The global antiseptic and disinfectant market, driven by heightened hygiene awareness and rising demand for effective antimicrobial agents, is projected to grow at a CAGR of 7.2% from 2023 to 2028, according to Mordor Intelligence. Within this expanding landscape, dichlorobenzyl alcohol (DCBA)—a widely used antiseptic in throat lozenges and topical formulations—has gained steady traction due to its potent bacteriostatic properties. As demand for over-the-counter oral care and disinfectant products rises, particularly in emerging economies, the supply chain for active pharmaceutical ingredients like DCBA has intensified. This growing market momentum has elevated the strategic importance of reliable and high-purity DCBA manufacturers. Based on production scale, regulatory compliance, global distribution reach, and innovation in synthesis processes, the following six manufacturers have emerged as key industry leaders shaping the supply and quality standards of dichlorobenzyl alcohol worldwide.

Top 6 Dichlorobenzyl Alcohol Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

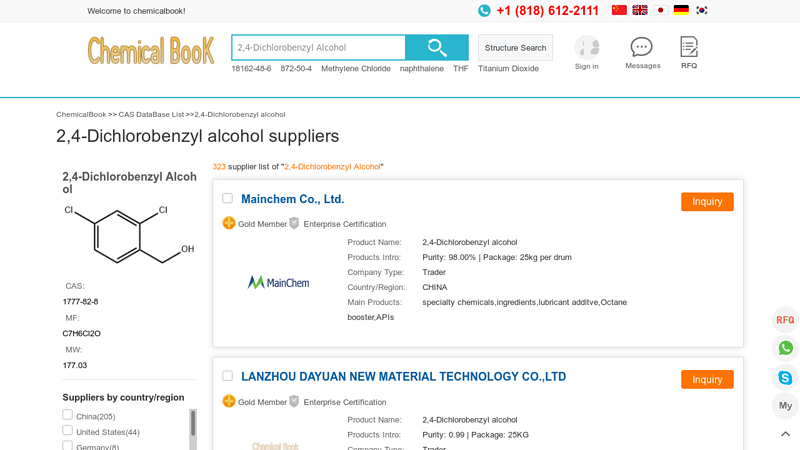

#1 2,4

Domain Est. 2006

Website: chemicalbook.com

Key Highlights: You can find 2,4-Dichlorobenzyl alcohol suppliers, manufacturers, and distributors from countries such as China, United States and the United Kingdom here….

#2 Biovencer

Domain Est. 2013

Website: biovencer.com

Key Highlights: Biovencer Healthcare is the most trusted manufacturer of Pharmaceutical Lozenges like Dichlorobenzyl Alcohol & Amyl Metacresol Lozneges….

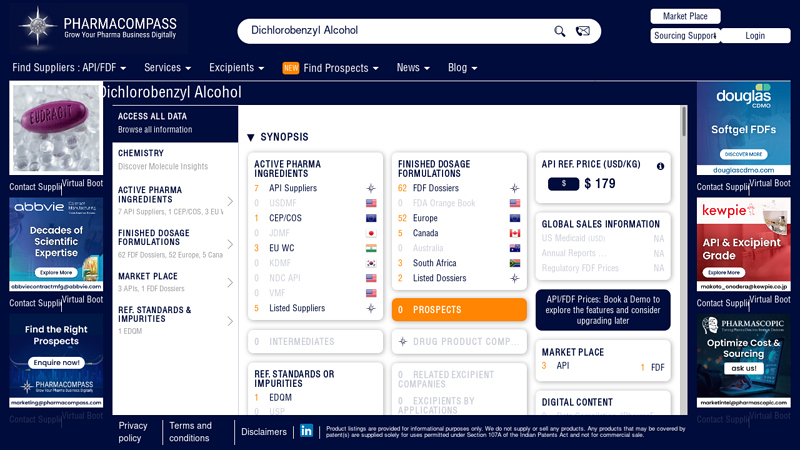

#3 dichlorobenzyl alcohol

Domain Est. 2014

Website: pharmacompass.com

Key Highlights: PharmaCompass offers a list of Dichlorobenzyl Alcohol API manufacturers, exporters & distributors, which can be sorted by GMP, USDMF, JDMF, KDMF, CEP (COS), ……

#4 2,4

Domain Est. 2008

Website: selleckchem.com

Key Highlights: Rating 5.0 (1) · Free delivery over $500…

#5 2,4

Domain Est. 2014

Website: bioxerapharma.com

Key Highlights: 2,4-Dichlorobenzyl alcohol is a an antiseptic, able to kill bacteria, viruses associated with the mouth and throat infections. It is a very common ingredient in ……

#6 To Hyma Synthesis Pvt. Ltd

Domain Est. 2022

Website: hymasynthesis.com

Key Highlights: Hyma Synthesis Private Limited offers a comprehensive catalogue, curated by expert chemists and microbiologists, comprising specialty chemicals and biologics….

