The global demand for efficient warehouse and logistics infrastructure continues to rise, driven by the rapid expansion of e-commerce and just-in-time supply chain models. This growth has directly fueled the market for commercial loading dock equipment, including dock doors—critical components in ensuring energy efficiency, safety, and operational throughput. According to a report by Mordor Intelligence, the global loading dock equipment market was valued at USD 2.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% through 2029. Similarly, Grand View Research estimates the market will expand at a CAGR of 5.2% from 2023 to 2030, citing increasing investments in modern warehousing facilities across North America, Europe, and Asia-Pacific. As demand for high-performance dock doors rises—driven by regulatory standards, sustainability goals, and automation trends—several manufacturers have emerged as leaders in innovation, durability, and service coverage. These top players are shaping the future of material handling by integrating smart technology, thermal efficiency, and robust safety features into their solutions.

Top 10 Dock Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rite

Domain Est. 1995

Website: ritehite.com

Key Highlights: Rite-Hite is the world leader in the manufacture and sale of loading dock equipment, industrial doors, safety barriers and high-volume, low-speed industrial ……

#2 Commercial Overhead Doors

Domain Est. 1998

Website: rytecdoors.com

Key Highlights: Rytec commercial overhead doors offer the highest value and day in, day out performance for a variety of applications and industries….

#3 Systems, LLC

Domain Est. 2013

Website: loadingdocksystems.com

Key Highlights: Systems, LLC manufactures Poweramp, DLM, and McGuire loading dock equipment, including dock levelers, truck restraints, dock seals, and more….

#4 Dock Doors

Domain Est. 1995

Website: raynor.com

Key Highlights: Raynor has a number of solutions to complement any dock needing a sectional overhead dock door. Choose from a variety of styles including pan doors….

#5 Dock and Door

Domain Est. 1998

Website: crown.com

Key Highlights: Crown offers a wide selection of products to help ensure safe and secure dock access. From rolling steel doors to dock bumpers and boards….

#6 C.H.I Overhead Doors

Domain Est. 1998

Website: chiohd.com

Key Highlights: C.H.I Overhead Doors provide high-quality garage doors for homes and businesses in a variety of styles and colors. Learn more….

#7 Dock & Door Systems: Dock Doors

Domain Est. 2006

Website: dockdoorsystems.com

Key Highlights: Dock & Door Systems Provides High-Quality Dock Doors, Dock Seals, and Dock Shelters Designed for Durability, Safety, and Efficiency. Enhance Loading Dock ……

#8 Dynamic Dock & Door

Domain Est. 2009

Website: dynamic-dock-door.com

Key Highlights: Dynamic Dock & Door is a complete materials handling company specializing in loading dock equipment, commercial door solutions, storage systems and energy ……

#9 Smooth operations with our overhead sectional dock doors

Domain Est. 2012

Website: assaabloyentrance.com

Key Highlights: Get smooth and reliable opening and closing with our overhead sectional dock doors. Designed to meet all EU operational and safety requirements….

#10 DuraServ: Loading Dock

Domain Est. 2015

Website: duraservcorp.com

Key Highlights: DuraServ provides loading dock, overhead doors & safety equipment solutions that keep your operation running. We maximize your uptime and ensure ……

Expert Sourcing Insights for Dock Doors

2026 Market Trends for Dock Doors

The global dock doors market is poised for significant transformation by 2026, driven by advancements in automation, growing emphasis on energy efficiency, and the rapid expansion of e-commerce and cold chain logistics. As industrial and commercial facilities strive to improve operational efficiency, safety, and sustainability, dock doors are evolving from basic access points into intelligent, integrated components of modern material handling systems.

Rising Demand from E-Commerce and Logistics Expansion

The continued growth of e-commerce is reshaping supply chain dynamics, necessitating faster order fulfillment and higher throughput in distribution centers. This trend is fueling demand for high-speed, durable dock doors that minimize loading and unloading times while maintaining climate control and security. By 2026, facilities are expected to prioritize rapid-cycle doors capable of withstanding constant use, particularly in automated fulfillment centers where efficiency is paramount.

Adoption of Smart and Automated Dock Door Systems

Integration with smart warehouse technologies is a key trend shaping the 2026 landscape. Dock doors equipped with IoT sensors, real-time monitoring, and automated operation are becoming standard in advanced logistics hubs. These systems enable remote diagnostics, predictive maintenance, and seamless coordination with dock levelers and vehicle restraints. The push toward Industry 4.0 and smart logistics is accelerating the adoption of connected dock door solutions, enhancing safety and operational transparency.

