The global market for DC and AC power systems has experienced robust growth, driven by rising energy demands, increased adoption of renewable energy sources, and advancements in power electronics. According to a report by Mordor Intelligence, the global AC power supply market was valued at USD 25.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. Similarly, Grand View Research estimates that the global DC power supply market size reached USD 7.1 billion in 2022, with a forecasted CAGR of 6.3% from 2023 to 2030. This sustained expansion is fueled by growing industrial automation, expanding data center infrastructure, and rising investments in electric mobility and energy storage systems. As demand intensifies for reliable, efficient, and scalable power solutions, manufacturers are innovating rapidly to capture market share across diverse applications—from telecommunications and healthcare to aerospace and renewable integration. The following list highlights the top 10 DC and AC power manufacturers shaping this evolving landscape through technological leadership, global reach, and a strong commitment to performance and sustainability.

Top 10 Dc And Ac Power Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

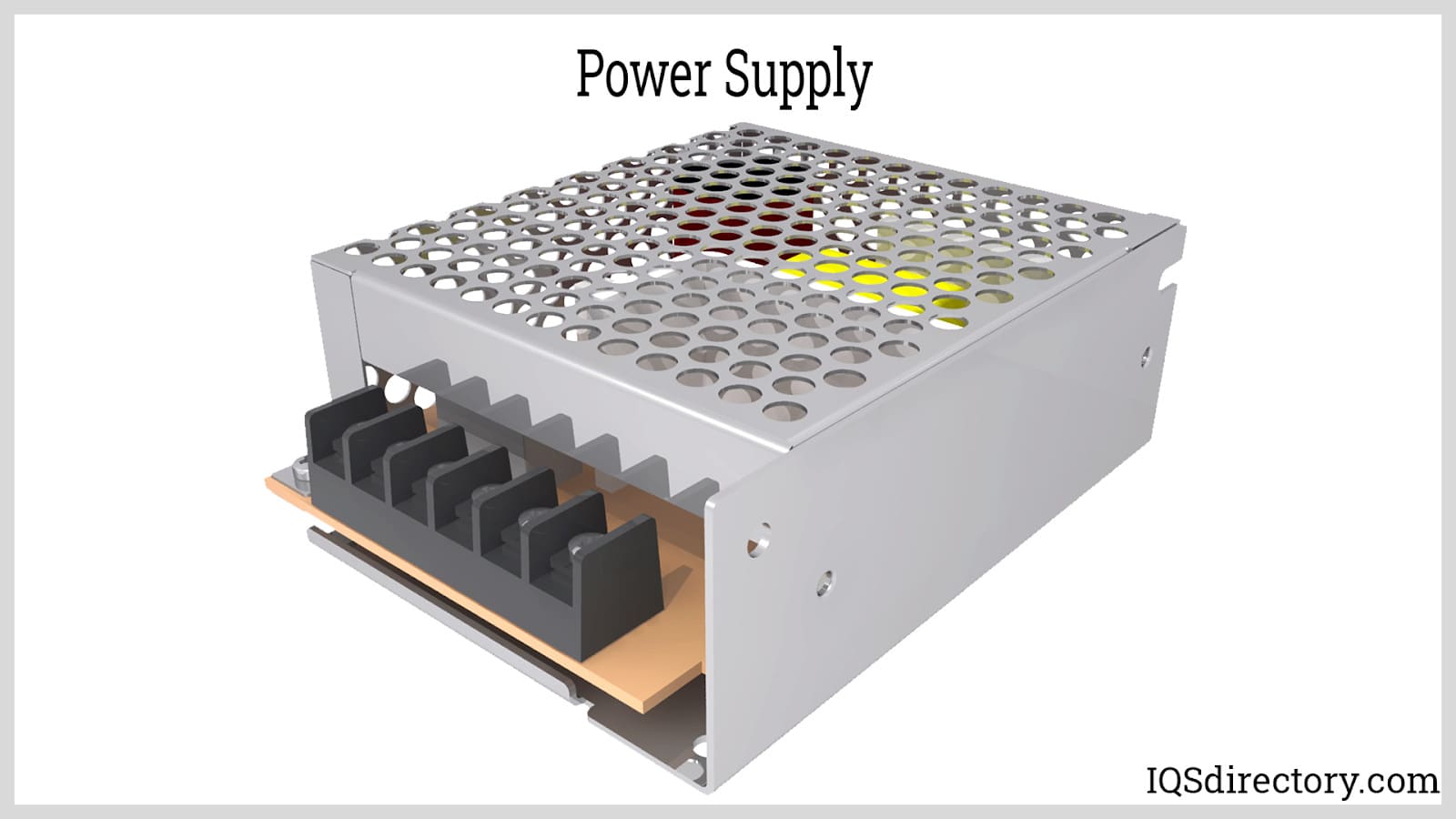

#1 AC-DC Switching Power Supplies

Domain Est. 1997

Website: technologydynamicsinc.com

Key Highlights: Technology Dynamics Inc. is the leading designer and manufacturer of Switching Power Supplies, DC-DC Converters and DC-UPS Systems for Military, Industrial and ……

