The global market for industrial containers, including 55-gallon steel and plastic drums, has experienced steady growth driven by rising demand across sectors such as chemicals, pharmaceuticals, food and beverage, and oil & gas. According to Grand View Research, the global steel drums market size was valued at USD 14.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. Similarly, Mordor Intelligence projects continued momentum in industrial packaging, citing increased logistics activity and regulatory compliance needs as key growth enablers. Within this expanding landscape, 55-gallon barrel manufacturers are differentiating themselves across multiple dimensions—ranging from material innovation and sustainability practices to geographic reach and customization capabilities. As competition intensifies, understanding the top seven dimensions that define leading manufacturers becomes critical for procurement teams, distributors, and end users aiming to align with reliable, efficient, and future-ready suppliers.

Top 7 Dimensions Of 55 Gallon Barrel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Poly/Plastic Drums

Domain Est. 1999

Website: bronsteincontainer.com

Key Highlights: Nestable Poly Drums are available in 6 different sizes, ranging from 10 to 55-Gallons, with the following Standard Colors – Yellow, Blue and Black….

#2 55 Gallon Drum Manufacturers

Website: 55gallondrumcompanies.com

Key Highlights: For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons ……

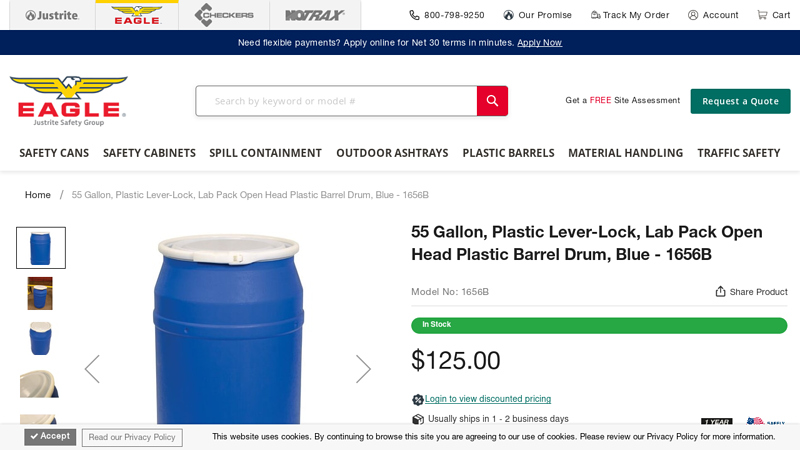

#3 Blue 55 Gal Plastic Drum Barrel

Domain Est. 1997

Website: eagle.justrite.com

Key Highlights: In stock $49.15 deliveryExterior Dimensions, inches, 21D x 36.375H. Dimensions … A: Eagle Manufacturing’s straight sided 55 gallon drum is not DOT rated to hold free liquids….

#4 55 Gallon Drum with Lid

Domain Est. 1997

Website: big-dipper.com

Key Highlights: Free delivery over $1,400Height · 36″ (91.4 cm) [35 5/8″ (90.5 cm) without lid] ; Diameter · 22 3/4″ (57.8 cm) ; Thickness · 2.2 mm ; Capacity · 55 Gallons (208.2 L) ; Material · H…

#5 55 Gallon Drum Dimensions

Domain Est. 1997

Website: bascousa.com

Key Highlights: What are the Dimensions of a 55 Gallon Drum? ; STEEL ; Tight-Head. Open-Head ; Outside Height. 33”. 34-3/4” ; Outside Diameter. 23”. 24-1/2”….

