The global metal forming machinery market, which includes sheet metal bending equipment such as dobladoras de lámina (sheet metal brakes), is experiencing steady expansion driven by rising demand in construction, automotive, and industrial manufacturing sectors. According to Mordor Intelligence, the global sheet metal fabrication market was valued at USD 154.3 billion in 2023 and is projected to grow at a CAGR of 6.8% through 2029. This growth is largely attributed to advancements in precision machinery, increasing automation, and the expansion of metalworking industries across Asia-Pacific and Latin America. As demand for high-accuracy bending solutions rises, manufacturers of dobladoras de lámina are innovating rapidly to deliver durable, efficient, and CNC-integrated machines. In this evolving landscape, four leading manufacturers have distinguished themselves through technological leadership, global reach, and strong product reliability—setting the benchmark for performance in sheet metal fabrication worldwide.

Top 4 Dobladora De Lamina Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dobladoras de lámina

Domain Est. 2000

Website: metalmecanica.com

Key Highlights: Una dobladora de lámina es una máquina diseñada para aplicar una fuerza controlada sobre una pieza metálica plana con el propósito de generar un ……

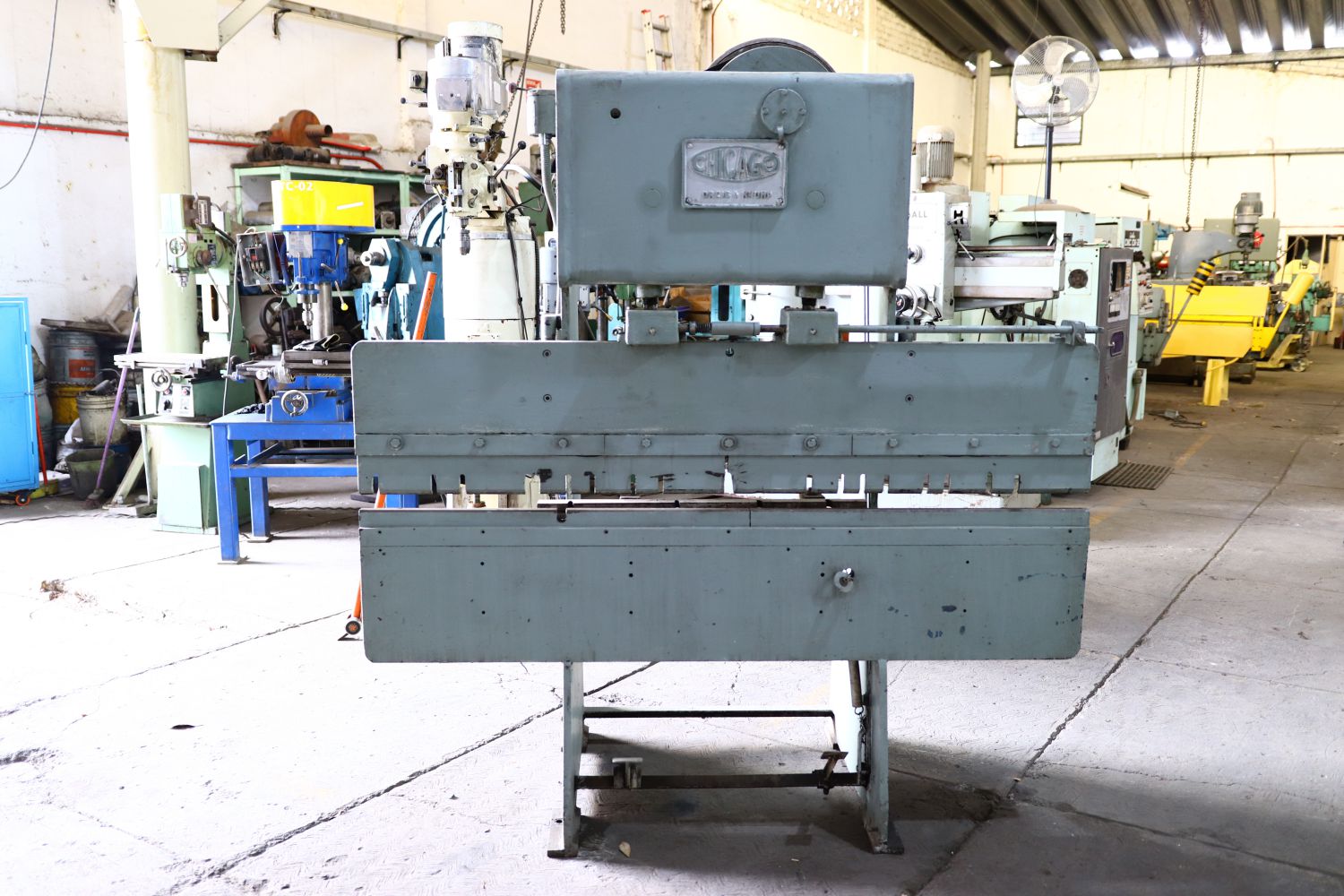

#2 Dobladora de Lámina Chicago 15T 6′

Domain Est. 2017

Website: mgmaquinaria.com

Key Highlights: Dobladora. Marca, Chicago Dreis & Krump, Profundidad Garganta, 6.125″ (155mm). Modelo, M 135, Ajuste de Carnero, 4″ (101.6mm). Origen, EUA, GPM máx….

#3 Dobladora de Lámina –15 toneladas

Domain Est. 2021

Website: sawyermfg.mx

Key Highlights: La dobladora de lámina – 15 toneladas de Sawyer realiza pruebas de doblado guiado con precisión y durabilidad, ideal para certificaciones ASME y API….

#4 Dobladora De Lamina Chicago 4×16

Domain Est. 2024

Expert Sourcing Insights for Dobladora De Lamina

H2: 2026 Market Trends for Dobladora De Lámina

The global market for dobladoras de lámina (sheet metal bending machines) is poised for significant evolution by 2026, driven by technological innovation, shifting industrial demands, and regional manufacturing growth. Below are the key trends expected to shape the dobladora de lámina market in 2026:

1. Increased Adoption of Automation and CNC Technology

