The global detent ball market is experiencing steady growth, driven by rising demand in automotive, industrial equipment, and consumer electronics sectors. According to Grand View Research, the global spring market—under which detent balls are often categorized due to their functional use in mechanical assemblies—was valued at USD 11.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. Detent balls play a critical role in precision mechanisms, including locking systems, rotary controls, and valve actuation, where reliability and repeatable performance are paramount. As automation and miniaturization accelerate across industries, the need for high-quality detent components has intensified. This increasing demand has elevated the importance of manufacturers who combine engineering excellence with scalable production capabilities. Based on market presence, product range, innovation, and global reach, the following seven companies have emerged as leading detent ball manufacturers shaping the future of mechanical locking solutions.

Top 7 Detent Ball Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Detent Pins Balls Manufacturer

Domain Est. 2002

Website: hartfordtechnologies.com

Key Highlights: Hartford Technologies offers modified/drilled balls for valve and industrial applications, with customizable materials and sizes….

#2 Detent Quick

Domain Est. 1995

Website: jergensinc.com

Key Highlights: All products: Detent Quick-Release Pins Unit Inch (1) Metric (1) Grip Length 0.50 In (1) 0.75 In (1) 1 In (1) 1.25 In (1) 1.50 In (1)…

#3 Ball Detent Pins Frequently Asked Questions

Domain Est. 1996

Website: pivotpins.com

Key Highlights: Find answers to all your questions about Pivot Pins products, including sizing, materials, installation, and best practices for non-threaded fasteners….

#4 Ball Plunger Detent

Domain Est. 1996

Website: workholdingcomponents.mortonmachine.com

Key Highlights: Morton offers a full selection of Ball Plungers manufactured from steel, stainless steel, brass, and nylon. Most spring loaded devices are available in inch ……

#5 BALL DETENTS

Domain Est. 2000

Website: imao.com

Key Highlights: BALL DETENTS. BALL DETENTS. CAD Data. PDF Catalog. Latest Datasheet Down Load … Company. Newsletter. Subscribe to get the latest news and updates. Subscribe….

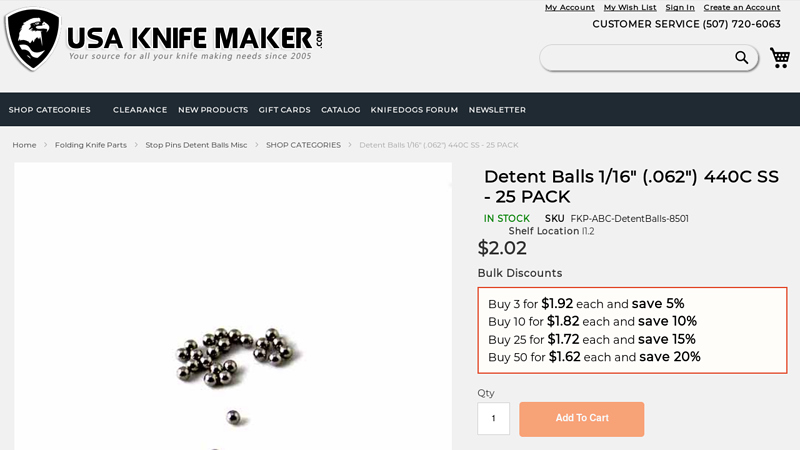

#6 Detent Balls 1/16″ (.062″) 440C SS

Domain Est. 2007

Website: usaknifemaker.com

Key Highlights: Detent Balls 1/16″ 25pack. – 1/16″ Diameter. – 440C Stainless steel. – Hardened and Cryo treated to 59/62 HRC. -Made in the USA….

#7 DETENT BALL

Domain Est. 2013

Expert Sourcing Insights for Detent Ball

H2: 2026 Market Trends for Detent Balls

The global detent ball market is poised for notable evolution by 2026, driven by advancements in automation, rising demand across industrial and consumer sectors, and shifts in manufacturing technologies. Detent balls—small spring-loaded components used to provide tactile feedback and positional stability in mechanical assemblies—are integral to a wide range of applications, including automotive controls, aerospace systems, medical devices, industrial machinery, and consumer electronics.

1. Increasing Automation and Precision Engineering Demand

As industries continue to adopt precision engineering and automated systems, the need for reliable mechanical feedback mechanisms like detent balls is growing. In automotive and aerospace sectors, detent mechanisms are critical in gear selectors, control knobs, and safety interlocks. The push toward electric vehicles (EVs) and advanced driver-assistance systems (ADAS) emphasizes user interface reliability, boosting demand for high-performance detent solutions.

