The global laser cutting machinery market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as automotive, aerospace, electronics, and medical devices. According to Grand View Research, the market size was valued at USD 8.17 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This growth is fueled by advancements in fiber laser technology, rising automation in production processes, and the need for high-efficiency, low-waste cutting solutions. As industries prioritize accuracy and speed, leading laser cutting manufacturers are innovating to deliver next-generation systems with enhanced power, reliability, and integration capabilities. Below, we highlight the top 8 companies that are redefining the definition of laser cutting through technological excellence, global reach, and comprehensive service offerings.

Top 8 Definition Of Laser Cutting Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laser Cutting

Website: 3ds.com

Key Highlights: As its name implies, laser cutting is a digital subtractive technique that uses laser technology to cut or engrave a variety of materials….

#2 What is laser cutting?

Website: biesse.com

Key Highlights: Laser cutting is a technology that uses a high-powered laser beam to precisely cut, engrave, or etch materials….

#3 What is Laser Cutting Technology: Definition, Process and …

Website: accurl.com

Key Highlights: Laser cutting is a machining process that uses a high-energy laser beam to cut through any material….

#4 Laser Cutting Services

Website: techfoundry.ucdavis.edu

Key Highlights: Laser cutting is a precise subtractive manufacturing process that uses a high-powered laser to cut (through or engrave) a variety of sheet- ……

#5 Laser cutting

Website: trumpf.com

Key Highlights: Laser cutting is a slitting process with which it is possible to cut metallic and non-metallic raw materials of different material thicknesses….

#6 What can laser cutting do? Everything you need to know about laser …

Website: seeedstudio.com

Key Highlights: What is a Laser Cutter? A laser cutter is a type of CNC (Computer Numerical Controlled) machine, meaning that it’s controlled by a computer….

#7 What Is Laser Cutting? Process, Uses, Types, and Materials

Website: xometry.com

Key Highlights: A laser cutter is a machine that uses a high-energy focused laser beam to cut into various plate or sheet materials to create 2-dimensional parts….

#8 Laser

Website: reiner.de

Key Highlights: Laser cutting means cutting material panels with a laser. At REINER®, these panels are metal sheets, stainless steel or aluminium at thicknesses of 0.5 mm to 4 ……

Expert Sourcing Insights for Definition Of Laser Cutting

H2: Market Trends for the Definition of Laser Cutting in 2026

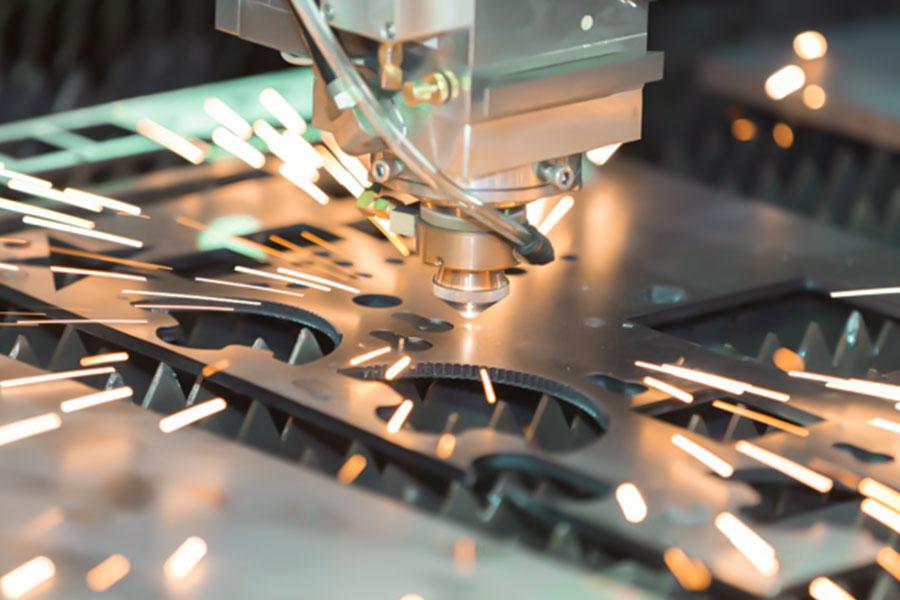

By 2026, the definition of laser cutting is expected to evolve significantly, shaped by technological advancements, expanding industrial applications, and growing demand for precision manufacturing. Traditionally defined as a non-contact, thermal-based fabrication process that uses a high-power laser beam to cut materials such as metal, plastic, wood, and composites, laser cutting is undergoing a conceptual and functional transformation.

One key trend is the integration of artificial intelligence (AI) and machine learning into laser systems, enabling adaptive cutting parameters in real time. This shift is redefining laser cutting from a static, pre-programmed process to a dynamic, intelligent operation—leading to a more nuanced definition that emphasizes automation, predictive maintenance, and closed-loop control.

