The precision measurement tools market has witnessed steady growth, driven by rising demand for accuracy in manufacturing, automotive, and aerospace applications. According to Grand View Research, the global measuring instruments market size was valued at USD 10.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further supported by increasing automation in quality control processes and stringent regulatory standards across industries. Within this landscape, dial gauges with magnetic bases have become essential tools for alignment, inspection, and calibration tasks due to their portability, reliability, and ease of use. As industrial digitization accelerates and demand for high-precision instruments grows, manufacturers of dial gauges with magnetic bases are scaling innovation and production to meet evolving customer needs. Here, we spotlight the top seven manufacturers leading the charge in product quality, technological enhancement, and global market reach.

Top 7 Dial Gauge With Magnetic Base Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Digital Dial Indicator With Magnetic Base Manufacturer

Domain Est. 2014

Website: dasquatools.com

Key Highlights: Digital Dial Indicator With Magnetic Base Manufacturer – DASQUA High Accuracy Dial Indicator with Calibration Certificate – DASQUA Manufacture and Factory | ……

#2 Dial Indicators and Bases

Domain Est. 1996

Website: kmstools.com

Key Highlights: 4.7 27 iGaging 1″ Dial Indicator Magnetic Base Set. iGaging. iGaging 1″ Dial Indicator Magnetic Base Set. Special Price$64.99Reg.$69.99. You save $5.00. IGA-34510. In ……

#3 mag base dial indicator

Domain Est. 1998

Website: starrett.com

Key Highlights: 15-day returnsBrowse through a huge selection of fixturing options for you Starrett Indicator. Range include Cast Iron bases, Granite bases, well as Magnetic bases. Choose ……

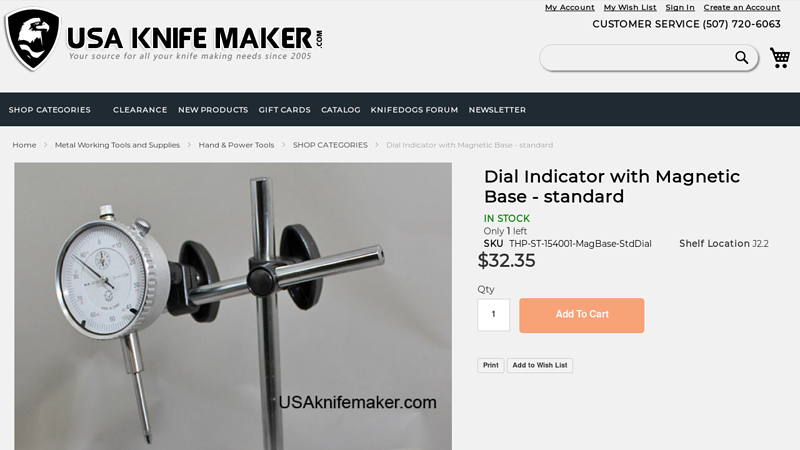

#4 Dial Indicator with Magnetic Base

Domain Est. 2007

Website: usaknifemaker.com

Key Highlights: The dial indicator has 1″ of travel and indicates to .001″ precision. Adjustable bezel face locks with knurled set screw. Roller ball end point….

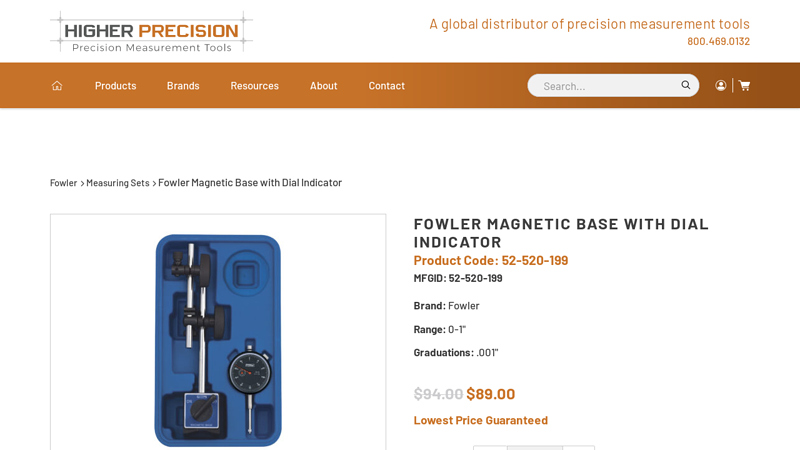

#5 52

Domain Est. 2010

#6 Dial Indicators & Measuring Stands

Domain Est. 2011

Website: hoffmanngroupusa.com

Key Highlights: 4–9 day deliveryHG Hydraulic Magnetic Measuring Stand (with Base) with Mechanical Fine Adjustment. MSRP: Was: Now: $281.87 – $428.18….

