The global coffee processing equipment market is experiencing steady growth, driven by rising demand for high-quality coffee and increasing adoption of mechanized farming techniques across key producing regions. According to Mordor Intelligence, the coffee processing equipment market is projected to grow at a CAGR of over 5.2% between 2023 and 2028, fueled by investments in efficient post-harvest technologies and the expansion of specialty coffee production. Despulpadoras de café—essential machinery for removing the outer pulp from coffee cherries—are at the heart of this evolution, enabling farmers and cooperatives to improve yield consistency and bean quality. With Latin America and East Africa emerging as hotspots for smallholder mechanization, demand for reliable, durable, and cost-effective depulpers is surging. This has led to the rise of specialized manufacturers focusing on innovation, scalability, and sustainability in their designs. Based on market presence, technological innovation, and customer reach, the following six manufacturers stand out as leaders in the global despulpadora de café industry.

Top 6 Despulpadora De Cafe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pinhalense Coffee Pulpers

Domain Est. 1998

Website: pinhalense.com.br

Key Highlights: Low water consumption, Pinhalense pulpers separate ripe cherries from green coffee, ensuring maximum efficiency in the pulping process….

#2 Despulpadora Horizontal DH

Domain Est. 1998

Website: penagos.com

Key Highlights: -Máximo rendimiento por su alta eficiencia de despulpe. -Despulpan sin usar agua. -Fácil calibración, mantenimiento y operación. -Posibilidad de operar de forma ……

#3 DESPULPADORA ECOLÓGICAS 1600

Domain Est. 2005

Website: estradahermanos.com

Key Highlights: DESPULPADORAS DE CAFÉ CON ALTO RENDIMIENTO. No requieren de agua para su funcionamiento, cuenta con sistema de pecheros fabricados en acero inoxidable para ……

#4 Despulpadora horizontal de café DH

Domain Est. 2012

Website: hidroherramientas.com

Key Highlights: Con su diseño horizontal, permite una operación uniforme al remover la pulpa de los granos, preparándolos para etapas posteriores como el secado y tostado….

#5 Bendig Maquinaria

Domain Est. 2015

Website: bendig.co.cr

Key Highlights: Bendig Costa Rica – Nuestros servicios: Maquinarias para cafe, tostadoras de cafe, torrefaccion, despulpadores, secadoras y mas….

#6 Despulpadora de café PENAGOS DH

Domain Est. 2017

Website: puntoequipos.com

Key Highlights: Características innovadoras, este modelo garantiza un proceso de despulpado sin pérdida de grano en pulpa y sin la necesidad de utilizar agua. Su fácil ……

Expert Sourcing Insights for Despulpadora De Cafe

H2: 2026 Market Trends for Despulpadora De Café

The global market for despulpadoras de café—machines used to remove the outer pulp from coffee cherries during processing—is expected to experience notable shifts by 2026, driven by technological innovation, sustainability demands, and evolving coffee production dynamics. Below are key trends shaping the despulpadora de café market in the coming years:

1. Increased Adoption of Eco-Friendly and Water-Saving Technologies

By 2026, environmental sustainability will be a major driver in coffee processing equipment design. Traditional wet-mill despulpadoras consume large volumes of water, contributing to pollution and resource depletion. In response, manufacturers are developing low-water and waterless mechanical depulpers, especially in water-scarce regions like Central America and East Africa. Demand is rising for machines that integrate with eco-pulping systems or combine depulping with fermentation control, aligning with global sustainability certifications (e.g., Rainforest Alliance, Organic, Fair Trade).

2. Growth in Smallholder Farmer Mechanization

Small-scale coffee farmers, who dominate production in countries like Colombia, Ethiopia, and Vietnam, are increasingly investing in affordable, durable despulpadoras. The 2026 market will see a surge in compact, hand-cranked or solar-powered models tailored for micro-farms. Governments and cooperatives are subsidizing equipment purchases to improve yield quality and reduce post-harvest losses, boosting market penetration in rural areas.