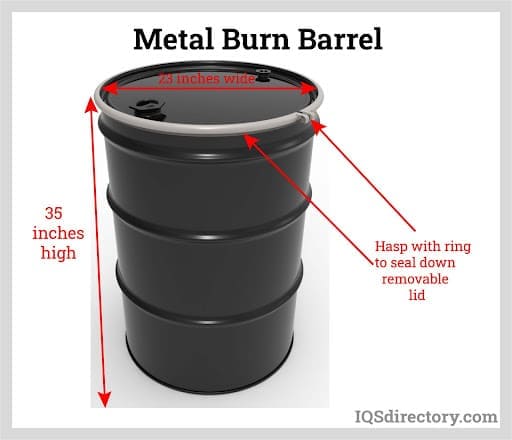

#6 55 Gallon Steel Drums

Domain Est. 2000

Website: con-techinternational.com

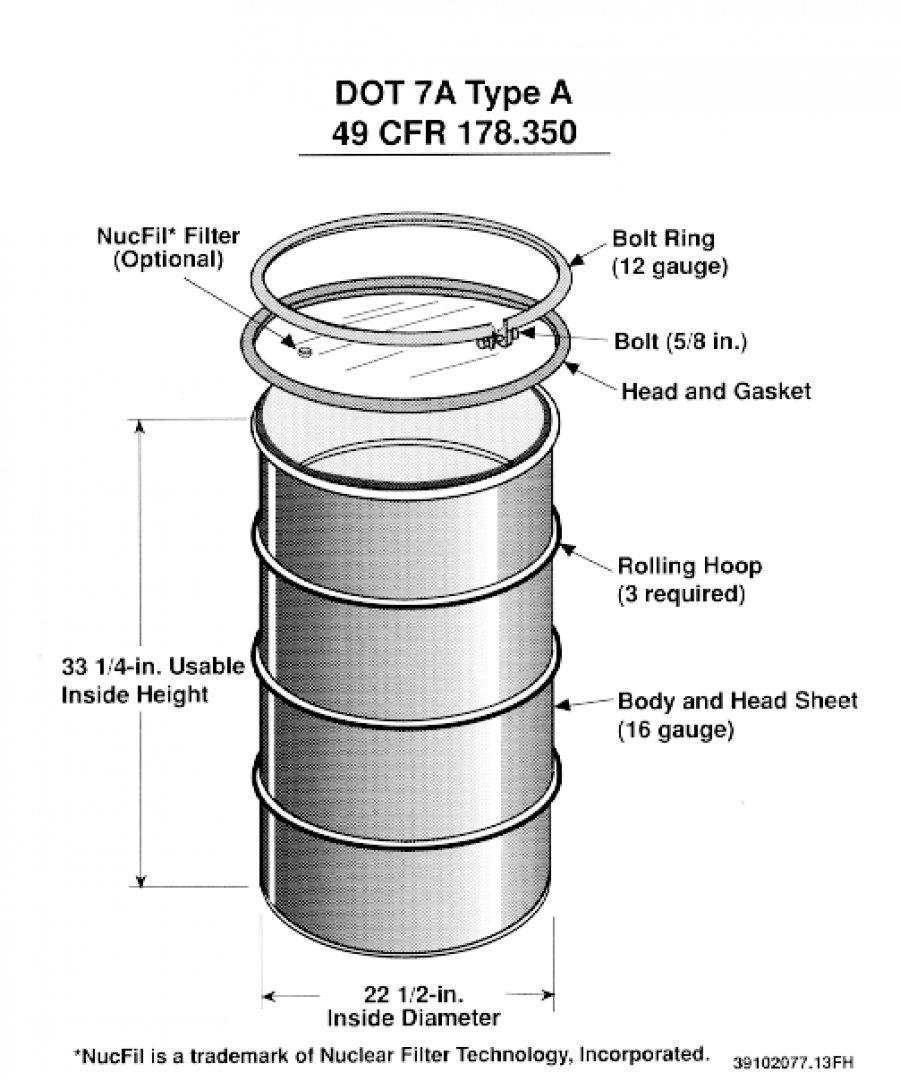

Key Highlights: The standard thickness of the steel is between 0.9 and 1.5 mm (20-16 gauge steel), and the drums are often reinforced with ribs or rolling hoops ……

