The global electrical connectors market is experiencing robust growth, driven by rising demand across automotive, industrial equipment, and consumer electronics sectors. According to Mordor Intelligence, the market was valued at USD 76.5 billion in 2023 and is projected to reach USD 109.3 billion by 2029, growing at a CAGR of 6.2% during the forecast period. A key contributor to this expansion is the increasing need for reliable, high-performance connectors in harsh environments—spurring demand for specialized solutions like those offered by Dean connector manufacturers. Dean connectors, known for their durability in RF and microwave applications, are increasingly critical in telecommunications, defense, and test equipment industries. As technological advancements push the boundaries of signal integrity and miniaturization, a select group of manufacturers has emerged at the forefront of innovation, quality, and global supply. Based on market presence, product range, and technical capabilities, the following eight companies represent the leading Dean connector manufacturers shaping the future of high-frequency connectivity.

Top 8 Dean Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Company Profile

Domain Est. 2004

Website: yuandean.com

Key Highlights: We are the leading manufacturer with ISO 9001/ISO 14001/IATF 16949 certified and specializes in various products such as DC/DC converter, AC/DC converter, RJ45 ……

#2

Domain Est. 1997

Website: dmctools.com

Key Highlights: For 75 years, DMC® has manufactured tooling for mission-critical electrical systems in aerospace and defense, rail, marine, and several other industries….

#3 Deans T Plug Connector Male and Female for RC LiPo Battery

Domain Est. 2009

Website: probots.co.in

Key Highlights: This connector is perfect to connect your RC and Robotics Electronics to a Battery. Made from high-temp Nylon and gold plated spring connectors….

