The global forklift market is experiencing steady growth, driven by rising demand for material handling equipment across logistics, manufacturing, and e-commerce sectors. According to a report by Mordor Intelligence, the forklift market was valued at USD 22.5 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. This expansion is fueled by increasing automation in warehouses, a shift toward electric forklifts due to sustainability initiatives, and growing infrastructure development in emerging economies. As competition intensifies, a select group of manufacturers continue to lead in innovation, production volume, and global market share. Here are the top 9 forklift manufacturers shaping the industry’s future.

Top 9 Define Forklift Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Heavy Duty Forklifts Manufacturers, Lift Trucks Suppliers

Domain Est. 2008

Website: unforklift.com

Key Highlights: Zhejiang UN Forklift Co., Ltd. is China lift trucks manufacturers and heavy duty forklifts suppliers, our factory offer wholesale heavy duty lift trucks for ……

#2 Crown Equipment Corporation

Domain Est. 1998

Website: crown.com

Key Highlights: Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks and technology, with a network of more than 500 forklift ……

#3 UniCarriers Forklifts

Domain Est. 2020

Website: logisnextamericas.com

Key Highlights: As an American forklift manufacturer that’s proudly part of a global corporation, UniCarriers is committed to enabling our customers to efficiently move goods ……

#4 Yale Lift Truck Technologies

Domain Est. 1994

Website: yale.com

Key Highlights: Yale’s forklifts and lift trucks are designed to tackle your biggest challenges. Discover how our technology can boost your warehouse productivity!…

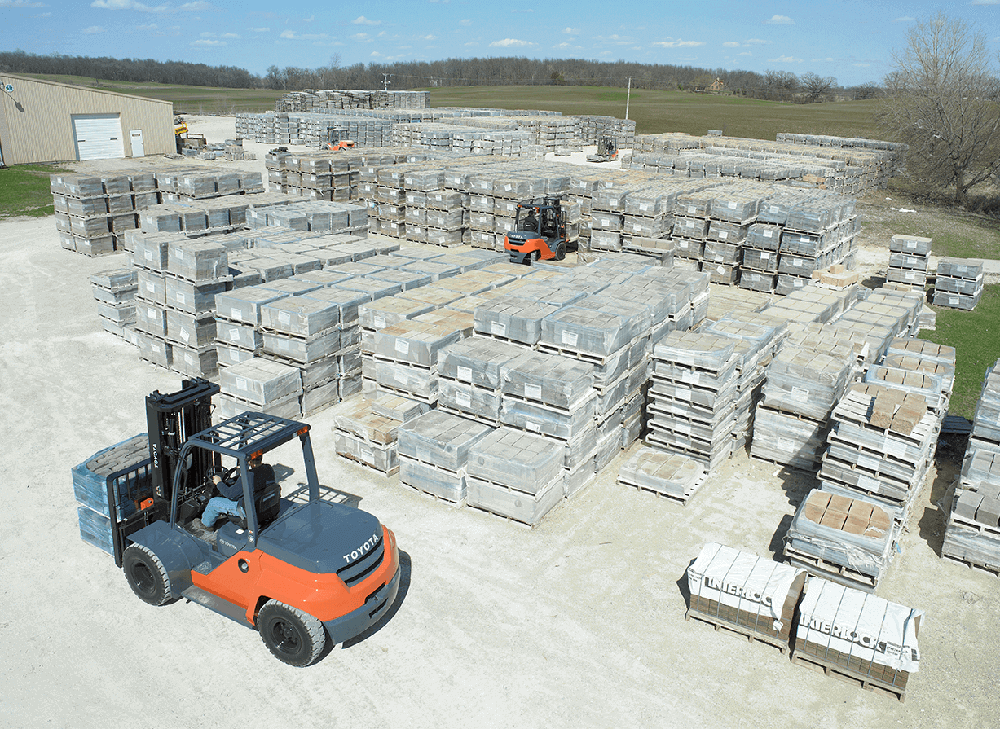

#5 Toyota Forklifts

Domain Est. 1996

Website: toyotaforklift.com

Key Highlights: Toyota Forklifts is the leader in material handling and industrial lift trucks and equipment. Learn about our solutions to maximize your warehouse ……

#6 Powered Industrial Trucks (Forklift) eTool

Domain Est. 1997

Website: osha.gov

Key Highlights: Powered industrial trucks, commonly called forklifts or lift trucks, are used in many industries, primarily to move materials. They can be used to move, raise, ……

#7 Industrial Truck Association

Domain Est. 1997

Website: indtrk.org

Key Highlights: We are ITA. Who We Serve. United States. ITA’s manufacturing Members represent more than 90% of the forklift market in North America….

