The global boiler manufacturing market is experiencing steady expansion, driven by increasing industrialization, rising energy demands, and a growing focus on energy-efficient heating systems. According to a report by Mordor Intelligence, the boiler market was valued at USD 34.5 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. A significant portion of this growth is attributed to the increasing adoption of industrial process boilers, particularly in power generation, chemical processing, and food & beverage sectors. With sustainability and operational efficiency becoming key priorities, manufacturers are innovating to meet stringent emissions standards and higher thermal efficiency requirements. In this evolving landscape, Diagram stands out as a leading name in boiler technology, consistently ranking among the top manufacturers in Europe and expanding its global footprint. Here are the top 5 Diagram boiler manufacturers known for reliability, advanced engineering, and performance—backed by market demand and industry recognition.

Top 5 Diagram Boiler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

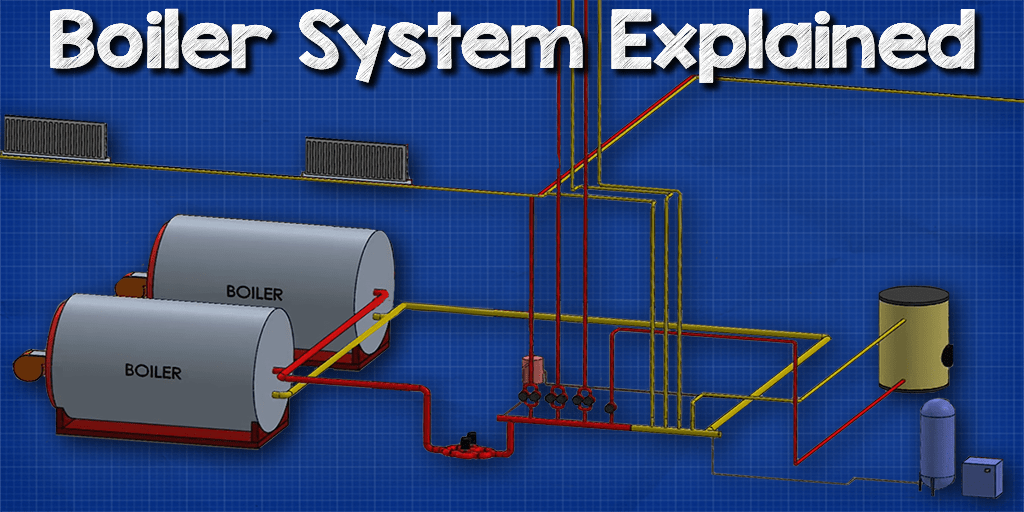

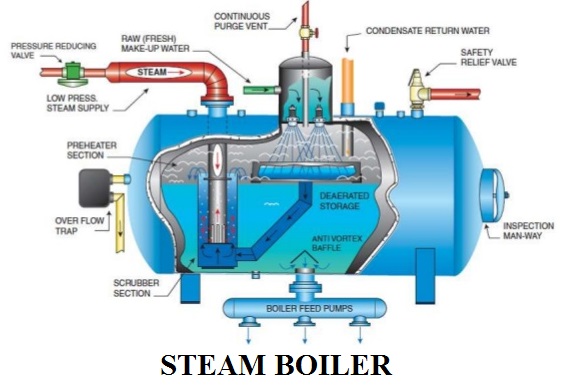

#1 Industrial Boiler Diagram of System

Domain Est. 1999

Website: en.tuffboiler.com

Key Highlights: Industrial Boiler Diagram of System: Types and Designs ; Control Systems: Monitor and manage boiler operations for efficiency and safety. ; Hospitals: Supplies ……

#2 Complete Hydronic Boiler Solutions

Domain Est. 2001 | Founded: 2000

Website: camus-hydronics.com

Key Highlights: Founded in 2000, CAMUS Hydronics Ltd. is a manufacturer of an extensive line of gas fired high efficiency copper tube and stainless steel boilers….