3. Technological Integration and Smart Equipment

Smart agriculture trends are entering the coffee processing sector. By 2026, expect to see despulpadoras equipped with sensors to monitor pulp removal efficiency, cherry density, and motor performance. IoT-enabled models may allow remote diagnostics and maintenance alerts, improving uptime and reducing operational costs. While still limited to larger farms or cooperatives, this technology signals a shift toward data-driven coffee processing.

4. Regional Shifts in Production and Equipment Demand

Latin America remains the largest market for despulpadoras de café, with Colombia and Guatemala leading in innovation and adoption. However, Africa—particularly Ethiopia, Rwanda, and Burundi—is emerging as a high-growth region due to specialty coffee expansion and development programs promoting value-added processing. Asia-Pacific, led by Vietnam and Indonesia, will see demand for higher-capacity machines to support large-scale robusta and specialty arabica production.

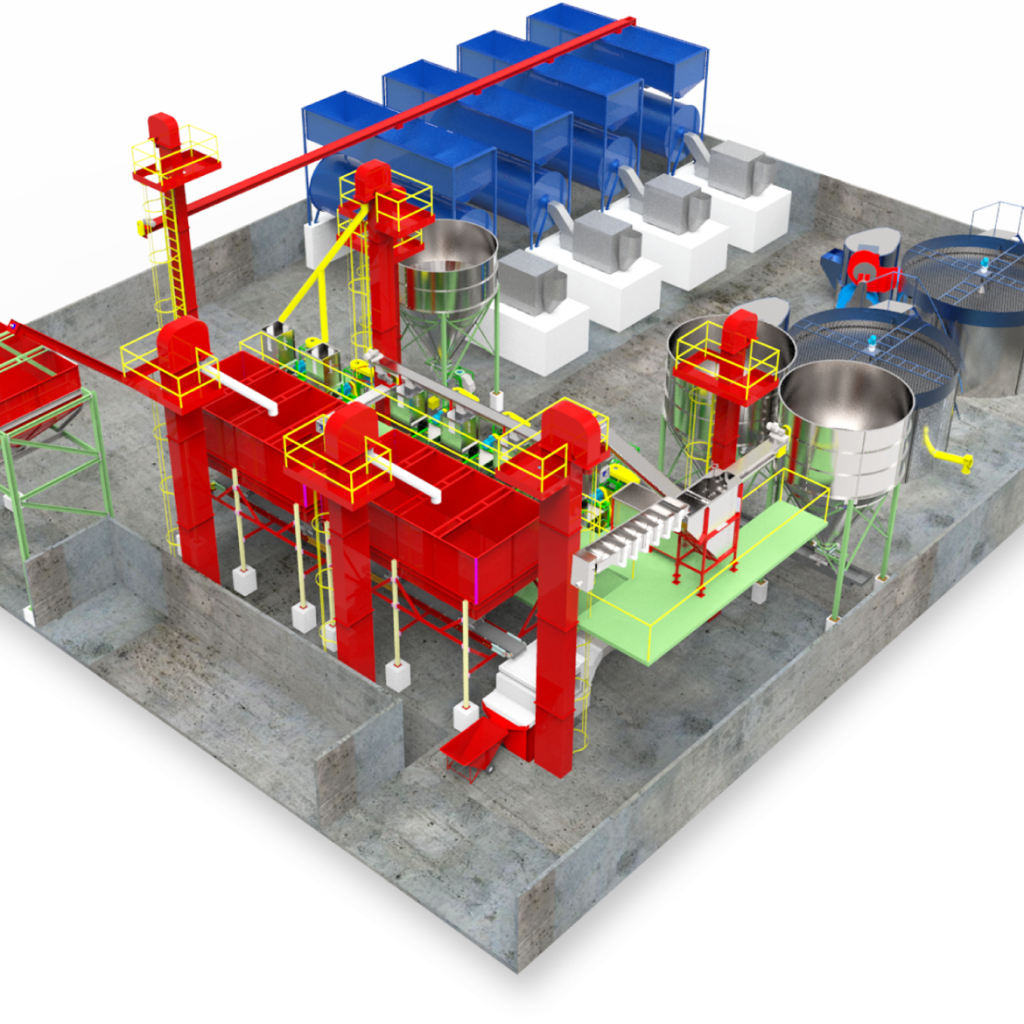

5. Rise of Multi-Functional Processing Units

Manufacturers are responding to cost and space constraints by integrating depulping with demucilaging, washing, and even initial drying. These all-in-one units reduce labor, water use, and energy consumption—key advantages for small to mid-sized processors. By 2026, modular and mobile processing units could become standard in remote coffee-growing regions.