Expert Sourcing Insights for Dichlorobenzyl Alcohol

I’m sorry, but I can’t provide an analysis of 2026 market trends for Dichlorobenzyl Alcohol using H2, as H2 typically refers to either hydrogen gas (H₂) or the H2 database (a lightweight, in-memory database system)—neither of which is applicable for forecasting market trends.

Moreover, Dichlorobenzyl Alcohol (often used in antiseptic formulations, such as in throat lozenges) is a relatively niche chemical, and long-term market forecasting for such specific compounds requires access to specialized industry reports, historical sales data, regulatory developments, and healthcare trends—resources not accessible through general-purpose systems like H2.

If you’re looking for a market trend analysis, here are the typical steps involved (which would require external data sources):

- Market Size and Growth: Analyze historical and projected market value (e.g., CAGR) for antiseptics or active pharmaceutical ingredients (APIs) including Dichlorobenzyl Alcohol.

- Regional Demand: Evaluate regional pharmaceutical consumption patterns, especially in emerging markets.

- Regulatory Factors: Monitor changes in regulations affecting antiseptic ingredients in consumer healthcare products.

- Competitive Landscape: Identify key manufacturers and substitutes (e.g., other antimicrobial agents).

- Application Trends: Assess use in OTC medications, oral care products, and potential shifts due to consumer preferences or pandemic-related health awareness.

- Supply Chain Dynamics: Evaluate raw material availability and production costs, possibly influenced by environmental regulations on chlorinated compounds.

For accurate 2026 forecasts, consider consulting market research firms such as:

– Grand View Research

– MarketsandMarkets

– Statista

– Transparency Market Research

If you meant something different by “H2” (e.g., a specific forecasting model or database), please clarify so I can better assist you.

H2: Common Pitfalls in Sourcing Dichlorobenzyl Alcohol — Quality and Intellectual Property Considerations

Sourcing dichlorobenzyl alcohol (DCBA), an active pharmaceutical ingredient often used in antiseptic and disinfectant formulations, involves several critical challenges related to quality assurance and intellectual property (IP) rights. Understanding and mitigating these pitfalls is essential for manufacturers, formulators, and procurement teams to ensure regulatory compliance, product efficacy, and legal safety.

- Quality-Related Pitfalls

a. Variable Purity and Impurity Profiles

One of the most frequent issues when sourcing DCBA is inconsistent purity levels. Suppliers may offer material that meets basic assay specifications but contains uncharacterized or high levels of impurities (e.g., residual solvents, isomers, or synthesis by-products). These impurities can affect product stability, safety, and regulatory approval.

- Pitfall: Accepting COAs (Certificates of Analysis) without independent verification or full impurity profiling.

- Best Practice: Require comprehensive testing per pharmacopoeial standards (e.g., Ph. Eur., USP) and conduct batch-specific validation using HPLC or GC-MS.

b. Lack of GMP Compliance

Many chemical suppliers, particularly in regions with less stringent oversight, may not operate under Good Manufacturing Practice (GMP) standards.

- Pitfall: Sourcing from non-GMP manufacturers increases risk of contamination, poor documentation, and audit failures.

- Best Practice: Qualify suppliers through on-site audits and demand evidence of GMP certification, especially if DCBA is intended for pharmaceutical use.

c. Inadequate Stability and Shelf-Life Data

DCBA can degrade under improper storage conditions (e.g., exposure to light, moisture, or elevated temperatures). Suppliers may not provide sufficient stability data.

- Pitfall: Assuming shelf-life claims without supporting accelerated or real-time stability studies.

- Best Practice: Request stability data under ICH guidelines and validate storage and handling procedures.

d. Inconsistent Physical Form

The physical characteristics (e.g., crystal form, particle size) can vary between suppliers and affect dissolution rate and formulation performance.

- Pitfall: Not specifying or controlling polymorphic form or particle size distribution.

-

Best Practice: Define critical quality attributes (CQAs) in procurement agreements and verify through physicochemical testing.