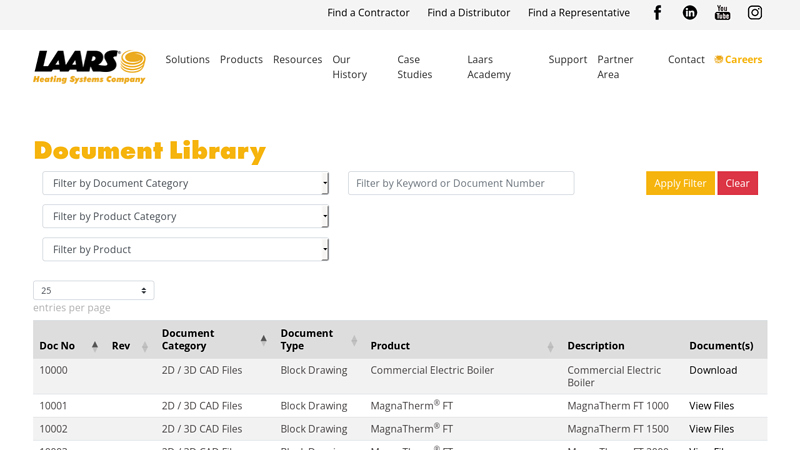

#3 Document Library

Domain Est. 1998

Website: laars.com

Key Highlights: 10000, 2D / 3D CAD Files, Block Drawing, Commercial Electric Boiler, Commercial Electric Boiler, Download. 10001, 2D / 3D CAD Files, Block Drawing ……

#4 Boiler Models

Domain Est. 1998

Website: hurstboiler.com

Key Highlights: Hurst boiler literature downloads, boiler models, plan views, manuals and spec sheets available for download….

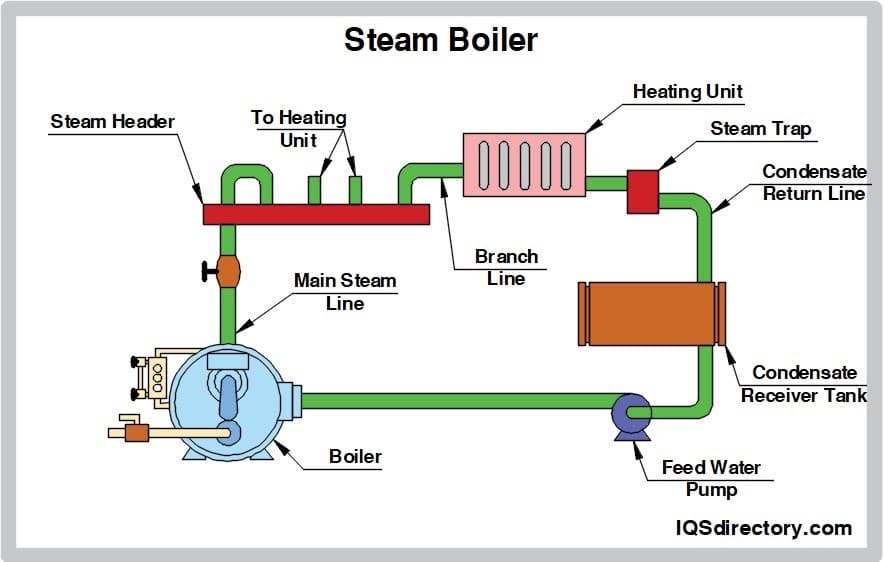

#5 Boiler Diagrams & Schematics

Domain Est. 2006

Website: heatingspareparts.com

Key Highlights: Boiler Diagrams and Manuals – 1000’s of exploded boiler diagrams and user manuals. View thousands of high resolution images, allowing you to find part ……

Expert Sourcing Insights for Diagram Boiler

H2: 2026 Market Trends for Diagram Boiler

As the global energy landscape evolves toward greater efficiency and sustainability, the market for diagram boilers—technical schematics and design models used in boiler manufacturing and engineering—is expected to reflect broader industrial and technological shifts. By 2026, several key trends are poised to shape the demand, development, and application of diagram boilers across residential, commercial, and industrial sectors.

