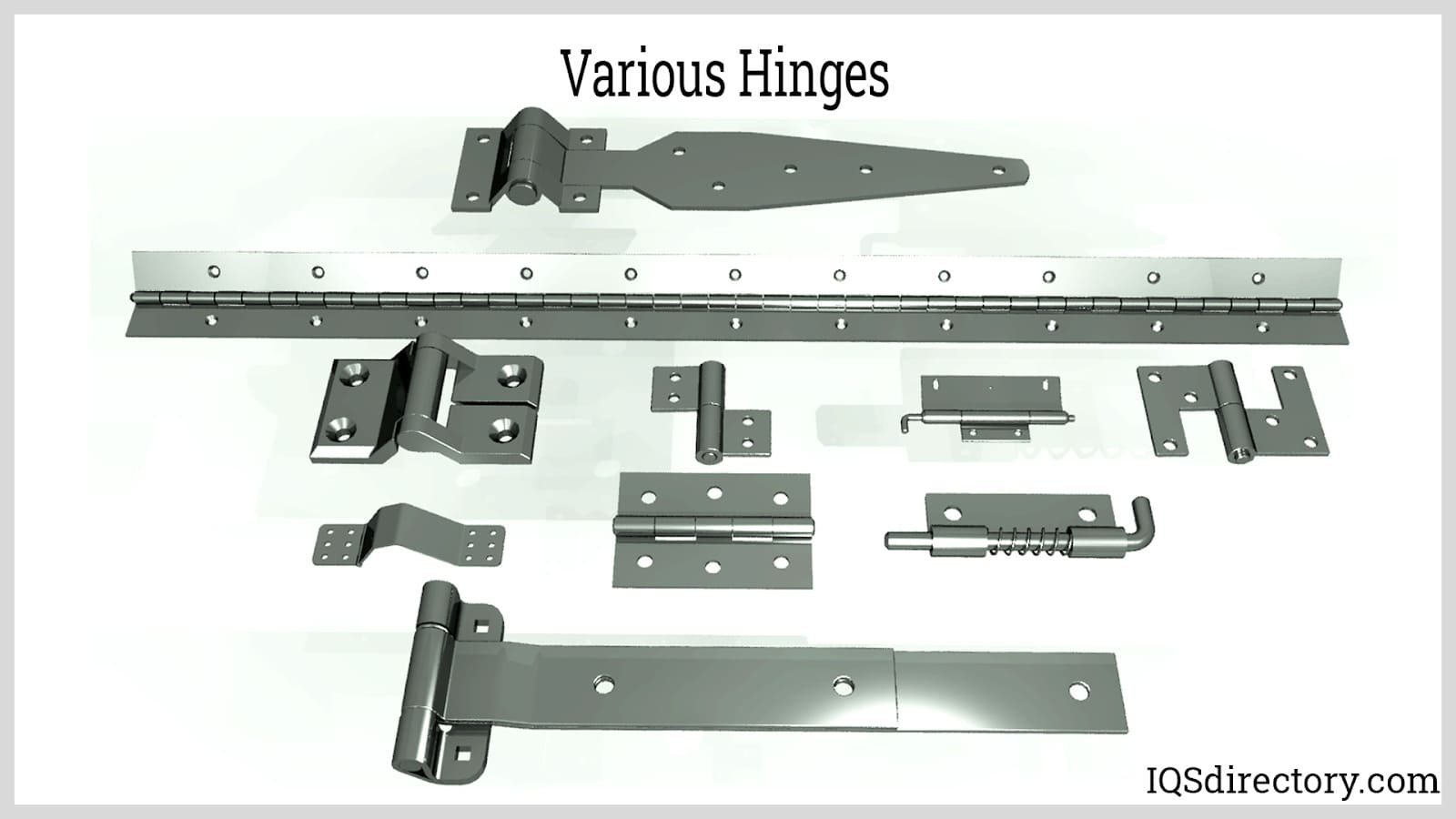

The global door hinges market is experiencing steady growth, driven by rising construction activities and increasing demand for durable and aesthetically appealing architectural hardware. According to Mordor Intelligence, the global architectural hardware market, which includes door hinges, was valued at USD 54.3 billion in 2022 and is projected to grow at a CAGR of over 6.5% from 2023 to 2028. Similarly, Grand View Research estimates that the global hinges market size was valued at USD 16.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by advancements in material science and growing emphasis on smart and automated building systems. In this evolving landscape, manufacturers are diversifying their product offerings to include butt hinges, pivot hinges, concealed hinges, continuous hinges, and more—catering to residential, commercial, and industrial applications. As innovation and regional demand continue to shape the industry, a closer look at the top 10 door hinge manufacturers reveals how technological capabilities, production scale, and global reach are redefining performance and reliability in building components.