#8 CLARK Material Handling Company

Domain Est. 1996

Website: clarkmhc.com

Key Highlights: CLARK offers products in all five classes, including powered pallet jacks, electric standup forklifts, narrow aisle forklifts, walkie pallet stackers, order ……

#9 Combilift Forklifts

Domain Est. 1999

Website: combilift.com

Key Highlights: Maximise your warehouse efficiency with Combilift’s award-winning forklifts, including multidirectional and sideloader options for various industries….

Expert Sourcing Insights for Define Forklift

H2: 2026 Market Trends Analysis for Forklifts

The global forklift market is poised for significant transformation by 2026, driven by technological innovation, sustainability mandates, and evolving supply chain demands. This analysis explores key trends expected to shape the forklift industry through 2026, focusing on electrification, automation, connectivity, regional dynamics, and regulatory pressures.

1. Accelerated Shift Toward Electrification

By 2026, electric forklifts are projected to dominate new equipment sales, surpassing traditional internal combustion (IC) models in many regions. Advances in lithium-ion battery technology have improved energy density, reduced charging times, and extended operational life—making electric forklifts more viable for 24/7 operations. Major markets like Europe and North America are enforcing stricter emissions regulations, further accelerating this transition. Original equipment manufacturers (OEMs) are expanding their electric portfolios, with several launching fully electric counterbalance, warehouse, and heavy-duty models tailored for diverse industrial environments.

2. Growth of Automation and Smart Logistics

Autonomous Mobile Robots (AMRs) and automated guided forklifts (AGFs) are expected to gain substantial traction by 2026. Driven by labor shortages and the need for operational efficiency, warehouses and distribution centers are investing in automated material handling solutions. Integration with warehouse management systems (WMS) and real-time fleet management platforms enables predictive maintenance, route optimization, and enhanced safety. AI-powered vision systems and sensor fusion technologies will allow forklifts to navigate dynamic environments with minimal human intervention.

3. IoT and Data-Driven Fleet Management

Connectivity is becoming a standard feature in modern forklifts. By 2026, most new units are expected to come equipped with IoT sensors that collect data on usage patterns, operator behavior, and equipment health. This data enables fleet managers to optimize utilization, reduce downtime, and enhance safety compliance. Cloud-based platforms will offer real-time dashboards and analytics, supporting data-driven decision-making across logistics operations.

4. Regional Market Dynamics

Asia-Pacific, particularly China and India, will remain the largest market for forklifts due to rapid industrialization, e-commerce growth, and infrastructure development. However, Europe leads in adopting sustainable and smart forklift technologies, supported by EU Green Deal initiatives. North America is witnessing strong demand for electric and automated solutions, especially in last-mile logistics and cold storage facilities. Latin America and Africa show emerging potential, with increasing foreign direct investment in manufacturing and logistics.

5. Regulatory and Sustainability Pressures

Environmental regulations will play a pivotal role in shaping forklift design and deployment. Cities implementing low-emission zones will restrict IC forklift usage indoors and in urban logistics hubs. OEMs are responding by developing zero-emission models and exploring alternative power sources like hydrogen fuel cells, particularly for heavy-duty and outdoor applications. By 2026, sustainability will be a key differentiator in procurement decisions, with companies favoring suppliers committed to circular economy practices and carbon-neutral manufacturing.

6. Impact of E-Commerce and Supply Chain Resilience

The continued rise of e-commerce demands faster order fulfillment and flexible warehousing solutions. Forklifts designed for high-density storage, narrow aisles, and multi-shift operations will see increased demand. Additionally, supply chain disruptions have emphasized the need for resilient logistics infrastructure, prompting investments in modular, scalable material handling equipment—including versatile forklifts that can adapt to changing operational needs.

