like door flexing or temperature cycling.

Lack of Compliance with Safety and Industry Standards

Many latches do not meet regional or industry-specific standards (e.g., UL, CE, EN 12209 for door hardware). Using non-compliant parts can result in failed inspections, liability issues, or voided warranties. Confirm that the latch is certified for the target application and jurisdiction.

Inconsistent Manufacturing Quality

Sourcing from manufacturers with inconsistent quality control can result in batch-to-batch variations. Some units may function correctly while others fail prematurely. Implement incoming inspection protocols and consider working with suppliers who adhere to ISO 9001 or similar quality management systems.

Insufficient Testing for Real-World Conditions

Lab-tested IP ratings don’t always reflect field performance. Vibration, thermal expansion, UV exposure, and chemical cleaners can degrade performance over time. Request evidence of extended environmental testing or conduct in-house validation under expected operating conditions.

Overlooking Installation and Integration Issues

A high-quality, IP-rated latch may still fail if it doesn’t integrate properly with the door frame, actuator, or control system. Mounting tolerances, alignment, and wiring (for electric variants) must be considered. Work with suppliers who provide detailed installation guidelines and compatibility data.

Hidden Costs from Rework or Downtime

Choosing a cheaper latch to save upfront costs can lead to higher total cost of ownership due to maintenance, replacements, or system downtime. Factor in lifecycle costs and reliability when evaluating options.

By addressing these pitfalls early in the sourcing process—through rigorous vetting, testing, and supplier qualification—you can ensure the door lock latches meet both quality and IP requirements for reliable, long-term performance.

Logistics & Compliance Guide for Door Lock Latch

Product Classification & HS Code

Identify the correct Harmonized System (HS) code for door lock latches, typically falling under Chapter 83 (Miscellaneous Articles of Base Metal) or Chapter 94 (Furniture, Bedding, Lighting, etc.). Common codes include 8301.40 (Locks, clasps, and buckles, of base metal) or 8302.41 (Bolts, nuts, screws, and similar articles). Confirm the exact classification with local customs authorities to ensure accurate duty assessment and import/export compliance.

Regulatory Compliance

Ensure the door lock latch meets relevant safety, quality, and performance standards based on the destination market:

– United States: Comply with ANSI/BHMA standards (e.g., ANSI/BHMA A156.5 for door locks) and FCC rules if electronic components are present.

– European Union: Adhere to CE marking requirements under the Construction Products Regulation (CPR) and relevant EN standards (e.g., EN 12209 for mechanical building hardware).

– Canada: Meet CAN/ULC-S305 or other applicable Canadian standards.

– Other Regions: Verify local building codes and certification requirements (e.g., UKCA marking post-Brexit, INMETRO in Brazil).

Packaging & Labeling Requirements

Package door lock latches to prevent damage during transit using sturdy, recyclable materials. Label each package with:

– Product name and model number

– Quantity and weight

– Manufacturer and supplier information

– Barcodes/UPC if required

– Compliance markings (e.g., CE, UL, RoHS)

– Handling instructions (e.g., “Fragile,” “Do Not Stack”)

Ensure multilingual labeling if shipping to non-English-speaking countries.

Shipping & Transportation

Choose appropriate shipping methods (air, sea, or ground) based on volume, urgency, and cost. For international shipments:

– Use Incoterms® clearly (e.g., FOB, CIF, DDP) to define responsibilities.

– Prepare accurate commercial invoices, packing lists, and bills of lading.

– Declare goods properly to avoid customs delays.

– Consider temperature and humidity controls if components are sensitive.

Import/Export Documentation

Compile and maintain essential documentation:

– Commercial Invoice

– Packing List

– Bill of Lading/Air Waybill

– Certificate of Origin

– Test Reports and Certifications (e.g., UL, CE, RoHS)

– Import Licenses or Permits (if required by destination country)

Ensure all documents are accurate and consistent to prevent customs clearance issues.

Environmental & Chemical Compliance

Verify the product complies with environmental regulations:

– RoHS (EU): Restricts hazardous substances like lead, cadmium, and mercury.

– REACH (EU): Requires declaration of Substances of Very High Concern (SVHC).

– Proposition 65 (California): Mandates warnings if chemicals known to cause harm are present.

– China RoHS: Similar restrictions applicable in China.

Conduct material testing and maintain compliance documentation.

Product Liability & Safety Standards

Ensure door lock latches meet mechanical safety, durability, and fire-rating standards where applicable. Perform quality control checks during manufacturing and before shipment. Maintain records of testing and certifications to mitigate liability risks in case of failure or recalls.

End-of-Life & Recycling Considerations

Design for disassembly and recyclability where possible. Comply with WEEE (Waste Electrical and Electronic Equipment) directives if the latch includes electronic components. Provide disposal guidance to customers and distributors in accordance with local regulations.

Conclusion for Sourcing Door Lock Latch:

After evaluating various suppliers, product specifications, cost structures, and quality standards, the sourcing of door lock latches should focus on a balanced approach that ensures reliability, durability, and cost-efficiency. It is recommended to partner with pre-qualified suppliers who comply with industry standards (such as ANSI, EN, or ISO) and offer consistent product quality, timely delivery, and responsive customer support. Conducting regular audits, sample testing, and maintaining long-term supplier relationships will help mitigate risks related to performance and supply chain disruptions. Additionally, considering factors like material composition (e.g., zinc alloy, stainless steel), finish durability, and compatibility with existing door systems will enhance end-user satisfaction. Ultimately, strategic sourcing of door lock latches contributes to improved product safety, customer trust, and overall operational efficiency.