The global protractor market is experiencing steady growth, driven by increasing demand across education, engineering, construction, and manufacturing sectors. According to Mordor Intelligence, the global measuring tools market—which includes protractors—is projected to grow at a CAGR of over 4.5% from 2023 to 2028, fueled by rising infrastructure development and precision requirements in industrial applications. As educational institutions and technical fields continue to emphasize accurate angular measurement, the need for high-quality degree protractors has surged. This demand has led to a competitive landscape where manufacturers prioritize durability, precision, and innovation. Based on production scale, global reach, product accuracy, and industry reputation, the following eight companies have emerged as leading degree protractor manufacturers shaping the market today.

Top 8 Degree Protractor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Protractor

Domain Est. 1999

Website: directindustry.com

Key Highlights: Protractor is a state of the art product manufactured by Mitutoyo. It features precision in angle measurement by utilizing it’s high-precision angle gage….

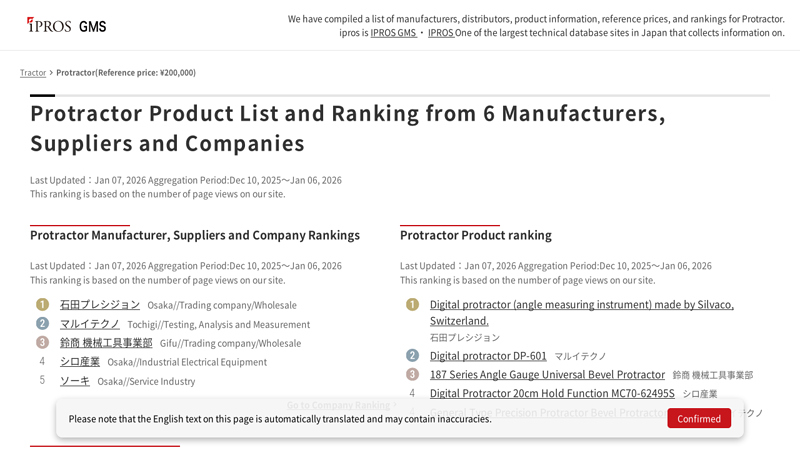

#2 Protractor Product List and Ranking from 6 Manufacturers, Suppliers …

Domain Est. 2002

Website: mono.ipros.com

Key Highlights: We have compiled a list of manufacturers, distributors, product information, reference prices, and rankings for Protractor. ipros is IPROS GMS ……

#3 6″ 180 Degree Protractor

Domain Est. 2010

Website: shopaztecs.com

Key Highlights: In stock Rating 5.0 2 Helix 6 inch Professional Protractor. Shatter resistant. Helix is a leading manufacturer of a wide range of products designed for use either in the home or …

#4 Degree Protractor – Manufacturer, Supplier

Domain Est. 2014

Website: m.dasquatools.com

Key Highlights: As a globally trusted precision measuring tool brand originated from Italy, DASQUA will present its latest high-accuracy measurement solutions to the South ……

