The global DC power connector market is experiencing steady growth, driven by rising demand across consumer electronics, industrial equipment, and automotive applications. According to a report by Mordor Intelligence, the global power connectors market size was valued at USD 10.9 billion in 2023 and is projected to reach USD 14.3 billion by 2029, growing at a CAGR of approximately 4.8% during the forecast period. A key segment within this market—DC power plug types—has seen increased innovation and production, particularly as portable and battery-powered devices become more prevalent. This surge in demand has positioned leading manufacturers to advance product reliability, miniaturization, and compatibility. Based on market presence, product range, and technological innovation, the following list highlights the top 10 DC power plug types manufacturers shaping the industry in 2024.

Top 10 Dc Power Plug Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 US Power Supply Manufacturer & Engineering

Domain Est. 1996

Website: eta-usa.com

Key Highlights: Manufacturer of AC/DC & DC/DC power supplies & converter for Industrial, Medical, Military, & Transportation. U.S. based, ITAR registered….

#2 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

#3 AC/DC Power Supplies Catalog

Domain Est. 1998

Website: fsp-group.com

Key Highlights: FSP Group offers a huge AC/DC power supplies selection, including PC/IPC power supplies, medical power supplies, open frame power supplies. High efficiency….

#4 DC Power Connectors

Domain Est. 1995

Website: mouser.com

Key Highlights: $4.99 delivery · 30-day returnsMouser is an authorized distributor for many DC power connector manufacturers including CUI Devices, Kobiconn, Kycon, Switchcraft & more….

#5 CUI Inc.

Domain Est. 1996

Website: belfuse.com

Key Highlights: The range of CUI products includes AC-DC power supplies and DC-DC converters, featuring desktop adapters, wall plug adapters, custom adapters, board mount, and ……

#6 Wall Industries

Domain Est. 1998

Website: wallindustries.com

Key Highlights: Wall Industries manufactures and markets a full line of DC DC converters and AC DC power supplies. Browse our standard and customized power solutions ……

#7 Wall Plug

Domain Est. 2003

Website: triadmagnetics.com

Key Highlights: Wall Plug-Ins DC Power Supplies (For Industrial and Commercial Use Only) ; Input Voltage (AC) · 120 V ; Input Power · 4.5 W ; Output Voltage (DC) · 7.5 V ; Output ……

#8 Anderson Power

Domain Est. 1996

Website: andersonpower.com

Key Highlights: Anderson Power is an international leader in high-powered, interconnect solutions. We offer innovative, state-of-the-art electrical power connector ……

#9 Powerwerx

Domain Est. 1999

Website: powerwerx.com

Key Highlights: 10–21 day delivery · 30-day returnsPowerwerx offers Anderson Powerpole Connectors, Power Supplies, Battery Chargers, Wire & Cable, Mobile Timers much more. Shop online today!…

#10 Dc Power Plugs

Domain Est. 2024

Expert Sourcing Insights for Dc Power Plug Types

H2: 2026 Market Trends for DC Power Plug Types

The global market for DC power plug types is poised for significant transformation by 2026, driven by evolving consumer electronics, the rise of renewable energy systems, and heightened demand for standardization and interoperability. As portable devices, electric vehicles (EVs), IoT systems, and off-grid power solutions continue to proliferate, the design, compatibility, and safety of DC power connectors are becoming critical factors in product development and user experience.

-

Growing Demand for Standardization

One of the most prominent trends shaping the DC power plug market in 2026 is the push for universal standards. Fragmentation in plug types—such as barrel connectors, USB-C, Anderson Powerpoles, and proprietary designs—has long plagued consumers and manufacturers alike. Regulatory bodies and industry consortia, including the USB Implementers Forum (USB-IF) and the International Electrotechnical Commission (IEC), are expected to expand the adoption of standardized DC connectors, particularly USB-C with Power Delivery (USB-PD). By 2026, USB-C is projected to dominate consumer electronics, reducing e-waste and enhancing cross-device compatibility. -

Expansion of USB-C and GaN Technology Integration

Gallium Nitride (GaN) chargers are accelerating the transition toward more compact, efficient DC power solutions. These high-efficiency chargers are increasingly paired with USB-C connectors, enabling higher wattage delivery (up to 240W with USB PD 3.1) across laptops, monitors, and even small appliances. By 2026, the integration of GaN semiconductors with standardized DC plugs will likely become the norm, especially in premium electronics and enterprise hardware. -

Rise of Modular and Locking DC Connectors in Industrial Applications

In industrial, automotive, and renewable energy sectors, demand is growing for robust, locking DC connectors that ensure stable power transmission in harsh environments. Connectors such as Anderson Powerpole, XT60, and M12 DC variants are gaining traction due to their reliability, high current capacity, and resistance to vibration and moisture. The expansion of solar power installations and EV charging infrastructure will further drive demand for these specialized plug types. -