2. Growth in Consumer Electronics and Smart Devices

The proliferation of smart home devices, wearable technology, and compact electronic interfaces is driving innovation in miniaturized detent mechanisms. By 2026, manufacturers are expected to focus on micro-scale detent balls capable of operating in tight spaces while maintaining durability and consistent tactile response. This trend is particularly evident in high-end audio equipment, smartphones, and haptic feedback systems.

3. Material and Coating Innovations

To meet stringent performance and environmental standards, detent ball producers are increasingly adopting advanced materials such as stainless steel, ceramic composites, and corrosion-resistant coatings. Trends point toward longer service life, reduced friction, and improved resistance to extreme temperatures and moisture—key factors in aerospace and industrial automation applications.

4. Regional Market Shifts

Asia-Pacific, especially China, Japan, and South Korea, is expected to dominate the detent ball market by 2026 due to robust manufacturing ecosystems and high electronics production. Meanwhile, North America and Europe will maintain strong demand in aerospace, medical, and automotive sectors, with an emphasis on high-precision, certified components compliant with ISO and AS standards.

5. Sustainability and Supply Chain Optimization

Sustainability concerns are influencing material sourcing and production methods. By 2026, leading manufacturers are projected to adopt leaner, more transparent supply chains and eco-friendly manufacturing processes. Recycling of metal components and energy-efficient production lines will become competitive differentiators.

6. Integration with Smart and IoT-Enabled Systems

Emerging applications in IoT-connected devices are prompting hybrid solutions where mechanical detent systems interface with digital sensors. This integration allows for real-time monitoring of wear and position, enabling predictive maintenance—especially valuable in industrial and medical equipment.

Conclusion

By 2026, the detent ball market will be shaped by technological refinement, cross-sector demand, and sustainability imperatives. Companies that innovate in miniaturization, materials science, and smart integration will be best positioned to capture value in this niche but essential component segment.

Common Pitfalls Sourcing Detent Balls: Quality and Intellectual Property (IP) Concerns

Sourcing detent balls—small, precision-engineered components used in locking, positioning, and indexing mechanisms—can present significant challenges, particularly regarding quality consistency and intellectual property (IP) risks. Overlooking these factors can lead to product failure, legal disputes, and reputational damage. Below are key pitfalls to avoid.

Inconsistent Material and Surface Quality

Detent balls must be manufactured from high-grade materials such as hardened stainless steel or chrome steel to resist wear, corrosion, and deformation. A common pitfall is sourcing from suppliers who use substandard alloys or inadequate heat treatment processes. Poor surface finish or improper ball roundness (out-of-roundness) can lead to inconsistent engagement, accelerated wear, or jamming in precision assemblies. Without proper quality certifications (e.g., ISO 3290, ABMA standards), there’s no assurance of dimensional accuracy or performance.

Lack of Traceability and Certification

Many low-cost suppliers, especially in unregulated markets, fail to provide material test reports (MTRs) or process certifications. This lack of traceability makes it difficult to verify compliance with industry standards or to investigate root causes in case of field failures. For regulated industries such as medical, aerospace, or automotive, this can result in non-compliance and audit failures.

Counterfeit or Non-Specification Parts

Some suppliers may offer detent balls that appear identical to OEM or branded components but are counterfeit or manufactured to looser tolerances. These parts may not meet load-bearing, hardness (e.g., HRC 58–65), or geometric specifications. Over time, such components degrade system reliability and can compromise safety-critical functions.

Intellectual Property Infringement

Detent mechanisms are often protected by patents, especially when part of a proprietary assembly or tooling system. Sourcing generic detent balls may seem safe, but if they are reverse-engineered to replicate a patented design or system-specific feature (e.g., exact diameter, coating, or engagement profile), it can expose the buyer to IP infringement claims. Using such components in end products may lead to legal action, product recalls, or injunctions.

Inadequate Supplier Vetting and Due Diligence

Procurement teams often prioritize cost and lead time over technical vetting. Without evaluating a supplier’s manufacturing capabilities, quality control processes, and IP compliance history, companies risk introducing defective or legally problematic components into their supply chain. This is especially true when engaging new or offshore suppliers without on-site audits.

Conclusion

To mitigate these pitfalls, buyers should:

– Require full material and process certifications.

– Source from reputable, audited suppliers with proven quality systems (e.g., ISO 9001).