-

Increased Adoption of Smart and Connected Boiler Systems

The integration of Internet of Things (IoT) technology into heating systems is accelerating. By 2026, diagram boilers will increasingly reflect designs for smart boilers equipped with sensors, remote monitoring capabilities, and predictive maintenance features. These advanced schematics will support the engineering of boilers that communicate with building management systems, optimizing energy use and reducing downtime. As a result, diagram boiler templates will emphasize connectivity modules, data integration points, and cybersecurity considerations. -

Shift Toward Low-Carbon and Hybrid Boiler Technologies

With tightening global emissions regulations, particularly in the EU, North America, and parts of Asia, boiler manufacturers are transitioning from traditional fossil-fuel-based systems to low-carbon alternatives. Diagram boilers in 2026 will prominently feature hybrid heat systems combining condensing gas boilers with heat pumps, as well as hydrogen-ready boiler configurations. These designs will include annotations for fuel flexibility, retrofit compatibility, and integration with renewable energy sources. -

Standardization and Digitalization of Engineering Documentation

The engineering and construction industries are moving toward Building Information Modeling (BIM) and digital twin technologies. By 2026, diagram boilers are expected to be embedded within comprehensive digital models, allowing for real-time simulation, clash detection, and lifecycle analysis. This trend will drive demand for standardized, interoperable diagram formats (e.g., DWG, IFC, or cloud-based CAD platforms), increasing the need for precise, up-to-date boiler schematics that comply with international design standards. -

Growth in Prefabrication and Modular Boiler Systems

To reduce on-site labor and construction time, modular boiler plants are gaining popularity, especially in commercial and district heating projects. Diagram boilers will increasingly reflect pre-assembled, skid-mounted units with plug-and-play connectivity. These designs will emphasize compact layouts, standardized interfaces, and transportability, requiring more detailed installation and connection schematics. -

Rising Demand in Emerging Markets with Urbanization

Rapid urbanization in regions such as Southeast Asia, Africa, and Latin America will drive demand for efficient heating and hot water solutions. By 2026, diagram boilers tailored to localized conditions—such as variable water quality, voltage fluctuations, or extreme climates—will become more prevalent. Localized design adaptations will necessitate region-specific boiler schematics, increasing the need for customizable and scalable diagram libraries. -

Focus on Sustainability and Lifecycle Efficiency

End-users and regulators are placing greater emphasis on the full lifecycle impact of equipment. Diagram boilers in 2026 will begin to include annotations related to recyclability, material sourcing, and end-of-life disassembly. Designers will incorporate energy efficiency metrics directly into schematics, supporting compliance with green building certifications like LEED or BREEAM.

In summary, the 2026 market for diagram boilers will be characterized by digital integration, environmental compliance, and modular innovation. As boiler systems become smarter and more sustainable, the schematics that guide their construction must evolve in parallel—driving demand for accurate, adaptable, and future-ready diagram solutions across global markets.

Common Pitfalls Sourcing Diagram Boilers (Quality, IP)

Sourcing diagram boilers—detailed technical schematics used in engineering, manufacturing, or system design—can present significant challenges, particularly concerning quality and intellectual property (IP). Falling into these pitfalls can lead to project delays, legal exposure, or substandard outcomes. Below are the key risks to be aware of:

Poor Quality and Inaccurate Technical Details

One of the most frequent issues when sourcing diagram boilers is receiving low-quality or technically inaccurate schematics. This often occurs when suppliers prioritize speed or cost over precision. Common manifestations include outdated standards, incorrect dimensions, missing components, or inconsistent labeling. Using such diagrams can result in design flaws, safety hazards, or costly rework during implementation.

Lack of Standardization and Compatibility

Diagrams sourced from different vendors may follow varying formats, symbols, or conventions (e.g., ANSI vs. ISO standards). This lack of standardization complicates integration into existing engineering workflows and increases the risk of misinterpretation. Without consistent formatting, teams may struggle with collaboration or face errors during system assembly and maintenance.

Intellectual Property (IP) Infringement Risks

Sourcing diagram boilers from unverified or third-party suppliers raises serious IP concerns. Many diagrams are protected by copyright or are part of proprietary system designs. Using such materials without proper licensing or authorization can expose organizations to legal action, fines, or reputational damage. It’s crucial to verify the provenance of diagrams and ensure they are either openly licensed or provided with explicit usage rights.

Incomplete or Outdated Documentation

Suppliers may provide diagram boilers that are incomplete—missing key subsystems, annotations, or revision histories. Outdated diagrams reflecting obsolete technologies or deprecated configurations can mislead engineering teams and compromise system reliability. Always confirm the revision status and request supporting documentation such as bills of materials (BOMs) or design specifications.

