The global market for def (diesel exhaust fluid) injectors has seen steady expansion, driven by increasingly stringent emission regulations and the widespread adoption of selective catalytic reduction (SCR) technology in diesel-powered vehicles. According to a report by Mordor Intelligence, the global DEF injector market was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. This growth is fueled by rising demand across commercial transportation, construction, and agricultural sectors, particularly in regions enforcing Euro 6 and equivalent emission standards. As environmental compliance becomes a priority, leading manufacturers are investing in precision engineering and durability improvements to meet OEM specifications. The following list highlights the top 8 DEF injector manufacturers shaping the industry through innovation, global supply capabilities, and strong partnerships with major engine and vehicle producers.

Top 8 Def Injector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Air Products:

Domain Est. 1995

Website: airproducts.com

Key Highlights: Air Products provide essential industrial gases, related equipment and applications expertise to customers in dozens of industries. Find out more….

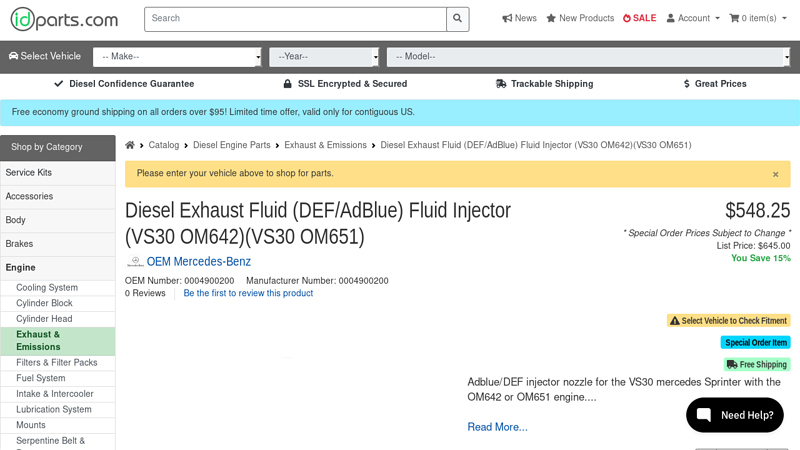

#2 Diesel Exhaust Fluid (DEF/AdBlue) Fluid Injector (VS30 OM642 …

Domain Est. 1999

Website: idparts.com

Key Highlights: In stock $9.95 deliveryAdblue/DEF injector nozzle for the VS30 mercedes Sprinter with the OM642 or OM651 engine. OEM Mercedes Parts come directly from official Mercedes dealerships…

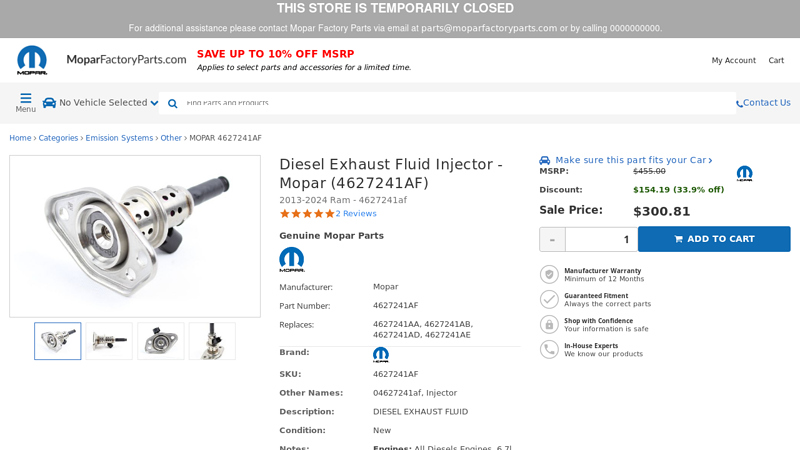

#3 Diesel Exhaust Fluid Injector

Domain Est. 2013

Website: moparfactoryparts.com

Key Highlights: In stock Rating 5.0 (2) Your Diesel Exhaust Fluid Injector will specifically fit your 2013-2024 Ram vehicle. Affordable, reliable and built to last, OEM Mopar parts stand out as …