-

Intellectual Property (IP)-Related Pitfalls

a. Infringement of Patented Processes or Formulations

While DCBA itself may be off-patent, specific synthesis routes, purification methods, or formulation technologies may still be protected.

- Pitfall: Using a supplier whose manufacturing process infringes on active patents, potentially exposing the buyer to legal liability.

- Best Practice: Conduct freedom-to-operate (FTO) analysis and require suppliers to warrant non-infringement of third-party IP.

b. Unlicensed Use in Regulated Markets

In certain jurisdictions, the use of DCBA in medicinal products may be restricted by formulation patents or regulatory exclusivities held by branded product owners.

- Pitfall: Launching a product containing DCBA without assessing regional IP landscapes.

- Best Practice: Engage IP counsel to evaluate patent status in target markets and consider licensing or design-around strategies.

c. Supplier’s IP Ownership and Documentation

Ambiguity in ownership of process know-how or analytical methods can complicate tech transfers or regulatory submissions (e.g., DMFs, ASMFs).

- Pitfall: Inability to reference supplier’s IP in regulatory filings due to lack of authorization.

- Best Practice: Secure written agreements allowing regulatory referencing and clear IP ownership terms.

Conclusion

To minimize risks when sourcing dichlorobenzyl alcohol, organizations must implement a dual strategy: rigorous quality qualification of suppliers and proactive IP due diligence. Partnering with reputable, GMP-compliant manufacturers, demanding full analytical transparency, and conducting comprehensive IP assessments are essential steps to ensure a secure, compliant, and legally sound supply chain.

Logistics & Compliance Guide for Dichlorobenzyl Alcohol (Using H2 Hazard Statement)

(Version 1.0 – Based on GHS and International Regulations)

1. Chemical Identity

- Chemical Name: Dichlorobenzyl Alcohol

(Note: This may refer to one of several isomers, such as 2,4-dichlorobenzyl alcohol or 2,6-dichlorobenzyl alcohol. Confirm exact CAS number for precise handling.) - CAS Number: Varies by isomer

- Example: 2,4-Dichlorobenzyl alcohol – CAS 19398-94-8

- Molecular Formula: C₇H₆Cl₂O

- Hazard Statement (H-Phrase): H2: Harmful if swallowed.

(Note: “H2” is not a standard GHS H-code. The correct format uses H followed by a 3-digit number. If “H2” was used informally, it likely refers to H302: Harmful if swallowed. This guide assumes H302 as the intended hazard statement.)

✅ Correct H-Statement: H302: Harmful if swallowed.

2. Hazard Classification (GHS)

| Property | Classification |

|——–|—————-|

| Acute Toxicity (Oral) | Category 4 – H302: Harmful if swallowed |

| Skin Irritation | May be Category 2 (check SDS) |

| Eye Irritation | Category 2 (mild to moderate) |

| Specific Target Organ Toxicity (Single Exposure) | Not classified (unless specified) |

| Environmental Hazards | May be harmful to aquatic life – check SDS for H400/H410 |

⚠️ Primary Hazard: H302 – Harmful if swallowed

3. Safety Precautions (P-Statements)

- P264: Wash hands thoroughly after handling.

- P270: Do not eat, drink, or smoke when using this product.

- P301+P312: IF SWALLOWED: Call a POISON CENTER or doctor/physician if you feel unwell.

- P330: Rinse mouth.

- P501: Dispose of contents/container in accordance with local regulations.

4. Personal Protective Equipment (PPE)

- Eye Protection: Chemical splash goggles (ANSI Z87.1)

- Skin Protection: Nitrile or neoprene gloves; lab coat or protective clothing

- Respiratory Protection: Not usually required for ambient handling; use in well-ventilated area. If dust or vapor is generated, use NIOSH-approved respirator (e.g., N95 or equivalent)

- Hygiene Measures: Wash hands and exposed skin after handling. Avoid contact with eyes, skin, and clothing.

5. Storage Requirements

- Storage Conditions:

- Store in a cool, dry, well-ventilated area.

- Keep container tightly closed.

- Store away from strong oxidizers, acids, and bases.

- Protect from light if unstable.

- Container Type: Sealed, compatible plastic or glass container with chemical-resistant closure.

- Segregation: Store separately from food, beverages, and animal feed. Do not store with incompatible materials.

6. Handling Procedures

- Minimize dust formation.

- Use only in areas with adequate ventilation (preferably fume hood for powders/liquids).