Focus on Energy Efficiency and Sustainability

With increasing regulatory pressure and corporate sustainability goals, energy-efficient dock doors are gaining traction. Thermal curtains, insulated panels, and tight-sealing designs help reduce energy loss in temperature-controlled environments—critical in cold storage and pharmaceutical logistics. By 2026, manufacturers are expected to emphasize eco-friendly materials and low-carbon production processes to meet green building standards and reduce the environmental footprint of industrial facilities.

Growth in Cold Chain and Food & Beverage Sectors

The expansion of the global cold chain, driven by rising demand for fresh and frozen goods, is boosting the need for specialized refrigerated dock doors. These doors maintain temperature integrity during loading operations, preventing spoilage and ensuring compliance with food safety regulations. Innovations such as heated edges and vapor barriers are becoming more common, particularly in regions with extreme climates.

Regional Market Dynamics

North America and Europe will remain dominant markets due to mature logistics infrastructure and stringent energy regulations. However, Asia-Pacific is expected to witness the fastest growth, fueled by urbanization, industrialization, and the rise of regional e-commerce giants. Emerging markets in Southeast Asia and India are investing heavily in modern warehousing, creating new opportunities for advanced dock door solutions.

Conclusion

By 2026, the dock doors market will be defined by intelligence, efficiency, and sustainability. Companies that invest in innovative, integrated, and energy-conscious solutions will be best positioned to capitalize on evolving industry demands across logistics, manufacturing, and cold chain applications.

Common Pitfalls Sourcing Dock Doors (Quality, IP)

Sourcing dock doors involves more than just selecting a product based on price or appearance. Overlooking critical quality and ingress protection (IP) factors can lead to safety hazards, operational inefficiencies, and increased long-term costs. Below are common pitfalls to avoid:

Inadequate Ingress Protection (IP) Rating for the Environment

One of the most frequent oversights is selecting a dock door with an insufficient IP rating for its intended environment. IP ratings indicate protection against solid objects and liquids. For example, using a dock door rated IP54 (protected against dust and water splashes) in a cold storage facility or outdoor loading bay with heavy rain may result in water ingress, insulation damage, and mold growth. Always match the IP rating to environmental conditions—such as humidity, washdowns, dust levels, or outdoor exposure—to ensure long-term durability.

Compromising on Build Quality to Reduce Costs

Choosing lower-cost dock doors often means sacrificing material thickness, corrosion resistance, or structural integrity. Thin steel skins, substandard seals, or weak hinges can lead to premature wear, air leakage, and increased maintenance. Over time, poor build quality undermines energy efficiency and safety. Investing in higher-quality components—even at a higher initial cost—typically results in better performance, fewer repairs, and longer service life.

Ignoring Sealing Performance and Insulation Value

Dock doors are critical for maintaining indoor climate control, especially in temperature-sensitive environments like food processing or pharmaceutical facilities. Poor sealing due to inadequate compression, low-quality foam seals, or improper fit allows air, moisture, and contaminants to enter. Similarly, doors with low R-values or insufficient insulation contribute to energy loss. Ensure the door’s thermal performance aligns with your facility’s energy efficiency and regulatory requirements.

Overlooking Structural Compatibility and Installation Requirements

Dock doors must integrate seamlessly with existing dock shelters, bumpers, and building structures. Sourcing a door without verifying mounting dimensions, weight capacity, or headroom requirements can lead to installation issues or structural failure. Additionally, improper installation—often due to lack of manufacturer guidance or unqualified labor—can void warranties and compromise safety and performance.

Failing to Verify Compliance with Industry Standards

Dock doors used in certain industries must meet specific safety and performance standards (e.g., EN 13241 for industrial doors, FM approvals for fire resistance, or FDA compliance for food safety). Skipping verification of these certifications can result in non-compliance, failed audits, or liability risks. Always confirm that the dock door meets relevant regional and industry-specific standards.

Underestimating Maintenance and Service Support

Even high-quality dock doors require routine maintenance. Sourcing from suppliers with poor after-sales support or limited spare parts availability can lead to extended downtime during repairs. Evaluate the vendor’s service network, warranty terms, and technical support before procurement to ensure long-term reliability.

Avoiding these pitfalls ensures that your dock door investment supports operational efficiency, safety, and facility integrity over its lifecycle.