Top 10 Different Types Of Door Hinges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Brookfield Industries

Domain Est. 2011

Website: bfimfg.com

Key Highlights: We offer an extensive range of heavy duty door closers (aka operators). Types included swinging door, low energy, in floor, sliding door and direct couple….

#2 Types of hinges

Domain Est. 1996

Website: assaabloy.com

Key Highlights: From traditional butt hinges to sophisticated concealed hinges, a wide variety caters to different needs, from domestic to heavy-duty commercial applications….

#3 Hinges for furniture & offices

Domain Est. 1996

Website: hettich.com

Key Highlights: Hettich hinges offer practical solutions for every application. Find out more about: ✓ Fast-assembly hinges ✓ Damping ✓ Opening systems….

#4 McKinney Hinge

Domain Est. 1997

Website: mckinneyhinge.com

Key Highlights: McKinney Products Company is an ASSA ABLOY product line that manufactures & designs high quality architectural hinges for commercial use….

#5 Hinges

Domain Est. 1997

Website: agb.it

Key Highlights: AGB proposes hinges for all types of windows and doors: from simple hinges for wooden frames to up-to-date and complex adjustable hinges….

#6 Hinges

Domain Est. 1997

Website: salice.com

Key Highlights: Innovation and continuous technical development: Salice hinges. An infinite range to suit every application….

#7 Motion in cabinetry

Domain Est. 1998

Website: blum.com

Key Highlights: They’re three-dimensional. All Blum hinges come with side, depth and height adjustment, giving you a perfectly precise gap layout every time….

#8 IVES

Domain Est. 1999

Website: us.allegion.com

Key Highlights: As the leader in door accessory hardware, Ives provides premium-quality products that are tough, durable and attractive. Available in a full ……

#9 SIMONSWERK

Domain Est. 2000

Website: us.simonswerk.com

Key Highlights: Discover premium hinge systems by SIMONSWERK: solutions for timber, glass, PVC-u, aluminium and steel doors. 135 + years of German craftsmanship, ……

#10 Penrod

Domain Est. 2017

Website: hardwarebypenrod.com

Key Highlights: Penrod supplies high-quality door hardware—hinges, weather stripping, sweeps, barn door hardware, and PVC mouldings—with 35+ years of trusted expertise….

Expert Sourcing Insights for Different Types Of Door Hinges

2026 Market Trends for Different Types of Door Hinges

The global door hinges market is poised for significant transformation by 2026, driven by advancements in materials, evolving architectural designs, and increasing demand for smart and sustainable building solutions. Below is an analysis of key trends expected to shape the market for different types of door hinges:

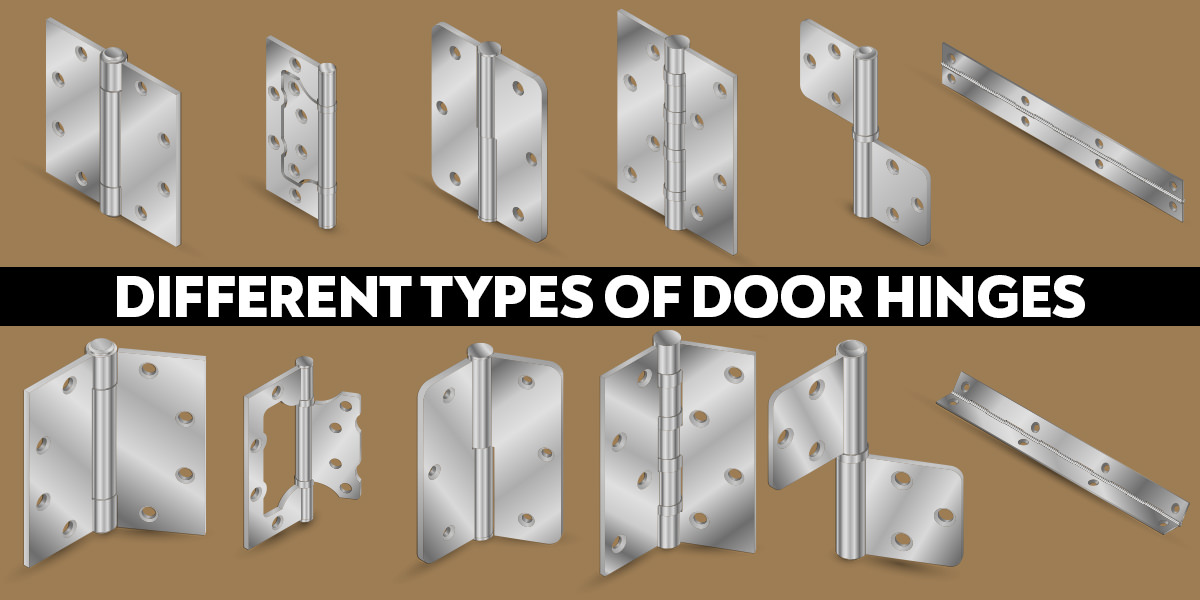

Butt Hinges

Butt hinges remain the most widely used type due to their simplicity and reliability. By 2026, trends will focus on enhanced durability and aesthetics. Stainless steel and brass finishes will dominate, especially in high-moisture environments like bathrooms and coastal areas. There will be a surge in concealed butt hinges that offer clean, minimalist appearances preferred in modern interiors. Additionally, manufacturers will emphasize corrosion-resistant coatings and higher load-bearing capacities to meet demands in both residential and commercial applications.

Continuous (Piano) Hinges

Continuous hinges are expected to gain traction in commercial, institutional, and industrial settings due to their superior strength and even weight distribution. In 2026, demand will be driven by stringent safety and fire regulations, particularly in schools, hospitals, and data centers. Customizable lengths and finishes will become more prevalent, allowing architects greater design flexibility. Integration with fire and smoke door systems will also be a key growth area, with hinges engineered to withstand high temperatures and maintain door integrity during emergencies.

Pivot Hinges

Pivot hinges will experience notable growth, especially in luxury residential and high-end commercial projects. Their ability to support heavy, oversized doors and enable smooth, dramatic swinging motion aligns with contemporary architectural trends favoring grand entrances and open-concept spaces. By 2026, innovations in concealed pivot mechanisms and floor spring systems will enhance both functionality and visual appeal. Increased use in glass and frameless door applications will further boost market demand, particularly in urban developments and modernist designs.

Spring and Self-Closing Hinges

With growing emphasis on accessibility and safety, self-closing hinges will see accelerated adoption. By 2026, compliance with building codes requiring automatic door closure—especially in fire-rated and ADA-accessible environments—will drive demand. Smart spring hinges with adjustable torque and silent closing mechanisms will become standard. Integration with building automation systems will allow for remote monitoring and performance tracking, appealing to facility managers in smart buildings.

Butterfly and Strap Hinges

While traditionally used in decorative or rustic applications, butterfly and strap hinges will benefit from the revival of vintage and industrial design aesthetics. In 2026, artisanal and customizable finishes—such as black iron, antique brass, and powder-coated colors—will cater to niche markets in boutique hospitality and heritage restoration projects. The trend toward personalized home interiors will support continued demand, particularly in Europe and North America.

Lift-Off and Detachable Hinges

Lift-off hinges will grow in popularity in modular and prefabricated construction, where ease of assembly and disassembly is crucial. By 2026, these hinges will be increasingly used in multifamily housing, temporary structures, and service access panels. Enhanced security versions with tamper-resistant pins will appeal to both residential and commercial sectors. Their utility in maintenance-heavy environments like laboratories and cleanrooms will further drive adoption.

Concealed and European Hinges

Concealed hinges, particularly European-style cup hinges, will dominate the cabinetry and interior door markets. The trend toward seamless, handle-less furniture and minimalist interiors will fuel demand. In 2026, expect widespread integration with soft-close and damping technologies, enhancing user experience. Smart hinges with embedded sensors for monitoring door usage or enabling automated lighting will begin to enter the premium segment, especially in smart homes and automated offices.

Smart and IoT-Enabled Hinges

A transformative trend by 2026 will be the emergence of smart hinges embedded with sensors and connectivity. These hinges will enable real-time monitoring of door position, usage frequency, and security status, feeding data into IoT platforms for energy management, security, and predictive maintenance. Initially adopted in commercial smart buildings, this technology will gradually penetrate high-end residential markets, offering enhanced safety and convenience.

Sustainability and Materials Innovation

Across all hinge types, sustainability will be a major driver. Recycled metals, low-impact manufacturing processes, and longer product lifecycles will become standard. Bio-based coatings and non-toxic finishes will appeal to eco-conscious consumers and green building certifications like LEED and BREEAM. Manufacturers investing in circular economy models—such as take-back programs and recyclable packaging—will gain a competitive edge.