Sustainability and E-Waste Reduction Initiatives

Environmental regulations, particularly in the European Union and North America, are influencing DC plug design. The EU’s common charger directive, which mandates USB-C for most electronic devices by 2024, will have lasting ripple effects into 2026. This regulatory shift is expected to reduce redundant chargers and lower electronic waste, prompting manufacturers to phase out proprietary DC plugs in favor of universally accepted alternatives. -

Wireless DC Power and Hybrid Solutions

While not replacing physical plugs entirely, wireless power transfer (e.g., magnetic resonance and inductive charging) is emerging as a complementary trend. However, for high-power applications, wired DC plugs will remain dominant. By 2026, hybrid systems combining wireless convenience with standardized DC backup ports are anticipated in consumer devices and smart furniture. -

Regional Market Variations and Emerging Economies

While developed markets move toward standardization, emerging economies may continue using a mix of legacy DC plug types due to cost sensitivity and infrastructure limitations. However, increasing smartphone and solar product penetration in regions like Southeast Asia, Africa, and Latin America will gradually align these markets with global standards, particularly USB-C.

Conclusion

By 2026, the DC power plug market will be characterized by consolidation around USB-C for consumer electronics, increased use of ruggedized connectors in industrial applications, and a stronger emphasis on sustainability and regulatory compliance. Innovation in materials, efficiency, and safety will continue to shape plug design, ensuring that DC power delivery evolves in step with the broader energy and digital ecosystems.

Common Pitfalls When Sourcing DC Power Plug Types (Quality, IP Rating)

Sourcing the right DC power plug involves more than just matching voltage and current specs. Overlooking quality and Ingress Protection (IP) ratings can lead to reliability issues, safety hazards, and product failures. Below are key pitfalls to avoid.

Poor Quality Materials and Construction

Many low-cost DC power plugs use substandard materials such as brittle plastic housings or low-grade metal contacts. These can crack under stress, corrode easily, or lose conductivity over time. Poor solder joints or loose internal connections increase resistance, leading to overheating and potential fire risks. Always verify material certifications and conduct mechanical stress tests during supplier evaluation.

Misunderstanding or Falsifying IP Ratings

A common pitfall is assuming that a plug labeled with an IP rating (e.g., IP67) genuinely meets that standard. Some suppliers exaggerate or falsify IP claims without proper testing. For instance, a plug may claim dust and water resistance but fail under real-world conditions due to inadequate sealing or poorly designed gaskets. Always request third-party test reports and validate IP compliance through independent testing when used in harsh environments.

Inconsistent Tolerances and Interchangeability Issues

DC power plugs from different manufacturers—even with the same nominal dimensions—can exhibit significant tolerance variations. This leads to unreliable mating, intermittent connections, or difficulty in assembly. Using non-standard or proprietary designs without clear documentation increases the risk of sourcing incompatible replacements later in the product lifecycle.

Overlooking Environmental and Regulatory Compliance

Some DC plugs may not comply with RoHS, REACH, or UL/CE standards, especially when sourced from uncertified suppliers. Non-compliant materials can lead to regulatory rejection or field recalls. Additionally, lack of flame-retardant ratings (e.g., UL94 V-0) in the housing material poses fire safety risks in enclosed or high-temperature applications.

Inadequate Current and Voltage Derating

Suppliers may advertise maximum current ratings under ideal lab conditions, but real-world performance often degrades due to temperature rise, contact resistance, or poor ventilation. Failing to derate appropriately—especially in high-temperature environments—can result in overheating, insulation failure, or connector meltdown. Always cross-check rated values with application-specific thermal and load profiles.

Insufficient Mechanical Durability for Intended Use

Plugs designed for consumer electronics may not withstand industrial or outdoor use. Frequent insertions, vibration, or exposure to chemicals can degrade performance quickly if the plug isn’t built for such conditions. Choosing connectors without adequate mating cycle ratings (e.g., 1,000+ cycles) leads to premature wear and field failures.

Lack of Traceability and Supplier Reliability

Sourcing from suppliers with poor quality control systems or no batch traceability increases the risk of inconsistent quality and counterfeit components. Without reliable data, diagnosing field failures becomes difficult. Always vet suppliers for ISO certifications, quality management systems, and long-term support capability.

Logistics & Compliance Guide for DC Power Plug Types

Understanding DC power plug types is essential for global logistics, product distribution, and regulatory compliance. This guide outlines key considerations related to shipping, safety standards, and regional requirements when dealing with various DC power plug configurations.