#2 FSP TECHNOLOGY INC. |AC/DC Power Supply Manufacturer

Domain Est. 1998

Website: fsp-group.com

Key Highlights: Explore FSP TECHNOLOGY INC.|AC DC Power Supply Manufacturer. A world-class innovator in AC/DC power supply design and manufacturing. Power Never Ends….

#3 Cincon

Domain Est. 1998

Website: cincon.com

Key Highlights: Cincon Electronics is a leading manufacturer of DC/DC converters and AC/DC power supplies offering the high-quality and reliable power module solutions….

#4 Wall Industries

Domain Est. 1998

Website: wallindustries.com

Key Highlights: Wall Industries manufactures and markets a full line of DC DC converters and AC DC power supplies. Browse our standard and customized power solutions ……

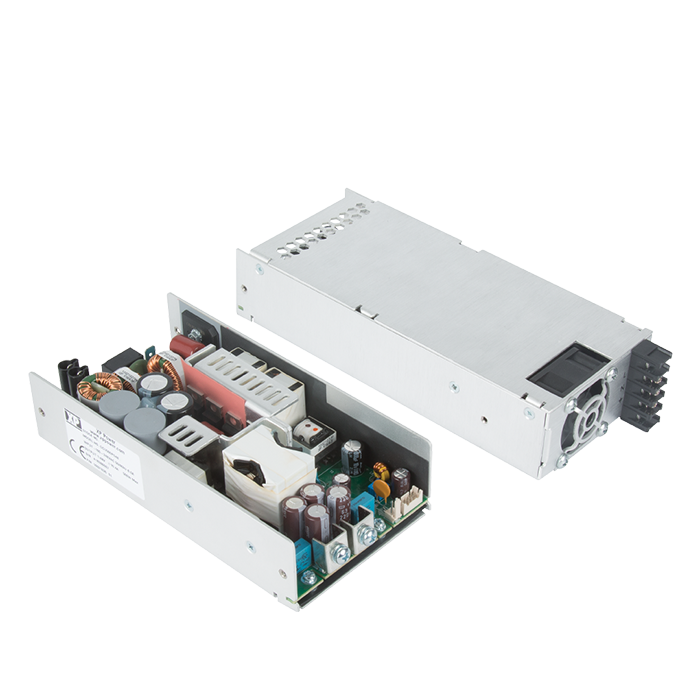

#5 XP Power

Domain Est. 2000

Website: xppower.com

Key Highlights: Looking for the leading manufacturer of AC-DC power supplies, DC-DC converters, high voltage, RF & custom power products? Discover our extensive range….

#6 RECOM: DC/DC & AC/DC Converter

Domain Est. 2006

Website: recom-power.com

Key Highlights: RECOM Power is a leading manufacturer of AC/DC electronic power supplies and DC/DC converters, with over 30,000 compact standard power supplies alongside ……

#7 Power Supplies

Domain Est. 1996

Website: acopian.com

Key Highlights: Millions of Reliable Power Supplies. Acopian can design, build and ship the power supply that meets your needs. The possibilities are endless….