By 2026, computer numerical control (CNC) bending machines are expected to dominate the market. Automation enhances precision, reduces labor costs, and improves production efficiency. Manufacturers are increasingly investing in smart bending machines integrated with IoT and AI for real-time monitoring, predictive maintenance, and remote operation.

2. Growth in Automotive and Aerospace Sectors

The automotive and aerospace industries are major consumers of precision sheet metal components. As these sectors adopt lightweight materials and complex geometries, demand for high-accuracy dobladoras de lámina is rising. Electric vehicle (EV) production, in particular, is expected to fuel demand for advanced bending solutions in battery enclosures and chassis components.

3. Expansion in Emerging Markets

Regions such as Latin America, Southeast Asia, and India are witnessing rapid industrialization and infrastructure development. Local manufacturing hubs are investing in modern fabrication equipment, including hydraulic and CNC press brakes, boosting regional demand for dobladoras de lámina.

4. Emphasis on Energy Efficiency and Sustainability

Environmental regulations and rising energy costs are pushing manufacturers to adopt energy-efficient machines. By 2026, eco-friendly models with reduced power consumption and lower hydraulic fluid usage are expected to gain market share. Additionally, recyclable tooling and modular designs will support sustainable manufacturing practices.

5. Rise of Hybrid and Electric Press Brakes

Electric servo-driven and hybrid bending machines are gaining traction due to their precision, speed, and lower environmental impact. These systems offer quieter operation and reduced maintenance compared to traditional hydraulic models, making them ideal for high-mix, low-volume production environments.

6. Integration with Industry 4.0 and Smart Factories

Sheet metal bending machines are becoming integral components of smart factories. By 2026, seamless integration with CAD/CAM software, digital twins, and production management systems will allow for faster setup, error reduction, and end-to-end process optimization.

7. Customization and Modular Designs

Manufacturers are increasingly offering customizable tooling and modular machine configurations to meet diverse industry needs. This trend supports flexibility in small-batch production and rapid retooling, especially relevant in sectors like electronics and custom fabrication.

