The global hinge manufacturing market is experiencing steady growth, driven by rising demand across residential, commercial, and industrial sectors. According to Grand View Research, the global hinges market size was valued at USD 19.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is fueled by increasing construction activities, rising adoption of smart and ergonomic furniture, and advancements in materials like stainless steel and polymer composites. As industries prioritize durability, precision, and design flexibility, the role of high-performance hinge manufacturers has become increasingly critical. In this evolving landscape, identifying the top definition hinge manufacturers—those leading in innovation, quality, and global reach—is essential for sourcing excellence and supply chain resilience.

Top 10 Definition Hinge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

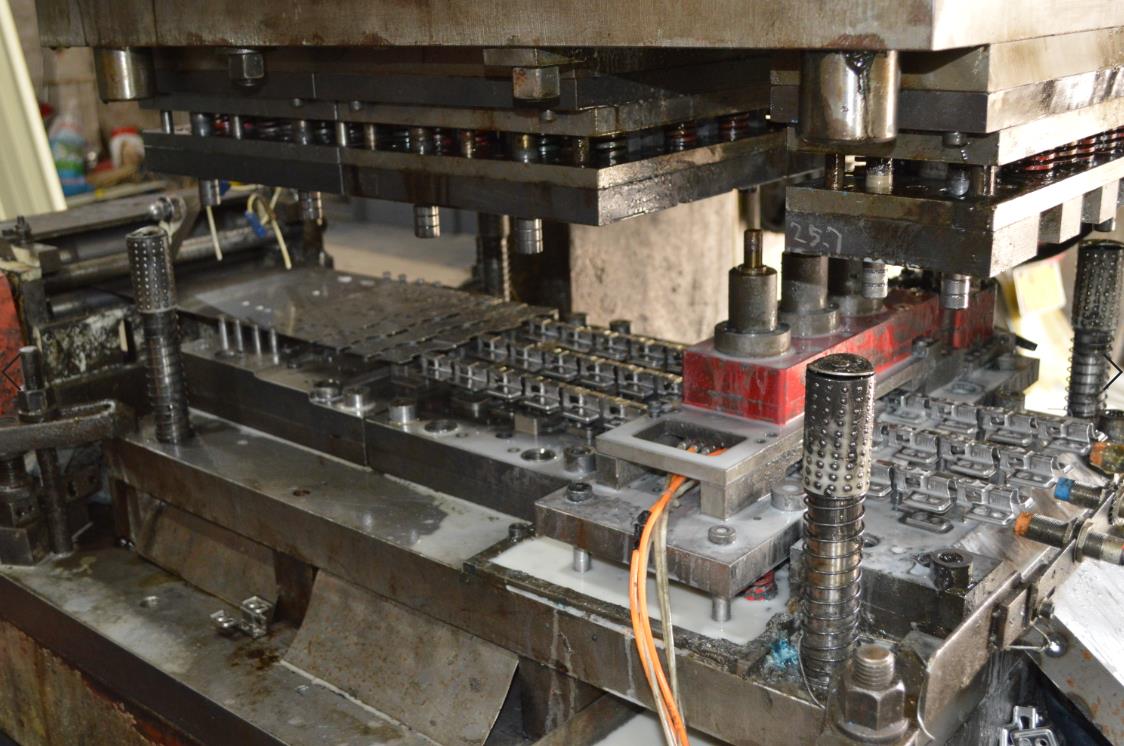

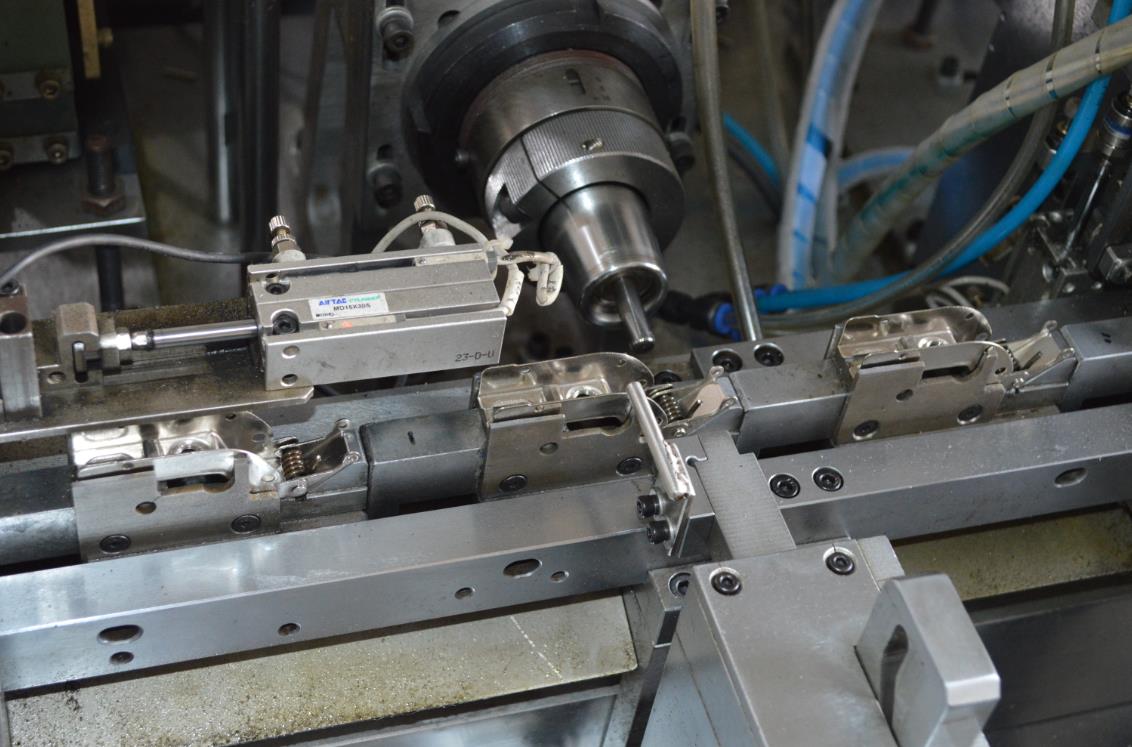