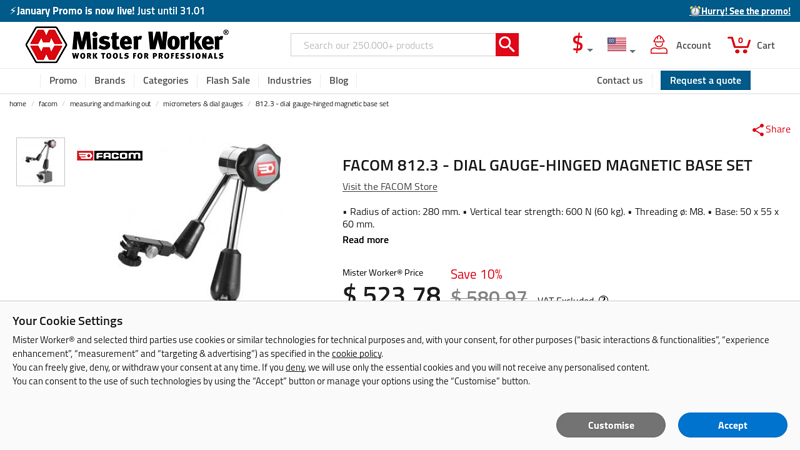

#7 FACOM 812.3 Dial gauge-hinged magnetic base set

Domain Est. 2017

Website: misterworker.com

Key Highlights: In stock $23.87 deliveryThis advanced combination integrates a dial gauge and a robust magnetic base, providing a reliable solution for assessing dimensions and alignments with ……

Expert Sourcing Insights for Dial Gauge With Magnetic Base

H2: 2026 Market Trends for Dial Gauge with Magnetic Base

The global market for dial gauges with magnetic bases is expected to undergo significant transformation by 2026, driven by advancements in precision engineering, growing demand across industrial sectors, and the integration of smart technologies. This analysis explores key trends shaping the market landscape, including technological innovations, regional demand shifts, industry applications, and competitive dynamics.

1. Rising Demand in Manufacturing and Automotive Industries

The manufacturing and automotive sectors remain primary drivers for dial gauges with magnetic bases. As precision measurement becomes increasingly critical in quality control processes, especially in engine assembly, gear manufacturing, and component alignment, demand for reliable and portable measurement tools continues to grow. By 2026, the expansion of electric vehicle (EV) production and advanced manufacturing techniques in emerging economies will further boost market adoption.

2. Technological Integration and Digitalization

While traditional analog dial gauges remain popular for their durability and ease of use, the market is witnessing a gradual shift toward digital variants. Hybrid models that combine the magnetic base with digital readouts offer enhanced accuracy, data recording, and connectivity options (e.g., Bluetooth or USB). By 2026, manufacturers are expected to focus on smart integration, enabling real-time data transmission to quality management systems—particularly in Industry 4.0 environments.

3. Growth in Asia-Pacific Markets

Asia-Pacific is projected to be the fastest-growing region for dial gauge with magnetic base demand, fueled by industrialization in China, India, and Southeast Asia. Increasing investments in infrastructure, automotive production, and electronics manufacturing are creating robust demand for precision measurement tools. Local production of cost-effective yet reliable instruments will also contribute to market expansion.

4. Emphasis on Ergonomics and Durability

As user experience becomes a competitive differentiator, manufacturers are focusing on ergonomic design, lightweight materials, and enhanced magnetic stability. By 2026, products featuring shock-resistant dials, improved magnetic adhesion, and modular setups will gain preference among technicians and quality inspectors.

5. Competitive Landscape and Market Consolidation

The market is moderately fragmented, with key players such as Mitutoyo, Starrett, Fowler, and SPI dominating through product innovation and global distribution networks. However, increasing competition from regional manufacturers offering budget-friendly alternatives is pushing established brands to innovate and differentiate through calibration accuracy, after-sales service, and smart features.

6. Sustainability and Calibration Standards

Environmental and regulatory compliance is gaining importance. By 2026, manufacturers will likely emphasize recyclable packaging, energy-efficient production, and adherence to international calibration standards (e.g., ISO 9001). Tools that support traceable and repeatable measurements will be preferred in regulated industries such as aerospace and medical device manufacturing.

