The global demand for disposable tableware continues to surge, driven by the rapid expansion of food delivery services, on-the-go consumption trends, and heightened hygiene awareness. According to Mordor Intelligence, the global disposable tableware market was valued at USD 12.8 billion in 2023 and is projected to grow at a CAGR of 5.6% through 2029. A key segment within this growth is disposable glassware with lids, increasingly adopted by cafes, restaurants, and beverage brands for cold drinks, smoothies, and ready-to-drink products. These containers combine the clarity and premium feel of glass with the convenience and portability of disposables, making them a preferred choice in both retail and foodservice sectors. As sustainability concerns rise, manufacturers are innovating with bio-based materials and recyclable designs to meet evolving regulatory and consumer demands. In this competitive landscape, identifying leading disposable glass with lid manufacturers is crucial for businesses aiming to balance performance, aesthetics, and environmental responsibility.

Top 10 Disposable Glass With Lid Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Disposable Glassware

Domain Est. 2003

Website: glasscolabs.com

Key Highlights: 2-day returnsBest Manufacturer, Suppliers & Exporters of High Quality Laboratory Disposable Glassware – Disposable Glassware Culture Tube | Pasteur Pipettes….

#2 Silgan Closures

Domain Est. 2014

Website: silgan-closures.com

Key Highlights: Leading manufacturer of rigid packaging for shelf-stable food and other consumer goods. Annual net sales of approximately $5,68 billion in 2021….

#3 PP & PET Lid

Domain Est. 2015

Website: prithvipolymer.com

Key Highlights: A top PP glass manufacturer can help provide you with good quality and perfect disposable glass wholesale price for all your drinks and dessert requirements….

#4

Domain Est. 1991

Website: ball.com

Key Highlights: Ball Corporation is the world’s leading provider of innovative, sustainable aluminum packaging for beverage, personal care and household products, ……

#5 Plastic Cups

Domain Est. 1995

Website: dartcontainer.com

Key Highlights: Plastic Cups · Solo® Ultra Clear™ PET Cold Cups · Cup Inserts · Conex ClearPro® Clear Polypropylene Cups · Conex ProMotions® White Polypropylene Cups · SOLO® ……

#6 Berlin Packaging

Domain Est. 1997

Website: berlinpackaging.com

Key Highlights: Berlin Packaging supplies plastic, glass, and metal containers, closures and dispensing systems to customers of all types. Hybrid packaging supplier means ……

#7 Govino

Domain Est. 1998

Website: govino.com

Key Highlights: Free delivery over $40 30-day returnsMade from BPA-free Tritan™, Govino is lightweight, shatterproof, and super durable. Plus it looks crystal clear – just like glass, but without …

#8 TricorBraun

Domain Est. 1998

Website: tricorbraun.com

Key Highlights: TricorBraun is a global wholesale packaging leader offering custom & stock packaging solutions with rigid & flexible options. Learn more at TricorBraun.com….

#9 Toyo Seikan Group Holdings, Ltd.

Domain Est. 2012

Website: tskg-hd.com

Key Highlights: A glass bottle cap that can be easily opened and closed due to the good engagement of the protrusion at the bottom of the cap and the glass bottle….

#10 Shalimar Plastic Industries

Domain Est. 2019

Website: shalimarplasticindustries.com

Key Highlights: Products Range · Pet Thermoforming Products · Disposable Glass With Lids · Disposable Bowls · P.P Food Box · SPI (New Products) · Pharmaceutical Products · Fruits Box….

Expert Sourcing Insights for Disposable Glass With Lid

H2: 2026 Market Trends Forecast for Disposable Glass with Lid

The disposable glass with lid market is poised for significant evolution by 2026, driven by escalating environmental concerns, shifting consumer preferences, and technological advancements in materials and manufacturing. Here’s a comprehensive analysis of the key trends shaping this market:

1. Dominance of Sustainable Materials & Biodegradability

- Shift from PLA to Advanced Compostables: While PLA (corn-based plastic) remains common, demand will surge for truly industrially compostable materials derived from rapidly renewable resources (e.g., sugarcane bagasse, bamboo, PHA, cellulose) that offer better temperature resistance and barrier properties. Home-compostable options will gain niche traction.

- Recycled Content Integration: Regulations and consumer demand will push manufacturers to incorporate post-consumer recycled (PCR) content into the glass body or lid, particularly in regions with extended producer responsibility (EPR) schemes. Recycled PET (rPET) for lids will become standard.