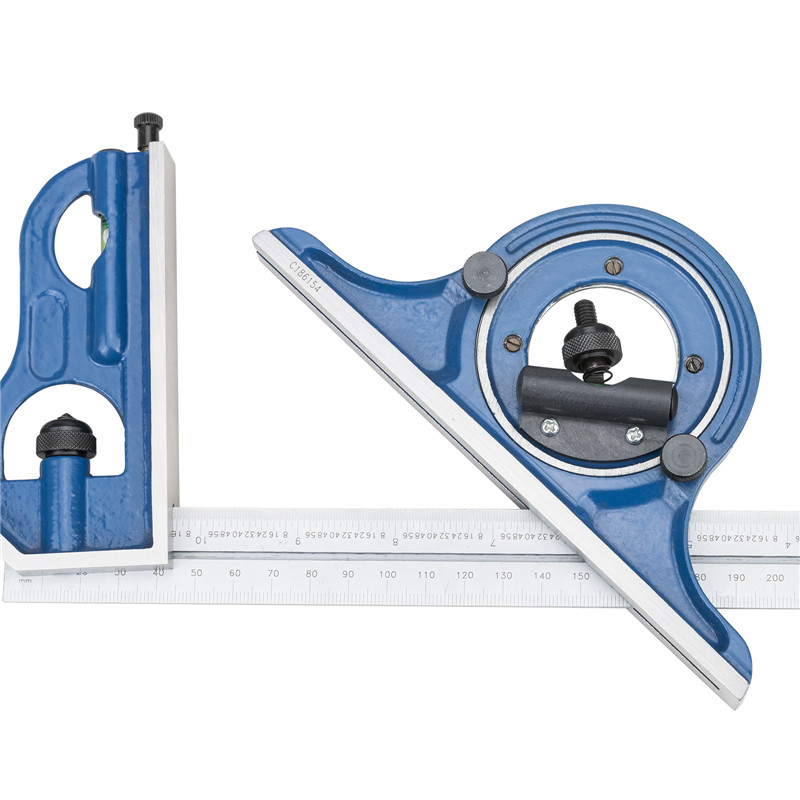

#5 HELIOS PREISSER 0412201 Stainless steel protractor with locking …

Domain Est. 2017

Website: misterworker.com

Key Highlights: In stock 8-day deliveryLocking screw. Stainless steel. Factory standard. 0 – 180°. High precision, laser graduated degree scale. Read more….

#6 ANGLE

Domain Est. 1997

Website: generaltools.com

Key Highlights: Constructed of durable stainless steel, the protractor with its 6″ adjustable arm is ideal for setting bevels, taking measurements and transferring angles….

#7 C359FZ Precision Universal Bevel Vernier Protractor, Graduations …

Domain Est. 1998

Website: starrett.com

Key Highlights: 15-day returnsStarrett 359 Precision Universal Bevel Vernier Protractors with fine adjustment are designed for precision measuring and for laying out angles….

#8 ANGLE, STRAIGHTNESS, FLAT MEASURING INSTRUMENTS

Domain Est. 2003

Website: insize.com

Key Highlights: ANGLE, STRAIGHTNESS, FLAT MEASURING INSTRUMENTS. 37 products. Flatness Measurement Stand Code: 6852 · Digital Angle Meter Code: 2177-121 ……

Expert Sourcing Insights for Degree Protractor

2026 Market Trends for Degree Protractor

The degree protractor market is poised for notable evolution by 2026, driven by technological advancements, shifts in educational methodologies, and increased demand across industrial sectors. This analysis explores key trends shaping the market landscape for degree protractors in the coming years.

Growing Demand in Education and STEM Learning

One of the primary drivers of the degree protractor market in 2026 is the global emphasis on STEM (Science, Technology, Engineering, and Mathematics) education. As schools and universities adopt more hands-on and practical learning models, the need for accurate and durable measuring tools like degree protractors continues to rise. Digital and interactive protractors are increasingly being integrated into classroom kits, especially in K-12 curricula focused on geometry and engineering fundamentals.

Additionally, the rise of e-learning platforms has led to higher demand for at-home learning tools. Parents and educators are investing in tangible tools that complement virtual lessons, giving traditional and digital protractors a dual role in hybrid education models.

Integration of Smart Technology

By 2026, smart protractors—equipped with digital displays, Bluetooth connectivity, and mobile app integration—are expected to gain significant market share. These advanced tools offer real-time angle measurement, data logging, and compatibility with CAD software, making them indispensable in technical fields such as architecture, civil engineering, and industrial design.

The integration of sensors and IoT capabilities allows for greater precision and data-sharing functionality. For example, a smart protractor used in construction can send angle measurements directly to a project management app, improving workflow efficiency and reducing human error.

Expansion in Industrial and Manufacturing Applications

The manufacturing and construction industries are adopting degree protractors for quality control, alignment, and precision assembly tasks. With the rise of automation and precision engineering, especially in automotive and aerospace sectors, the demand for high-accuracy angular measurement tools is increasing.

