The global power supply manufacturing market is experiencing robust growth, driven by rising demand for efficient energy solutions across industries such as consumer electronics, industrial automation, telecommunications, and renewable energy. According to Grand View Research, the global power supply market size was valued at USD 36.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This expansion is fueled by advancements in power conversion technologies, increasing adoption of switch-mode power supplies (SMPS), and the proliferation of IoT-enabled devices requiring stable and compact power solutions. Additionally, Mordor Intelligence forecasts a CAGR of approximately 4.8% over the 2023–2028 period, citing growing infrastructure investments and the shift toward energy-efficient systems as key growth catalysts. In this evolving landscape, leading power supply manufacturers distinguish themselves through innovation, reliability, scalability, and compliance with global standards, positioning them at the forefront of powering next-generation technologies. The following analysis highlights the top 10 manufacturers shaping the industry with exceptional product offerings and strategic market presence.

Top 10 Description Of A Power Supply Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FSP TECHNOLOGY INC. |AC/DC Power Supply Manufacturer

Domain Est. 1998

Website: fsp-group.com

Key Highlights: FSP Group is a global leader in power supply manufacturing and solution supplier. By combining innovative technologies with professional R&D capabilities, ……

#2 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

#3 PULS

Domain Est. 2000

Website: pulspower.com

Key Highlights: The PULS group is your partner for DIN rail power supplies, decentralised Field Power Supplies & wireless charging technology from Wiferion….

#4 TDK

Domain Est. 1996

Website: us.lambda.tdk.com

Key Highlights: Browse our wide range of AC-DC, DC-DC, Programmable and High Voltage power supplies, DIN rails and EMI filters, as well as Value Add solutions….

#5 Wall Industries

Domain Est. 1998

Website: wallindustries.com

Key Highlights: Wall Industries manufactures and markets a full line of DC DC converters and AC DC power supplies. Browse our standard and customized power solutions ……

#6 Power Supply Manufacturer

Domain Est. 1998

Website: synqor.com

Key Highlights: SynQor designs and manufactures high-efficiency, high-reliability DC-DC power converters, AC-DC power converters, EMI filters and power systems….

#7 Power Supply Products

Domain Est. 1997

Website: cyberpowersystems.com

Key Highlights: CyberPower manufactures high-quality power supply products, power management solutions, and connectivity products for consumers and IT professionals….

#8 External Power Supplies

Domain Est. 1999

Website: energy.gov

Key Highlights: External power supply means an external power supply circuit that is used to convert household electric current into DC current or lower-voltage AC current to ……

#9 XP Power

Domain Est. 2000

Website: xppower.com

Key Highlights: We’re a world leading power supply solution provider, whose end-to-end services enable the smooth design and development of your power systems….

#10 Vicor Power Systems

Domain Est. 2001

Website: vicorpower.com

Key Highlights: Vicor high-performance power supplies solve the toughest problems quickly and reliably. Explore turnkey, custom products, solutions and application ……

Expert Sourcing Insights for Description Of A Power Supply

2026 Market Trends for Description of a Power Supply

As we approach 2026, the power supply market is undergoing significant transformation driven by technological advancements, sustainability demands, and evolving consumer needs across industries. A modern power supply is no longer just a component that converts electrical energy; it is becoming an intelligent, efficient, and integral part of broader energy ecosystems. This analysis explores key trends shaping how power supplies are described, designed, and utilized in 2026.

Increased Focus on Energy Efficiency and Regulatory Compliance

In 2026, energy efficiency remains a dominant factor in the description and evaluation of power supplies. Global regulations, such as the U.S. Department of Energy (DoE) Level VI and the European Union’s Ecodesign Directive, continue to tighten efficiency standards. As a result, product descriptions now emphasize ultra-high efficiency metrics—often exceeding 94%—and low no-load power consumption. Terms like “80 PLUS Titanium certified,” “adaptive voltage regulation,” and “zero-load standby modes” are standard in technical specifications, reflecting consumer and industrial demand for energy-conscious designs.

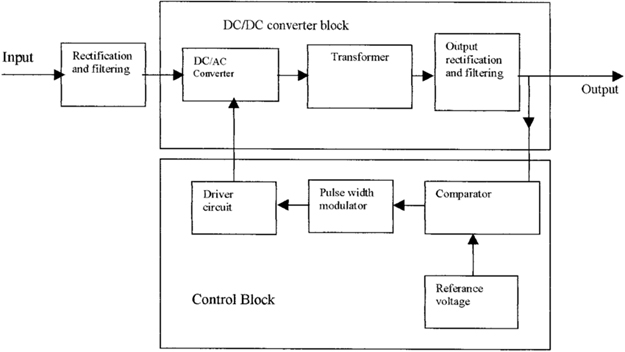

Integration of Smart and Digital Features

Power supplies in 2026 are increasingly described as “smart” or “digitally controlled.” With the proliferation of IoT and Industry 4.0, descriptions now include features such as PMBus (Power Management Bus) compatibility, remote monitoring, real-time diagnostics, and predictive maintenance capabilities. Manufacturers highlight digital signal processing (DSP) controllers and bidirectional communication, enabling systems to adjust voltage dynamically based on load conditions. These features are especially prominent in data centers, telecom infrastructure, and renewable energy systems.