- Material Innovation Focus: R&D will intensify on creating materials that maintain the “glass-like” clarity and premium feel consumers expect while being fully compostable or recyclable, addressing the current trade-off between performance and sustainability.

2. Regulatory Pressure Driving Change

- Global Expansion of Single-Use Plastics (SUP) Bans: The EU Single-Use Plastics Directive will be fully implemented, and similar bans on conventional plastic lids, straws, and potentially certain plastic types for food contact will spread globally (e.g., UK, Canada, parts of Asia-Pacific, US states). This will force rapid adoption of compliant alternatives.

- Standardization of Compostability Labels: Clearer, harmonized labeling (e.g., TUV Austria OK Compost INDUSTRIAL, BPI certification) will become crucial to avoid consumer confusion and greenwashing accusations, influencing purchasing decisions.

- Extended Producer Responsibility (EPR): Producers will face increasing financial and operational responsibility for the collection and recycling/composting of their products, incentivizing design for recyclability/compostability and investment in waste infrastructure.

3. Consumer Demand for Premiumization & Functionality

- “Premium Feel” Expectation: Consumers increasingly expect disposable items, even eco-friendly ones, to offer a high-quality experience. This drives demand for glasses with superior clarity, rigidity, smooth texture, and elegant designs mimicking reusable glassware.

- Enhanced Functional Features: Lids will evolve beyond basic sealing. Features like:

* Integrated Straws (Reusable or Compostable): Pre-attached, spill-proof straws made from paper, PLA, or reusable silicone (for hybrid models).

* Improved Sealing & Leak-Proofing: Crucial for takeaway beverages and soups, reducing waste and customer complaints.

* Ventilation Options: For hot beverages to prevent pressure build-up.

* Reusability Hybrids: Designs encouraging multiple uses before disposal (e.g., sturdy construction, dishwasher-safe lids) will gain popularity among environmentally conscious consumers. - Customization & Branding: High-quality printing on both the glass and lid for brand visibility, marketing, and personalized experiences will be a key differentiator.

4. Supply Chain Resilience & Cost Optimization

- Localization of Production: To mitigate supply chain disruptions and reduce carbon footprint, there will be a trend towards regionalizing manufacturing, especially for key markets (North America, Europe, Asia-Pacific).

- Scale & Efficiency: As sustainable materials become mainstream, economies of scale will reduce the price premium over conventional plastics, making them more accessible to a wider range of foodservice operators.

- Material Sourcing Transparency: Brands will demand greater traceability and sustainability certifications for raw materials (e.g., responsible forestry for paper-based composites, sustainable agriculture for bio-polymers).

5. Expansion of Application Segments

- Beyond Beverages: While cold drinks (smoothies, juices, cocktails) remain core, growth will accelerate in:

* Hot Beverages: Improved insulation and heat resistance will make them viable for coffee and tea, challenging traditional paper cups.

* Food-to-Go: Salads, desserts (parfaits, mousse), snacks, and even soups in premium disposable packaging.

* Catering & Events: Demand for elegant, sustainable servingware for weddings, corporate events, and festivals will rise significantly.

* Retail (On-the-Go): Convenience stores and supermarkets offering ready-to-drink products in these containers.

6. Technology Integration (Emerging)

- Smart Packaging (Niche): Exploration of QR codes or NFC tags on lids for brand engagement, promotions, recycling instructions, or supply chain tracking, though cost and scalability remain challenges.

