The global market for DC power connectors, including DC jack plug sizes, has experienced steady growth driven by rising demand in consumer electronics, telecommunications, and industrial equipment. According to Grand View Research, the global power connectors market was valued at USD 11.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by advancements in portable electronics and increasing adoption of IoT-enabled devices. Similarly, Mordor Intelligence forecasts continued momentum in the connector market, with particular growth in compact, reliable DC jacks used in smartphones, wearables, and automotive electronics. As device miniaturization and power efficiency become critical, manufacturers of DC jack plugs are under pressure to deliver precision-engineered, high-performance solutions. This has led to the emergence of key players dominating the landscape through innovation, scalability, and global supply chain reach. Below are the top 9 DC jack plug sizes manufacturers shaping the industry with proven technical expertise and market influence.

Top 9 Dc Jack Plug Sizes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 DC Power Connectors

Domain Est. 1995

Website: mouser.com

Key Highlights: $4.99 delivery · 30-day returnsMouser is an authorized distributor for many DC power connector manufacturers including CUI Devices, Kobiconn, Kycon, Switchcraft & more….

#2 CUI Inc.

Domain Est. 1996

Website: belfuse.com

Key Highlights: The range of CUI products includes AC-DC power supplies and DC-DC converters, featuring desktop adapters, wall plug adapters, custom adapters, board mount, and ……

#3 DC Jack Connectors

Domain Est. 1992

Website: te.com

Key Highlights: Free delivery 30-day returnsTE offers a wide variety of DC Jack connectors or battery jacks that provide superior battery connection to slim, portable hand-held devices, laptops an…

#4 Connectors

Domain Est. 1994

Website: molex.com

Key Highlights: Molex Easy-On FFC Connectors and FPC Connectors provide an extensive combination of actuators, pitch sizes (0.20 to 2.00mm) and circuit sizes (2 to 120) to ……

#5 Standard DC Power Jacks & Plugs

Domain Est. 1996

Website: switchcraft.com

Key Highlights: DC power jacks including straight and right angle PC mount, plastic or metal housings, solder terminals and a variety of center pin size options….

#6 DC Plugs / Sockets – Electronic Components Catalog

Domain Est. 1996

Website: schurter.com

Key Highlights: Find product versions, technical data, CAD files, approvals and more information about premium quality electronic components by SCHURTER. Click here….

#7 All DC Jack connectors

Domain Est. 2010

Website: gct.co

Key Highlights: Browse GCT’s DC jack connectors in horizontal and vertical, surface mount and thru hole with options for 2.5A thru 8.0A current rating….

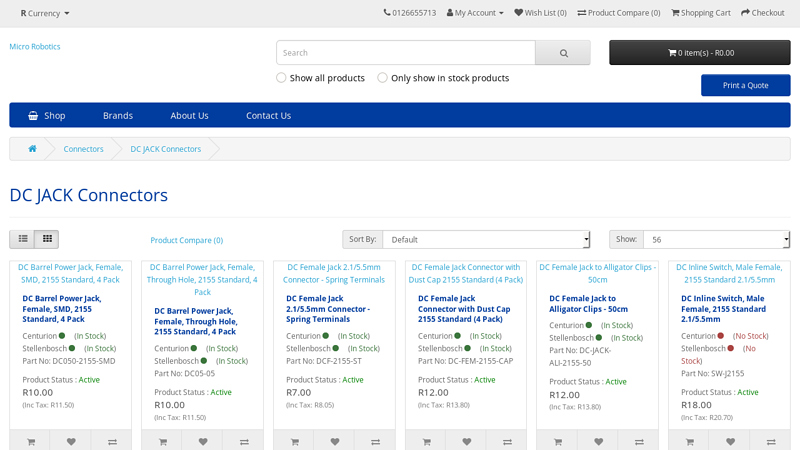

#8 DC JACK Connectors

Domain Est. 2010

Website: robotics.org.za

Key Highlights: DC Jack Connector 1.35/3.5mm Male (4 Pack) Centurion (In Stock) Stellenbosch (In Stock) Part No: DC135-35 Product Status : Active R12.00 (Inc Tax: R13.80)…