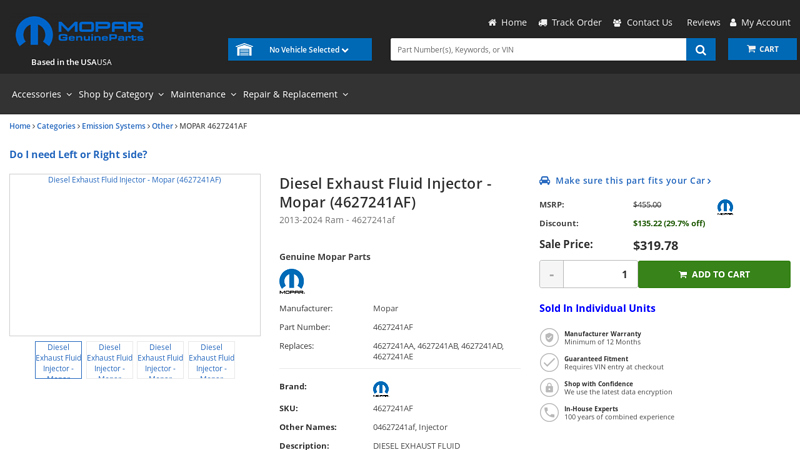

#4 Diesel Exhaust Fluid Injector

Domain Est. 2014

Website: parts.mopargenuineparts.com

Key Highlights: 5-day delivery 30-day returnsDiesel Exhaust Fluid Injector – Mopar (4627241AF) ; Manufacturer: Mopar ; Part Number: 4627241AF ; Replaces: 4627241AA, 4627241AB, 4627241AD, 4627241AE…

#5 DEF Injectors

Domain Est. 2007

Website: dinex.us

Key Highlights: The DEF injector sprays fluid at high pressure into the exhaust stream, where it mixes thoroughly and enables NOx reduction in the SCR catalyst….

#6 Dinex DEF Injector, International/Cummins/Paccar

Domain Est. 2008

Website: vehiclesafetysupply.com

Key Highlights: In stock Free deliveryDirectly replaceable with OE injectors · Tested at Dinex test center · Stock item for fast delivery · A cost effective balance between emission control and Ur…

#7 Dales Super Store

Domain Est. 2010

Website: dalessuperstore.com

Key Highlights: Free delivery over $100Diesel Exhaust Fluid (DEF) Injectors/Dosing Units are integral components of SCR systems & are instrumental in reducing harmful NOx ……

#8 DEF Injector/Pump

Domain Est. 2024

Website: dpfdiscounter.com

Key Highlights: Free delivery 15-day returnsShop DEF Injectors/Pumps for brands like Cummins, Volvo, Dodge, and more. Need assistance in finding the right part for your truck? Call us at (330)-573…

Expert Sourcing Insights for Def Injector

H2: 2026 Market Trends for Diesel Exhaust Fluid (DEF) Injectors

The global Diesel Exhaust Fluid (DEF) injector market is poised for significant transformation by 2026, shaped by tightening emissions regulations, advancements in engine technology, and the evolving landscape of vehicle electrification. DEF injectors—critical components in Selective Catalytic Reduction (SCR) systems—enable diesel engines to meet stringent NOx (nitrogen oxides) emission standards. The following analysis outlines key market trends expected to influence the DEF injector sector through 2026.

1. Stringent Emissions Regulations Driving Demand

Governments worldwide, particularly in North America, Europe, and parts of Asia-Pacific, are enforcing stricter emissions standards (e.g., Euro 7, U.S. EPA 2027+ proposals). These regulations mandate lower NOx emissions from heavy-duty vehicles, agricultural machinery, and marine engines, reinforcing the necessity of SCR systems and, by extension, DEF injectors. As compliance becomes non-negotiable, OEMs and aftermarket suppliers will continue investing in reliable and precise DEF injection technologies.

2. Growth in Heavy-Duty and Commercial Vehicle Segments

The freight and logistics industry remains heavily reliant on diesel-powered trucks. Despite the rise of electric alternatives, long-haul transportation still favors diesel due to range and refueling infrastructure. This sustained demand for diesel engines in commercial fleets will support steady growth in the DEF injector market. Additionally, emerging markets in Southeast Asia, India, and Africa are expanding their transportation infrastructure, increasing diesel vehicle adoption and associated DEF system requirements.

3. Technological Advancements in Injector Precision and Durability

By 2026, manufacturers are expected to focus on enhancing the accuracy, durability, and responsiveness of DEF injectors. Innovations such as piezoelectric actuators, improved nozzle designs, and real-time feedback systems will enable more efficient urea dosing, reducing DEF consumption and minimizing deposit formation (e.g., crystallization). These improvements will be critical for maintaining system efficiency and reducing maintenance costs.