#7 55

Domain Est. 2005

Website: powerblanket.com

Key Highlights: Standard 55-gallon drums usually measure between 33 to 36-3/4 inches in height and 22-3/8 to 24-1/2 inches in diameter, depending on the ……

Expert Sourcing Insights for Dimensions Of 55 Gallon Barrel

H2: Projected Market Trends for Dimensions of 55 Gallon Barrels in 2026

As global industrial activity evolves toward sustainability, automation, and supply chain efficiency, the demand for standardized containers such as the 55 gallon barrel is expected to shift in both application and design specifications. By 2026, several key market trends are anticipated to influence the dimensions and usage of 55 gallon barrels across industries.

-

Standardization with Flexibility in Dimensions

While the traditional 55 gallon barrel maintains a standard outer diameter of approximately 22.5 inches (57.2 cm) and a height of about 34.5 inches (87.6 cm), the market is moving toward modular designs that allow slight dimensional variations to meet sector-specific needs—such as pharmaceuticals, food-grade storage, or hazardous material transport. By 2026, manufacturers are expected to offer customizable height-to-diameter ratios while adhering to ISO and OSHA compliance, enabling better stacking, transport, and storage efficiency. -

Growth in Reusable and Returnable Packaging

With heightened emphasis on circular economy models, reusable 55 gallon barrels—particularly those made from high-density polyethylene (HDPE) or stainless steel—are gaining traction. These designs often maintain standard dimensions but incorporate reinforced walls and optimized weight-to-capacity ratios. This trend supports logistics efficiency and reduces environmental impact, influencing barrel design to prioritize durability without altering core dimensions significantly. -

Smart Barrels and IoT Integration

The integration of IoT sensors into 55 gallon barrels is projected to expand by 2026, especially in chemical, oil & gas, and pharmaceutical sectors. While internal dimensions may remain consistent, external modifications such as sensor housings or RFID tags could slightly affect overall footprint or lid design. However, standard dimensions will likely remain dominant to ensure compatibility with existing handling systems (e.g., pallets, forklifts, and storage racks). -

Regional Regulatory Influences on Dimensions

Regulatory standards in North America (DOT, EPA) and the EU (ADR, REACH) continue to shape barrel construction. Though not directly mandating dimensional changes, safety requirements for pressure resistance and drop testing may lead to thicker walls or reinforced rims, subtly affecting internal volume and tolerance. Manufacturers may adjust internal dimensions slightly to preserve the nominal 55 gallon (208-liter) capacity while meeting safety benchmarks. -

Shift Toward Lightweight Materials Without Sacrificing Volume

Advances in composite and polymer materials are enabling barrels with thinner walls and reduced weight while maintaining structural integrity. By 2026, this could result in barrels that keep standard external dimensions but offer improved payload efficiency. This trend supports transportation cost reduction and aligns with carbon footprint goals. -

E-Commerce and Niche Market Demand

The rise of small-scale chemical blending, artisan manufacturing, and home-based industrial use is creating demand for non-traditional barrel sizes. However, the 55 gallon barrel will remain a benchmark due to its logistical advantages. As a result, standard dimensions are expected to persist as a reference, even as derivative sizes (e.g., 50 or 57 gallon variants) emerge for specialized uses.

In conclusion, while the core dimensions of the 55 gallon barrel are expected to remain largely unchanged by 2026, advancements in materials, smart technology, and sustainability will drive subtle adaptations in wall thickness, weight, and accessory integration—all while preserving compatibility with global handling systems. The standard dimensions will continue to serve as a critical anchor in industrial packaging, with innovation focusing on performance rather than fundamental size alteration.

Common Pitfalls When Sourcing Dimensions of a 55 Gallon Barrel (Quality, IP)

When sourcing specifications for a 55-gallon barrel—especially in industrial or regulated environments such as pharmaceuticals, food processing, or hazardous materials handling—relying solely on nominal dimensions can lead to significant operational and compliance issues. Below are common pitfalls related to quality and intellectual property (IP) concerns when obtaining dimensional data.