#8 AC & DC Power Technologies

Domain Est. 2003

Website: acdcpowertechnologies.com

Key Highlights: AC & DC Power Technologies offers a full range of uninterruptible power supply products and services to deliver clean, continuous, and dependable power….

#9 AMETEK Programmable Power

Domain Est. 2007

Website: programmablepower.com

Key Highlights: The AMETEK Programmable Power designs, manufactures, and markets precision, ac & dc programmable power supplies, electronic loads, application-specific ……

#10 AC/DC Power Supplies, Solutions & Equipment Supplier

Domain Est. 2013

Website: preenpower.com

Key Highlights: We boast one of the broadest product line of power supply, includes AC Power Source, DC Power Supplies, Power Supplies for , Renewable Energy Simulators, Line ……

Expert Sourcing Insights for Dc And Ac Power

2026 Market Trends for DC and AC Power

As the global energy landscape evolves rapidly, the power sector is witnessing significant shifts in the adoption, infrastructure, and technological advancements of both Direct Current (DC) and Alternating Current (AC) systems. By 2026, several key trends are expected to shape the DC and AC power markets, driven by renewable energy integration, electrification of transport, digitalization, and energy efficiency demands.

Growth of DC Power in Modern Applications

Direct Current (DC) power is experiencing a resurgence due to its compatibility with modern electronic devices, renewable energy sources, and energy storage systems. By 2026, DC power is anticipated to play a more prominent role in specific sectors:

-

Renewable Energy Integration: Solar photovoltaic (PV) systems generate DC power natively. With global solar capacity projected to expand significantly by 2026, the need for efficient DC-DC converters and DC microgrids will increase. DC microgrids reduce conversion losses associated with AC systems, improving overall efficiency in residential, commercial, and industrial applications.

-

Electric Vehicles (EVs) and Charging Infrastructure: EVs operate on DC power, and fast-charging stations rely on high-power DC chargers. The global push toward EV adoption, supported by government regulations and incentives, will drive demand for DC fast-charging networks, especially in urban centers and along major transportation corridors.

-

Data Centers and High-Efficiency Buildings: Data centers, which consume vast amounts of electricity, are increasingly adopting DC power distribution to minimize energy losses from AC-to-DC conversions in servers and IT equipment. By 2026, more energy-efficient buildings may integrate hybrid AC/DC systems to power LED lighting, HVAC controls, and office electronics directly with DC.