4. Integration with Connected and Predictive Maintenance Systems

The rise of IoT-enabled vehicles and telematics is leading to smarter emission control systems. Future DEF injectors may be integrated with onboard diagnostics (OBD) and cloud-based monitoring platforms, allowing for predictive maintenance, remote troubleshooting, and real-time performance optimization. This trend will appeal to fleet operators seeking to reduce downtime and improve compliance tracking.

5. Competition from Electrification and Hybrid Technologies

While diesel engines will remain prevalent, the growing adoption of battery-electric and hydrogen fuel cell vehicles—especially in urban delivery and light commercial applications—poses a long-term challenge to the DEF injector market. However, the transition will be gradual, and hybrid diesel-electric systems may still utilize SCR technology, preserving demand for DEF injectors in transitional vehicle platforms.

6. Aftermarket Expansion and Regional Growth Opportunities

As the installed base of SCR-equipped vehicles grows, the aftermarket for DEF injectors and related components is expected to expand significantly by 2026. Regions with large fleets of aging diesel vehicles—such as North America and Western Europe—will see increased demand for replacement injectors, recalibration services, and retrofit solutions. Additionally, regulatory enforcement in developing economies will drive new installations and upgrades.

7. Sustainability and Supply Chain Considerations

Manufacturers are increasingly focusing on sustainable production methods and recyclable materials. By 2026, there will likely be greater emphasis on reducing the environmental footprint of DEF injector manufacturing, including energy-efficient production and end-of-life component recycling. Supply chain resilience, particularly for rare metals and precision electronics, will also be a key concern amid geopolitical uncertainties.

Conclusion:

The DEF injector market in 2026 will be characterized by resilience amid regulatory pressure, technological innovation, and regional diversification. While electrification presents a long-term challenge, the continued dominance of diesel in key transportation sectors ensures sustained demand. Companies that invest in smart, durable, and efficient injector technologies—while adapting to digital integration and sustainability trends—will be best positioned to lead the market through 2026 and beyond.

Common Pitfalls When Sourcing Diesel Injectors (Quality, IP)

Sourcing diesel injectors—especially high-pressure common rail types—requires careful attention to both quality and intellectual property (IP) concerns. Falling into common traps can result in poor engine performance, costly downtime, or even legal liabilities. Below are key pitfalls to avoid:

Poor Quality and Counterfeit Components

One of the most widespread issues when sourcing diesel injectors is inadvertently purchasing substandard or counterfeit parts. These components often fail prematurely and can cause significant engine damage.

- Inconsistent Performance: Low-quality injectors may deliver incorrect fuel spray patterns or timing, leading to reduced fuel efficiency, increased emissions, and engine knocking.

- Short Lifespan: Counterfeit or poorly remanufactured injectors frequently fail within months due to inferior materials or improper calibration.

- Lack of Testing: Reputable manufacturers test injectors on specialized rigs for flow rate, atomization, and sealing. Many low-cost suppliers skip this critical step.

Intellectual Property (IP) Infringement

Using or distributing diesel injectors that copy patented designs without authorization exposes buyers and suppliers to legal risk.

- Unauthorized Replicas: Some third-party injectors replicate proprietary designs from OEMs (e.g., Bosch, Delphi, Denso) without licensing, violating IP rights.

- Legal Exposure: Distributors or fleets using infringing parts may face lawsuits, product seizures, or reputational damage.

- Voided Warranties: OEM engine warranties are often voided if non-licensed or counterfeit injectors are detected.

Inadequate Traceability and Certification

Without proper documentation and traceability, it’s difficult to verify authenticity or support compliance.

- Missing Serial Numbers or Barcodes: Genuine injectors include unique identifiers for tracking and warranty claims.

- No Certification to Industry Standards: Reputable injectors comply with standards such as ISO 9001 or OEM-specific specs. Lack of certification is a red flag.

Choosing Based on Price Alone

Opting for the cheapest injector often leads to higher total cost of ownership due to failures, repairs, and downtime.

- Hidden Costs: Frequent replacements, tow trucks, and lost productivity outweigh initial savings.

- Compromised Engine Health: Poor injectors can damage fuel pumps, rails, and even pistons over time.

Lack of Technical Support and Calibration Data

High-pressure injectors require precise calibration. Sourcing from suppliers without technical expertise can lead to misapplication.

- Incorrect Part Matching: Not all injectors are interchangeable, even within the same engine model family.

- No Access to Calibration Codes: Modern engines require injector-specific calibration data. Missing or incorrect codes trigger fault codes and limp mode.

Conclusion

To mitigate these risks, always source diesel injectors from authorized distributors or reputable remanufacturers with verifiable quality controls and IP compliance. Prioritize traceability, testing documentation, and technical support over upfront cost savings.