#1 Industrial Hinge Manufacturers: Machining Capabilities

Domain Est. 1995

Website: weberknapp.com

Key Highlights: Industrial hinge manufacturing isn’t easy — there’s a lot of sweat involved in making custom motion control and counterbalance hinges….

#2 Slip Hinge Suppliers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: Instantly discover Slip Hinge manufacturers, who have options for immediate shopping from a large selection of industrial products made to match your specs….

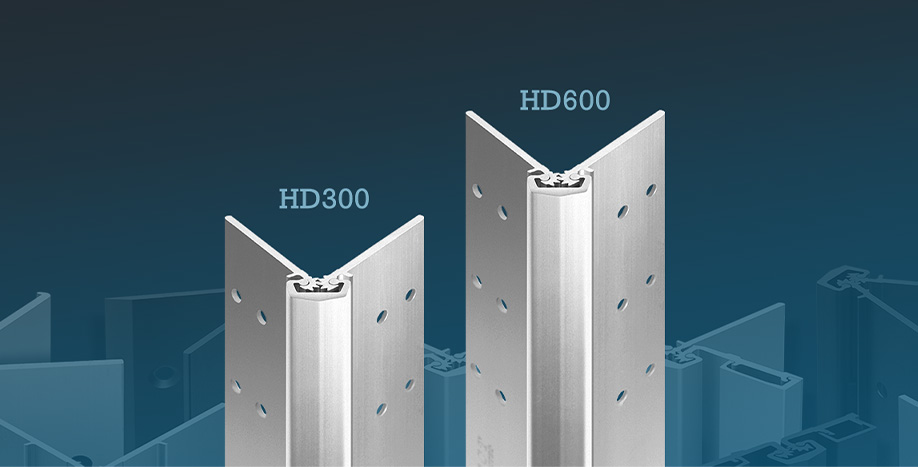

#3 Heavy Duty Door Hinge Manufacturers: How to Evaluate a …

Domain Est. 2016

Website: fornd.com

Key Highlights: A heavy duty door hinge manufacturer is a producer capable of designing, machining, finishing, and verifying hinges that reliably carry high ……

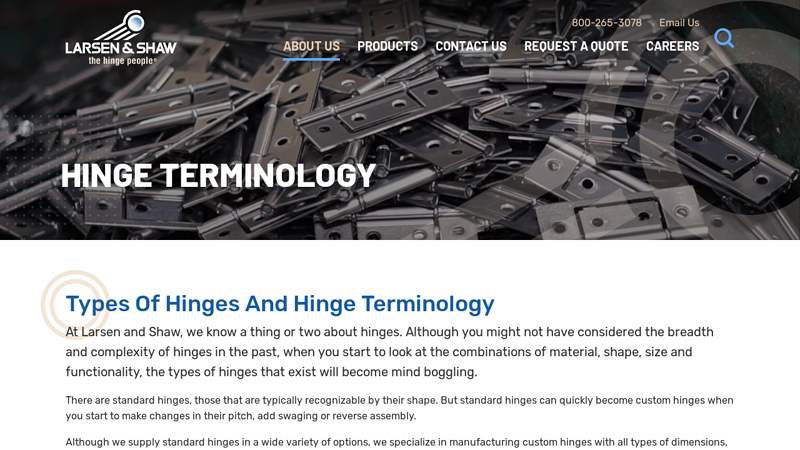

#4 Hinge Terminology

Domain Est. 1997

Website: larsenhinge.com

Key Highlights: We specialize in manufacturing custom hinges with all types of dimensions, knuckle sizes, offsets and so much more….