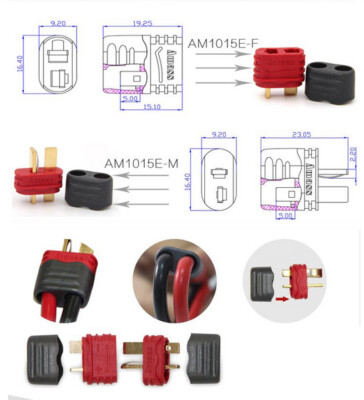

#4 Battery Connectors, Deans Plug, XT60, XT90, Amass…

Domain Est. 2011

#5 T Plug Deans Connector

Domain Est. 2011

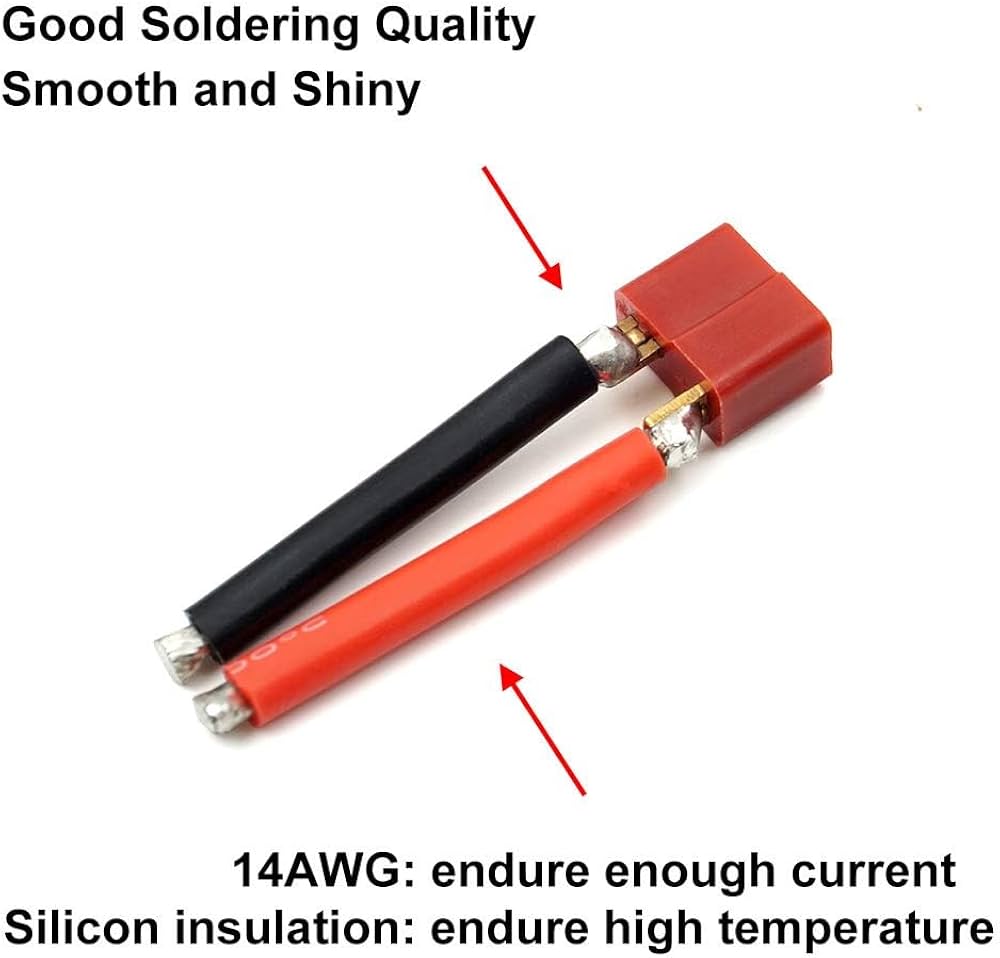

#6 Dean T Male Connector with 14AWG Wire

Domain Est. 2017

Website: cytron.io

Key Highlights: The 15cm length dean-T wire extension allows you to connect your LiPo battery directly to your board easily….

#7 Deans

Website: gatee.eu

Key Highlights: Pair of Deans-T Connectors. Low resistance T-Connector type connectors, T-shape….

#8 Deans Connectors & Leads

Website: 54-077-20-080.plesk.page

Key Highlights: Deans Connectors & Leads · Deans Connector Set 10prs · Deans Pairs with Cap End (10pcs) · Pigtail Connector Pack, Deans Male, 4in Lead, 12AWG, 100mm (5pcs)….

Expert Sourcing Insights for Dean Connector

H2: Market Trends Forecast for Dean Connector in 2026

As the global electronics and connectivity landscape continues to evolve rapidly, Dean Connector is poised to navigate a dynamic market environment in 2026. Driven by advancements in industrial automation, electric vehicles (EVs), 5G infrastructure, and the Internet of Things (IoT), the demand for high-performance, reliable interconnect solutions is expected to surge. Below is an analysis of key market trends shaping Dean Connector’s opportunities and challenges in 2026, under the H2 framework—highlighting Hybrid Innovation and Hyper-Connectivity as central themes.

1. Hybrid Innovation: Merging Analog and Digital, Physical and Smart

By 2026, the concept of hybrid innovation will dominate the connector industry. Dean Connector is expected to respond by integrating traditional electromechanical reliability with smart, sensor-enabled functionalities.

-

Smart Connectors: Rising demand for condition monitoring and predictive maintenance in industrial and automotive sectors will drive adoption of connectors embedded with sensors (e.g., temperature, current, vibration). Dean Connector can leverage this trend by launching hybrid products that offer real-time diagnostics.

-

Energy Efficiency & Miniaturization: As devices grow smaller and more power-efficient, Dean Connector will need to focus on compact, high-density interconnects—especially for consumer electronics and wearable tech. This includes advancements in micro-coaxial and board-to-board connectors.

-

Sustainability Integration: Hybrid innovation also extends to environmental performance. By 2026, Dean Connector is likely to emphasize eco-design principles—using recyclable materials, reducing e-waste, and ensuring compliance with RoHS and REACH regulations—appealing to ESG-conscious clients.

2. Hyper-Connectivity: The Rise of Ubiquitous, High-Speed Networks

The proliferation of 5G, edge computing, and AI-driven systems will fuel a hyper-connected world, significantly impacting Dean Connector’s core markets.

-

5G and Telecom Infrastructure: With global 5G rollout maturing by 2026, demand for high-frequency RF connectors and ruggedized outdoor solutions will remain strong. Dean Connector can expand its RF and fiber optic product lines to serve base stations, small cells, and data centers.