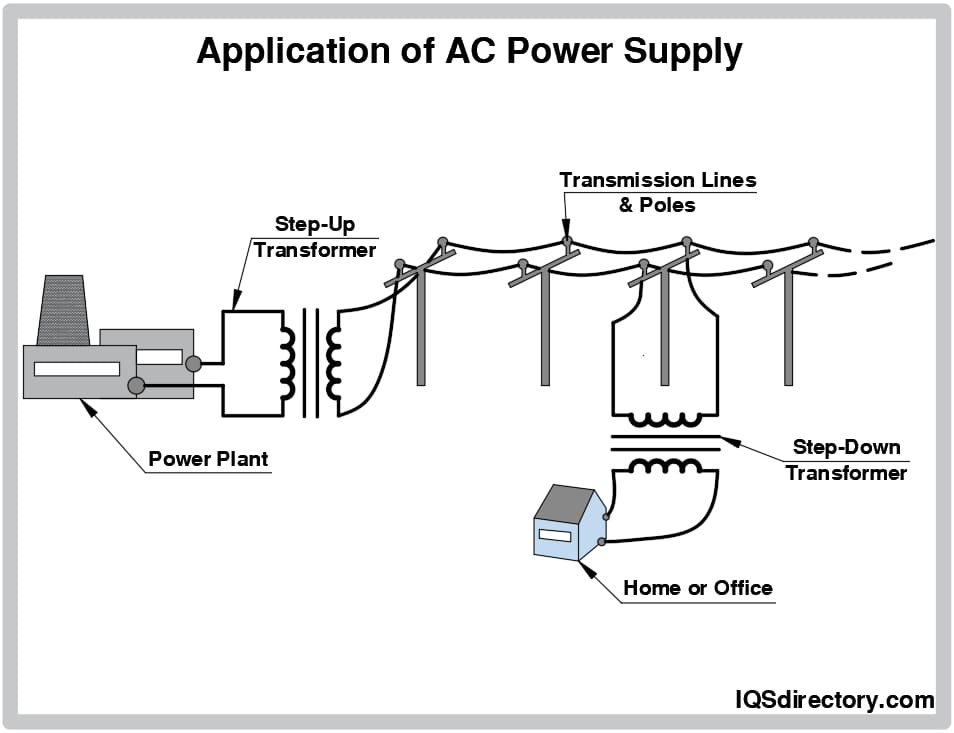

Evolution of AC Power Infrastructure

While DC gains traction in niche applications, Alternating Current (AC) remains the backbone of global power transmission and distribution due to its established infrastructure and ease of voltage transformation.

-

Grid Modernization and Smart Grids: Utilities worldwide are investing in smart grid technologies to enhance reliability, integrate renewables, and enable bidirectional power flow. By 2026, advanced AC grid systems incorporating IoT sensors, AI-driven load balancing, and real-time monitoring will become standard in developed markets.

-

HVAC Transmission and Long-Distance Efficiency: High-voltage AC (HVAC) continues to dominate long-distance power transmission, especially in regions with well-established grids. However, it will increasingly complement High-Voltage DC (HVDC) lines for cross-border and offshore wind integration, where DC offers lower losses over very long distances.

-

Residential and Industrial Demand: AC power will remain the primary choice for residential and heavy industrial applications due to the widespread use of AC motors, appliances, and legacy equipment. Motor-driven systems in manufacturing, pumping, and HVAC will continue to rely on AC, supported by variable frequency drives (VFDs) for improved efficiency.

Convergence of AC and DC Ecosystems

By 2026, the boundary between AC and DC systems is expected to blur, leading to hybrid power architectures:

-

Hybrid Microgrids: Urban districts, campuses, and remote communities will adopt hybrid AC/DC microgrids that combine the strengths of both systems. These microgrids can seamlessly switch between sources, integrate solar and battery storage (DC), and interface with the main AC grid.

-

Power Electronics Advancements: Innovations in semiconductor materials (e.g., silicon carbide and gallium nitride) will enable more efficient and compact AC-DC and DC-AC inverters and converters. This will reduce energy losses and support the interoperability of AC and DC systems.

-

Standardization and Safety Protocols: As DC systems become more common in buildings and urban infrastructure, international standards for DC voltage levels, connectors, and safety will mature. This will accelerate adoption and ensure compatibility across regions.

Regional Market Dynamics

-

Asia-Pacific: Led by China, India, and South Korea, this region will see aggressive deployment of both DC fast-charging networks and smart AC grids. Government initiatives in renewable energy and EVs will drive DC market growth.

-

North America and Europe: These regions will focus on grid resilience and decarbonization. HVDC links for offshore wind and cross-border transmission will expand, while building-integrated DC systems gain momentum in green construction.

-

Emerging Markets: In regions with limited grid access, standalone DC solar home systems and mini-grids will provide affordable electrification, bypassing traditional AC infrastructure.

Conclusion

By 2026, the DC and AC power markets will coexist and converge in response to technological innovation and sustainability goals. While AC remains dominant in transmission and legacy systems, DC will gain ground in renewable integration, transportation, and digital infrastructure. The future power ecosystem will be characterized by flexibility, efficiency, and intelligent hybridization—ushering in a new era of energy management.

Common Pitfalls Sourcing DC and AC Power (Quality, IP)

When integrating power solutions—whether AC from the grid or DC from batteries, solar, or converters—several critical pitfalls can compromise performance, safety, and reliability. Understanding these issues related to power quality and Ingress Protection (IP) ratings is essential for robust system design.

Power Quality Issues in AC Sourcing

One of the most common challenges with AC power sourcing is poor power quality, which can lead to equipment malfunction or premature failure. Key concerns include voltage sags, surges, harmonics, and frequency instability. For instance, voltage fluctuations from an unreliable grid or generator can disrupt sensitive electronics. Harmonic distortion, often caused by non-linear loads like variable frequency drives or switch-mode power supplies, can overheat transformers and reduce system efficiency. Additionally, inadequate grounding or improper neutral connections may introduce noise and increase the risk of electric shock.