In 2026, we expect a shift towards rugged, industrial-grade protractors that can withstand harsh environments while maintaining calibration over time. These tools are often part of larger metrology systems and are used alongside laser levels and 3D scanners.

Sustainability and Material Innovation

Environmental concerns are influencing product design in the measuring instrument sector. By 2026, manufacturers are likely to prioritize sustainable materials—such as recycled plastics and biodegradable composites—in the production of degree protractors. This trend aligns with broader corporate sustainability goals and consumer preferences for eco-friendly products.

Moreover, modular and repairable designs are gaining traction, reducing electronic waste from digital protractors and extending product lifespans.

Regional Market Growth

Asia-Pacific is expected to emerge as a high-growth region for degree protractors, driven by rapid industrialization, infrastructure development, and government investments in education. Countries like India, China, and Vietnam are expanding their technical education programs and manufacturing bases, fueling demand for precision instruments.

Meanwhile, North America and Europe maintain steady demand, primarily due to technological innovation and the integration of smart tools in professional and educational settings.

Conclusion

The degree protractor market in 2026 will be shaped by digital transformation, educational demand, industrial precision needs, and sustainability. While traditional protractors will remain relevant in basic education, the future lies in smart, connected, and durable tools that serve both learners and professionals. Companies that innovate in functionality, usability, and environmental impact will lead the market in this evolving landscape.

Common Pitfalls When Sourcing a Degree Protractor (Quality and Intellectual Property)

Sourcing a degree protractor—especially for industrial, educational, or precision measurement applications—can present several challenges. Two major areas where buyers often encounter issues are product quality and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure reliable procurement and legal compliance.

Quality-Related Pitfalls

1. Inaccurate Graduations and Calibration

A primary concern is receiving protractors with misaligned, poorly marked, or imprecise degree scales. Low-cost suppliers may cut corners during manufacturing, resulting in tools that deliver inconsistent or unreliable measurements. Always verify calibration standards (e.g., ISO, ANSI) and request calibration certificates when high precision is required.

2. Inferior Materials and Durability

Some protractors, particularly plastic models, may warp over time or under temperature variations. Metal protractors might use subpar alloys that corrode or wear quickly. Ensure the material specifications match the intended use environment—e.g., stainless steel for industrial settings.

3. Poor Ergonomics and Build Quality

Issues like stiff or loose pivots, unclear viewing windows, or fragile locking mechanisms can hinder usability. These defects may not be apparent from product images or descriptions, making sample testing essential before bulk ordering.

4. Lack of Compliance with Industry Standards

Not all protractors meet recognized measurement standards. Sourcing from suppliers who don’t adhere to international standards (such as ISO 89 or ASTM E131) can lead to compatibility and accuracy problems in regulated industries.

Intellectual Property (IP) Pitfalls

1. Counterfeit or Copycat Designs

Many precision protractors, especially digital or specialized models, are protected by patents or design rights. Sourcing from unauthorized manufacturers may result in purchasing counterfeit products that infringe on IP, exposing your business to legal risk and reputational damage.

2. Unauthorized Use of Brand Names or Logos

Suppliers may falsely label generic products with well-known brand names (e.g., Starrett, Mitutoyo) to suggest higher quality. This not only violates trademark laws but also misleads buyers about product origin and performance.

3. Lack of IP Documentation from Suppliers

Reputable suppliers should be able to provide proof of IP ownership or licensing for branded or patented tools. Failing to verify this documentation increases the risk of unwittingly distributing infringing products.

4. Grey Market Imports

Purchasing protractors through unofficial distribution channels may result in IP violations, especially if the products were not intended for your market. These items might lack warranties, support, or compliance with local regulations.

Mitigation Strategies

- Request product samples and conduct accuracy tests.

- Audit suppliers for certifications (ISO, CE, etc.).

- Verify IP rights and request licensing documentation.