Inaccurate or Generic Dimensional Data

Many suppliers and online sources provide only nominal or average dimensions for 55-gallon barrels (e.g., “23” diameter x 34.5” height”). However, actual dimensions can vary significantly based on material (steel, plastic, fiber), wall thickness, rim style, and manufacturer tolerances. Using generic data risks incompatibility with storage racks, transport systems, or filling/sealing equipment. This can result in costly downtime, safety hazards, or product damage.

Lack of Certified Quality Documentation

Sourcing dimensional specs without accompanying quality certifications (e.g., ISO, FDA, UN/DOT for hazardous materials) is a critical oversight. In regulated industries (IP-sensitive or quality-controlled), dimensional accuracy must be traceable and verified. Without certified drawings, material test reports (MTRs), or conformance certificates, organizations risk non-compliance during audits and potential rejection of raw materials or finished goods.

Intellectual Property (IP) Risks in Design Replication

Using publicly available dimensional data to reverse-engineer or manufacture proprietary barrel designs—especially for specialized applications—can lead to IP infringement. Some barrel designs, including unique closure systems or liner configurations, are protected by patents or trade secrets. Sourcing dimensions from unofficial channels (e.g., third-party websites, unlicensed distributors) increases the risk of unintentional IP violation, exposing the buyer to legal action or supply chain disruptions.

Overlooking Application-Specific Tolerances

Not all 55-gallon barrels are interchangeable. For example, a pharmaceutical-grade HDPE drum with precise neck finish dimensions for sterile filling differs significantly from a standard steel drum for bulk chemical transport. Failing to source dimensionally accurate, application-specific data can compromise product integrity, contaminate batches, or void regulatory approvals—especially where IP-protected processes depend on exact container geometry.

Dependence on Unverified Supplier Claims

Some suppliers provide dimension charts without traceability to actual manufactured lots. Relying on unverified claims—especially from low-cost or offshore vendors—can result in receiving barrels that do not meet stated specs. This is particularly problematic when the dimensional accuracy affects the performance of automated handling systems or when the barrel is part of an IP-protected packaging line.

Best Practices to Avoid Pitfalls

- Obtain dimensional drawings directly from the original equipment manufacturer (OEM) or authorized distributor.

- Request certified conformance documentation with each shipment.

- Verify that dimensional specs align with industry standards (e.g., UN certification for dangerous goods, FDA 21 CFR for food/pharma).

- Conduct incoming inspections using calibrated tools to validate critical dimensions.

- Consult legal or IP counsel before using dimensional data for replication or integration into proprietary systems.

By addressing these pitfalls, organizations can ensure the quality, compliance, and legal safety of their barrel sourcing strategy.

H2: Dimensions of 55 Gallon Barrel – Logistics & Compliance Guide

Understanding the standard dimensions of a 55-gallon barrel is essential for efficient logistics planning, safe handling, regulatory compliance, and proper storage. These barrels are ubiquitous in industrial, chemical, petroleum, and waste management sectors, making dimensional accuracy critical.