Power Quality Issues in DC Sourcing

DC power sources such as batteries, solar panels, or DC-DC converters are prone to their own set of quality concerns. Voltage ripple and noise from switching regulators can interfere with analog circuits or communication systems. Poorly regulated DC outputs—especially in wide input range converters—may deliver unstable voltages under varying load conditions. Furthermore, battery degradation over time can result in reduced capacity and voltage instability, particularly under high current draw, leading to unexpected system shutdowns.

Mismatched or Inadequate IP Ratings

A frequent oversight when sourcing power supplies or enclosures is selecting components with inappropriate Ingress Protection (IP) ratings for the operating environment. Using an IP20-rated power supply in a dusty industrial setting or a damp outdoor location invites damage from particulate or moisture intrusion. For example, a power supply with insufficient IP protection near a washdown area in a food processing plant may fail due to water ingress. Conversely, over-specifying IP ratings can unnecessarily increase costs and reduce thermal efficiency due to sealed enclosures limiting airflow.

Neglecting Environmental and Installation Factors

Environmental conditions such as temperature, humidity, and altitude significantly impact both AC and DC power performance. A power supply rated for indoor use may overheat in a sealed outdoor cabinet without proper ventilation. Similarly, high-altitude installations reduce cooling efficiency and dielectric strength, increasing the risk of arcing in AC systems. Failing to consider these factors during sourcing can result in undervalued reliability and shortened lifespan.

Inadequate Compliance and Certification

Another common pitfall is sourcing power components without proper safety or electromagnetic compatibility (EMC) certifications. Using non-compliant AC/DC adapters or power supplies may violate regional regulations (e.g., CE, UL, FCC), pose fire hazards, or interfere with other equipment. This is especially critical in medical, industrial, or railway applications where strict standards apply.

Conclusion

To avoid these pitfalls, engineers must thoroughly assess power quality requirements and environmental conditions during the sourcing phase. Selecting power solutions with stable output, low ripple, appropriate regulation, and correct IP ratings—backed by relevant certifications—ensures long-term reliability and system safety.

Logistics & Compliance Guide for DC and AC Power

Understanding the logistics and compliance requirements for handling, transporting, storing, and deploying DC (Direct Current) and AC (Alternating Current) power systems is essential for safety, regulatory adherence, and operational efficiency. This guide outlines key considerations for both power types across various industries, including renewable energy, telecommunications, data centers, and industrial manufacturing.

Regulatory Standards and Certifications

Compliance with international, national, and regional electrical standards is mandatory for all DC and AC power equipment. Key standards include:

- IEC (International Electrotechnical Commission): Standards such as IEC 60364 (electrical installations), IEC 62109 (power converters for renewable energy), and IEC 61439 (low-voltage switchgear) apply to both AC and DC systems.

- NEC (National Electrical Code, USA): Article 690 covers solar PV systems (DC), while Article 230 governs AC service conductors. Special attention is required for DC arc-fault protection and rapid shutdown compliance.

- UL (Underwriters Laboratories): Equipment must carry UL certification (e.g., UL 1741 for inverters and UL 480 for wire and cable) to be legally installed in North America.

- CE Marking (Europe): Required for electrical products sold in the EU, ensuring compliance with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

- RoHS and REACH: Environmental compliance for hazardous substances in electrical components.

Ensure all power equipment—batteries, inverters, rectifiers, cables, and switchgear—carries valid certifications relevant to the region of deployment.

Transportation and Handling

Safe logistics operations begin with proper packaging, labeling, and handling procedures:

- Lithium-Ion Batteries (DC Storage): Classified as UN 3480 (lithium-ion) or UN 3090 (lithium metal), requiring:

- UN-certified packaging.

- Proper hazard labels (Class 9 – Miscellaneous Dangerous Goods).

- State of charge (SoC) limited to ≤30% for air transport (per IATA DGR).

- Documentation including Safety Data Sheets (SDS) and transport declarations.

- Lead-Acid Batteries (DC): Regulated under UN 2794/2800; must be leak-proof and packaged to prevent short circuits.