-

Electric Vehicles and Automotive Electrification: The EV market is projected to grow at over 20% CAGR through 2026. Dean Connector is well-positioned to capture market share with high-voltage, high-current connectors for battery packs, charging systems, and vehicle-to-everything (V2X) communication modules.

-

Industrial IoT (IIoT): Factories and logistics hubs will increasingly rely on wireless and wired connectivity for machine-to-machine (M2M) communication. Rugged, IP-rated connectors capable of withstanding harsh environments will be in high demand—aligning with Dean Connector’s strengths in industrial solutions.

-

Data Center Expansion: As cloud computing and AI workloads grow, data centers will require high-speed, low-latency interconnects. Dean Connector can explore opportunities in high-speed backplane and I/O connectors, possibly through strategic partnerships or product diversification.

Strategic Implications for Dean Connector

To capitalize on H2 trends in 2026, Dean Connector should consider the following strategic moves:

- R&D Investment: Prioritize R&D in high-speed signal integrity, EMI shielding, and thermal management to support next-gen applications.

- Vertical Market Focus: Target high-growth verticals—automotive, renewable energy, medical devices, and smart cities—with tailored connector solutions.

- Global Supply Chain Resilience: Diversify manufacturing and sourcing to mitigate geopolitical and logistical risks, especially amid ongoing semiconductor and material shortages.

- Digital Transformation: Implement digital sales platforms and data analytics to enhance customer engagement and forecast demand more accurately.

Conclusion

By 2026, Dean Connector’s success will hinge on its ability to embrace Hybrid Innovation and enable Hyper-Connectivity across emerging technological ecosystems. With a strategic focus on smart, sustainable, and high-performance connectivity solutions, Dean Connector can solidify its position as a key enabler in the next wave of digital and industrial transformation.

Common Pitfalls When Sourcing Dean Connectors (Quality, IP)

Sourcing Dean connectors—commonly used in high-frequency RF applications—can present several challenges, particularly concerning quality assurance and intellectual property (IP) risks. Being aware of these pitfalls is crucial to ensuring reliable performance and legal compliance in your designs.

Inconsistent Quality and Material Standards

One of the most prevalent issues when sourcing Dean connectors is variability in quality, especially with non-OEM or third-party suppliers. Many manufacturers, particularly those in less regulated markets, may use substandard materials such as inferior brass alloys or poor plating (e.g., inadequate gold or nickel thickness). This leads to increased insertion loss, poor signal integrity, higher VSWR, and reduced durability. Additionally, inconsistent machining tolerances can result in unreliable mating, leading to intermittent connections or mechanical failure over time.

Counterfeit or Non-Compliant Components

The market is flooded with counterfeit or mislabeled Dean connectors that claim to meet industry standards (e.g., MIL-DTL-39012) but fail under real-world conditions. These components often mimic the appearance of genuine connectors but lack proper testing, certification, or traceability. Using such parts can jeopardize system reliability, especially in critical applications like aerospace, medical devices, or defense systems.

Lack of IP Protection and Design Infringement

Dean connectors are often protected by patents or proprietary designs. Sourcing from suppliers who replicate these designs without licensing can expose your company to intellectual property (IP) infringement claims. Even if the connector functions adequately, using a design that violates existing IP rights can result in legal action, product recalls, or supply chain disruptions. It’s essential to verify that suppliers have the right to manufacture and sell the connectors, particularly if they are marketed as compatible or equivalent.

Insufficient Documentation and Traceability

Many low-cost suppliers fail to provide comprehensive documentation, including material specifications, test reports, or RoHS/REACH compliance certificates. Without proper traceability, it becomes difficult to validate quality or respond to field failures. This lack of transparency also complicates audits and regulatory compliance, especially in industries requiring strict component traceability.

Conclusion

To avoid these pitfalls, work with reputable suppliers, request full certification and test data, and conduct due diligence on IP rights. Prioritizing quality and compliance over initial cost savings ensures long-term reliability and mitigates legal and operational risks.

Logistics & Compliance Guide for Dean Connector

This guide outlines the essential logistics processes and compliance requirements for managing operations with Dean Connector. Adhering to these standards ensures efficient shipping, regulatory adherence, and seamless collaboration.