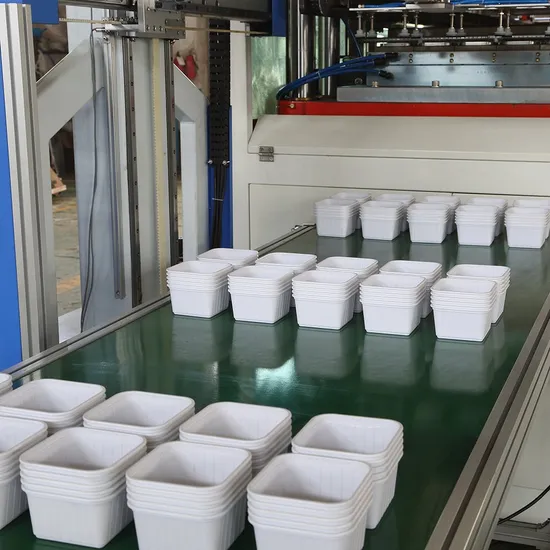

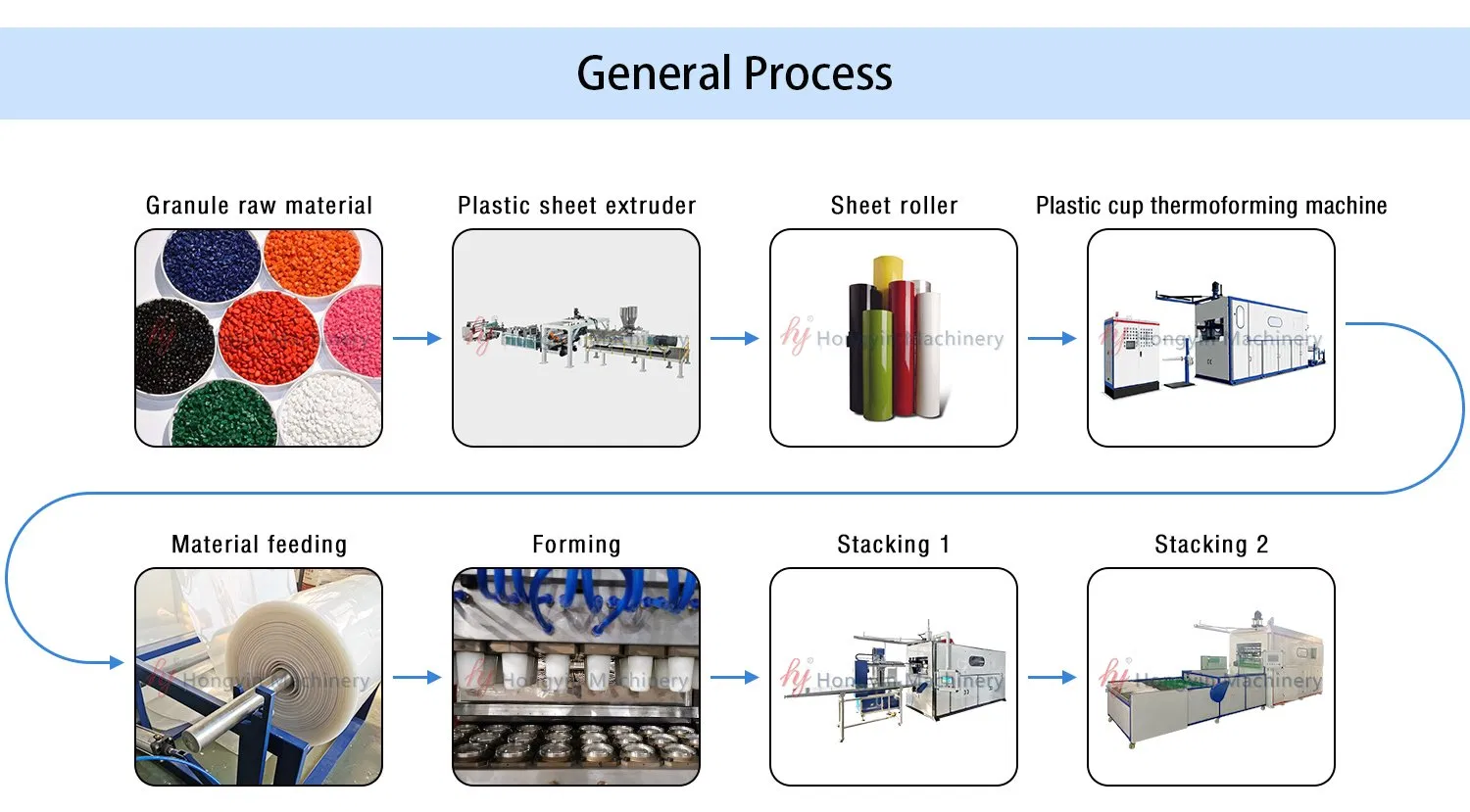

- Improved Manufacturing Efficiency: Automation and AI-driven design optimization will enhance production speed, reduce waste, and ensure consistent quality for complex sustainable materials.

Conclusion for 2026:

The disposable glass with lid market in 2026 will be fundamentally defined by sustainability as a non-negotiable baseline. Success will belong to innovators who master the trifecta of genuine environmental performance (truly compostable/recyclable materials), superior functionality and premium consumer experience, and cost-effective, resilient supply chains. Regulatory tailwinds and heightened consumer eco-awareness will accelerate the displacement of conventional plastics, making sustainable disposable glassware a standard, not a niche, across diverse foodservice and retail applications. The market will be highly competitive, favoring companies with strong R&D, material science expertise, and agile manufacturing.