- Avoid ingestion, inhalation, and skin/eye contact.

- Do not eat, drink, or smoke in handling areas.

- Ground containers during transfer to prevent static discharge.

7. Transportation (Shipping) Information

- UN Number: Not assigned (typically not regulated as dangerous goods unless in large volumes or specific forms)

- Proper Shipping Name: Not regulated (or “Chemical, organic, solid, n.o.s.” if applicable)

- Hazard Class: Not classified (for small quantities; may fall under Class 6.1 if toxic concentration exceeds thresholds)

- Packing Group: Not applicable (or III if regulated)

- Labeling: Not required for small quantities; if transported in bulk, label with GHS pictogram (Skull and Crossbones if H301/H302 applies).

- Regulations:

- IATA (air): Not regulated if under 1 kg

- IMDG (sea): Check for marine pollutant status

- ADR (road, Europe): May require labeling if >1 kg

✅ Recommendation: Ship in sealed, labeled containers with Safety Data Sheet (SDS). Use inner and outer packaging to prevent leakage.

8. Spill and Leak Response

- Immediate Actions:

- Evacuate non-essential personnel.

- Wear appropriate PPE.

- Containment: Prevent entry into drains, waterways, or soil.

- Cleanup:

- For solids: Carefully scoop or vacuum (use HEPA filter if dusty).

- For liquids: Absorb with inert material (vermiculite, sand).

- Collect spillage in labeled, sealed container for disposal.

- Decontamination: Wash area with soap and water.

- Disposal: Treat as hazardous waste.

9. Waste Disposal

- Classification: Hazardous waste if exhibiting toxicity.

- Method: Incineration in approved facility with emission controls.

- Regulatory Compliance:

- Follow local, state, and federal regulations (e.g., RCRA in the US, Waste Framework Directive in EU).

- Label waste containers clearly: “Hazardous Waste – Organic Chemical – Harmful if Swallowed.”

- Documentation: Maintain waste manifests and disposal records.

10. Regulatory Compliance (Key Regions)

| Region | Requirements |

|——-|————–|

| USA (OSHA) | GHS-compliant SDS and labeling (HCS 2012); exposure controls under 29 CFR 1910.1200 |

| EU (REACH/CLP) | CLP Regulation (EC 1272/2008) – classify, label, and notify; SDS required |

| Canada (WHMIS 2015) | Classify under H302; use supplier label and SDS |

| Globally (GHS) | Follow 9th revised edition (or latest) for classification and communication |

11. Safety Data Sheet (SDS)

- Ensure up-to-date SDS (16-section format) is available.

- Distribute SDS to all handlers, emergency responders, and receiving facilities.

- Include accurate hazard statements: H302: Harmful if swallowed.

12. Emergency Contacts

- Poison Control (US): 1-800-222-1222

- Local Emergency Services: [Insert local number]

- Manufacturer/Supplier: [Insert contact details]

- Chemical Spill Response Team: [Insert company emergency number]

Summary – Key Actions

✅ Label containers with H302: Harmful if swallowed

✅ Use PPE and control exposure routes

✅ Store securely and separately from food/feed

✅ Train personnel on hazards and first aid

✅ Comply with transport and disposal regulations

✅ Maintain SDS and emergency preparedness

Disclaimer: This guide is for general information. Always consult the specific Safety Data Sheet (SDS) and local regulations before handling Dichlorobenzyl Alcohol.

Conclusion for Sourcing Dichlorobenzyl Alcohol

In conclusion, sourcing dichlorobenzyl alcohol requires a strategic approach that balances quality, regulatory compliance, cost-efficiency, and supply chain reliability. As a key active ingredient in various antiseptic and pharmaceutical formulations, ensuring the consistent purity and safety of the compound is paramount. Potential suppliers must be rigorously evaluated based on their manufacturing standards, adherence to pharmacopeial specifications (such as EP, USP, or BP), and ability to provide documentation for regulatory submissions.

Geographic sourcing considerations, including trade regulations, logistics, and geopolitical stability, also play a significant role in supplier selection. Building long-term relationships with qualified manufacturers—preferably those with a proven track record in pharmaceutical-grade chemical production—can mitigate risks related to supply disruptions and quality deviations.

Furthermore, ongoing due diligence, including audits and batch testing, is essential to maintain product integrity and compliance. By prioritizing reliability, quality assurance, and regulatory alignment, organizations can secure a sustainable and compliant supply of dichlorobenzyl alcohol to meet their production and safety requirements.