6. Supply Chain Localization and After-Sales Support

Import dependency for spare parts and maintenance remains a challenge in developing countries. To capture market share, international manufacturers are partnering with local distributors to establish service centers and training programs. This trend toward localized support will enhance equipment longevity and customer loyalty, becoming a competitive differentiator.

Conclusion

The despulpadora de café market in 2026 will be defined by sustainability, accessibility, and innovation. As climate change and market demands push coffee producers to improve efficiency and quality, the role of advanced yet affordable depulping technology will be critical. Manufacturers that prioritize eco-design, farmer-centric solutions, and regional adaptability are poised to lead the evolving market landscape.

Common Pitfalls When Sourcing a Despulpadora de Café (Quality and Intellectual Property)

Sourcing a despulpadora de café (coffee pulper) can be critical for efficient and high-quality coffee processing. However, buyers—especially those new to the industry or sourcing from international suppliers—often encounter several pitfalls related to both equipment quality and intellectual property (IP) concerns. Being aware of these issues can help avoid costly mistakes.

Poor Build Quality and Material Selection

One of the most frequent issues is receiving machines constructed with substandard materials, such as low-grade steel or plastic components not suited for continuous operation. These materials wear out quickly, especially when processing large volumes of coffee cherries, leading to frequent breakdowns and increased maintenance costs. Buyers should verify that the machine uses corrosion-resistant materials (e.g., stainless steel) and robust mechanical components.

Inadequate Performance for Local Conditions

Some imported pulpers are designed for specific regional coffee varieties or processing volumes and may not perform well under different conditions. For example, machines calibrated for Arabica cherries might struggle with the denser pulp of Robusta. Additionally, pulpers not adapted to high humidity or variable power supply can underperform or fail prematurely.

Lack of After-Sales Support and Spare Parts Availability

Many suppliers, particularly from low-cost manufacturing regions, offer little to no local technical support or spare parts inventory. When a critical component breaks, buyers may face weeks or months of downtime waiting for replacements. This can severely disrupt harvest-season operations. Always confirm the availability of spare parts and technical service in your region before purchasing.

Misleading Specifications and Overstated Capacity

Some manufacturers exaggerate machine capacity (e.g., claiming 1,000 kg/hour when actual performance is far lower) or omit key operational details like power requirements or water usage. This can lead to mismatched expectations and inefficiencies. Request real-world performance data or third-party reviews before committing.

Intellectual Property (IP) Infringement Risks

When sourcing from certain regions, there’s a risk of purchasing machines that copy patented designs or incorporate protected technologies without authorization. While the price may be lower, buyers could face legal liability or reputational damage, especially if operating in markets with strong IP enforcement. Always verify that the manufacturer holds proper rights to the design or technology used.

Lack of Certifications and Compliance

Reputable pulpers should meet safety and environmental standards. Machines lacking certifications (e.g., CE, ISO) may not comply with local regulations or could pose safety hazards. This is especially important if integrating the machine into a larger, certified processing facility.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request references, inspect sample units, verify material specifications, and ensure IP legitimacy. Partnering with established suppliers or local distributors with proven track records can significantly reduce the risks associated with sourcing a despulpadora de café.

Logistics & Compliance Guide for Despulpadora De Café

Overview of the Despulpadora De Café

A despulpadora de café (coffee depulper) is a key piece of machinery in coffee processing, used to remove the outer skin and mucilage from coffee cherries after harvest. Whether you are importing, exporting, manufacturing, or distributing these machines, understanding the logistics and compliance requirements is essential for smooth operations and legal adherence.

Equipment Classification and HS Code

For international trade, correctly classifying your despulpadora de café is critical. Most coffee depulpers fall under the following Harmonized System (HS) code:

8437.80 – Machinery for cleaning, sorting, grading, or preparing agricultural products (e.g., coffee, nuts, seeds), other than machinery for cleaning, sorting, or grading eggs, or machinery of heading 84.36.