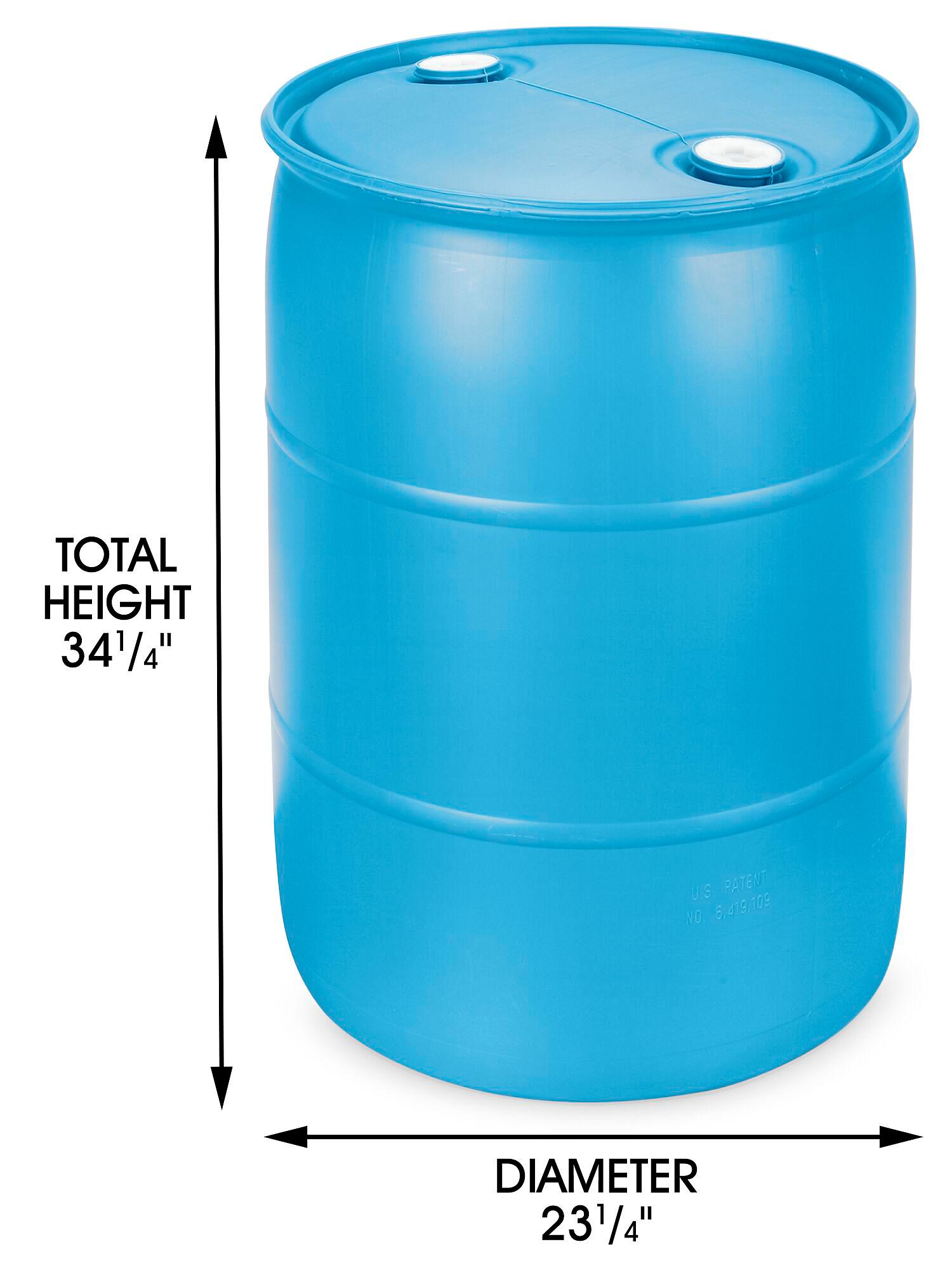

Standard Dimensions

While minor variations exist based on manufacturer, material (steel, plastic, or fiber), and construction (open-head vs. tight-head), the following are the widely accepted nominal dimensions for a standard 55-gallon drum:

- Diameter (Width): 22.5 inches (572 mm)

- Height: 34.5 inches (876 mm)

- Volume Capacity: 55 U.S. gallons (208 liters)

- Weight (Empty):

- Steel: ~48 lbs (22 kg)

- Plastic (HDPE): ~22–25 lbs (10–11 kg)

- Fiber (Cardboard): ~18–22 lbs (8–10 kg)

Note: Actual capacity may vary slightly (typically 54–57 gallons) due to headspace and manufacturing tolerances.