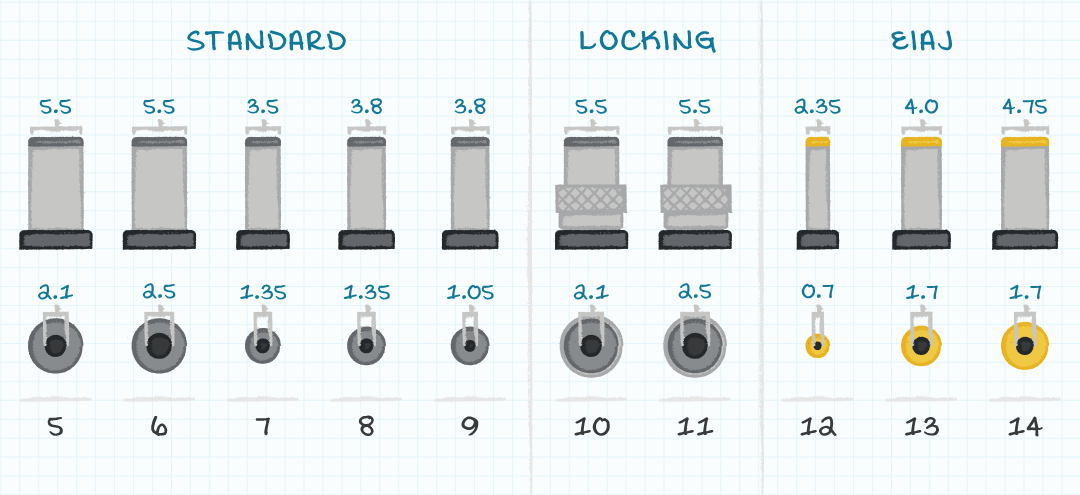

Overview of Common DC Power Plug Types

DC power plugs come in numerous sizes and configurations, with the most common being barrel connectors. Key specifications include:

– Outer diameter (OD) – Typically 2.1mm, 2.5mm, 3.5mm, or 5.5mm

– Inner diameter (ID) – Commonly 0.7mm, 1.0mm, or 2.1mm

– Polarity – Center-positive or center-negative (critical for device compatibility)