Dependency on Unreliable or Non-Supportive Vendors

Relying on vendors who lack technical support or refuse to offer updates can become a long-term liability. If modifications are needed or errors are discovered, the absence of vendor cooperation can stall projects. Establish clear service-level agreements (SLAs) and ensure the supplier can provide ongoing support, updates, and validation when sourcing diagram boilers.

Failure to Verify Source Authenticity

Open marketplaces and freelance platforms may offer diagram boilers at competitive prices, but without vetting the authenticity of the creator or the accuracy of the content. Counterfeit or misrepresented diagrams can infiltrate supply chains easily. Always conduct due diligence: request credentials, verify affiliations with reputable engineering firms, and cross-check diagrams against industry standards.

Conclusion

To mitigate these pitfalls, organizations should establish a structured sourcing process that includes quality validation, IP clearance, and supplier vetting. Engaging directly with OEMs or certified engineering partners, using trusted repositories, and maintaining internal review protocols can significantly reduce risks associated with diagram boiler acquisition.

Logistics & Compliance Guide for Diagram Boiler

This guide outlines the essential logistics and compliance considerations for the safe and legal handling, transportation, storage, and operation of Diagram Boiler systems. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and workplace safety.

Regulatory Compliance Requirements

Diagram Boiler systems must comply with a range of national and international regulations depending on jurisdiction and application. Key compliance areas include:

- Pressure Equipment Directive (PED) 2014/68/EU – Applies to boilers within the European Union; requires CE marking and conformity assessment.

- ASME Boiler and Pressure Vessel Code (BPVC) – Mandatory in the U.S. and widely adopted globally; ensures design, fabrication, and inspection standards.

- OSHA Standards (29 CFR 1910.168) – Governs safe operation, maintenance, and employee training in the United States.

- Local Environmental Regulations – Emissions controls, noise levels, and waste disposal must align with regional environmental protection laws.

- National Board Inspection Code (NBIC) – Required for installation, inspection, and repair in North America; mandates proper documentation and stamping.

Ensure all Diagram Boilers are registered with the appropriate regulatory body and undergo periodic inspections by certified inspectors.

Transportation and Handling Procedures

Safe transportation and handling are critical to prevent damage and ensure personnel safety:

- Pre-Transport Inspection: Confirm secure mounting of internal components and verify that all valves and connections are sealed.

- Packaging Standards: Use manufacturer-approved crating with moisture barriers and shock-absorbing materials. Clearly label with “Fragile,” “This Side Up,” and “Heavy Equipment.”

- Lifting Protocols: Use rated lifting gear only at designated lifting points. Never lift by pipes, valves, or ancillary components.

- Vehicle Requirements: Transport on flatbed trucks or trailers with adequate load securing (e.g., chains, straps). Avoid abrupt stops or turns during transit.

- Site Delivery: Ensure unloading area is level and free of obstructions. Use forklifts or cranes with appropriate capacity and trained operators.

Storage Guidelines

Proper storage prevents corrosion and component degradation:

- Indoor Storage Preferred: Store in a dry, climate-controlled environment to avoid moisture and temperature extremes.

- Outdoor Storage Precautions: If stored outdoors, cover completely with waterproof, UV-resistant tarps and elevate on wooden skids to prevent ground moisture contact.

- Preservation Measures: Apply internal and external corrosion inhibitors as recommended by the manufacturer. Seal all openings to prevent debris or moisture ingress.

- Inventory Control: Maintain logs of storage duration and conditions; inspect every 30 days for signs of damage or environmental exposure.

Installation and Commissioning Compliance

Installation must follow manufacturer specifications and regulatory codes:

- Permitting: Obtain all required local permits prior to installation.

- Qualified Personnel: Only licensed engineers or certified technicians may install and commission the boiler.

- Alignment and Piping: Ensure proper support of connected piping to avoid stress on boiler nozzles. Follow ASME B31.1 for power piping standards.

- Safety Devices: Install and test pressure relief valves, low-water cutoffs, and flame safeguard controls per code requirements.