Common Pitfalls When Sourcing Disposable Glass With Lid: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Disposable Glass With Lid

Product Overview and Classification

Disposable glasses with lids are typically single-use containers made from materials such as plastic, paperboard with plastic lining, or bioplastics. These products are widely used in food service, catering, and retail environments. Proper classification under international trade codes (e.g., HS Code) is essential. Common HS codes include 3923.29 (plastic tableware) or 4823.90 (paper-based disposable containers), depending on material composition. Accurate classification ensures correct duty assessment and regulatory compliance.

Regulatory Compliance Requirements

Compliance with food contact material (FCM) regulations is mandatory. In the U.S., the FDA regulates materials under 21 CFR, requiring that all components are safe for direct food contact. In the EU, Regulation (EC) No 1935/2004 and specific measures such as Regulation (EU) No 10/2011 for plastic materials must be met. Manufacturers must provide Declaration of Compliance (DoC) and, where applicable, FDA Food Contact Notifications or EU compliance certificates. Additionally, products marketed as compostable or biodegradable must meet standards such as ASTM D6400 (U.S.) or EN 13432 (EU), supported by third-party certifications.

Packaging and Labeling Standards

Proper packaging ensures product integrity during transit. Disposable glasses with lids should be packed in moisture-resistant, durable outer packaging (e.g., corrugated cardboard) to prevent contamination and damage. Labels must include: product name, material composition, food safety compliance statements, usage instructions, and any relevant certifications (e.g., “BPA-Free,” “Compostable”). For export, labeling must comply with destination country requirements—e.g., bilingual labeling in Canada, CE marking in the EU, or FDA labeling guidelines in the U.S.

Transportation and Storage Conditions

During logistics, maintain dry, temperature-controlled environments to prevent deformation or contamination. Avoid exposure to direct sunlight, extreme heat, or humidity, especially for bioplastic or paper-based products. Stack pallets securely using stretch wrap to prevent shifting. Use clean, pest-free transport vehicles. For long-term storage, ensure the warehouse is sanitized and free from strong odors that could be absorbed by the packaging materials.

Import/Export Documentation

Complete and accurate documentation is vital for customs clearance. Required documents typically include: commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and FCM compliance documentation (e.g., DoC, test reports). For shipments to the EU, a Responsible Person must be designated under Regulation (EU) No 1935/2004. In some countries, additional import permits or sanitary certificates may be required for food-contact items.

Environmental and Sustainability Compliance

Increasing regulations govern single-use plastics. Many jurisdictions (e.g., EU Single-Use Plastics Directive, Canadian Plastic Ban) restrict or tax certain disposable items. Verify if your product falls under banned or regulated categories. If marketed as eco-friendly, ensure claims are substantiated and avoid greenwashing. Maintain records of sustainability certifications (e.g., FSC for paper components, OK Compost) and comply with Extended Producer Responsibility (EPR) schemes where applicable.

Quality Control and Supplier Verification

Implement a supplier approval process to ensure consistent compliance. Require suppliers to provide up-to-date compliance documentation and material test reports (e.g., for heavy metals, migration tests). Conduct periodic audits and random batch testing. Maintain traceability records for each production lot to support recalls or regulatory inquiries.

End-of-Life and Disposal Guidance

Provide clear disposal instructions to end users. Indicate whether the product is recyclable, compostable, or landfill-only, based on local waste management infrastructure. Note that many disposable cups require separation of lid and cup due to mixed materials. Compliance with local labeling rules for waste sorting (e.g., How2Recycle label in the U.S.) enhances sustainability and reduces regulatory risk.

Conclusion:

After evaluating various suppliers and options, sourcing disposable glassware with lids presents a practical and hygienic solution for food and beverage service, particularly in takeaway, catering, and events. Materials such as clear PET plastic or biodegradable PLA offer a glass-like appearance with the convenience of disposability, while secure-fit lids ensure spill resistance and portability. Key considerations including product quality, environmental impact, cost-effectiveness, and supplier reliability have guided the decision-making process. Prioritizing eco-friendly materials and responsible sourcing aligns with sustainability goals and consumer expectations. Overall, the selected supplier provides a balanced combination of durability, aesthetic appeal, and environmental responsibility, making it a reliable choice for long-term partnership in meeting operational and branding needs.