Logistics & Compliance Guide for DEF Injector

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and use of Diesel Exhaust Fluid (DEF) in conjunction with DEF injectors. Proper adherence ensures system performance, regulatory compliance, and environmental responsibility.

Regulatory Compliance

DEF is subject to various international and national regulations due to its role in emissions control. Compliance is mandatory under environmental protection laws such as the U.S. Environmental Protection Agency (EPA) regulations and the European Euro 6 standards.

- ISO 22241 Standards: DEF must meet ISO 22241-1 for quality and ISO 22241-2 for testing. Non-compliant DEF can damage the DEF injector and SCR (Selective Catalytic Reduction) system.

- Emissions Regulations: Vehicles equipped with DEF injectors must operate with certified DEF to meet mandated NOx reduction levels. Using non-compliant fluid may result in violation penalties and engine derating.

- Labeling and Traceability: Ensure all DEF containers are properly labeled with ISO certification, batch number, and expiration date to support traceability and audits.

Storage Requirements

Proper storage is critical to maintaining DEF quality and preventing injector malfunction.

- Temperature Control: Store DEF between 12°F (−11°C) and 86°F (30°C). Prolonged exposure to temperatures above 86°F accelerates decomposition; below 12°F, DEF may crystallize but returns to liquid without quality loss upon thawing.

- Container Materials: Use only approved materials—stainless steel (grades 304/316), polyethylene (HDPE), or polypropylene. Avoid copper, brass, zinc, aluminum, or carbon steel, which cause contamination.

- Ventilation and Light: Store in a cool, dry, well-ventilated area away from direct sunlight to prevent degradation.

Transportation Guidelines

Transporting DEF requires adherence to safety and quality protocols to maintain integrity.

- Approved Containers: Use UN-certified, DEF-compatible containers. Ensure seals are intact to prevent contamination.

- Segregation: Keep DEF separate from fuels, oils, and other chemicals during transport to avoid cross-contamination.

- Documentation: Maintain transport records, including batch numbers, supplier certifications, and delivery dates for compliance tracking.

Handling and Dispensing

Improper handling can compromise DEF quality and damage the DEF injector.

- Clean Equipment: Use dedicated, clean dispensing tools. Never use equipment previously used for fuel or oil.

- Avoid Contamination: Even small amounts of contaminants (e.g., dust, dirt, water) can clog the DEF injector or impair SCR function. Always keep containers closed when not in use.

- Personal Protection: While DEF is non-toxic, wear gloves and eye protection during handling. Wash skin immediately if contact occurs.

DEF Injector Maintenance & Monitoring

The DEF injector is sensitive to fluid quality and operational conditions.

- Regular Inspection: Monitor for clogs, leaks, or deposits. Clean or replace injectors per OEM guidelines.

- System Diagnostics: Use onboard diagnostic (OBD) tools to detect injector faults or DEF quality issues (e.g., low NOx conversion efficiency).

- Record Keeping: Maintain logs of DEF usage, injector maintenance, and fluid sourcing for audit and compliance purposes.

Environmental & Safety Considerations

- Spill Management: In case of spill, contain with inert absorbent material. Flush with water—DEF is biodegradable but can be corrosive to certain surfaces.

- Disposal: Dispose of contaminated DEF or packaging per local hazardous waste regulations. Recycle containers when possible.

Supplier Verification

Use only DEF from ISO 22241-certified suppliers. Request Certificates of Analysis (CoA) and verify batch traceability to ensure compliance and protect injector performance.

Adherence to this guide ensures reliable DEF injector operation, regulatory compliance, and contribution to cleaner emissions.

Conclusion on Sourcing Diesel Injectors:

Sourcing diesel injectors requires a strategic approach that balances quality, cost, compatibility, and reliability. Whether procuring new, remanufactured, or aftermarket injectors, it is essential to partner with reputable suppliers or manufacturers that adhere to industry standards and offer proper warranties. Factors such as vehicle make and model, engine specifications, and application (e.g., heavy-duty, OEM replacement, or performance tuning) must be carefully considered to ensure optimal engine performance and longevity.

Additionally, verifying certifications, testing procedures, and availability of technical support can significantly reduce downtime and maintenance costs. While cost is an important factor, prioritizing long-term value over initial savings helps prevent injector failure, fuel inefficiency, and potential engine damage. In conclusion, a well-informed sourcing strategy—based on product quality, supplier credibility, and technical compatibility—is critical to maintaining engine efficiency, compliance, and operational reliability.