- Documentation: Retain as-built drawings, material test reports, and commissioning records for audit and inspection purposes.

Operational and Maintenance Compliance

Ongoing compliance ensures long-term reliability and safety:

- Routine Inspections: Conduct internal and external inspections per NBIC or local code schedules (typically annually).

- Water Quality Management: Maintain proper water chemistry to prevent scaling, corrosion, and carryover; test regularly and document results.

- Emission Monitoring: Where applicable, monitor flue gas emissions (NOx, CO, SOx) and maintain compliance with environmental permits.

- Operator Training: Provide certified training for all personnel; maintain training records.

- Recordkeeping: Keep logs of maintenance, repairs, inspections, and safety tests for a minimum of five years or as required by law.

Emergency Response and Reporting

Prepare for potential incidents with defined procedures:

- Emergency Shutdown Protocol: Clearly posted steps for rapid boiler isolation in case of overpressure, flame failure, or leaks.

- Spill and Leak Response: Equip site with containment tools and PPE; report hazardous material releases to authorities as required.

- Incident Reporting: Notify regulatory agencies (e.g., OSHA, EPA) immediately in case of accidents involving injury, explosion, or environmental harm.

Adhering to this guide ensures Diagram Boiler systems operate safely, legally, and efficiently throughout their lifecycle. Regular audits and updates to procedures in line with changing regulations are strongly recommended.

Conclusion for Sourcing Diagram of a Boiler:

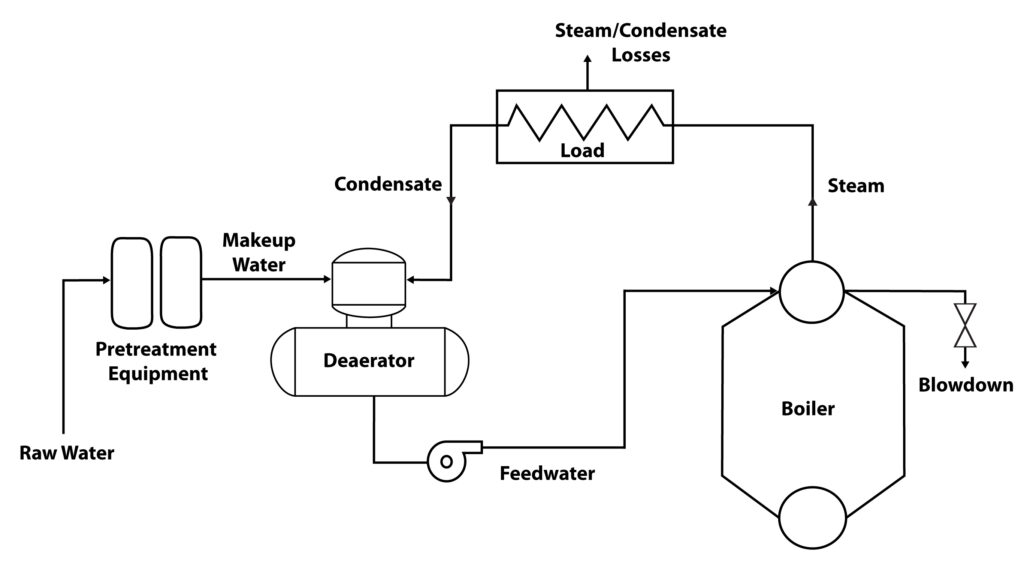

The sourcing diagram for a boiler system highlights the entire supply chain and procurement process involved in acquiring components, materials, and services necessary for boiler manufacturing, installation, and maintenance. It underscores the importance of selecting reliable suppliers for critical parts such as pressure vessels, burners, control systems, safety valves, and heat exchangers, ensuring compliance with safety standards and regulatory requirements.

Effective sourcing contributes to the boiler’s efficiency, reliability, and longevity. Strategic supplier partnerships, quality assurance, cost optimization, and adherence to sustainability practices are essential in building a resilient supply chain. Moreover, localization of suppliers can reduce lead times and logistical costs, while global sourcing may offer access to advanced technology and competitive pricing.

In conclusion, a well-structured sourcing diagram enables better decision-making, risk mitigation, and operational performance in boiler systems—supporting both industrial efficiency and long-term sustainability goals.