#9 Dc Power Connectors

Domain Est. 2024

Website: sameskydevices.com

Key Highlights: Our dc power connectors feature current ratings up to 13 A, center pin diameters ranging from 0.6 mm to 5.5 mm, and compact package sizes with heights down to 3 ……

Expert Sourcing Insights for Dc Jack Plug Sizes

H2: 2026 Market Trends for DC Jack Plug Sizes

The global market for DC jack plug sizes is poised for significant evolution by 2026, driven by advancements in consumer electronics, industrial automation, and the proliferation of portable and IoT-enabled devices. As power delivery standards evolve and device miniaturization continues, the demand for standardized, efficient, and compact DC power connectors is reshaping the landscape. Below are the key market trends for DC jack plug sizes expected to define the 2026 outlook.

1. Dominance of Miniaturized Plug Sizes

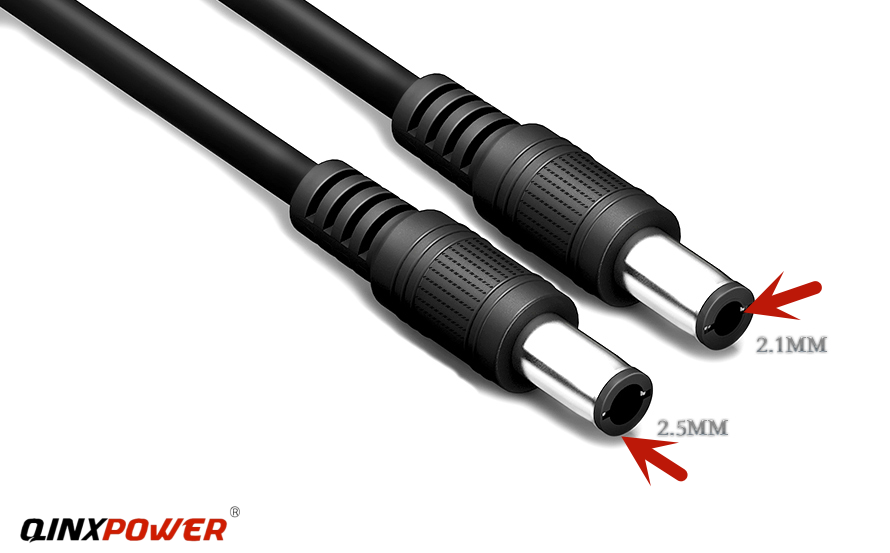

By 2026, smaller DC jack plug sizes—particularly the 2.1mm and 2.5mm outer diameter (OD) variants—are expected to maintain dominance in consumer electronics such as wearables, Bluetooth devices, and compact IoT sensors. The push toward slimmer, lighter devices is accelerating demand for micro and sub-mini DC jacks, including 1.5mm and 1.7mm OD connectors, especially in medical and aerospace applications.

2. Standardization and Interoperability Push

Growing emphasis on cross-device compatibility is driving industry-wide efforts to standardize DC plug dimensions. The 2.1mm (center-positive) configuration remains the de facto standard for many low-voltage applications. In 2026, manufacturers are expected to increasingly adopt unified specifications to reduce e-waste and improve user experience, with regulatory bodies potentially mandating interoperability in certain regions.

3. Shift Toward Reversible and Hybrid Connectors

While traditional barrel-type DC jacks remain prevalent, there is a rising trend toward hybrid power/data connectors and reversible designs. Although USB-C is encroaching on traditional DC jack applications, niche markets continue to rely on barrel connectors for cost and simplicity. In 2026, expect innovations in dual-function jacks that combine DC power input with signal transmission, especially in industrial control systems.