Logistics & Compliance Guide for Dock Doors

Effective management of dock doors is essential for ensuring operational efficiency, workplace safety, and regulatory compliance in warehouses, distribution centers, and manufacturing facilities. This guide outlines key logistics considerations and compliance requirements related to dock door operations.

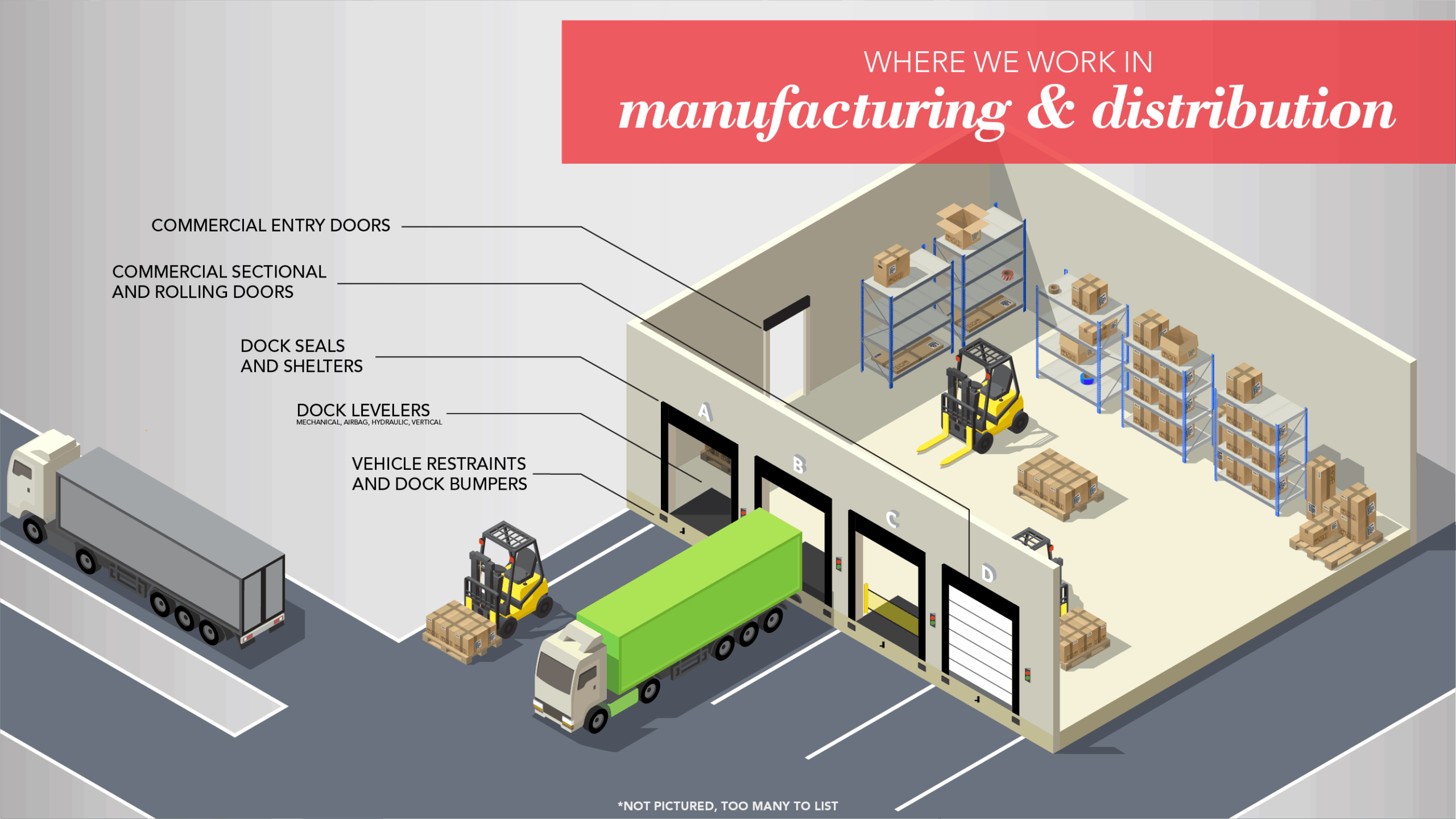

Purpose and Importance of Dock Doors

Dock doors serve as the primary interface between transportation vehicles and facility interiors. They facilitate the movement of goods, support inventory control, and play a critical role in maintaining environmental conditions (e.g., temperature control in cold storage). Proper dock door management enhances supply chain reliability and minimizes delays.