8. Competitive Pricing and After-Sales Services

As the market becomes more competitive, vendors are differentiating through value-added services, including training, remote diagnostics, and extended warranties. Localized service networks will be critical, especially in emerging markets where uptime and technical support are key purchasing factors.

In conclusion, the dobladora de lámina market in 2026 will be defined by digitalization, sustainability, and increasing demand from high-tech industries. Manufacturers who innovate in automation, energy efficiency, and integration capabilities will be best positioned to lead the market.

Common Pitfalls When Sourcing Dobladora De Lámina (Quality and Intellectual Property)

Sourcing a Dobladora de Lámina (sheet metal bending machine) from international suppliers, particularly from regions with less stringent regulatory oversight, can present significant challenges related to both product quality and intellectual property (IP) rights. Being aware of these pitfalls is essential to avoid costly mistakes, production delays, and legal complications.

Inconsistent or Substandard Build Quality

One of the most frequent issues when sourcing bending machines is encountering inconsistent or substandard build quality. Machines may appear identical to reputable models but are constructed with inferior materials—such as lower-grade steel, subpar welds, or low-cost hydraulic components—that compromise durability, precision, and safety. These machines often fail prematurely under regular industrial use, leading to unplanned downtime and increased maintenance costs.

Misrepresentation of Specifications and Capabilities

Suppliers may exaggerate or falsify machine specifications, such as maximum tonnage, bending length, accuracy, and repeatability. A Dobladora de Lámina advertised to handle 3mm stainless steel across a 3-meter length may, in reality, struggle with thinner materials or shorter spans. This misrepresentation can result in the machine being unsuitable for your production needs, forcing costly replacements or upgrades.

Lack of Quality Control and Testing

Many low-cost suppliers lack rigorous quality control processes. Machines may be assembled without proper calibration or performance testing, leading to inconsistencies between units. Without certification to international standards (e.g., ISO, CE), there is little assurance that the equipment meets safety or performance benchmarks, increasing the risk of workplace accidents or non-compliance with local regulations.

Counterfeit or Clone Machines (IP Infringement)

A major intellectual property concern is the proliferation of counterfeit or cloned machines that mimic well-known brands such as Amada, Trumpf, or Bystronic. These unauthorized copies often infringe on patented designs, control systems, and software. Purchasing such equipment can indirectly expose your business to legal liability, especially if the original IP holder pursues action against users of infringing products.

Use of Pirated or Unlicensed Software

Modern bending machines rely on proprietary CNC software for programming and operation. Some suppliers install pirated or reverse-engineered versions of licensed software to reduce costs. This not only violates copyright laws but also poses cybersecurity risks and limits access to updates, technical support, and warranty services. In the event of a software failure, recovery may be impossible without legitimate licenses.

Voided Warranties and Lack of After-Sales Support

Due to IP violations or poor manufacturing, many cloned or low-quality machines come with limited or unenforceable warranties. Moreover, suppliers may lack the technical expertise or spare parts inventory to provide effective after-sales support. This lack of service infrastructure can lead to extended machine downtime and difficulty sourcing replacement components.

Regulatory and Compliance Risks

Importing a machine that infringes on intellectual property rights can result in customs seizures, fines, or legal action. Additionally, machines not compliant with local safety standards (e.g., OSHA in the U.S. or CE in Europe) may be barred from operation, requiring costly retrofits or removal from the facility.

Recommendations to Mitigate Risks

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request third-party inspections, insist on original equipment documentation, and ensure software is legally licensed. Consider working with authorized distributors or manufacturers with a proven track record to safeguard both quality and IP compliance.

Logistics & Compliance Guide for Dobladora De Lamina

Overview of Dobladora De Lamina Equipment

A Dobladora De Lamina, or sheet metal bending machine, is a key industrial tool used in metal fabrication to bend and shape sheet metal with precision. These machines come in various types—including manual, hydraulic, and CNC models—and are essential in industries such as construction, automotive, and manufacturing. Proper logistics and compliance planning is crucial for the safe, legal, and efficient transport, import/export, and operation of this equipment.