4. Growth in Industrial and Automotive Applications

The industrial automation and electric vehicle (EV) accessory markets are contributing to increased demand for ruggedized DC jacks in larger sizes (e.g., 3.5mm and 5.5mm OD). These sizes offer higher current ratings and durability for harsh environments. By 2026, the 5.5mm x 2.1mm and 5.5mm x 2.5mm configurations are projected to see sustained growth in power tools, robotics, and off-grid solar systems.

5. Regional Market Variations

Asia-Pacific, led by China and Japan, will remain the largest producer and consumer of DC jacks due to its robust electronics manufacturing base. In contrast, North America and Europe are expected to prioritize environmentally compliant and RoHS-certified connectors, influencing material choices and design specifications for DC plug sizes.

6. Sustainability and Circular Design Considerations

By 2026, environmental regulations will increasingly influence DC jack design. Manufacturers are anticipated to focus on recyclable materials, longer product lifecycles, and modular designs that reduce the need for frequent replacements. This shift may favor standardized plug sizes to support repairability and component reuse.

7. Supply Chain Optimization and Smart Manufacturing

Automation in connector production and AI-driven supply chain management are expected to improve consistency in DC jack dimensions. Tighter tolerances and quality control will reduce field failures, enhancing reliability—especially critical for mission-critical applications using precise plug sizes.

Conclusion

The 2026 market for DC jack plug sizes reflects a balance between legacy compatibility and innovation. While miniaturization and standardization remain central, emerging applications in smart infrastructure and renewable energy will sustain demand for a diverse range of plug sizes. Manufacturers who adapt to evolving form factors, regulatory landscapes, and sustainability goals will be best positioned to capture growth in this mature yet dynamic segment.

Common Pitfalls When Sourcing DC Jack Plug Sizes (Quality and IP Ratings)

Sourcing the correct DC jack plug size is critical for ensuring compatibility, performance, and durability in electronic devices. However, several common pitfalls can lead to poor quality, reliability issues, or incorrect specifications—especially concerning physical dimensions and Ingress Protection (IP) ratings. Below are key areas to watch for:

Inaccurate or Inconsistent Size Specifications

One of the most frequent issues is confusion around DC jack plug dimensions, typically described by outer diameter (OD), inner diameter (ID), and length. Suppliers may provide vague or incorrect measurements, such as listing only the outer diameter while neglecting the inner pin size or sleeve length. This can result in poor fit, intermittent connections, or physical damage to the device. Always verify full specifications (e.g., 5.5mm x 2.1mm) and request detailed mechanical drawings when possible.

Poor Build Quality and Material Selection

Low-cost DC jacks often use substandard materials such as brittle plastics or thin plating on metal contacts. This leads to premature wear, loose fits, or solder joint failure. Look for jacks made with robust materials like brass contacts with nickel or gold plating and high-temperature thermoplastics. Poor quality can also manifest in weak strain relief, causing cable detachment over time.

Misrepresented or Missing IP Ratings

Many suppliers claim their DC jacks are “waterproof” or “dustproof” without providing certified IP ratings. Even when IP ratings are listed (e.g., IP67), they may not be independently tested or certified. Using a jack without proper IP protection in harsh environments can lead to corrosion, short circuits, or device failure. Always request test reports or certifications to validate IP claims.

Lack of Standardization Across Suppliers

Different manufacturers may slightly vary internal tolerances or spring contact pressure, even within the same nominal size. This inconsistency can affect electrical performance and mechanical fit. To mitigate this, standardize on reputable brands and conduct sample testing before full-scale procurement.

Overlooking Electrical and Current Rating Compatibility

While focusing on physical dimensions, buyers often neglect electrical specifications such as current rating and contact resistance. A DC jack rated for 2A may overheat if used in a 3A application. Ensure the jack’s electrical specs match or exceed your system’s requirements.