– Voltage and current ratings – Must match device requirements

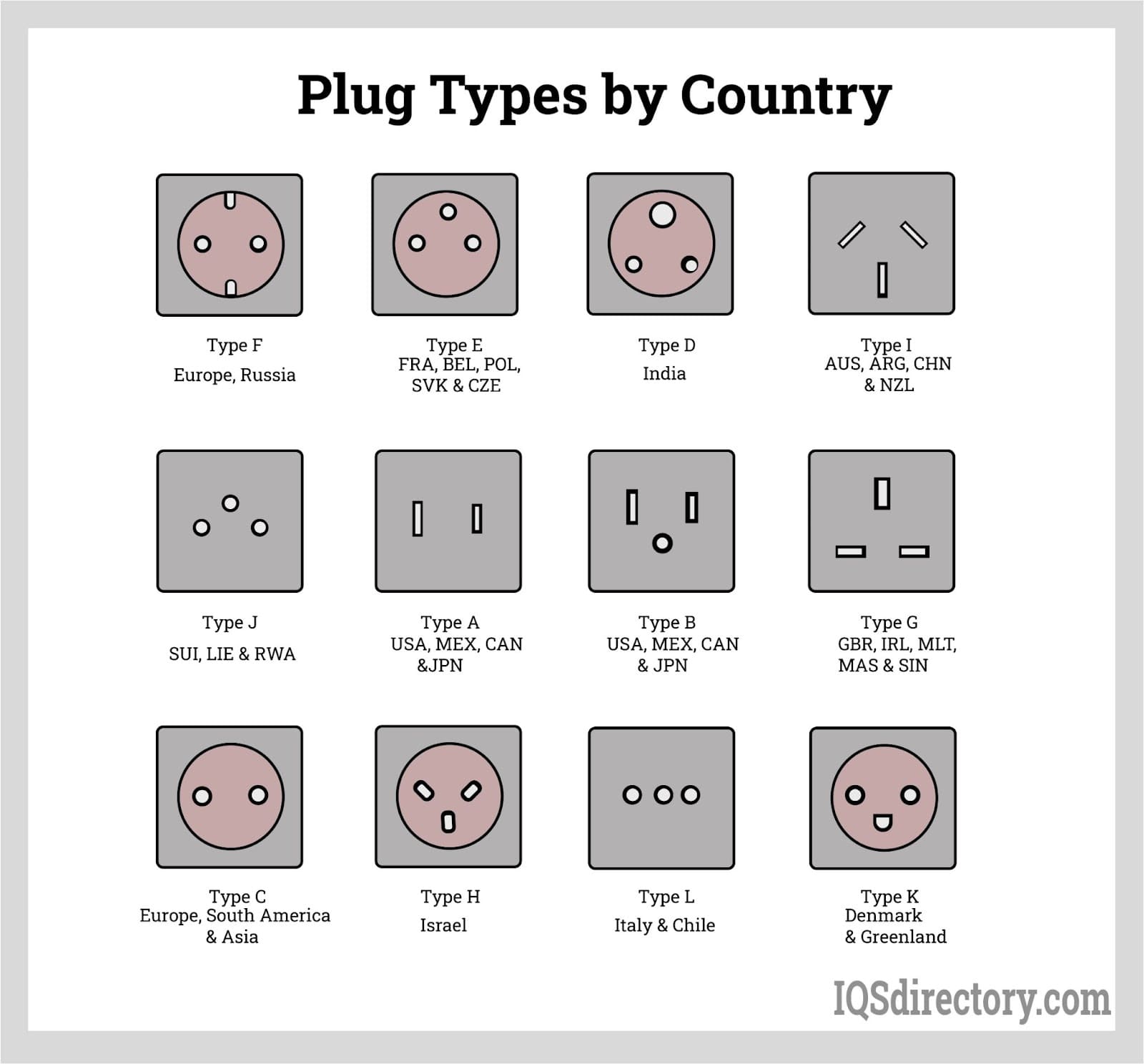

Other types include USB-based connectors (e.g., USB-C for DC power), coaxial plugs, and proprietary designs.

Regulatory Compliance Requirements

Compliance with regional and international standards is mandatory for market access and safe operation.

International Standards

- IEC 62368-1: Audio/video, information, and communication technology equipment safety standard. Applies to power supplies and DC-powered devices.

- RoHS (EU): Restriction of Hazardous Substances. Limits use of lead, mercury, cadmium, etc., in electronics.

- REACH (EU): Chemical safety regulation affecting materials used in plug manufacturing.

Regional Compliance

- North America (USA & Canada):

- UL/CSA Certification: Required for safety. UL 62368-1 and CSA C22.2 No. 62368-1 ensure safe power adapter and plug design.

- FCC Part 15: Electromagnetic interference (EMI) regulations for digital devices.

- European Union:

- CE Marking: Mandatory for DC power supplies and plugs. Includes compliance with Low Voltage Directive (LVD) and EMC Directive.

- UKCA Marking: Required for products sold in Great Britain (post-Brexit).

- Asia-Pacific:

- PSE (Japan): Required for electrical products, including DC power adapters.

- KC Mark (South Korea): Mandatory safety certification.

- CCC Mark (China): Required for specified electronic products and power supplies.

Logistics Considerations

Packaging and Labeling

- Clearly label DC plug specifications (voltage, polarity, dimensions) on packaging.

- Include multilingual user manuals and safety warnings for international shipments.

- Use tamper-evident and anti-static packaging where necessary.

Inventory Management

- Stock multiple plug types or interchangeable tips to serve different markets.

- Ensure plug compatibility with power adapters and end devices to avoid returns.

Import/Export Documentation

- Provide technical specifications (e.g., voltage, current, polarity) in customs declarations.

- Include compliance certificates (e.g., CE, UL, PSE) with shipments.

- Declare plug materials for RoHS/REACH compliance.

Safety and Risk Mitigation

- Polarity Mismatch Prevention: Clearly mark polarity on plugs and devices to prevent damage.

- Overvoltage Protection: Ensure DC power supplies include safeguards.

- Counterfeit Components: Source plugs from certified suppliers to avoid substandard parts.

Best Practices for Global Distribution

- Standardize Where Possible: Use common plug types (e.g., 5.5mm x 2.1mm center-positive) to reduce complexity.

- Localize Adapters: Bundle region-specific DC plugs or offer plug kits.

- Maintain Compliance Records: Keep updated certifications and test reports for audits.

- Train Staff: Ensure logistics and customer service teams understand plug types and compliance labels.

By adhering to regulatory standards and optimizing logistics practices, businesses can ensure safe, compliant, and efficient distribution of products using DC power plug types worldwide.

In conclusion, sourcing the appropriate DC power plug type requires careful consideration of several key factors including voltage and current ratings, plug dimensions (such as barrel size, pin diameter, and length), polarity configuration, and the specific requirements of the device being powered. Common types such as barrel plugs, USB connectors, and proprietary variants each have their own applications and standards. Ensuring compatibility between the power supply, cable, and equipment is essential to prevent damage and ensure safe, reliable operation. Additionally, adherence to industry standards and regional regulations, as well as attention to quality and durability in sourcing components, contributes to long-term performance. When in doubt, consulting manufacturer specifications or opting for standardized, widely available plug types can simplify procurement and improve interoperability across devices.