The dry ice blasting market has seen significant growth over the past decade, driven by increasing demand for non-abrasive, environmentally friendly cleaning solutions across industries such as automotive, food processing, and pharmaceuticals. According to Grand View Research, the global dry ice blasting market was valued at USD 368.9 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This surge is fueled by stricter environmental regulations and the need for residue-free cleaning methods that reduce equipment downtime. However, as the number of dry ice blasting equipment manufacturers increases to meet rising demand, several disadvantages have emerged—ranging from high initial investment costs to limited technical support and inconsistent product quality. Below are the top 9 drawbacks associated with dry ice blasting manufacturers that businesses should consider before procurement.

Top 9 Disadvantages Of Dry Ice Blasting Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 (PDF) Industrial use of dry ice blasting in surface cleaning

Website: researchgate.net

Key Highlights: Dry ice blasting is an up-to-date cleaning method which has become popular in many industries. This technology uses compressed air to accelerate dry ice ……

#2 Industrial use of dry ice blasting in surface cleaning

Website: sciencedirect.com

Key Highlights: Major advantages include a high speed of the cleaning process, low abrasiveness and the absence of secondary waste because of dry ice ……

#3 Disadvantages of Dry Ice Blasting: Is It Worth It?

Website: laserax.com

Key Highlights: Dry ice blasting comes with high consumable and operating costs, including recuring costs for dry ice pellets and compressed air. It is also an energy-hungry ……

#4 The Benefits and Risks of Dry Ice Blasting

Website: industrial.thompsonind.com

Key Highlights: There are two primary risks that dry ice cleaning technicians must protect against: burns and suffocation. Dry Ice Burns. Dry ice is frozen carbon dioxide….

#5 Comparing Dry Ice Cleaning to Dustless Blasting

Website: dustlessblasting.com

Key Highlights: One of the biggest disadvantages is that dry ice is incredibly expensive — not only to buy but also to store. Dry ice requires temperatures less ……

#6 Dry Ice Blasting: Reducing Machine

Website: mscdirect.com

Key Highlights: Dry ice blasting without appropriate safety precautions can cause health issues from frostbite to difficulty breathing and even suffocation, ……

#7 Leave No Trace with Dry Ice Blasting

Website: escablast.com

Key Highlights: Disadvantages of dry ice blasting: · Limited shelf life: Unlike other blast media, dry ice can only be stored for a short time. · Lead Time: ……

#8 Dry Ice Dangers, Uses, and Safety Best Practices

Website: co2meter.com

Key Highlights: From a “danger” perspective when dealing with dry ice there are two main hazards to look out for, cold burns and asphyxiation. As the ……

#9 Dry Ice Blasting vs. Laser Cleaning: Which method is best?

Website: keyence.com

Key Highlights: Some common disadvantages of dry ice blasting include: The equipment is easily prone to damage; Carbon dioxide buildup can lead to safety risks; Low ……

Expert Sourcing Insights for Disadvantages Of Dry Ice Blasting

H2: Disadvantages of Dry Ice Blasting in the 2026 Market Landscape

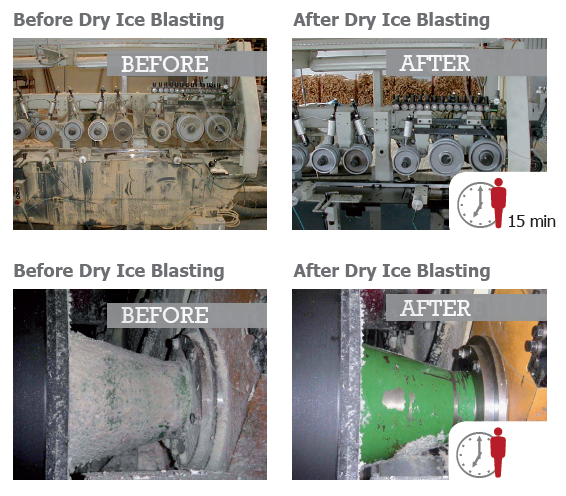

As dry ice blasting gains traction across industries for its eco-friendly and non-abrasive cleaning capabilities, the 2026 market reveals persistent and emerging disadvantages that may limit its widespread adoption. While the technology continues to evolve, several key drawbacks remain relevant, particularly in industrial, logistical, and operational contexts.

