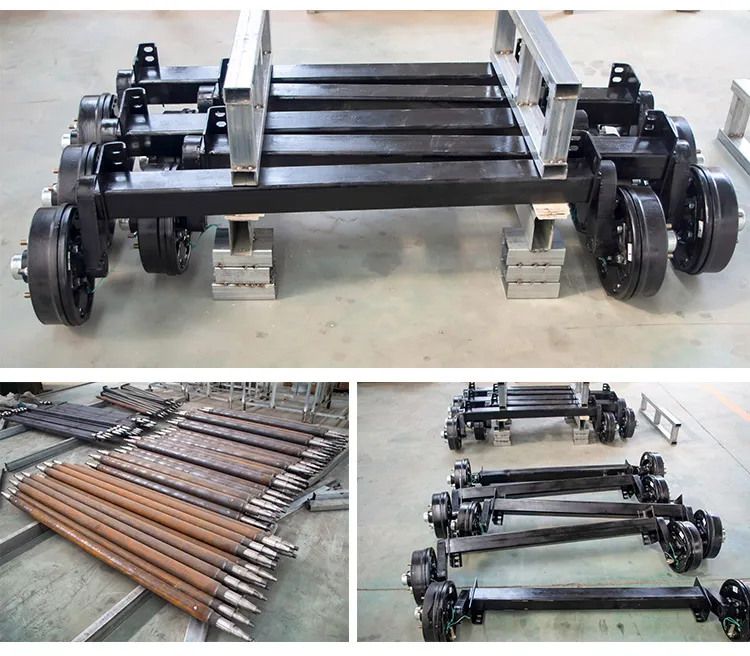

The global torsion axle market is experiencing steady expansion, driven by increasing demand for durability and enhanced ride performance in utility trailers, camping trailers, and specialty vehicles. According to Grand View Research, the global trailer suspension systems market was valued at USD 6.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. A key contributor to this growth is the rising preference for torsion axle systems over traditional spring axles due to their maintenance-free operation and superior shock absorption. Mordor Intelligence further supports this trend, forecasting continued market momentum, particularly in North America and Europe, where recreational vehicle ownership and DIY trailer usage are on the rise. As demand grows, Dexter Axle remains a dominant player, but several manufacturers have emerged as top contenders, innovating in materials, load capacity, and corrosion resistance. Below, we examine the top four Dexter torsion axle manufacturers shaping the industry through quality, performance, and technological advancement.

Top 4 Dexter Torsion Axles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading Manufacturer of Highly Engineered Components and …

Domain Est. 2018

Website: dexterindex.com

Key Highlights: Learn more about how Dexter is a leading manufacturer of highly-engineered running gear, and provides axles, chassis, and other components for trailer, RV, ……

#2 Torsion

Domain Est. 1997

Website: dexteraxle.com

Key Highlights: Fits Dexter Torflex #10 axles. Increases ride by 2.63″, for two axles. Note: Lift Kits cannot be used with Torflex axles produced with 3″ high profile brackets….

#3 Dexter Group

Domain Est. 2002

Website: dextergroup.com

Key Highlights: Dexter is the premier supplier of axles, doors, venting products, and related components in the utility trailer, RV, heavy duty, recreational boating, and ……

#4 Dexter FAQ’s, Dexter Axle Frequently Asked Questions

Domain Est. 2011

Website: dexterpartsonline.com

Key Highlights: AXLES – Can I buy axles directly from Dexter? All Dexter axles are manufactured specifically for each customer order. Since there are literally tens of ……

Expert Sourcing Insights for Dexter Torsion Axles

H2: Projected Market Trends for Dexter Torsion Axles in 2026

As the global trailer and specialty vehicle industry evolves, Dexter Torsion Axles are expected to experience significant shifts in demand, innovation, and market positioning by 2026. Driven by advancements in materials, regulatory standards, and end-user preferences, several key trends are shaping the trajectory of Dexter’s torsion axle business.