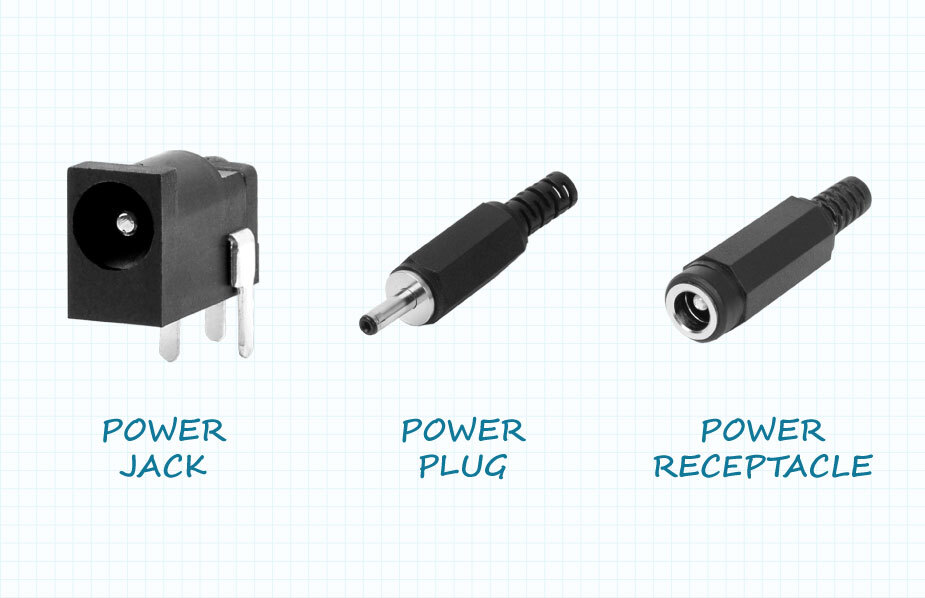

Insufficient Attention to Mounting and PCB Compatibility

Some DC jacks are designed for panel mounting, while others are PCB through-hole or surface-mount types. Choosing the wrong type can complicate assembly or compromise mechanical stability. Confirm mounting style, PCB footprint, and soldering requirements before sourcing.

By addressing these pitfalls—focusing on accurate sizing, verified quality, genuine IP ratings, and full specification alignment—designers and procurement teams can avoid costly errors and ensure reliable power connectivity in their products.

Logistics & Compliance Guide for DC Jack Plug Sizes

When integrating DC jack plugs into electronic devices or power supply systems, adherence to standardized dimensions and regulatory requirements is essential for compatibility, safety, and global market access. This guide outlines key logistics and compliance considerations related to common DC jack plug sizes.

Standard DC Jack Plug Sizes

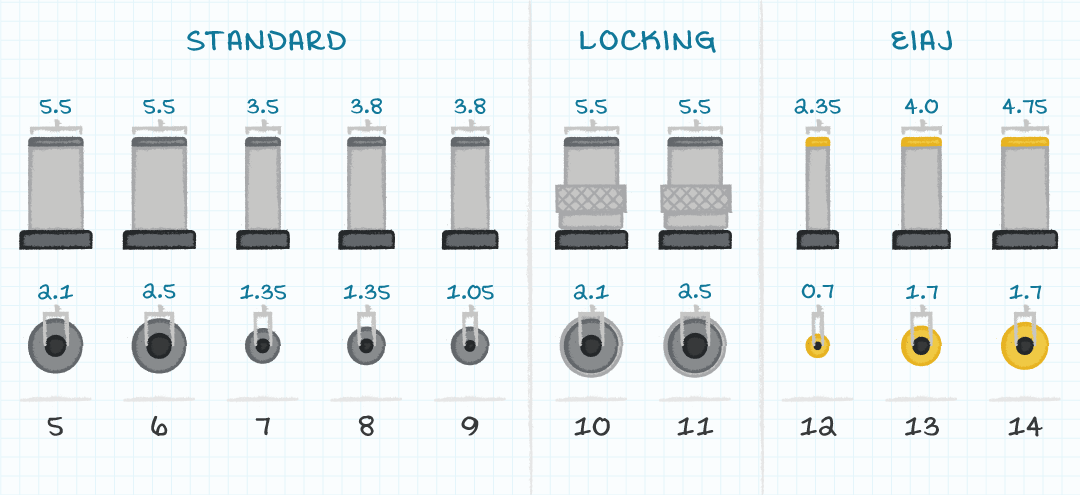

DC power jacks and plugs are available in various sizes, typically defined by two measurements: outer diameter (OD) and inner diameter (ID) of the plug barrel, measured in millimeters (mm). Common standardized sizes include:

- 5.5 mm × 2.1 mm – Most widely used; compatible with many consumer electronics

- 5.5 mm × 2.5 mm – Slightly higher current capacity due to thicker center pin

- 3.5 mm × 1.35 mm – Common in smaller devices such as portable audio equipment

- 4.0 mm × 1.7 mm – Used in compact devices like routers and small adapters

- 6.35 mm × 3.5 mm – Found in higher-power audio and industrial applications

Ensure mechanical compatibility between plugs and jacks during design and sourcing to prevent damage or unreliable connections.

Regulatory Compliance Requirements

DC power connectors must comply with regional and international safety and electromagnetic compatibility (EMC) standards. Key compliance frameworks include:

- IEC 62368-1 – Safety standard for audio/video and IT equipment; applies to power supply systems using DC jacks

- UL/CSA 62368-1 – North American adoption of IEC 62368-1; required for market entry in the U.S. and Canada

- EN 62368-1 – European harmonized standard under the Low Voltage Directive (LVD) and EMC Directive

- RoHS (Restriction of Hazardous Substances) – Restricts use of lead, cadmium, and other hazardous materials in electrical components

- REACH – Addresses chemical safety and requires disclosure of substances of very high concern (SVHC)

Manufacturers and importers must ensure that DC jack components and associated power supplies meet these standards through proper certification (e.g., CE, UKCA, FCC, UL).

Logistics & Supply Chain Considerations

- Standardization: Use common plug sizes (e.g., 5.5×2.1 mm) to simplify sourcing and reduce inventory complexity

- Interchangeability Risks: Clearly label plug dimensions to avoid mismatches; consider keyed or polarized designs to prevent reverse polarity damage

- Packaging and Handling: Protect DC jacks from deformation during shipping; use anti-static packaging if used in ESD-sensitive environments

- Global Sourcing: Verify that suppliers provide compliant, certified components with traceable documentation (e.g., CoC, test reports)

- Voltage and Current Ratings: Match plug/jack ratings to device requirements; exceeding ratings can create safety hazards and compliance failures

Marking and Documentation

Ensure all DC-powered products include:

- Clear labeling of input voltage, current, and polarity (e.g., center-positive symbol)

- User manuals specifying compatible adapter plug size and specifications

- Technical documentation supporting conformity with applicable directives (e.g., EU Declaration of Conformity)

Conclusion

Proper selection, compliance, and logistics planning for DC jack plug sizes are critical to product safety, reliability, and market success. By adhering to international standards and maintaining accurate documentation, businesses can streamline global distribution and minimize compliance risks. Always verify plug dimensions and certifications early in the product development cycle.

In conclusion, sourcing the correct DC jack plug size requires careful attention to specifications to ensure compatibility and reliable performance. Key parameters such as outer diameter (OD), inner diameter (ID), and length (or depth) of the plug must match the corresponding socket on the device. Additionally, factors like voltage/current ratings, polarity (center-positive or center-negative), and locking mechanism (if applicable) should be considered to prevent damage and ensure safety.

Due to the wide variety of DC jack plug sizes and the lack of universal standardization, it is essential to consult the device manufacturer’s documentation or physically measure the existing jack using calipers when possible. Standard sizes such as 5.5mm × 2.1mm and 3.5mm × 1.35mm are common, but variations abound. When sourcing replacements or designing power supplies, verifying exact dimensions and electrical requirements will help avoid poor connections, intermittent power, or equipment damage.

Ultimately, accurate identification and careful sourcing of DC jack plug sizes are critical steps in ensuring the proper function and longevity of electronic devices. When in doubt, contacting the manufacturer or using a trusted supplier with detailed specifications is recommended.