-

High Initial and Operational Costs

Despite long-term savings in equipment maintenance and reduced downtime, the upfront investment for dry ice blasting systems remains a significant barrier in 2026. High-cost blasting machines, specialized delivery nozzles, and the need for compressed air systems contribute to elevated capital expenses. Additionally, the ongoing cost of dry ice pellets—especially in regions with limited supply chains—can make operations expensive compared to traditional sand or water blasting. -

Dependence on Dry Ice Supply Chain

The logistical challenge of sourcing and storing dry ice is a notable disadvantage. Dry ice sublimates at room temperature, requiring continuous refrigerated transport and storage. In 2026, with increasing demand across pharmaceuticals, food, and logistics sectors, supply shortages or price volatility can disrupt cleaning schedules. Remote or rural facilities face particular challenges due to limited distribution networks. -

Limited Effectiveness on Certain Contaminants

While effective for organic residues, grease, and mold, dry ice blasting struggles with heavy rust, thick paint layers, or deeply embedded contaminants. In sectors like heavy manufacturing or marine maintenance, where abrasive methods remain necessary, dry ice is often insufficient. This limitation restricts its application scope, reducing ROI for companies needing multi-purpose cleaning solutions. -

Safety and Environmental Considerations

Although marketed as environmentally safe due to the absence of secondary waste, dry ice blasting poses safety risks. The extreme cold (-78.5°C) can cause frostbite upon skin contact, and high-pressure operations risk projectile injuries. In confined spaces, the release of CO₂ during sublimation can lead to hazardous gas buildup, requiring proper ventilation and monitoring—adding complexity and cost to operations. -

Noise and Equipment Wear

The high-pressure air systems used in dry ice blasting generate significant noise levels, often exceeding OSHA safety thresholds. In 2026, with heightened focus on worker health and compliance, companies must invest in hearing protection and sound-dampening enclosures. Additionally, repeated use can accelerate wear on nozzles and air compressors, increasing maintenance needs. -

Skill and Training Requirements

Effective dry ice blasting requires trained personnel to adjust blast pressure, nozzle distance, and angle for optimal results. As the technology becomes more prevalent, the shortage of skilled technicians in certain markets remains a bottleneck. Inadequate training can lead to inefficient cleaning or surface damage, undermining the perceived benefits.

Conclusion

While dry ice blasting aligns with 2026’s sustainability goals and offers non-abrasive cleaning advantages, its disadvantages—ranging from cost and logistics to technical limitations—continue to hinder universal adoption. Companies evaluating this method must conduct thorough cost-benefit analyses and consider hybrid cleaning strategies to overcome these constraints in evolving industrial environments.

Disadvantages Of Dry Ice Blasting (Quality, IP)

While dry ice blasting offers numerous benefits such as non-abrasive cleaning and reduced downtime, it also presents several disadvantages related to quality control and intellectual property (IP) considerations. Understanding these pitfalls is crucial for businesses evaluating this technology.

Quality-Related Drawbacks

1. Potential for Incomplete Cleaning on Heavily Contaminated Surfaces

Dry ice blasting may struggle with thick, tenacious residues like heavy grease, paint buildup, or carbon deposits. Unlike abrasive methods, it relies on thermal shock and kinetic energy, which can be insufficient for stubborn contaminants. This inconsistency can lead to variable cleaning quality and the need for rework or supplemental cleaning methods, undermining process reliability.

2. Limited Penetration in Complex Geometries

The line-of-sight nature of dry ice blasting makes it difficult to clean intricate parts, blind holes, or recessed areas effectively. This limitation can result in inconsistent surface preparation, especially in precision manufacturing or aerospace applications where uniform quality is critical. Residual contamination in hard-to-reach zones may compromise product performance or safety.

3. Substrate Sensitivity and Risk of Thermal Shock

Although non-abrasive, the extreme cold of dry ice (−78.5°C) can cause thermal stress in certain materials, such as brittle plastics or aged composites. Sudden temperature changes may lead to micro-cracking or dimensional instability, negatively affecting part integrity and long-term durability—particularly problematic in high-precision industries.

4. Lack of Surface Profiling

Unlike sandblasting, dry ice blasting does not create a surface profile (anchor pattern) necessary for optimal paint or coating adhesion. This can result in poor coating performance and premature failure, affecting product quality and warranty claims in finishing operations.

Intellectual Property (IP) and Operational Risks

1. Technology Dependence and Vendor Lock-In

Dry ice blasting systems often involve proprietary equipment and consumables. Companies may become reliant on specific suppliers for dry ice pellets, nozzles, or software controls, limiting flexibility and increasing long-term costs. This dependence can hinder innovation and create IP vulnerabilities if critical components are patented or restricted.

2. Limited Customization and Process Control

Many dry ice blasting machines offer preset parameters with limited user-adjustable settings. This lack of customization restricts the ability to fine-tune processes for unique applications, potentially exposing companies to reverse engineering risks if competitors analyze and replicate optimized cleaning procedures.