Shipping & Transportation

Dean Connector utilizes a network of trusted carriers to provide reliable domestic and international shipping solutions. All shipments must be coordinated through the designated Dean Connector logistics portal or authorized point of contact. Standard lead times vary by destination and service level (e.g., ground, expedited, air freight). Proper packaging, including cushioning and secure labeling, is required to prevent damage during transit. Shipments must be palletized where applicable, with weight and dimensions clearly documented.

Documentation Requirements

Accurate and complete documentation is mandatory for every shipment. Required documents include:

– Commercial Invoice (for international shipments)

– Packing List (itemized by SKU, quantity, weight, and dimensions)

– Bill of Lading (BOL)

– Certificate of Origin (where applicable)

– Any relevant permits or export licenses

All documents must be submitted electronically via the Dean Connector compliance portal at least 24 hours prior to pickup. Inaccurate or missing documentation may result in delays or rejection of goods.

Regulatory Compliance

Dean Connector adheres to all applicable international, federal, and regional regulations. Key compliance areas include:

– Export Controls: Compliance with EAR (Export Administration Regulations) and ITAR (International Traffic in Arms Regulations) when applicable.

– Customs Clearance: All goods must be classified under the correct HS code. Importers must ensure tariff classifications and duty payments align with local customs authorities.

– Prohibited Items: Certain goods (e.g., hazardous materials, counterfeit items, controlled substances) are strictly prohibited. Refer to the Dean Connector Restricted Commodities List for details.

– Data Privacy: Personal and transactional data must be handled in accordance with GDPR, CCPA, and other relevant data protection laws.

Labeling & Marking Standards

All packages must be labeled with:

– Dean Connector-provided tracking number

– Ship-to and return addresses (clearly printed)

– Handling instructions (e.g., “Fragile,” “This Side Up”)

– Hazardous material labels (if applicable and approved)

Barcodes must be scannable and placed on the largest, flat surface of the package. Use of non-compliant labels or handwritten labels is not permitted.

Returns & Reverse Logistics

Returns must be pre-authorized through the Dean Connector returns management system (RMA portal). Unauthorized returns will not be accepted. Approved returns must include the RMA number clearly displayed on the package. Product condition and packaging will be inspected upon receipt; refunds or credits are issued based on Dean Connector’s return policy. Environmental compliance regulations apply to the disposal or recycling of returned electronic items.

Performance & Audits

Dean Connector conducts regular logistics performance reviews and compliance audits. Key performance indicators (KPIs) include on-time pickup rate, shipment accuracy, documentation completeness, and damage rate. Facilities may be subject to periodic audits to ensure adherence to safety, security, and regulatory standards. Non-compliance may result in corrective action plans or suspension of shipping privileges.

Contact & Support

For logistics inquiries, documentation submission, or compliance questions, contact:

– Logistics Support: [email protected] | +1 (800) 555-0199

– Compliance Office: [email protected] | +1 (800) 555-0178

– 24/7 Emergency Line (for hazardous shipments): +1 (800) 555-0162

All communications should reference your vendor ID and contract number.

Conclusion for Sourcing Dean Connectors:

After a comprehensive evaluation of potential suppliers, technical specifications, quality standards, and pricing models, it is evident that sourcing Dean connectors requires a strategic approach that balances cost-efficiency with reliability and performance. These connectors are critical in high-frequency and RF applications, where signal integrity, durability, and precision are paramount. Therefore, selecting a reputable supplier with consistent quality control, compliance with industry standards (such as RoHS and ISO certifications), and the capability for volume scalability is essential.

Furthermore, considerations such as lead times, packaging, material quality (e.g., brass contacts, PTFE insulation), and post-sales support play a significant role in ensuring seamless integration into manufacturing processes. Establishing long-term partnerships with suppliers who offer technical support and flexibility can enhance supply chain resilience.

In conclusion, the optimal sourcing strategy for Dean connectors involves thorough due diligence, supplier audits, sample testing, and ongoing performance assessment. Prioritizing quality and reliability over minimal cost differences will ultimately lead to improved product performance, reduced failure rates, and greater customer satisfaction.