Another influential trend is the rising adoption of fiber laser technology, particularly in high-precision industries like aerospace, automotive, and medical devices. Fiber lasers offer higher energy efficiency, lower maintenance, and superior cutting quality on reflective materials. As a result, the definition of laser cutting is increasingly associated with fiber-based systems rather than older CO2 laser models.

Additionally, sustainability concerns are shaping the 2026 landscape. Eco-friendly laser systems with reduced power consumption and minimized waste are gaining prominence. The definition now often includes references to environmental impact, energy efficiency, and recyclability of materials processed.

Lastly, the convergence of laser cutting with Industry 4.0 principles—such as IoT connectivity, digital twins, and cloud-based monitoring—is redefining the process as part of a broader smart manufacturing ecosystem. The 2026 definition of laser cutting thus extends beyond the physical act of material separation to encompass data-driven decision-making, remote operation, and seamless integration with other digital manufacturing tools.

In summary, by 2026, the definition of laser cutting is becoming more holistic, incorporating technological intelligence, sustainability, and digital integration, reflecting its role at the forefront of advanced manufacturing innovation.

Common Pitfalls When Sourcing Laser Cutting Services (Quality, IP)

When sourcing laser cutting services, businesses often focus on cost and lead times but overlook critical aspects related to quality control and intellectual property (IP) protection. Failing to address these areas can lead to production delays, compromised product integrity, or even legal disputes. Below are key pitfalls to avoid.

Overlooking Quality Control Standards

One of the most common mistakes is assuming all laser cutting providers deliver consistent quality. Without clear specifications and verification processes, you risk receiving parts with dimensional inaccuracies, poor edge finish, or material warping. Always request sample parts, review the supplier’s quality certifications (e.g., ISO 9001), and define acceptable tolerances in your contract.