Logistics Considerations

1. Palletization & Stacking

- Standard Pallet Load:

- 4 drums per standard 48″ x 40″ GMA pallet (2×2 configuration)

- Maximum stack height: Typically 3–4 layers, depending on drum strength, contents, and warehouse regulations

- Stacking Limits:

- Steel drums: Up to 8 high when empty; 3–4 high when full (check manufacturer specs)

- Plastic drums: Generally lower stacking capacity—verify load-bearing limits

- Interlocking: Rotate drums 90° on alternate layers to enhance stability

2. Transportation

- Truck Loading:

- A standard 53′ dry van can hold ~48–60 pallets (192–240 drums) depending on weight and configuration

- Use load bars, straps, and dunnage to prevent shifting

- Weight Compliance:

- A full steel drum can weigh ~450 lbs (204 kg)

- Total load must comply with DOT weight limits per axle and gross vehicle weight (e.g., 80,000 lbs federal limit in the U.S.)

- Hazardous Materials (Hazmat):

- If transporting regulated substances, ensure drums meet 49 CFR (U.S.) or ADR (Europe) packaging requirements

- Use UN-rated drums with proper certification markings

3. Storage

- Racking Compatibility:

- Standard pallet racking: Ensure beam levels accommodate drum height + pallet (typically 42″ between beams)

- Drum storage racks: Use cradles or flow racks designed for 22.5″ diameter drums

- Clearances:

- Maintain 18–24″ clearance from walls and sprinkler systems per fire codes (e.g., NFPA 30)

- Store corrosive or flammable materials in approved cabinets or secondary containment

Compliance Requirements

1. UN/DOT Certification

- Required for shipping hazardous materials

- Drums must pass rigorous testing (drop, vibration, pressure, leakage)

- Markings must include:

- UN symbol

- Packaging code (e.g., 1A2/Y for steel open-head)

- Manufacturer ID, year/month of manufacture

- Maximum gross mass and specific gravity rating

2. Hazard Communication (HazCom)

- Proper labeling per GHS and OSHA 29 CFR 1910.1200

- Include: Product identifier, pictograms, signal word, hazard statements, precautionary measures

- Ensure drums are clearly marked with contents and hazards

3. Secondary Containment

- Required by EPA Spill Prevention, Control, and Countermeasure (SPCC) and RCRA

- Use spill pallets or berms capable of holding 110% of the largest container or 10% of total volume

- Prevents environmental contamination from leaks or ruptures

4. Reconditioned/Used Drums

- Must be reconditioned and recertified per 49 CFR 178.605 if used for hazardous materials

- Verify interior cleanliness and structural integrity

- Clearly mark “RECONDITIONED” if applicable

Best Practices

- Measure Before You Ship: Confirm actual drum dimensions with supplier, especially for non-standard or specialty drums

- Use Compatible Liners: For chemical compatibility, use drum liners (e.g., HDPE, fluoropolymer)

- Inspect Regularly: Check for dents, corrosion, or leaks—especially in reused drums

- Train Staff: Ensure personnel are trained in safe drum handling, stacking, and emergency response

By adhering to standardized dimensions and compliance protocols, organizations can ensure safe, efficient, and legally compliant handling of 55-gallon barrels across the supply chain. Always consult local, national, and international regulations (e.g., DOT, EPA, OSHA, IATA, IMDG) based on your specific use case and region.

In conclusion, sourcing the correct dimensions of a 55-gallon barrel is essential for proper storage, transportation, compatibility with handling equipment, and regulatory compliance. Standard dimensions typically include a height of approximately 34.5 inches and a diameter of about 23 inches, though slight variations may exist depending on material (steel, plastic, or fiber) and intended use. It is crucial to verify exact specifications with the manufacturer or supplier, especially when integrating barrels into automated systems, storage racks, or shipping containers. Confirming these dimensions ensures operational efficiency, safety, and cost-effectiveness across supply chain and industrial applications.