-

Increased Demand in Recreational and Utility Trailers

The recreational vehicle (RV) and utility trailer markets are projected to remain strong through 2026, fueled by sustained consumer interest in outdoor lifestyles and DIY projects. Dexter Torsion Axles, known for their durability and low maintenance, are well-positioned to benefit from this growth. The torsion axle’s superior ride quality over traditional leaf-spring suspensions continues to drive adoption in consumer-grade trailers, particularly in North America. -

Expansion into Global Markets

Dexter is anticipated to expand its international footprint, especially in emerging markets across Latin America, Eastern Europe, and parts of Asia. As local manufacturing capabilities grow and infrastructure improves, demand for reliable trailer suspension systems is rising. Dexter’s reputation for quality and standardized designs makes its torsion axles attractive for global OEMs and aftermarket distributors. -

Emphasis on Lightweight and Sustainable Materials

A major trend in 2026 will be the shift toward lightweight axle designs that improve fuel efficiency and reduce emissions. Dexter is expected to invest in advanced composite materials and aluminum-based torsion systems to meet this demand. Sustainability initiatives, including recyclable components and energy-efficient production methods, will also play a role in product development. -

Integration with Smart Trailer Technologies

The convergence of trailer systems with smart technologies—such as integrated sensors for load monitoring, tire pressure, and suspension diagnostics—is gaining momentum. Dexter is likely to respond by developing “smart” torsion axles compatible with IoT-enabled trailer platforms. These innovations will appeal to commercial fleets and high-end recreational users seeking enhanced safety and performance. -

Regulatory and Safety Standards Compliance

Stricter safety and emissions regulations in both the U.S. and EU will influence axle design. By 2026, Dexter will need to ensure its torsion axles comply with updated standards for load capacity, braking integration, and crashworthiness. This could lead to new product lines tailored to specific regulatory environments. -

Growth in the Aftermarket and Replacement Segment

As the installed base of trailers ages, the aftermarket for replacement axles will expand. Dexter’s brand recognition and extensive distribution network give it a competitive edge in servicing repair and upgrade needs. Customization options, including adjustable torsion arms and corrosion-resistant coatings, will be key differentiators.

In summary, the 2026 market for Dexter Torsion Axles will be defined by innovation, globalization, and alignment with evolving consumer and regulatory demands. Dexter’s ability to adapt through product enhancements and strategic market expansion will determine its leadership in the trailer suspension industry.

Common Pitfalls When Sourcing Dexter Torsion Axles (Quality and Intellectual Property)

Sourcing Dexter torsion axles—whether genuine or aftermarket alternatives—requires careful attention to avoid quality issues and intellectual property (IP) risks. Here are key pitfalls to watch for:

Inconsistent Quality from Third-Party Suppliers

Many suppliers offer torsion axles marketed as “compatible with” or “similar to” Dexter designs. However, these products often lack the rigorous testing, materials, and manufacturing standards of genuine Dexter components. Using lower-grade rubber cords, inferior housing materials, or imprecise tolerances can lead to premature failure, uneven ride quality, and safety hazards.

Counterfeit or Misrepresented Products

Counterfeit Dexter axles are prevalent in some markets. These products mimic Dexter branding, packaging, or part numbers but are manufactured without authorization. They may appear identical but perform poorly under load or fail prematurely. Buyers risk receiving substandard components that compromise vehicle safety and violate warranty terms.

Intellectual Property Infringement Risks

Dexter holds patents and trademarks on its torsion axle designs, including specific rubber-in-tube technology and mounting configurations. Sourcing or selling unauthorized replicas—even if labeled generically—may expose buyers or resellers to legal liability for IP infringement. This is especially relevant for distributors or OEMs integrating axles into trailers or vehicles.

Lack of Traceability and Certification

Genuine Dexter axles come with traceable lot numbers, compliance certifications, and documentation supporting load ratings and safety standards. Many alternative suppliers do not provide equivalent documentation, making it difficult to verify compliance with DOT, CSA, or other regulatory requirements. This lack of traceability can lead to liability in the event of failure.

Voided Warranties and Limited Support

Using non-genuine or incompatible torsion axles may void the warranty on the trailer or other components. Dexter typically does not support systems that incorporate counterfeit or modified parts. This leaves users without recourse in case of product failure and increases long-term maintenance costs.

Inadequate Technical Support and Compatibility

Aftermarket suppliers may lack the engineering expertise to ensure proper fit, alignment, and load matching. Incorrect axle selection—based on flawed specifications or incomplete data—can result in improper tongue weight distribution, handling issues, or excessive wear on tires and suspension components.

To mitigate these risks, always purchase Dexter axles through authorized distributors, verify product authenticity, and ensure compliance with IP and safety standards. When considering alternatives, confirm they are legally manufactured and independently tested to meet applicable performance criteria.