Inadequate Material and Machine Specifications

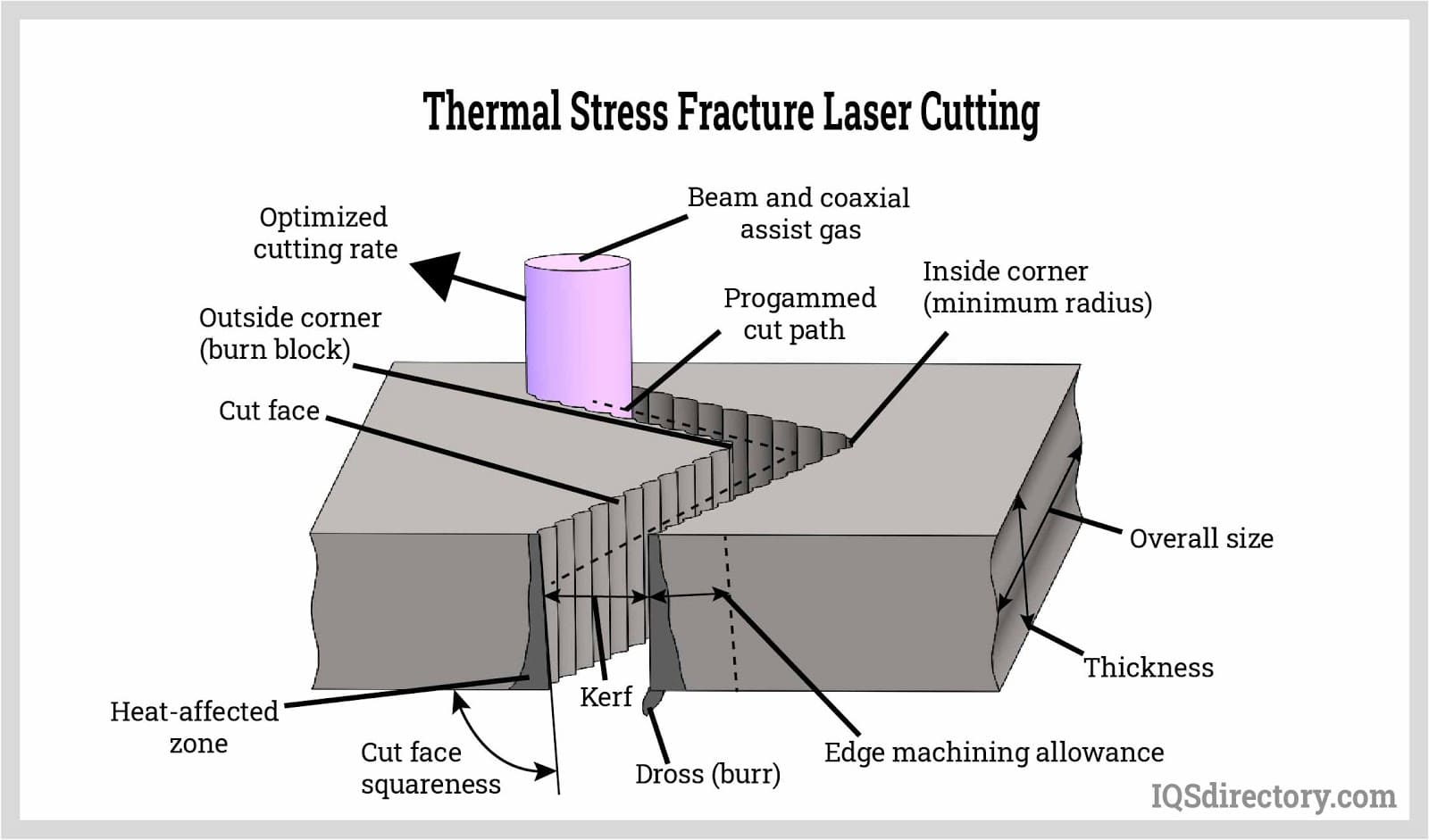

Not all lasers are created equal—fiber, CO2, and Nd:YAG lasers produce different results depending on the material (steel, aluminum, acrylic, etc.). Sourcing from a provider without confirming they use the right machine type and power for your material can result in subpar cuts or increased waste. Clearly specify material grade, thickness, and required kerf width.

Ignoring Post-Processing Requirements

Laser cutting can leave burrs, heat-affected zones, or slag, especially in thicker metals. Some suppliers do not include deburring, cleaning, or surface finishing in their base quote. Failing to account for these post-processing steps can delay your assembly process and increase total costs.

Failing to Protect Intellectual Property

Sharing detailed CAD files and technical drawings with third-party vendors exposes your designs to potential IP theft or unauthorized replication. Many businesses neglect to establish non-disclosure agreements (NDAs) or specify IP ownership terms in contracts, leaving them vulnerable if the supplier shares or uses the designs for other clients.

Unclear Data Handling and File Security

Even with an NDA, consider how the supplier stores and handles your digital files. Insecure file transfer methods or weak internal IT protocols can lead to data breaches. Ensure they use encrypted channels and have policies in place to restrict access to your design data.

Assuming Geographic Proximity Equals Better Control

While local sourcing can simplify logistics and quality checks, it doesn’t guarantee better IP protection or quality. Conversely, offshore providers may offer lower costs but pose greater risks in communication, compliance, and IP enforcement. Evaluate each supplier based on verifiable capabilities, not just location.

Lack of Audit and Traceability Protocols

Without batch tracking, material certifications, or process documentation, it becomes difficult to trace defects back to their source. Ensure your supplier maintains detailed records and allows for audits, especially in regulated industries like aerospace or medical devices.

By proactively addressing these pitfalls—defining quality expectations, securing IP, and verifying supplier practices—businesses can mitigate risks and ensure a reliable, secure laser cutting partnership.