Miniaturization and High Power Density

The demand for smaller, lighter devices has pushed power supply designs toward higher power density. In 2026, product descriptions emphasize compact form factors with wattages per cubic inch as a key performance metric. Wide-bandgap semiconductors—such as gallium nitride (GaN) and silicon carbide (SiC)—are now routinely mentioned in technical descriptions due to their ability to enable faster switching, reduced heat generation, and smaller magnetics. This trend is particularly visible in consumer electronics, electric vehicles (EVs), and portable medical devices.

Sustainability and Circular Design

Environmental impact plays a central role in how power supplies are described. By 2026, product datasheets and marketing materials routinely include information on recyclable materials, reduced hazardous substances (RoHS compliance), and carbon footprint during manufacturing. Descriptions may also mention modular designs that allow for easy repair and component replacement, aligning with the EU’s Circular Economy Action Plan. “Eco-mode,” “green packaging,” and “end-of-life recyclability” are increasingly common terms in product narratives.

Customization and Application-Specific Solutions

As industries diversify, generic power supply descriptions are being replaced by application-specific narratives. In 2026, product descriptions are tailored to sectors such as EV charging, renewable energy storage, AI servers, and robotics. For example, a power supply for an AI data center might be described with emphasis on high-current delivery, thermal resilience, and redundancy, while one for medical use highlights isolation, low leakage current, and compliance with IEC 60601 standards.

Rising Demand for Wide Input Voltage and Global Compatibility

Global market integration has led to power supplies being described with broad input voltage ranges (e.g., 85–264 VAC), making them suitable for use across regions without modification. This universality is a selling point in product descriptions, especially for OEMs serving international markets. Enhanced surge protection and compatibility with unstable grids are also highlighted, catering to emerging economies and off-grid applications.

Conclusion

By 2026, the description of a power supply reflects a convergence of efficiency, intelligence, sustainability, and specialization. No longer a background component, the power supply is described as a critical enabler of performance, reliability, and environmental responsibility. As innovation continues, the language used to describe these units will increasingly focus on system integration, lifecycle value, and adaptability to future energy landscapes.

Common Pitfalls Sourcing a Power Supply (Quality, IP)

When sourcing a power supply, overlooking key quality and IP (Ingress Protection) considerations can lead to premature failures, safety hazards, or non-compliance. Avoid these common pitfalls:

1. Ignoring IP Rating Requirements for the Environment

Choosing a power supply without verifying the appropriate IP rating for the operating environment is a frequent mistake. Using an IP20-rated unit in a dusty or damp industrial setting, for example, can result in short circuits or corrosion. Always match the IP rating (e.g., IP65 for dust-tight and water-resistant) to the environmental conditions.

2. Prioritizing Cost Over Long-Term Reliability

Opting for the cheapest option often sacrifices build quality, component lifespan, and thermal management. Low-cost supplies may use inferior capacitors or lack proper safety certifications, increasing the risk of failure and downtime. Invest in reputable brands with proven reliability records.

3. Overlooking Safety and Regulatory Certifications

Failing to verify essential certifications such as UL, CE, or IEC standards can result in non-compliance and legal issues. Different regions require specific approvals—ensure the power supply meets all relevant safety, EMC, and environmental regulations for your target market.

4. Assuming All Power Supplies Are Interchangeable

Even with matching voltage and wattage, power supplies can differ in efficiency, ripple/noise levels, and thermal performance. Substituting without checking these parameters can affect the performance and lifespan of sensitive downstream electronics.

5. Neglecting Thermal Management and Derating

Power supplies often need derating at higher temperatures. Sourcing a unit without considering ambient temperature and ventilation can lead to overheating and reduced efficiency. Always review the manufacturer’s derating curves and ensure adequate heat dissipation in the final application.

6. Underestimating Surge and Transient Protection

Environments with unstable power grids or frequent lightning strikes require robust surge protection. Many low-cost supplies lack adequate transient voltage suppression, increasing the risk of damage. Confirm the unit includes appropriate protection features like MOVs or TVS diodes.

7. Failing to Verify Component Longevity and MTBF

Mean Time Between Failures (MTBF) varies significantly between models. Overlooking this metric can lead to frequent replacements and maintenance. Check for high-quality components (e.g., Japanese capacitors) and realistic MTBF claims backed by testing.

8. Not Considering Future Serviceability and Support

Choosing obscure brands or discontinued models may lead to supply chain issues. Ensure the supplier offers long-term availability, technical support, and accessible spare parts to support maintenance and scalability.

Avoiding these pitfalls ensures a reliable, safe, and compliant power supply that meets both performance needs and environmental demands.

Logistics & Compliance Guide for Description of a Power Supply

Properly describing a power supply in logistics and compliance documentation is critical for safe handling, accurate classification, regulatory compliance, and efficient supply chain operations. This guide outlines key information to include and relevant regulatory considerations.