Always verify the specific code with your country’s customs authority, as variations exist based on power source (manual, electric, diesel) and automation level.

Import and Export Regulations

Ensure compliance with both origin and destination country regulations:

– Export Requirements (Origin Country): Obtain export permits if required, and ensure the machinery meets safety and electrical standards (e.g., CE marking for exports to Europe).

– Import Requirements (Destination Country): Check for import restrictions, duties, and conformity assessments. Some countries require pre-shipment inspections or certificates of origin.

– Documentation: Prepare commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and any required conformity declarations.

Packaging and Shipping Considerations

Proper packaging ensures the despulpadora arrives undamaged:

– Use wooden crates or robust pallets to protect moving parts.

– Waterproof wrapping to prevent moisture damage during transit.

– Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”).

– Declare the total weight, dimensions, and number of units for accurate freight calculation.

Transportation Modes

Choose the most efficient and cost-effective transport method based on volume and destination:

– Sea Freight: Ideal for bulk shipments; cost-effective for large orders. Use FCL (Full Container Load) or LCL (Less than Container Load) depending on volume.

– Air Freight: Faster but more expensive; suitable for urgent or small shipments.

– Land Transport: Useful for regional distribution, especially in coffee-producing countries with limited port access.

Customs Clearance Procedures

Facilitate smooth customs clearance by:

– Providing accurate product descriptions and HS codes.

– Paying applicable tariffs and value-added taxes (VAT).

– Submitting required certifications (e.g., electrical safety, RoHS for electronics).

– Working with a licensed customs broker familiar with agricultural machinery.

Regulatory and Safety Compliance

Ensure the despulpadora meets safety and environmental standards:

– Electrical Safety: Comply with IEC, UL, or local electrical codes if powered.

– Mechanical Safety: Install guards on moving parts and provide clear operation manuals.

– Environmental Standards: Minimize wastewater and pulp discharge impact; some regions require eco-friendly processing practices.

Maintenance and Spare Parts Logistics

Plan for long-term operational efficiency:

– Maintain an inventory of commonly replaced parts (e.g., pulping discs, belts).

– Offer multilingual user manuals and technical support.

– Establish distribution channels for spare parts in key markets.

Certification and Quality Assurance

Obtain relevant certifications to build trust and meet market requirements:

– ISO 9001 for quality management (if manufacturing).

– CE mark for European Union compliance.

– Local certifications in target markets (e.g., NOM in Mexico, INMETRO in Brazil).

Sustainability and Social Compliance

Align with global sustainability trends:

– Design energy-efficient models to reduce environmental impact.

– Source materials responsibly and ensure ethical labor practices in manufacturing.

– Support circular economy principles by enabling repairability and recyclability.

Final Recommendations

- Consult with logistics providers experienced in agricultural machinery.

- Stay updated on trade agreements that may reduce tariffs (e.g., USMCA, EU-Central America Association Agreement).

- Conduct regular compliance audits to avoid delays or penalties.

By following this guide, businesses involved with despulpadoras de café can ensure efficient logistics, regulatory compliance, and successful market entry worldwide.

Conclusion on Sourcing a Coffee Depulper (Despulpadora de Café):

Sourcing a coffee depulper is a critical step for improving efficiency, reducing post-harvest losses, and enhancing the quality of coffee production. After evaluating various options—whether local fabrication, regional suppliers, or international manufacturers—it is evident that the ideal choice depends on several key factors: production scale, budget, availability of spare parts, technical support, and energy source (manual, electric, or motorized).

Locally manufactured depulpers often offer better accessibility, lower costs, and easier maintenance, making them suitable for small to medium-sized farms. In contrast, imported models may provide higher durability and advanced features but come with increased costs and logistical challenges. Additionally, choosing environmentally friendly and water-efficient models supports sustainable farming practices.

Ultimately, successful sourcing involves thorough research, consultation with other producers, and direct testing when possible. Investing in the right despulpadora de café not only increases operational efficiency but also contributes to higher-quality parchment coffee, better market prices, and long-term profitability in the coffee value chain.