3. Data and Monitoring Gaps

Unlike advanced cleaning systems with integrated IoT sensors and data logging, many dry ice blasters lack real-time quality monitoring or process documentation. This absence of traceable data complicates compliance with quality standards (e.g., ISO 9001) and weakens IP protection by making it harder to prove proprietary cleaning methods or defend against imitation.

4. Training and Knowledge Transfer Challenges

Effective dry ice blasting requires specialized training to avoid damage and ensure consistency. Poor operator knowledge can result in subpar outcomes and inadvertent disclosure of process details during third-party service engagements, increasing the risk of IP leakage.

In summary, while dry ice blasting is an environmentally friendly and efficient cleaning method, its limitations in achieving consistent quality and safeguarding proprietary processes must be carefully managed to avoid operational setbacks and IP exposure.

Disadvantages Of Dry Ice Blasting

While dry ice blasting offers numerous benefits such as non-abrasive cleaning and reduced downtime, it also comes with several logistical and compliance-related drawbacks that businesses must carefully consider before adoption.

High Initial Equipment and Operational Costs

Dry ice blasting systems require a significant upfront investment in specialized blasting equipment, delivery systems, and safety gear. Additionally, ongoing operational costs—such as the purchase and transportation of dry ice, maintenance of equipment, and energy consumption—can be considerably higher than traditional cleaning methods like sandblasting or water jetting. These expenses may be prohibitive for smaller operations or infrequent users.

Specialized Handling and Storage Requirements

Dry ice must be stored at extremely low temperatures (−78.5°C or −109.3°F) in insulated containers to prevent sublimation. This necessitates dedicated storage space and careful inventory management to minimize waste. Improper handling can lead to rapid loss of material, increasing costs and reducing efficiency. Logistics become more complex when transporting dry ice to remote or temporary job sites, requiring temperature-controlled containers and adherence to strict delivery timelines.

Safety and Health Hazards

The use of dry ice poses several safety risks. Exposure to extreme cold can cause frostbite or cold burns upon skin contact. Additionally, as dry ice sublimates, it releases large volumes of carbon dioxide (CO₂) gas. In confined or poorly ventilated areas, this can lead to hazardous CO₂ buildup, posing asphyxiation risks. Employers must implement strict safety protocols, including proper ventilation, gas monitoring, and the use of personal protective equipment (PPE), to comply with occupational health and safety regulations.

Regulatory and Compliance Challenges

Transporting and storing dry ice is subject to regulations from agencies such as the Department of Transportation (DOT) in the U.S. and the International Air Transport Association (IATA) for air shipments. Dry ice is classified as a hazardous material (UN 1845), requiring proper labeling, packaging, and documentation. Non-compliance can result in fines, shipment delays, or safety incidents. Organizations must ensure staff are trained in handling and reporting procedures to meet regulatory standards.

Limited Effectiveness on Certain Contaminants

Dry ice blasting may not be effective for removing thick, tenacious coatings such as heavy rust, weld slag, or certain types of paint. In such cases, supplementary cleaning methods may be required, reducing overall efficiency and offsetting time-saving benefits. This limitation affects planning and resource allocation, especially in industrial maintenance scenarios where diverse surface conditions exist.

Environmental Venting and Workplace Considerations

Though dry ice blasting produces no secondary waste, the release of CO₂ gas during operation contributes to localized greenhouse gas emissions. While carbon dioxide is naturally occurring, high concentrations in the workplace require monitoring and mitigation. Facilities must ensure adequate ventilation systems are in place and may need to account for CO₂ emissions under environmental reporting requirements, depending on local regulations.

Dependence on Supply Chain Reliability

Dry ice has a short shelf life and is not typically stockpiled long-term. Operations relying on dry ice blasting are vulnerable to supply chain disruptions, including delivery delays or regional shortages. This dependence can impact scheduling, particularly for time-sensitive projects, and necessitates contingency planning to avoid costly downtime.

Addressing these disadvantages requires comprehensive planning, investment in training, and adherence to safety and regulatory standards to ensure safe, compliant, and efficient operations.

In conclusion, while dry ice blasting offers numerous advantages such as being non-abrasive, non-conductive, and leaving no secondary waste, it also comes with several sourcing disadvantages. The primary challenges include the limited availability of dry ice suppliers, especially in remote or rural areas, which can lead to logistical complexities and increased transportation costs. Additionally, dry ice has a short shelf life due to sublimation, requiring careful planning and just-in-time delivery to prevent product loss. The dependency on a consistent supply chain for carbon dioxide and specialized production equipment can also affect reliability and increase operational risks. Furthermore, the cost associated with sourcing, handling, and storing dry ice can be significantly higher compared to more conventional blasting media. These factors collectively make the sourcing of dry ice a potential constraint for businesses considering or currently using dry ice blasting as a cleaning method.