– Conduct dimensional and material testing in independent labs.

– Perform IP landscaping to ensure compatibility with existing patents.

– Include quality and IP warranties in supplier contracts.

Proactive management of quality and IP risks ensures reliable performance and legal compliance when sourcing detent balls.

Logistics & Compliance Guide for Detent Ball

This guide outlines the key logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to detent balls—small, spring-loaded components commonly used in mechanical assemblies, valves, and connectors.

Overview of Detent Balls

Detent balls are typically made from hardened steel, stainless steel, or other durable metals and are used to provide positional feedback or secure mechanisms in various industrial, automotive, and aerospace applications. Their small size and metallic composition influence packaging, shipping, and compliance requirements.

Packaging Requirements

Detent balls must be packaged to prevent loss, contamination, and physical damage during transit. Recommended practices include:

– Use of sealed, static-dissipative plastic bags for individual or small batch storage.

– Secondary packaging in rigid containers or trays to prevent crushing.

– Clearly labeled inner and outer packaging indicating contents and part numbers.

– Anti-corrosion measures such as desiccants or vapor corrosion inhibitors (VCI) for long-term storage or international shipping.

Transportation & Handling

Due to their small size and metallic nature, detent balls are generally not classified as hazardous materials under most transport regulations (e.g., IATA, IMDG, 49 CFR). However:

– Ensure secure packaging to prevent spillage or loss during handling.

– Use appropriate cushioning and fillers to avoid shifting in transit.

– Label packages with handling instructions if required (e.g., “Fragile,” “Do Not Crush”).

– Follow carrier-specific guidelines for small industrial components.

Regulatory Compliance

Compliance varies by region and application. Key areas include:

– REACH (EU): Verify that materials used (e.g., steel alloys) comply with SVHC (Substances of Very High Concern) restrictions.

– RoHS (EU): Ensure compliance if detent balls are part of electronic or electrical equipment.

– Conflict Minerals (U.S. SEC Rule 13p-1): If applicable, disclose use of tin, tungsten, tantalum, or gold in the supply chain.

– ITAR/EAR (U.S.): Assess whether the components or end-use applications fall under export control regulations, particularly in defense or aerospace sectors.

Import & Export Documentation

When shipping internationally:

– Provide accurate HS (Harmonized System) code—typically 7320.90 (other springs and spring parts) or 8487.90 (parts of machinery).

– Include commercial invoices, packing lists, and certificates of origin.

– Verify destination country regulations on metal components and industrial parts.

– Obtain export licenses if required under EAR or ITAR.

Storage Conditions

Store detent balls in a controlled environment to maintain integrity:

– Temperature: Maintain between 15°C and 25°C (59°F–77°F).

– Humidity: Keep below 60% RH to prevent oxidation.

– Storage containers should be clean, dry, and free from contaminants.

– Use first-in, first-out (FIFO) inventory practices to prevent long-term storage issues.

Quality & Traceability

- Each batch should be traceable via lot or batch numbers.

- Maintain records of material certifications (e.g., mill test reports).

- Implement inspection procedures upon receipt and before shipment to verify dimensions and surface quality.

Disposal & Environmental Considerations

- Non-hazardous metallic components can typically be recycled as scrap metal.

- Follow local regulations for disposal of packaging materials (e.g., plastics, desiccants).

- Avoid landfill disposal; prioritize metal recycling programs.

By adhering to these logistics and compliance guidelines, organizations can ensure the safe, legal, and efficient handling of detent balls throughout the supply chain.

Conclusion for Sourcing Detent Ball:

After a thorough evaluation of potential suppliers, material specifications, cost considerations, and quality requirements, the sourcing strategy for detent balls should focus on partnering with reliable suppliers who offer a balance of high-quality materials, consistent manufacturing precision, and competitive pricing. Key factors such as material grade (typically hardened steel or stainless steel), dimensional accuracy, surface finish, and durability under cyclic loading are critical to ensure reliable performance in the intended application.

It is recommended to establish long-term agreements with suppliers who comply with industry standards (e.g., ISO, ASTM) and demonstrate strong quality control processes, including batch testing and traceability. Additionally, conducting supplier audits and sample testing prior to full-scale procurement will mitigate risks related to performance failure or supply chain disruption.

In conclusion, a strategic sourcing approach that prioritizes quality, reliability, and supplier capability will ensure optimal functionality of detent balls within the assembly, contributing to overall product performance and longevity.