#5 Lock & Hinge Manufacturing in the UK industry analysis

Domain Est. 1997

Website: ibisworld.com

Key Highlights: Products and services covered in the Lock & Hinge Manufacturing industry in the United Kingdom include Hinges, Locks for armoured cupboards and bicycles, Metal ……

#6 SELECT Hinges

Domain Est. 1999

Website: select-hinges.com

Key Highlights: SELECT geared hinges, designed for new construction or retrofit applications, reduce maintenance costs while outperforming traditional hinges….

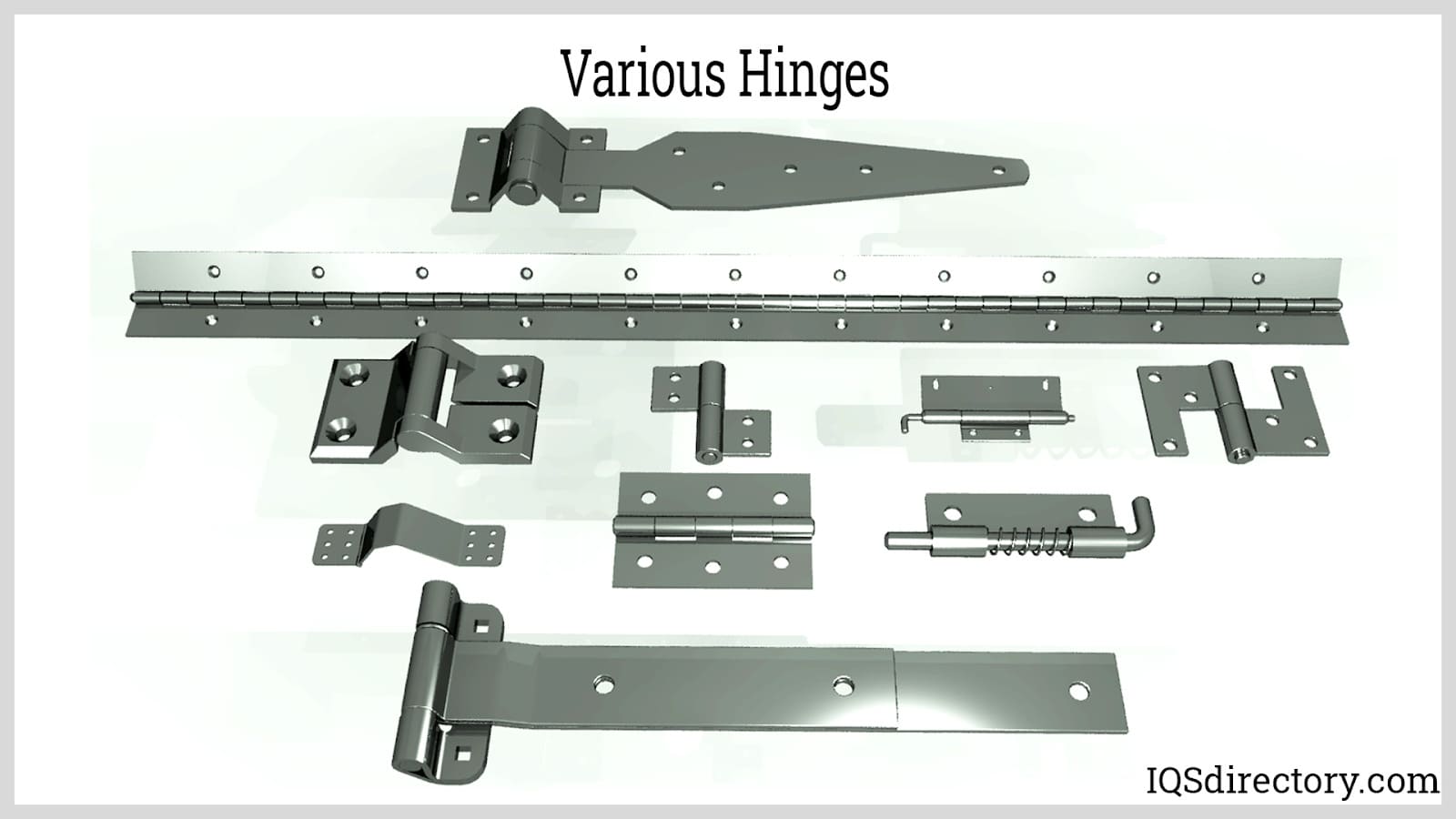

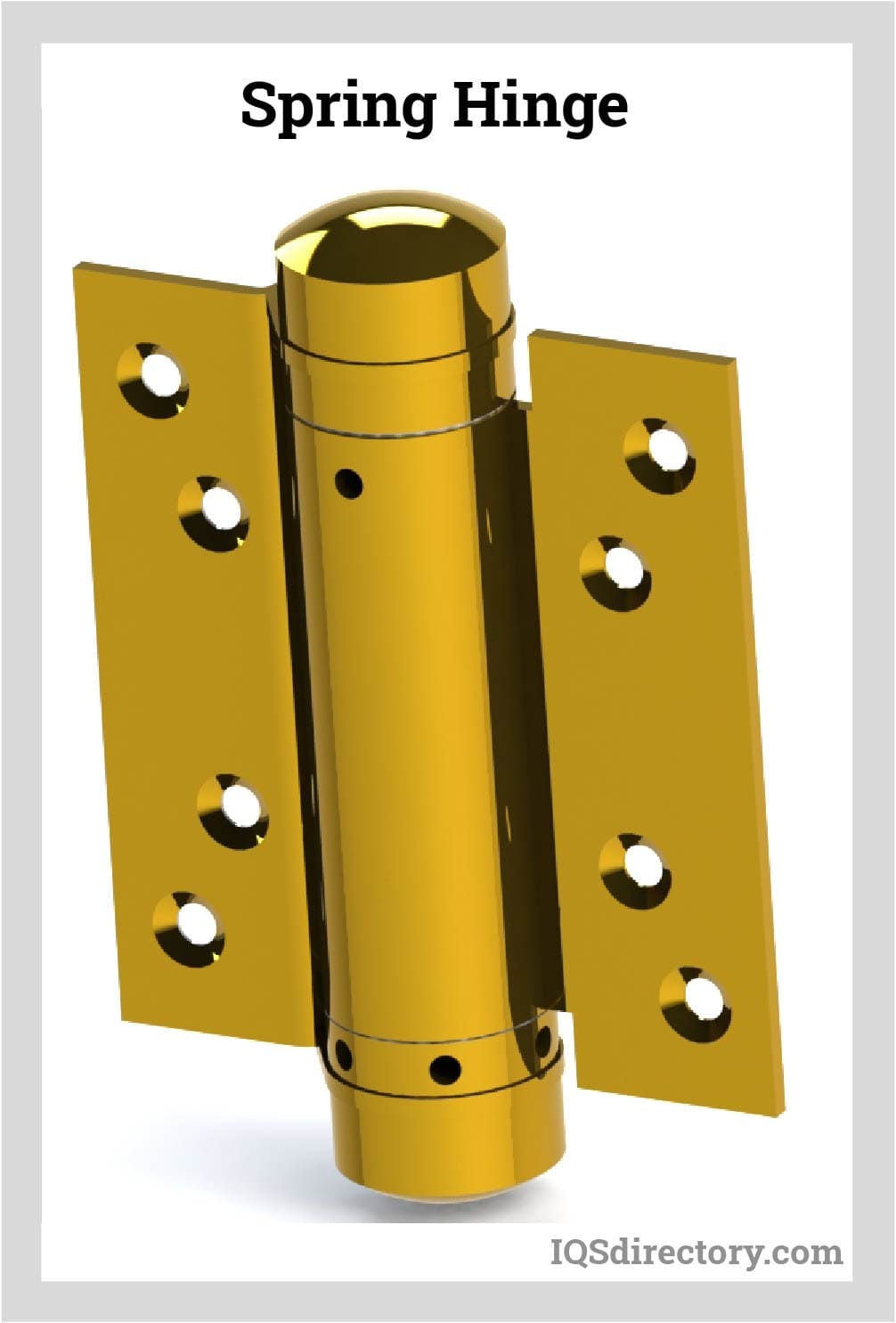

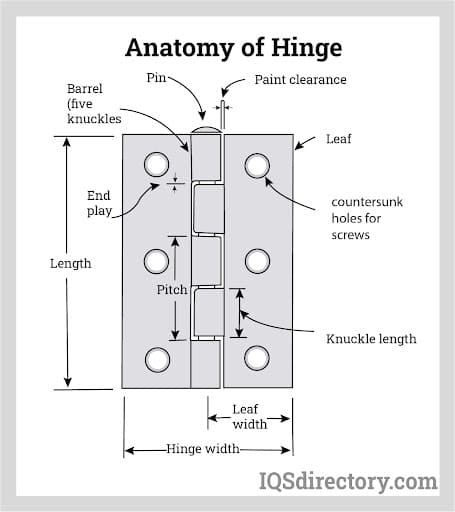

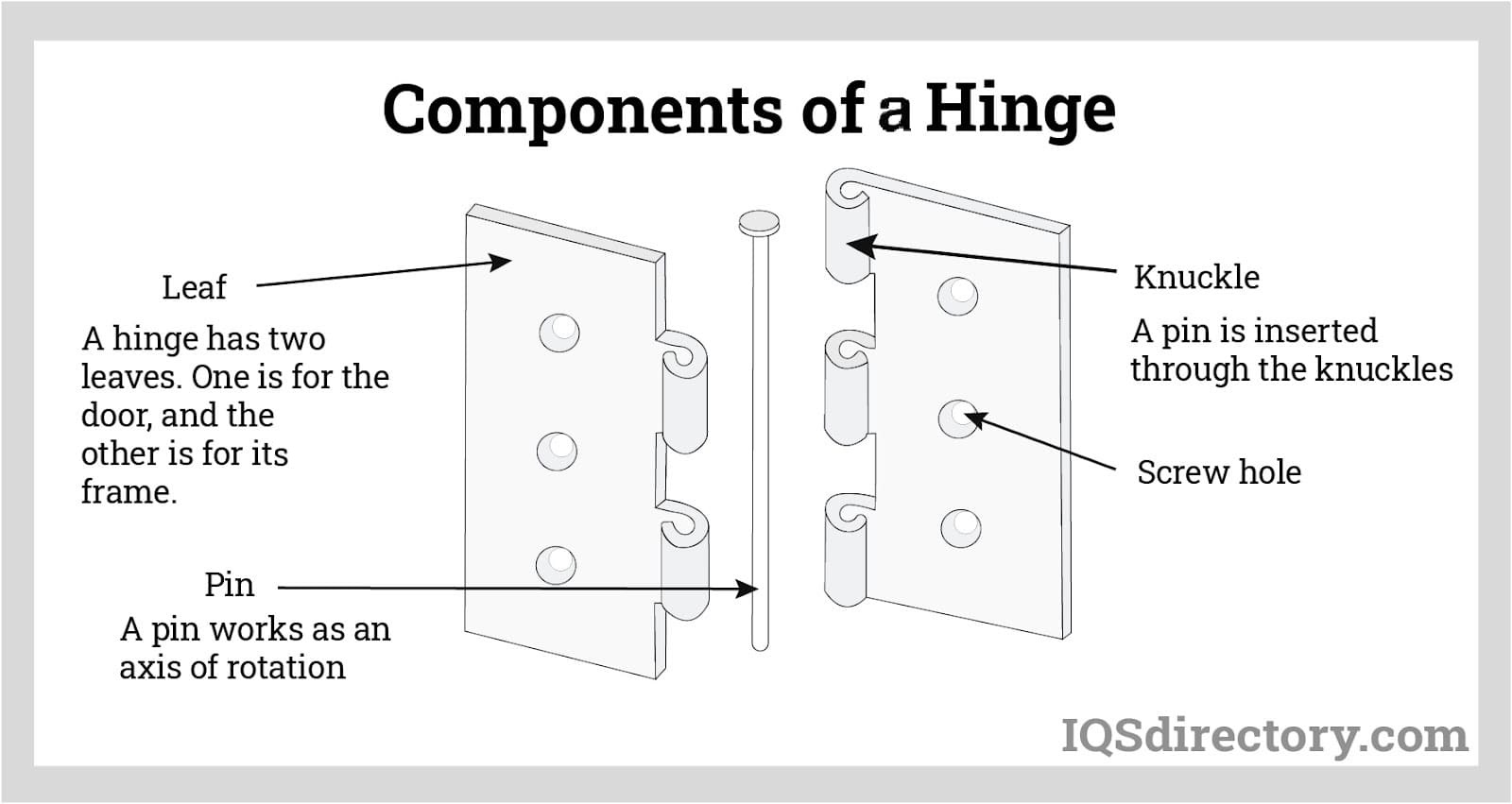

#7 Types, Uses, Components, and Considerations of Hinges

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: Chapter 1: Understanding What a Hinge Is: A hinge is a mechanical device designed to join two elements, allowing them to pivot around a fixed axis while ……

#8 Terms

Domain Est. 2012

Website: hinge.co

Key Highlights: You may cancel your subscription, without penalty or obligation, at any time prior to midnight of the third business day following the date you subscribed….