In summary, the dial gauge with magnetic base market in 2026 will be shaped by digital transformation, regional industrial growth, and evolving user expectations. While analog models will retain relevance, the integration of digital features and smart capabilities will define the next phase of innovation, ensuring continued relevance in precision measurement applications.

Common Pitfalls When Sourcing Dial Gauge With Magnetic Base (Quality and IP Considerations)

Logistics & Compliance Guide for Dial Gauge With Magnetic Base

Product Overview

A dial gauge with magnetic base is a precision measuring instrument used to measure small linear distances or deviations. The magnetic base allows for secure attachment to ferromagnetic surfaces, enabling hands-free operation during inspection or alignment tasks. This guide outlines the logistics and compliance considerations for the safe handling, transport, import/export, and regulatory adherence of this instrument.

Packaging & Handling

Ensure the dial gauge and magnetic base are securely packed to prevent damage during transit. Use protective materials such as foam inserts, bubble wrap, or molded plastic trays to immobilize the gauge. Store in a closed container to shield from dust, moisture, and physical shock. Avoid placing heavy items on top of the packaged gauge. Handle with care to protect the delicate spindle and dial face.

Shipping & Transportation

Ship via ground or air freight depending on urgency and destination. For air transport, ensure packaging meets IATA standards for general cargo. The magnetic base may be subject to restrictions due to its magnetic field. If the magnetic field strength exceeds 0.00525 gauss at a distance of 2.1 meters (7 feet), special labeling and documentation per IATA Dangerous Goods Regulations (Class 9 – Miscellaneous Dangerous Goods) may be required. Confirm magnetic characteristics with the manufacturer and perform field testing if necessary.

Import & Export Compliance

Classify the dial gauge under the appropriate Harmonized System (HS) code. A common classification is 9031.80 – “Other measuring or checking instruments, not elsewhere specified.” Confirm the exact code with local customs authorities, as classifications may vary by country.

– Export Controls: Verify if the item is subject to export control regulations such as the U.S. Export Administration Regulations (EAR). Most standard dial gauges are EAR99 and do not require a license for most destinations, but check for exceptions.

– Import Duties & Taxes: Research duty rates and VAT/GST requirements in the destination country. Provide accurate commercial invoices and packing lists.

Regulatory & Safety Standards

Ensure the dial gauge complies with relevant international and regional standards, such as:

– ISO 463: Geometrical product specifications – Coordinate measuring machines – Vocabulary.

– ISO 6506: Calibration and verification of dial indicators.

– CE Marking (if sold in the European Economic Area): Demonstrates conformity with health, safety, and environmental protection standards.

– RoHS Compliance: Confirm the product is free of restricted hazardous substances (e.g., lead, cadmium), especially if electrical components are present.

Labeling & Documentation

Clearly label packaging with handling instructions: “Fragile,” “This Side Up,” and “Protect from Moisture.” If the magnetic base is strong enough to require hazardous materials classification, apply the required Class 9 label. Include in the shipping documents:

– Commercial invoice

– Packing list

– Certificate of Conformity (if applicable)

– Material Safety Data Sheet (MSDS) – typically not required unless hazardous materials are involved

– Export declaration (if required)

Storage & Inventory Management

Store in a climate-controlled environment with low humidity and minimal temperature fluctuations to maintain measurement accuracy. Keep away from strong electromagnetic fields, which may affect the magnetic base or gauge performance. Rotate stock using first-in, first-out (FIFO) principles to avoid prolonged storage of unused units.

End-of-Life & Environmental Compliance

Dispose of or recycle the dial gauge in accordance with local environmental regulations. If the device contains batteries or electronic components, follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. The magnetic base may be recyclable as ferrous metal.

Summary

Proper logistics and compliance management for a dial gauge with magnetic base involves secure packaging, adherence to magnetic material transport rules, accurate customs classification, and conformity with regional safety and environmental standards. By following this guide, businesses can ensure safe, legal, and efficient handling throughout the product lifecycle.

Conclusion:

After evaluating various suppliers and options, sourcing a dial gauge with a magnetic base is a practical investment for achieving precise, reliable, and repeatable measurements in industrial, mechanical, and quality control applications. The combination of a high-accuracy dial indicator and a versatile magnetic base ensures ease of use, secure positioning on ferromagnetic surfaces, and adaptability across different work environments. When selecting a supplier, factors such as product quality, calibration certification, durability, and cost-effectiveness should be prioritized. Opting for reputable manufacturers or suppliers with positive performance reviews and technical support can ensure long-term reliability and accuracy. Ultimately, sourcing a dial gauge with a magnetic base enhances measurement efficiency and contributes to improved precision in manufacturing and inspection processes.