Logistics & Compliance Guide for Dexter Torsion Axles

Product Identification and Specifications

Ensure all Dexter Torsion Axles are correctly identified by model number, load rating, hub configuration, wheel bolt pattern, and applicable vehicle fitment. Accurate product specifications are critical for compliance and proper installation. Refer to Dexter’s official product catalog or technical datasheets for detailed information.

Packaging and Handling Requirements

Dexter Torsion Axles must be shipped in protective packaging to prevent damage during transit. Use crated or skid-mounted packaging with secure strapping. Handle axles with appropriate lifting equipment (e.g., forklifts or overhead cranes) to avoid deformation or stress on the rubber torsion elements. Never drag or drop axle assemblies.

Storage Conditions

Store Dexter Torsion Axles in a dry, climate-controlled environment away from direct sunlight, ozone sources (e.g., electric motors), and corrosive chemicals. Prolonged UV exposure or extreme temperatures can degrade rubber components. Keep axles elevated off the ground on pallets and limit stack height to prevent crushing.

Transportation and Shipping

Use enclosed transport vehicles whenever possible to protect axles from weather and road debris. Secure loads with straps or chains to prevent shifting during transit. Comply with Department of Transportation (DOT) regulations for cargo securement. For international shipments, ensure adherence to Incoterms and proper export documentation.

Import/Export Compliance

Verify compliance with U.S. Customs and Border Protection (CBP) requirements when importing or exporting Dexter Torsion Axles. Include accurate Harmonized System (HS) codes (e.g., 8708.80 for axles and parts), country of origin labeling, and commercial invoices. Adhere to International Trade Administration (ITA) regulations and any applicable trade agreements.

Regulatory and Safety Standards

Dexter Torsion Axles are designed and manufactured to meet Federal Motor Vehicle Safety Standards (FMVSS), including FMVSS 122 (Motorcycle Brake Systems, where applicable) and general vehicle equipment standards. Confirm compliance with DOT FMVSS and Canadian Motor Vehicle Safety Standards (CMVSS) for North American markets. For trailers, ensure axles meet relevant weight rating and certification requirements.

Certification and Documentation

Maintain access to Dexter’s Certificate of Conformance (CoC), ISO 9001 certification documentation, and any third-party test reports. Distributors and installers must retain product traceability records, including batch numbers and dates of shipment, for audit and recall preparedness.

Installation and End-User Compliance

Only certified or trained personnel should install Dexter Torsion Axles. Follow Dexter’s official installation guidelines precisely. Improper installation may void warranties and create safety hazards. Ensure end-users register their axles with Dexter, where applicable, to receive recall notices and service updates.

Warranty and Recall Procedures

Familiarize yourself with Dexter’s warranty terms, which typically cover defects in materials and workmanship for a specified period. Report any suspected defects or field failures immediately to Dexter Customer Service. In the event of a recall, follow the manufacturer’s instructions for notification, return logistics, and replacement procedures.

Environmental and Disposal Considerations

At end-of-life, dispose of Dexter Torsion Axles in accordance with local, state, and federal environmental regulations. Recycle metal components through certified scrap metal processors. Rubber and composite parts may require specialized handling; consult local waste management authorities for proper disposal methods.

Conclusion for Sourcing Dexter Torsion Axles

In conclusion, sourcing Dexter torsion axles presents a reliable and efficient solution for enhancing trailer performance, durability, and ride quality. Known for their industry-leading design, torsion axle systems from Dexter offer superior vibration absorption, reduced maintenance, and a smoother ride compared to traditional leaf spring suspensions—making them ideal for utility trailers, boat trailers, and recreational vehicles.

When sourcing these components, it is essential to partner with authorized distributors or reputable suppliers to ensure product authenticity, warranty coverage, and compliance with safety standards. Considering factors such as axle weight capacity, mounting type, hub configuration, and compatibility with your trailer’s specifications will ensure optimal performance and longevity.

Additionally, evaluating total cost of ownership—factoring in durability, reduced maintenance, and improved load handling—reveals that Dexter torsion axles represent a sound long-term investment. As demand for high-performance trailer suspensions continues to grow, Dexter remains a trusted brand in the market, and strategic sourcing of their torsion axles supports both quality and operational efficiency.

Ultimately, careful supplier selection, attention to technical specifications, and adherence to installation best practices will ensure that Dexter torsion axles deliver reliable performance, safety, and customer satisfaction for years to come.