#9 What are Adjustable Torque Hinges

Domain Est. 2024

Website: hingesmanufacturers.com

Key Highlights: HTAN adjustable torque hinges—smooth, durable, and customizable. Perfect for doors, lids, and screens in electronics, medical, ……

#10 The Hinge brand guidelines

Website: hinge-preview.vercel.app

Key Highlights: Black and white are the primary colors of the Hinge brand. They are intentionally not absolute in value to give them a more organic feel….

Expert Sourcing Insights for Definition Hinge

H2: 2026 Market Trends Forecast for Definition Hinge

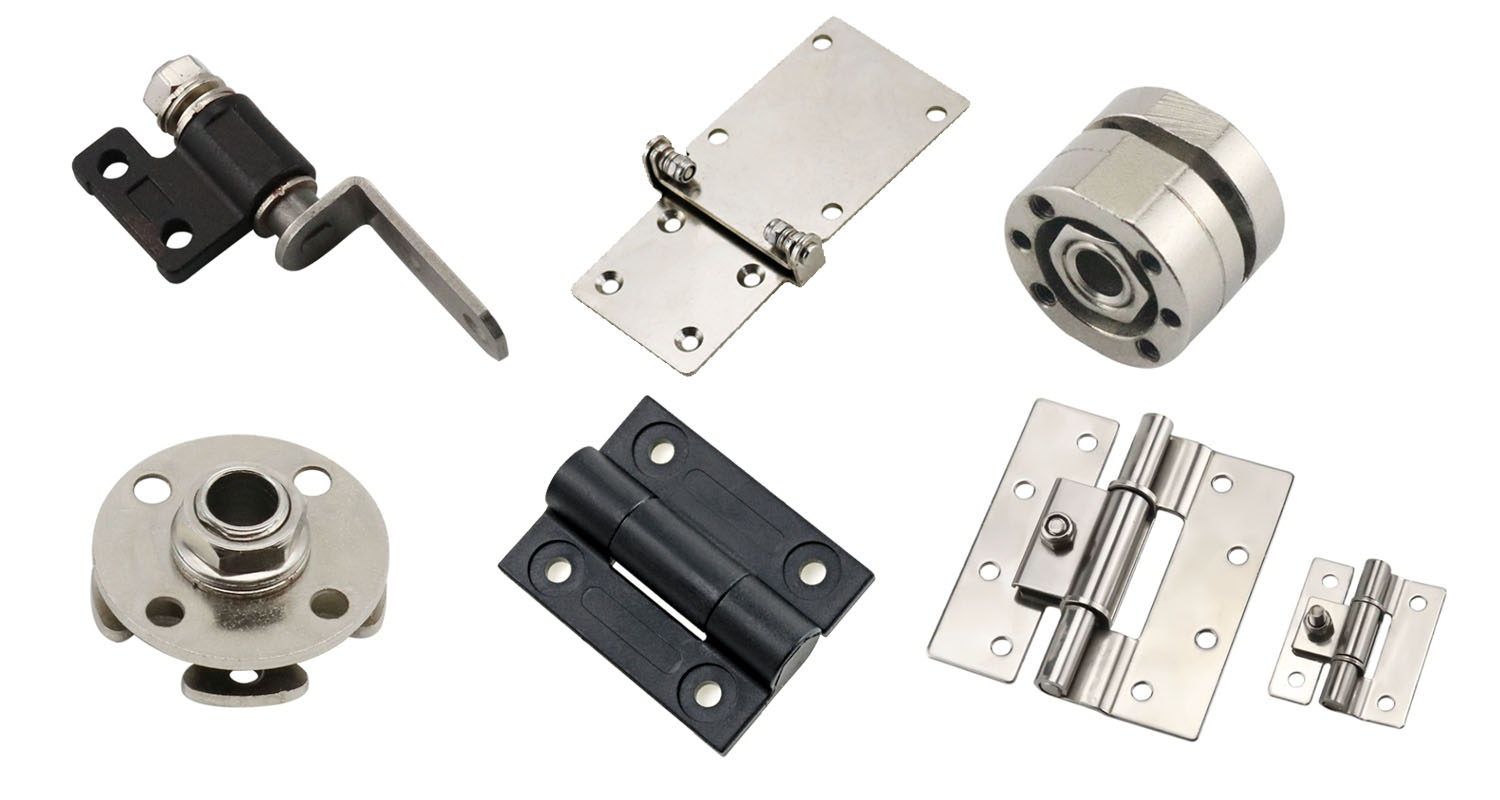

As we approach 2026, the market for Definition Hinges—specialized mechanical hinges designed to offer precise motion control, durability, and application-specific performance in industrial, architectural, and consumer applications—is poised for significant transformation. Driven by advances in materials science, smart technologies, and evolving industry demands, several key trends are expected to shape the Definition Hinge market during this period.