In conclusion, the 2026 door hinges market will be defined by technological innovation, aesthetic refinement, and a strong focus on sustainability and smart integration. Different hinge types will evolve to meet specialized functional and design needs, positioning the industry at the intersection of construction, technology, and environmental responsibility.

Common Pitfalls When Sourcing Different Types of Door Hinges (Quality and IP Ratings)

Sourcing door hinges—especially with varying quality standards and Ingress Protection (IP) ratings—can be challenging. Buyers often encounter several common pitfalls that affect performance, durability, and compliance. Below are key issues to watch for:

Poor Material Quality Leading to Premature Failure

One of the most frequent issues is selecting hinges made from substandard materials. Low-grade metals such as inferior stainless steel, zinc-plated steel, or weak alloys corrode quickly, especially in humid or outdoor environments. Always verify the actual material composition (e.g., 304 vs. 316 stainless steel) and avoid suppliers offering unusually low prices, as this often signals compromised quality.

Overlooking IP Ratings for Outdoor or Harsh Environments

Many buyers fail to consider Ingress Protection (IP) ratings when sourcing hinges for exterior or industrial use. Hinges used in wet, dusty, or corrosive environments should have appropriate sealing. For example, IP65 or higher may be required for dust-tight and water-jet resistance. Sourcing hinges without proper IP certification can lead to rust, mechanical failure, or safety hazards.

Misunderstanding Load Capacity and Application Needs

Using hinges not rated for the door’s weight or frequency of use leads to sagging, misalignment, or breakage. For instance, residential hinges may not suffice for heavy commercial or fire-rated doors. Always match hinge type (e.g., butt, continuous, pivot) and load capacity to the specific application.

Inadequate Corrosion Resistance Despite Claims

Some suppliers advertise “rust-proof” or “weather-resistant” hinges without actual testing or certification. Look for standardized corrosion resistance data (e.g., salt spray test results) and ensure the finish or plating meets industry norms (e.g., ASTM B117). Beware of vague marketing terms without verifiable specifications.

Ignoring Hinge Compatibility with Fire or Security Ratings

In commercial and public buildings, hinges must often comply with fire safety or security standards. Using non-rated hinges on fire doors, for example, can compromise the entire assembly’s certification. Always confirm that hinges are tested and listed for use in rated door systems.

Supplier Reliability and Lack of Traceability

Sourcing from unknown or unverified suppliers—especially online—can result in inconsistent quality, counterfeit products, or lack of documentation. Ensure suppliers provide material certifications, test reports, and batch traceability, particularly for projects requiring compliance (e.g., construction, healthcare, marine).

Cost-Cutting Compromises on Precision and Tolerances

Cheap hinges often have poor machining, leading to misalignment, binding, or noisy operation. Precision in hinge pin alignment, bore diameter, and leaf flatness is critical for smooth performance and long-term reliability. Avoid hinges with visible defects or inconsistent dimensions.

Failure to Consider Environmental and Regulatory Compliance

In regulated industries, hinges may need to comply with standards like RoHS, REACH, or ADA. Overlooking these can result in legal or safety issues. Always confirm that the hinges meet relevant environmental, health, and safety regulations for your region and application.

Avoiding these pitfalls requires due diligence: request samples, verify certifications, and work with reputable suppliers who provide clear technical documentation on both quality and IP performance.

Logistics & Compliance Guide for Different Types of Door Hinges

Overview

Door hinges are essential hardware components used across residential, commercial, and industrial applications. Understanding the logistics and compliance requirements for various hinge types ensures smooth supply chain operations, regulatory adherence, and product safety. This guide outlines key considerations for common door hinge types.

Butt Hinges

Butt hinges are the most common type, consisting of two plates joined by a pin, typically mortised into the door and frame.

Logistics Considerations:

– Packaging: Typically shipped in bulk packs or individual boxes. Use anti-corrosion packaging for metal hinges (e.g., stainless steel or brass).

– Storage: Store in dry, climate-controlled environments to prevent rust, especially for ferrous metals.

– Shipping: Low weight and compact size allow for high-density palletization. Ensure separation to avoid surface damage during transit.

Compliance Requirements:

– Material Safety: Must comply with RoHS (Restriction of Hazardous Substances) if sold in the EU.

– Fire Ratings: In commercial buildings, hinges may need to meet fire door certification standards (e.g., UL 10C, BS 476).

– Labeling: Include material type, load rating, and fire certification (if applicable) on packaging.

Continuous (Piano) Hinges

These long hinges span the entire length of a door and are used for heavy-duty or high-security applications.