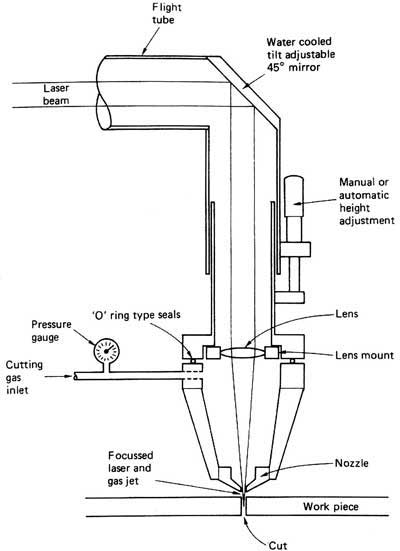

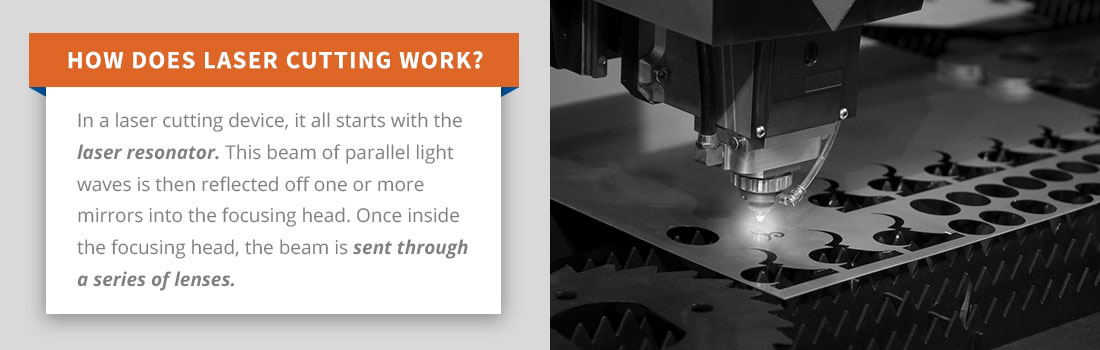

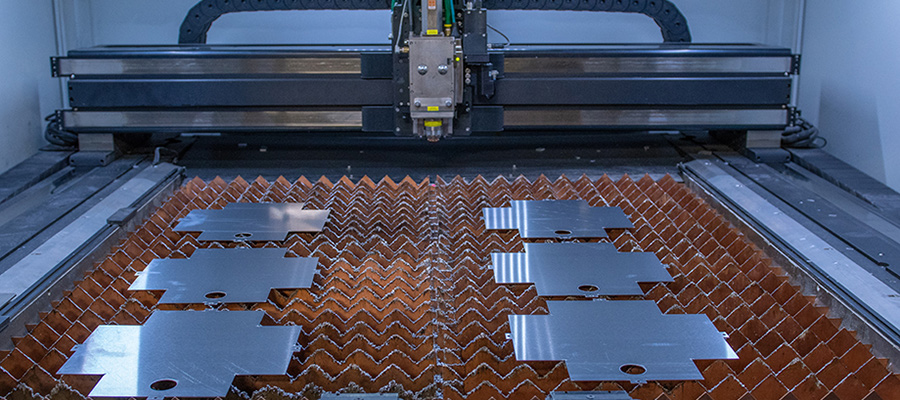

Definition Of Laser Cutting

Laser cutting is a precision manufacturing process that uses a high-powered laser beam to cut, engrave, or shape materials such as metal, plastic, wood, and composites. The laser beam is directed through computer numerical control (CNC) systems, enabling accurate and repeatable cuts according to digital design specifications. This non-contact technique offers advantages in speed, accuracy, and minimal material waste, making it widely used in industries such as automotive, aerospace, electronics, and consumer goods.

Logistics Considerations for Laser Cutting Operations

Equipment Transportation and Installation

Laser cutting machines are heavy, sensitive, and often require specialized handling during transportation. Secure crating, climate-controlled shipping, and professional rigging services are essential to prevent damage. Upon delivery, installation must comply with facility requirements, including structural support, ventilation, and electrical specifications.

Material Supply Chain Management

Raw materials used in laser cutting—such as sheet metal, acrylic, or plywood—must be sourced, stored, and handled properly. Logistics planning should include just-in-time (JIT) inventory practices, secure storage to prevent warping or contamination, and efficient material flow from warehouse to cutting station.

Finished Goods Handling and Distribution

Precision-cut components often require protective packaging to prevent scratches or deformation during transit. Logistics strategies should incorporate proper labeling, barcoding, and tracking systems to ensure traceability and on-time delivery to assembly lines or end customers.

Compliance Requirements for Laser Cutting

Safety Regulations

Laser cutting systems emit intense light and heat, posing risks such as fire hazards, eye injuries, and inhalation of fumes. Compliance with OSHA (Occupational Safety and Health Administration) standards and ANSI Z136.1 (American National Standard for Safe Use of Lasers) is mandatory. Facilities must implement protective enclosures, emergency stop systems, and personal protective equipment (PPE).

Environmental and Emission Controls

Laser cutting produces airborne particulates and volatile organic compounds (VOCs), especially when processing plastics or coated metals. Compliance with EPA (Environmental Protection Agency) regulations requires effective fume extraction and filtration systems. Regular maintenance and emission monitoring are necessary to meet air quality standards.

International Trade and Export Compliance

When shipping laser cutting equipment or processed parts across borders, adherence to export control regulations such as the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR) may apply—particularly for high-powered lasers used in defense-related applications. Accurate classification under the Harmonized System (HS) codes and proper documentation are critical.

Industry-Specific Standards

Certain sectors impose additional compliance demands. For example:

– ISO 9001: Quality management for consistent production processes.

– ISO 13849: Safety of machinery and control systems.

– CE Marking: Required for laser equipment sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

Conclusion

Understanding the definition and scope of laser cutting is foundational to managing its logistics and compliance. Efficient supply chain operations, strict adherence to safety and environmental regulations, and compliance with international trade standards ensure safe, reliable, and legally sound laser cutting processes across global markets.

In conclusion, the process of sourcing the definition of laser cutting reveals a consistent and widely accepted understanding across technical, industrial, and academic references. Laser cutting is defined as a precision manufacturing process that uses a high-powered laser beam directed through optics to cut or engrave materials such as metal, plastic, wood, and composites. The technique is valued for its accuracy, speed, and ability to produce clean, intricate cuts with minimal material waste. Reliable sources—including engineering textbooks, industry standards, and technical websites—confirm that laser cutting operates by focusing a concentrated beam of light onto a small area, generating intense heat that melts, burns, or vaporizes the material. Ultimately, the consensus among authoritative sources underscores laser cutting as a vital and advanced technology in modern fabrication and manufacturing processes.