-

Increased Demand for Smart and IoT-Integrated Hinges

By 2026, integration with smart technologies and the Internet of Things (IoT) will become a dominant trend in the hinge sector. Definition Hinges are increasingly being embedded with sensors, micro-actuators, and connectivity modules to enable real-time monitoring of door usage, alignment, wear, and tamper detection. This is particularly relevant in smart buildings, automotive systems, and medical equipment, where predictive maintenance and automation are priorities. -

Growth in High-Performance Materials

The adoption of advanced materials such as carbon fiber composites, high-grade stainless steel alloys, and polymer-based hybrids will accelerate. These materials enhance the durability, corrosion resistance, and weight efficiency of Definition Hinges—critical factors in aerospace, automotive, and outdoor architectural applications. As sustainability becomes more central, recyclable and low-carbon footprint materials will also gain traction. -

Expansion in Healthcare and Medical Device Applications

The medical equipment sector is expected to be a high-growth market for Definition Hinges by 2026. Precision hinges are essential in imaging devices, surgical robots, and adjustable hospital furniture, where reliability and sterile design are paramount. Demand will be fueled by aging populations and increased investments in healthcare infrastructure globally. -

Customization and Modular Design

Manufacturers will increasingly focus on modular and customizable hinge solutions to meet the diverse requirements across industries. With digital manufacturing tools like 3D printing and AI-driven design software, companies can offer low-volume, high-precision hinges tailored to specific load, motion, or environmental conditions—without significantly increasing production costs. -

Sustainability and Circular Economy Practices

Environmental regulations and corporate sustainability goals will push hinge manufacturers toward longer product lifecycles, repairability, and recyclability. By 2026, leaders in the Definition Hinge market are expected to adopt circular economy principles, including take-back programs, remanufacturing, and the use of recycled materials in production. -

Geographic Shifts and Supply Chain Resilience

Asia-Pacific, particularly China and India, will continue to be major hubs for both production and consumption of Definition Hinges due to rapid industrialization and urban development. However, North America and Europe are expected to see growth in high-value, precision-engineered hinges driven by automation and defense sectors. Companies will also localize supply chains to mitigate geopolitical and logistical risks, increasing regional manufacturing capacity. -

Rise of Automation and Robotics

The growing deployment of industrial robots and automated guided vehicles (AGVs) will require hinges capable of withstanding repetitive stress and precise articulation. Definition Hinges that support modular robotic joints or protective enclosures will see heightened demand, especially in logistics, manufacturing, and warehouse automation.

In conclusion, the 2026 market for Definition Hinges will be characterized by technological innovation, sector-specific customization, and a stronger emphasis on sustainability and intelligence. Companies that invest in R&D, digital manufacturing, and cross-industry collaboration will be best positioned to capture emerging opportunities in this evolving landscape.

Common Pitfalls Sourcing Definition Hinges (Quality, IP)

Sourcing definition hinges—components critical to the functionality and reliability of many mechanical systems—can present significant challenges, especially when quality and intellectual property (IP) concerns are involved. Below are some common pitfalls organizations encounter during the procurement process.

Poor Quality Control and Inconsistent Manufacturing Standards

One of the most frequent issues in sourcing definition hinges is inconsistent product quality. Suppliers, particularly those in low-cost regions, may lack stringent quality control processes, leading to dimensional inaccuracies, substandard materials, or poor surface finishes. These inconsistencies can compromise the performance and safety of the final product, resulting in costly rework, recalls, or warranty claims.

To mitigate this, it’s essential to:

– Require detailed material certifications and production process documentation.

– Conduct on-site supplier audits and implement regular quality inspections.

– Enforce adherence to international standards (e.g., ISO 9001, AS9100 for aerospace applications).

Lack of Technical Specifications and Miscommunication

Definition hinges are often highly engineered components requiring precise technical specifications. A common pitfall occurs when sourcing teams fail to communicate clear design requirements, tolerances, load specifications, or environmental resistance needs. Ambiguities in RFQs (Request for Quotation) can result in non-conforming parts or functional mismatches.

Best practices include:

– Providing comprehensive engineering drawings and 3D models.

– Establishing a clear definition of “definition hinge” within the procurement context (e.g., proprietary designs or custom configurations).

– Engaging engineering teams early in the sourcing process to validate supplier capabilities.

Intellectual Property (IP) Risks and Unauthorized Replication

Definition hinges, especially those with proprietary designs or performance characteristics, are vulnerable to IP theft. When sourcing from third-party manufacturers—particularly in regions with weak IP enforcement—there is a risk that design specifications may be copied, reverse-engineered, or sold to competitors.