Logistics Considerations:

– Packaging: Require rigid protection (e.g., cardboard tubes or edge protectors) to prevent bending.

– Storage: Store flat or vertically to avoid warping; avoid stacking heavy items on top.

– Shipping: Subject to freight class based on length and material; longer hinges may require LTL (Less Than Truckload) shipping.

Compliance Requirements:

– Structural Integrity: Must meet load and cycle testing standards such as ANSI/BHMA A156.1.

– Corrosion Resistance: Salt spray testing (e.g., ASTM B117) may be required for outdoor or marine environments.

– ADA Compliance: In public buildings, hinges must support doors that meet ADA accessibility standards (e.g., closing speed, opening force).

Pivot Hinges

Pivot hinges support doors from the top and bottom, allowing rotation around a central axis, often used for heavy or decorative doors.

Logistics Considerations:

– Packaging: Fragile pivot mechanisms require protective foam or molded inserts.

– Storage: Keep components in original packaging to avoid misalignment or damage to precision parts.

– Shipping: Higher value and complexity may require insurance and special handling labels (e.g., “Fragile,” “This Side Up”).

Compliance Requirements:

– Load Certification: Must be rated for door weight and meet structural building codes (e.g., IBC Section 1010).

– Fire Door Compliance: When used in fire-rated doors, pivot hinges must be part of a certified fire assembly.

– Installation Standards: Manufacturer specifications must align with local building codes for alignment and safety.

Spring (Automatic) Hinges

Equipped with a spring mechanism to automatically close doors, often used in commercial and public buildings.

Logistics Considerations:

– Packaging: Internal springs can be sensitive to shock; use cushioned packaging.

– Storage: Avoid extreme temperatures that may degrade spring tension or lubricants.

– Shipping: Classify as mechanical hardware; may be subject to special handling due to moving parts.

Compliance Requirements:

– Closing Force: Must comply with ADA standards (max 5 lbf opening force) and ANSI A156.4 for performance.

– Fire Safety: Approved for use on fire-rated doors only if listed by a certified testing laboratory (e.g., UL, FM).

– Durability Testing: Must pass minimum cycle tests (e.g., 100,000+ cycles) as per BHMA standards.

Concealed Hinges

Installed within the door and frame, commonly used in modern cabinetry and frameless doors.

Logistics Considerations:

– Packaging: Small size allows for high-density packaging, but risk of loss requires secure compartmentalization.

– Storage: Sensitive adjustment mechanisms require protection from dust and moisture.

– Shipping: Low shipping cost due to size; often shipped with other hardware kits.

Compliance Requirements:

– Material Compliance: Nickel and chrome finishes may be subject to REACH regulations in the EU.

– Performance Standards: Must meet ANSI/BHMA A156.5 for cabinet hinges (resistance to load, corrosion, and wear).

– Child Safety: Where used in furniture, may need to comply with safety standards like ASTM F2057 (preventing tip-overs).

General Compliance and Logistics Best Practices

- Documentation: Maintain certificates of compliance (COC), material safety data sheets (MSDS), and test reports.

- Customs & Import: Declare proper HTS codes (e.g., 8302.41 for iron/steel hinges); be aware of anti-dumping duties on imports from certain countries.

- Sustainability: Use recyclable packaging and comply with environmental regulations (e.g., California Proposition 65 for lead content).

- Quality Control: Implement incoming inspections to verify dimensions, finish, and function per purchase specifications.

By adhering to these logistics and compliance guidelines, manufacturers, distributors, and installers can ensure safe, legal, and efficient handling of all types of door hinges across global markets.

In conclusion, sourcing different types of door hinges requires careful consideration of several key factors, including the door’s weight, size, material, usage frequency, and the desired aesthetic and functional outcome. Common hinge types—such as butt hinges, pivot hinges, continuous (piano) hinges, and concealed hinges—each serve specific purposes and are suited to different applications, from residential interior doors to heavy commercial or industrial use.

When sourcing hinges, it is essential to prioritize quality materials—like stainless steel, brass, or heavy-duty steel—based on environmental conditions, such as exposure to moisture or high traffic. Durability, ease of installation, load capacity, and compliance with safety standards should also guide the selection process.

Additionally, working with reputable suppliers and manufacturers ensures consistent product quality and access to technical support. Evaluating cost versus long-term performance helps balance budget constraints with longevity and reliability.

Ultimately, the right hinge not only supports smooth door operation but also contributes to overall safety, energy efficiency, and design integrity. A well-informed sourcing decision enhances both functionality and value across residential, commercial, and industrial building projects.