International Shipping and Transportation

When transporting a Dobladora De Lamina internationally, consider size, weight, and fragility. Most models require crating and secure palletization to prevent damage during transit. Choose between sea freight (cost-effective for heavy machinery) or air freight (faster but more expensive). Ensure accurate freight classification (e.g., HS Code 8462.21 for bending machines) and complete all required shipping documentation, including commercial invoices, packing lists, and bills of lading.

Import/Export Regulations and Customs Clearance

Compliance with import/export regulations is mandatory. Verify the destination country’s customs requirements, including applicable tariffs, import licenses, and conformity assessments. The Harmonized System (HS) code for Dobladora De Lamina is typically 8462.21. Some countries may require certifications such as CE (European Union), CCC (China), or UL (United States). Always declare the equipment’s origin, value, and technical specifications accurately to avoid customs delays or penalties.

Safety and Equipment Certification

Ensure the Dobladora De Lamina meets regional safety standards. Machines exported to the EU must carry the CE mark, indicating compliance with health, safety, and environmental protection standards. In North America, adherence to OSHA and ANSI B11 safety standards for metalworking machinery is required. Suppliers should provide a Declaration of Conformity and technical documentation, including electrical schematics and risk assessments.

Packaging and Handling Requirements

Due to the machine’s weight and mechanical components, proper packaging is essential. Use wooden crates with internal bracing and protective materials (e.g., foam, plastic wrap) to prevent movement and corrosion. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and weight specifications. Include anchor points for forklifts and lifting gear to ensure safe unloading at the destination.

Installation and On-Site Compliance

Upon delivery, verify that the installation site meets operational requirements: adequate floor load capacity, power supply (voltage, phase, frequency), and ventilation. Follow the manufacturer’s installation manual and involve certified technicians. Conduct an initial safety inspection and ensure emergency stop functions, guards, and safety interlocks are operational before commissioning.

Operator Training and Documentation

Compliance includes proper workforce training. Operators must be trained on machine functions, safety procedures, and emergency protocols per local labor regulations. Maintain training records and provide multilingual user manuals and safety signage if operating in diverse regions. Regular maintenance logs should also be kept to demonstrate compliance with equipment upkeep standards.

Environmental and Disposal Regulations

Address environmental compliance during the machine’s lifecycle. Hydraulic models may contain oils or coolants regulated under environmental laws (e.g., EPA in the U.S.). Dispose of fluids and packaging materials according to local waste management regulations. At end-of-life, follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions for proper recycling and disposal.

Recordkeeping and Audit Preparedness

Maintain comprehensive records of shipping documents, customs filings, certifications, maintenance logs, and operator training. These documents support compliance audits and facilitate future shipments or regulatory inspections. Digitize records for easy access and retention in accordance with local data storage laws.

Summary and Best Practices

To ensure smooth logistics and compliance for a Dobladora De Lamina:

– Accurately classify and document the equipment for customs.

– Use certified packaging and professional freight services.

– Verify compliance with destination safety and environmental regulations.

– Train operators and maintain detailed records.

– Partner with experienced logistics and compliance consultants when entering new markets.

Conclusion for Sourcing a Dobladora de Lámina (Sheet Metal Bending Machine)

After a thorough evaluation of the requirements, technical specifications, market options, and supplier capabilities, sourcing a dobladora de lámina (sheet metal bending machine) is a strategic investment that will significantly enhance manufacturing efficiency, precision, and production capacity. The selection process has highlighted the importance of balancing cost, quality, technological features, and after-sales support.

Key factors considered include the machine’s tonnage, bending length, accuracy, automation compatibility, ease of operation, and energy efficiency. Competitive quotations from both local and international suppliers were analyzed, with priority given to those offering reliable service networks, operator training, and warranty terms.

Ultimately, sourcing the most suitable dobladora de lámina ensures improved product consistency, reduced material waste, and increased competitiveness in delivering high-quality sheet metal components. Moving forward, establishing long-term partnerships with reputable suppliers and implementing proper maintenance protocols will maximize return on investment and support sustainable growth in production capabilities.