- Source from authorized distributors or directly from OEMs.

- Include quality and IP compliance clauses in procurement contracts.

Avoiding these pitfalls ensures you obtain reliable, legally compliant degree protractors that meet your operational and regulatory requirements.

Logistics & Compliance Guide for Degree Protractor

This guide outlines the essential logistics and compliance considerations for the distribution, import/export, and use of degree protractors—commonly used measuring tools in education, engineering, and design. Adhering to these guidelines ensures smooth operations and regulatory compliance across jurisdictions.

Product Classification & HS Code

Degree protractors are typically classified under the Harmonized System (HS) for international trade. The most common HS code is 9017.80, which covers “Drawing, marking-out or mathematical calculating instruments.” This classification affects tariffs, import duties, and customs clearance. Confirm the specific HS code with local customs authorities, as sub-classifications may vary by country and material composition (e.g., plastic vs. metal).

Packaging & Labeling Requirements

Protractors must be packaged to prevent damage during transit. Standard retail packaging should include:

– Clear identification of product type (e.g., “180° Transparent Protractor”)

– Measurement scale (degrees, sometimes radians)

– Material type (e.g., “Made of PS Plastic”)

– Manufacturer or brand name

– Safety and compliance markings (e.g., CE, UKCA, or FCC if applicable)

– Country of origin labeling (mandatory in most markets, including the U.S., EU, and UK)

Bulk shipments should use durable, recyclable packaging with proper handling labels (e.g., “Fragile,” “Keep Dry”).

Import/Export Regulations

When shipping internationally:

– Verify import restrictions; degree protractors are generally unrestricted but may require conformity assessment in certain regions.

– Complete commercial invoices, packing lists, and certificates of origin.

– For shipments to the EU, ensure compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) if the protractor contains regulated substances.

– In the U.S., customs clearance requires accurate declaration under HTS code 9017.80. No FDA or FCC licensing is required unless electronic components are included.

Safety & Compliance Standards

While mechanical protractors are low-risk, compliance with regional safety standards is recommended:

– EU: CE marking under the General Product Safety Directive (2001/95/EC). Ensure no sharp edges and non-toxic materials.

– UK: UKCA marking required for products sold in Great Britain; follow UK GPSR (General Product Safety Regulations 2005).

– USA: Comply with CPSIA (Consumer Product Safety Improvement Act) if intended for children—limit lead and phthalates in materials.

– Canada: Adhere to the Canada Consumer Product Safety Act (CCPSA); ensure labeling in English and French.

Transport & Handling

- Use standard parcel or freight services depending on volume.

- Avoid extreme temperatures and humidity to prevent warping (especially plastic models).

- Stack packages securely; use void fill to minimize movement.

- For air freight, ensure packaging meets IATA guidelines for general cargo.

Documentation & Recordkeeping

Maintain records for at least 5 years, including:

– Bills of lading

– Commercial invoices

– Certificates of compliance or conformity

– Test reports (e.g., REACH, CPSIA)

– Import/export licenses (if required)

End-of-Life & Environmental Compliance

- Design for recyclability; label plastic types (e.g., PS, PET).

- Comply with WEEE (EU) or similar e-waste directives if the protractor includes electronic components.

- Provide disposal guidance on packaging or website.

By following this guide, suppliers, distributors, and retailers can ensure efficient logistics and full regulatory compliance for degree protractors in global markets. Always consult local authorities for jurisdiction-specific requirements.

In conclusion, sourcing a degree protractor requires careful consideration of accuracy, material quality, durability, and intended use—whether for educational, engineering, architectural, or DIY purposes. Evaluating suppliers based on reliability, product certifications, cost-efficiency, and customer reviews ensures the acquisition of a high-quality instrument that meets technical and practical requirements. Additionally, opting for reputable manufacturers or established brands helps guarantee consistency in measurement precision and long-term usability. Ultimately, a well-sourced degree protractor enhances measurement accuracy and supports success in academic, professional, and technical applications.