Conclusion

By 2026, the forklift market will be defined by intelligence, sustainability, and integration. Companies that embrace electric propulsion, automation, and digital connectivity will lead the market, while those slow to adapt may face competitive disadvantages. As logistics operations become more complex and environmentally conscious, the forklift will evolve from a simple lifting tool to a central node in the smart warehouse ecosystem.

Common Pitfalls When Sourcing Forklifts: Quality and Intellectual Property (IP) Concerns

Sourcing forklifts, especially from international or unfamiliar suppliers, involves significant risks related to both product quality and intellectual property. Overlooking these factors can lead to safety hazards, operational inefficiencies, legal complications, and financial losses. Below are key pitfalls to avoid in these two critical areas.

Quality-Related Pitfalls

1. Selecting Suppliers Based Solely on Price

Choosing the cheapest forklift option often leads to compromised materials, poor workmanship, and substandard safety features. Low-cost models may use inferior components that wear out quickly or fail under load, increasing downtime and repair costs.

2. Inadequate Verification of Safety and Compliance Standards

Forklifts must meet regional and international safety standards (e.g., OSHA in the U.S., CE in Europe). Sourcing from suppliers who do not provide proper certification or documentation can result in non-compliant equipment that poses safety risks and fails regulatory inspections.

3. Lack of On-Site or Third-Party Inspections

Relying only on product photos or supplier claims without independent quality audits or pre-shipment inspections can lead to receiving defective or misrepresented units. Physical verification ensures the forklift meets specifications and functions as expected.

4. Overlooking After-Sales Support and Spare Parts Availability

Even high-quality forklifts require maintenance. Sourcing from suppliers without reliable after-sales service or access to genuine spare parts can result in prolonged downtimes and higher lifecycle costs.

Intellectual Property (IP)-Related Pitfalls

1. Sourcing from Suppliers Using Counterfeit or Cloned Designs

Some manufacturers produce “copycat” forklifts that mimic well-known brands, infringing on patented designs, trademarks, or proprietary technology. Purchasing such equipment exposes buyers to legal risks and potential seizure by customs authorities.

2. Infringement of Patented Technologies

Forklifts may incorporate patented features (e.g., ergonomic controls, hybrid powertrains, stability systems). Sourcing from suppliers who use these technologies without licensing can make the buyer complicit in IP violations, especially in strict enforcement regions.

3. Unclear Ownership of Custom-Built Forklifts

When ordering customized forklifts, failure to define IP ownership in contracts can lead to disputes. Suppliers might claim rights over design modifications, limiting the buyer’s ability to reproduce or modify the equipment in the future.

4. Weak Contractual IP Clauses

Purchase agreements that lack clear terms on warranties, infringement indemnification, and IP ownership leave buyers vulnerable. Without these protections, resolving IP disputes becomes costly and complex.

Conclusion

To mitigate these pitfalls, conduct thorough due diligence on suppliers, verify compliance and certifications, insist on third-party inspections, and include robust IP clauses in procurement contracts. Partnering with reputable manufacturers and legal experts ensures both quality assurance and IP safety in forklift sourcing.

Logistics & Compliance Guide for Define Forklift

Overview

This guide outlines the essential logistics and compliance requirements for the safe and legal operation, transportation, maintenance, and documentation of Define Forklift equipment. Adhering to these guidelines ensures operational efficiency, regulatory compliance, and workplace safety.

Regulatory Compliance

Define Forklift operations must comply with local, national, and international regulations, including but not limited to:

– OSHA (Occupational Safety and Health Administration) standards in the U.S.

– ANSI/ITSDF B56.1 safety standards for powered industrial trucks

– EU Machinery Directive 2006/42/EC and CE marking requirements

– Local labor and workplace safety laws

All forklifts must be operated in accordance with regional regulatory bodies and updated as laws evolve.