Safety Standards and Regulations

Compliance with occupational health and safety regulations is mandatory. Key standards include:

- OSHA (Occupational Safety and Health Administration) – Requires guardrails, proper lighting, and fall protection near dock openings.

- ANSI/ITSDF B56.1 – Covers safety requirements for powered industrial trucks, including their use at loading docks.

- International Building Code (IBC) – Specifies structural and fire-rated requirements for dock doors in certain facilities.

- FM Global Data Sheets – Provides engineering standards for property loss prevention, including dock door design and sealing.

Facilities must conduct regular safety audits and maintain documented compliance with applicable standards.

Dock Door Design and Configuration

Design considerations impact both logistics performance and compliance:

- Door Types: Choose between sectional, rolling steel, high-speed, or dock leveler-integrated doors based on traffic volume, climate, and security needs.

- Size and Clearance: Ensure adequate height and width to accommodate standard trailers (e.g., 53’ dry vans) and specialized vehicles (e.g., refrigerated units).

- Insulation and Sealing: Use dock seals or shelters to minimize energy loss and maintain indoor air quality, especially in temperature-controlled environments.

- Accessibility: Comply with ADA requirements for personnel access near dock areas.

Operational Best Practices

Efficient logistics depend on standardized operating procedures:

- Scheduling and Coordination: Use dock scheduling software to allocate doors, reduce wait times, and improve carrier turnaround.

- Pre-Use Inspection: Train staff to check door mechanisms, levelers, and restraints before each use.

- Trailer Restraint Systems: Use wheel chocks or vehicle restraint systems to prevent “trailer creep” and protect workers.

- Visual Management: Implement signage, floor markings, and traffic lights (dock status indicators) to guide drivers and forklift operators.

Security and Access Control

Protect cargo and ensure regulatory compliance through:

- Access Monitoring: Use keycards, PIN codes, or biometric systems to restrict unauthorized entry.

- Surveillance: Install cameras to monitor dock activity and deter theft.

- Seal Verification: Record and inspect trailer seals upon arrival and departure per TSA and C-TPAT guidelines (if applicable).

Maintenance and Inspection

Regular maintenance ensures reliability and compliance:

- Daily Checks: Operators should inspect door movement, safety edges, and leveler functionality.

- Preventive Maintenance: Schedule quarterly or semi-annual servicing of motors, springs, and electrical systems.

- Documentation: Keep logs of inspections, repairs, and safety tests for audit purposes.

Environmental and Sustainability Considerations

Sustainable dock operations contribute to corporate responsibility goals:

- Energy Efficiency: Install high-speed doors and dock shelters to reduce HVAC loss.

- LED Lighting: Use motion-sensor lighting in dock areas to cut energy use.

- Recycling Programs: Designate areas near docks for recyclable packaging materials.

Training and Compliance Documentation

Personnel must be trained in:

- Safe operation of dock equipment

- Emergency procedures (e.g., entrapment, fire)

- Reporting hazards and incidents

Maintain training records and ensure all compliance documentation (e.g., OSHA logs, inspection reports) is current and accessible.

Conclusion

Proper management of dock doors is a cornerstone of efficient and compliant logistics operations. By adhering to safety regulations, implementing best practices, and investing in proper training and maintenance, organizations can enhance productivity, reduce risk, and ensure smooth supply chain operations.

Conclusion for Sourcing Dock Doors:

Sourcing the right dock doors is a critical component in optimizing warehouse efficiency, ensuring operational safety, and maintaining energy efficiency within distribution and logistics facilities. A well-informed sourcing strategy should take into account factors such as door frequency of use, environmental conditions, security requirements, energy conservation goals, and compatibility with loading equipment. By evaluating leading manufacturers, comparing material durability (such as steel, aluminum, or insulated panels), and considering automated vs. manual operation, organizations can select dock doors that align with their operational demands and long-term cost objectives.

Additionally, partnering with reputable suppliers who offer strong warranties, reliable service support, and compliance with relevant safety standards (such as OSHA or energy codes) ensures both performance and regulatory compliance. Investing in high-quality dock doors not only reduces maintenance and energy costs but also enhances workplace safety and supply chain reliability.

In conclusion, strategic sourcing of dock doors—grounded in thorough needs assessment, total cost of ownership analysis, and supplier evaluation—delivers measurable improvements in facility operations and contributes to a more resilient and efficient supply chain.