Key IP protection strategies:

– Execute robust non-disclosure agreements (NDAs) and legal contracts with clear IP ownership clauses.

– Limit the distribution of full design data; use segmented or obfuscated drawings where possible.

– Partner with trusted suppliers with a proven track record of IP compliance.

– Consider patenting unique hinge mechanisms or filing design registrations where applicable.

Overlooking Supply Chain Transparency

A lack of visibility into the hinge supply chain increases risks related to sub-tier suppliers, material traceability, and counterfeit parts. Some suppliers may outsource production without disclosure, leading to uncontrolled quality variances and potential IP exposure.

Mitigation steps:

– Require full supply chain disclosure and conduct sub-tier audits.

– Implement traceability systems (e.g., lot numbering, material test reports).

– Use supplier qualification programs to assess compliance with ethical and legal standards.

Conclusion

Sourcing definition hinges requires a strategic balance between cost-efficiency and risk management. By proactively addressing quality inconsistencies, clarifying technical requirements, protecting intellectual property, and ensuring supply chain transparency, organizations can avoid common pitfalls and secure reliable, high-performance components.

Logistics & Compliance Guide for Definition Hinge

This guide outlines the essential logistics and compliance considerations for the distribution, handling, and regulatory adherence of Definition Hinge products. Adherence to these standards ensures operational efficiency, legal compliance, and customer satisfaction.

Product Classification & Documentation

Ensure all Definition Hinge products are accurately classified under the appropriate Harmonized System (HS) codes for import/export purposes. Maintain up-to-date technical specifications, material safety data sheets (MSDS), and product compliance certificates (e.g., CE, UKCA) in both digital and physical formats. All shipping documentation—commercial invoices, packing lists, and certificates of origin—must reflect exact product descriptions, quantities, and values to avoid customs delays.

Packaging & Labeling Standards

Package all hinges to prevent mechanical damage during transit, using moisture-resistant materials where applicable. Each package must display clear labeling including product SKU, quantity, weight, handling instructions (e.g., “Fragile,” “This Side Up”), and compliance marks. For international shipments, include bilingual labeling (e.g., English and local language) as required by the destination country.

International Shipping & Customs Clearance

Partner with certified freight forwarders experienced in hardware and industrial components. Provide complete and accurate customs documentation to facilitate smooth clearance. Monitor changes in trade regulations, tariffs, and sanctions affecting export destinations. Utilize Incoterms® (e.g., FOB, DDP) clearly defined in sales contracts to assign responsibility for shipping and compliance.

Regulatory Compliance

Ensure all Definition Hinge products comply with relevant regional regulations, including:

– European Union: REACH, RoHS, and CE marking directives

– United States: Consumer Product Safety Improvement Act (CPSIA) and FTC labeling requirements

– United Kingdom: UKCA marking and post-Brexit import rules

– Other Markets: Local building codes and safety standards as applicable

Conduct periodic audits to verify ongoing compliance and update technical files accordingly.

Inventory Management & Traceability

Implement a barcode or RFID-based inventory system to track hinge batches from production to delivery. Maintain records for a minimum of five years to support traceability in case of recalls or audits. Conduct regular cycle counts to ensure inventory accuracy and identify discrepancies early.

Environmental & Sustainability Requirements

Adhere to waste electrical and electronic equipment (WEEE) directives where applicable. Minimize packaging waste through recyclable materials and right-sized packaging. Report environmental performance metrics annually in alignment with corporate sustainability goals.

Training & Compliance Oversight

Provide regular training for logistics and operations staff on compliance protocols, hazardous materials handling (if applicable), and updated trade regulations. Appoint a compliance officer to oversee audits, manage documentation, and serve as the point of contact for regulatory inquiries.

By following this guide, Definition Hinge ensures reliable delivery, legal conformity, and long-term credibility in global markets.

Conclusion for Sourcing Definition of “Hinge”:

In conclusion, the sourcing definition of “hinge” extends beyond its common understanding as a mechanical joint that allows rotational movement. In procurement and supply chain contexts, “hinge” may refer to a critical component whose availability, quality, and cost significantly impact the final product’s functionality and assembly process. Proper sourcing of hinges involves evaluating material specifications, durability, compatibility, supplier reliability, and cost-efficiency. As a small but essential part in industries such as furniture, electronics, automotive, and construction, strategic sourcing of hinges ensures product integrity, reduces supply chain risks, and supports overall operational efficiency. Therefore, defining and sourcing hinges accurately is vital to maintaining quality, reducing costs, and ensuring timely production.