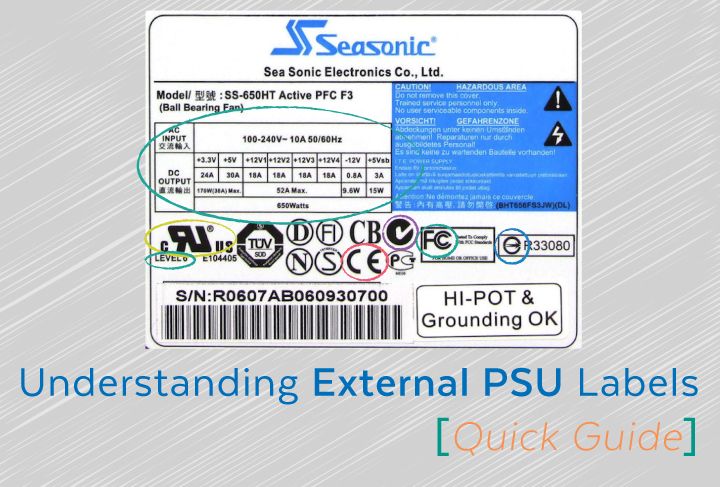

Product Identification and Specifications

Clearly define the power supply with precise technical details to ensure correct handling, compatibility, and regulatory alignment. Include:

– Model Number and Manufacturer: Unique identifiers for traceability.

– Type of Power Supply: e.g., AC/DC, DC/DC, switching, linear, external adapter, internal PSU.

– Input Voltage Range: e.g., 100–240 VAC, 50/60 Hz.

– Output Voltage(s) and Current(s): Specify all outputs (e.g., +12V DC, 5A).

– Power Rating: Total wattage (e.g., 65W).

– Efficiency Rating: e.g., 80 PLUS Bronze, Energy Star compliant.

– Connector Type(s): Physical plug or terminal specifications.

Packaging and Labeling Requirements

Ensure packaging and labeling meet international shipping and safety standards:

– Warning Labels: Include electrical safety symbols (e.g., high voltage), polarity diagrams, and manufacturer compliance marks.

– Compliance Marks: Display relevant certifications such as CE, FCC, UL, CSA, PSE, or KC, depending on target markets.

– Hazard Communication: If applicable, label for lithium batteries (e.g., UN3481 for integrated lithium-ion) under IATA/IMDG/ADR regulations.

– Barcodes and SKUs: For inventory and logistics tracking.

Regulatory Compliance

Adhere to region-specific and international regulations:

– RoHS (Restriction of Hazardous Substances): Confirm compliance with limits on lead, mercury, cadmium, etc. (EU, China, etc.).

– REACH: Ensure no restricted substances are present above thresholds.

– WEEE (Waste Electrical and Electronic Equipment): Provide take-back information where required.

– Energy Efficiency Regulations: Comply with DOE (USA), MEPS (Australia), or Ecodesign directives (EU).

– Safety Standards: Meet IEC/EN 62368-1 for audio/video and IT equipment safety.

Shipping and Transportation

Address logistics concerns based on composition and power source:

– Battery Integration: If the power supply includes a lithium battery, classify under UN3480 (lithium metal) or UN3481 (lithium-ion) and follow IATA DGR, IMDG Code, or 49 CFR regulations.

– Dangerous Goods Declaration: Required when shipping lithium-powered units by air or sea.

– Packaging Standards: Use anti-static, shock-resistant packaging; prevent short circuits.

– SDS (Safety Data Sheet): Provide if requested, especially for units with batteries or hazardous components.

Import/Export Documentation

Prepare accurate customs documentation:

– HS Code (Harmonized System Code): Typically 8504.40 (transformers) or 8504.50 (other electrical power converters), depending on design.

– Country of Origin: Required for tariffs and trade agreements.

– Commercial Invoice and Packing List: Include detailed product description, value, weight, and quantity.

– Certificate of Conformity (CoC): May be required for certain markets (e.g., CE, KC, INMETRO).

Environmental and End-of-Life Considerations

Include information supporting sustainable logistics:

– Recycling Instructions: Provide WEEE symbol and disposal guidance.

– Material Declarations: Share information on recyclable content and disassembly.

– Conflict Minerals Reporting: If applicable, comply with U.S. SEC Rule 13p-1 or EU Conflict Minerals Regulation.

Best Practices

- Use standardized, unambiguous language in all descriptions.

- Verify compliance requirements for each destination country.

- Regularly update documentation to reflect regulatory changes.

- Train logistics personnel on hazardous material handling when relevant.

Accurate and compliant power supply descriptions mitigate risks, avoid customs delays, ensure safety, and support global market access.

In conclusion, the sourcing of this power supply has been carefully evaluated to ensure reliability, efficiency, and compatibility with the intended application. Key factors such as electrical specifications, quality certifications, manufacturing standards, supplier reputation, and total cost of ownership have been considered to identify a solution that meets both performance requirements and long-term operational needs. By selecting a power supply from a reputable source with proven track record and robust technical support, the risk of system downtime or failure is minimized. This strategic sourcing approach ensures optimal performance, regulatory compliance, and scalability for future demands.