Equipment Certification and Documentation

Each Define Forklift must have the following documentation on file:

– Certificate of Conformity (CE or equivalent)

– Manufacturer’s operation and maintenance manuals

– Proof of compliance with emissions standards (e.g., EPA Tier 4, EU Stage V)

– Load capacity data plate permanently affixed to the forklift

– Registration and inspection records (where required by jurisdiction)

Operator Training and Certification

Only trained and certified personnel may operate Define Forklifts. Requirements include:

– Completion of a forklift operator training program compliant with OSHA or equivalent standards

– Practical evaluation and written assessment every three years, or after incidents or policy changes

– Site-specific training for unique operational environments (e.g., narrow aisles, racking systems)

– Records of training and certification maintained for audit purposes

Pre-Operation Inspections

Daily pre-use inspections are mandatory and must include checks of:

– Fluid levels (hydraulic, engine oil, coolant)

– Tire condition and pressure

– Fork integrity and mounting hardware

– Warning lights, horn, and backup alarms

– Hydraulic systems for leaks or malfunctions

– Brakes, steering, and control responsiveness

Any defects must be reported immediately and the forklift taken out of service until repaired.

Safe Operating Procedures

To ensure safety and efficiency, operators must:

– Observe posted speed limits and aisle width requirements

– Maintain a clear view at all times; reverse if load obstructs forward vision

– Use seat belts and ensure all safety restraints are functional

– Never carry passengers unless the forklift is specifically designed for it

– Follow load capacity limits and center loads properly

– Avoid ramps or inclines when possible; travel with load pointed uphill when necessary

Maintenance and Servicing

Define Forklifts must undergo regular preventive maintenance according to the manufacturer’s schedule:

– Scheduled oil changes, filter replacements, and lubrication

– Inspection and adjustment of critical components (brakes, chains, mast)

– Use of OEM or manufacturer-approved replacement parts

– All maintenance recorded in a service log with date, technician, and work performed

– Immediate repair of any safety-related issues

Transport and Delivery Logistics

When shipping or transporting Define Forklifts:

– Secure the forklift on trailers or containers using appropriate tie-downs and wheel chocks

– Ensure the battery is disconnected (for electric models) and fuel system secured (for IC models)

– Comply with DOT (Department of Transportation) or equivalent regulations for oversized loads

– Use certified carriers experienced in handling industrial equipment

– Provide shipping documentation, including bill of lading and equipment specifications

Environmental and Emissions Compliance

Define Forklifts must adhere to environmental standards:

– Electric models: Proper battery handling, charging in ventilated areas, and recycling protocols

– Internal combustion models: Compliance with emissions standards; routine exhaust testing where required

– Spill containment procedures for fuel or hydraulic fluid leaks

– Use of approved disposal methods for used oil, filters, and batteries

Incident Reporting and Investigation

All accidents, near-misses, or equipment failures must be:

– Reported immediately to supervisors or safety officers

– Documented with photos, witness statements, and incident reports

– Investigated to identify root causes and prevent recurrence

– Shared with relevant regulatory bodies if required by law

Audits and Compliance Monitoring

Regular audits should be conducted to verify adherence to this guide:

– Quarterly internal safety and compliance checks

– Review of training records, maintenance logs, and inspection reports

– Corrective action plans for non-compliance issues

– Third-party audits recommended annually for high-risk environments

Conclusion

Following this Logistics & Compliance Guide ensures that Define Forklift operations remain safe, efficient, and legally compliant. Continuous training, documentation, and proactive maintenance are critical to protecting personnel, assets, and regulatory standing.

Conclusion for Sourcing Decision: Define Forklift

In conclusion, defining the forklift requirements is a critical first step in the sourcing process that directly impacts operational efficiency, safety, and long-term cost-effectiveness. By clearly identifying key parameters such as load capacity, lift height, power source (electric, diesel, LPG), mast type, tire configuration, and intended operating environment, procurement teams can align specifications with actual business needs. This definition phase enables accurate supplier comparisons, ensures equipment compatibility with warehouse layout and workflows, and supports compliance with safety and environmental standards. A well-defined forklift specification minimizes the risks of underperformance, unnecessary expenditures, and downtime, ultimately contributing to optimized material handling operations. Therefore, investing time and resources in a thorough requirement definition process lays the foundation for a successful and sustainable sourcing decision.