- AC Power Equipment (Transformers, Switchgear): Heavy and sensitive to moisture and shock. Use:

- Crated packaging with shock-absorbing materials.

- Moisture barriers and desiccants for long-distance shipping.

- Tilt and shock indicators for monitoring during transit.

- Labeling Requirements: Clearly mark polarity (for DC), voltage ratings, “Do Not Invert,” “Fragile,” and “This Side Up.” Use bilingual labels where applicable.

Storage Conditions

Proper storage protects equipment integrity and ensures long-term reliability:

- Temperature Control:

- Batteries: Store between 10°C and 25°C (50°F–77°F). Avoid freezing or high heat (>40°C).

- Electronics (Inverters, Rectifiers): Temperature range: -20°C to +60°C; humidity <85% non-condensing.

- Ventilation: Required for battery rooms to prevent hydrogen gas accumulation (especially lead-acid).

- Shelf Life:

- Lithium batteries: 2–3 years maximum storage; periodic charge cycles (every 6 months) recommended.

- Capacitors and electrolytic components: Degrade over time; check manufacturer’s shelf life.

- Orientation: Follow manufacturer instructions—some batteries must be stored upright to prevent leakage.

Installation and Site Compliance

Installation must adhere to electrical codes and environmental conditions:

- DC Systems:

- Use color-coded cables: Red (+) and Black (-) per NEC; IEC recommends Brown (+) and Blue (-).

- Install DC disconnects within line of sight and accessible for emergency shutdown.

- Mitigate DC arc risks with rapid shutdown devices (especially in solar PV).

- AC Systems:

- Follow NEC Article 250 for grounding and bonding.

- Ensure proper phase balancing in three-phase systems.

- Use GFCI/AFCI protection where required (e.g., wet locations).

- Clearance and Ventilation: Maintain minimum clearance around transformers, battery racks, and power cabinets as per manufacturer specs (typically 12–36 inches).

- Environmental Protection: Use NEMA 3R or IP54 enclosures for outdoor installations to resist dust, rain, and corrosion.

Maintenance and Inspection

Regular compliance checks ensure ongoing safety and performance:

- Routine Inspections:

- Check for loose connections, corrosion (especially in DC terminals), and cable insulation degradation.

- Verify grounding continuity and insulation resistance (megger testing).

- Thermal Imaging: Conduct annually to detect hotspots in AC panels and DC combiner boxes.

- Battery Maintenance:

- Monitor voltage, SoC, and temperature.

- Perform equalization charges (for flooded lead-acid).

- Record data per IEEE 450/1188 standards.

- Documentation: Maintain logs of inspections, repairs, certifications, and compliance audits for regulatory review.

Decommissioning and Recycling

End-of-life management must follow environmental regulations:

- Battery Recycling:

- Lithium-ion: Recycle through certified facilities (e.g., RBRC or Call2Recycle in North America).

- Lead-acid: Recycle >99% of components; return to licensed smelters.

- Electronic Waste (E-Waste):

- Inverters, rectifiers, and control boards must be disposed of per WEEE (EU) or state-level e-waste laws (e.g., California).

- Hazardous Materials: PCBs in older transformers require special handling and disposal under EPA TSCA.

- Certificates of Destruction: Obtain documentation confirming proper disposal for audit purposes.

Training and Personnel Safety

Personnel must be trained in handling high-voltage DC and AC systems:

- Qualified Personnel: Only electricians or engineers licensed per local regulations should install or service systems.

- Arc Flash Training: Required for working on AC switchgear (per NFPA 70E).

- DC-Specific Hazards: Emphasize that DC arcs do not self-extinguish and require specialized PPE and tools.

- Lockout/Tagout (LOTO): Implement strict procedures before servicing any power equipment.

Conclusion

Effective logistics and compliance for DC and AC power systems require a holistic approach integrating safety, regulation, and best practices. Adhering to standards, ensuring proper handling and storage, conducting regular maintenance, and responsibly managing end-of-life equipment not only ensures compliance but also enhances system reliability and protects personnel and assets. Always consult local authorities and equipment manufacturers for site-specific requirements.

Conclusion on Sourcing DC and AC Power

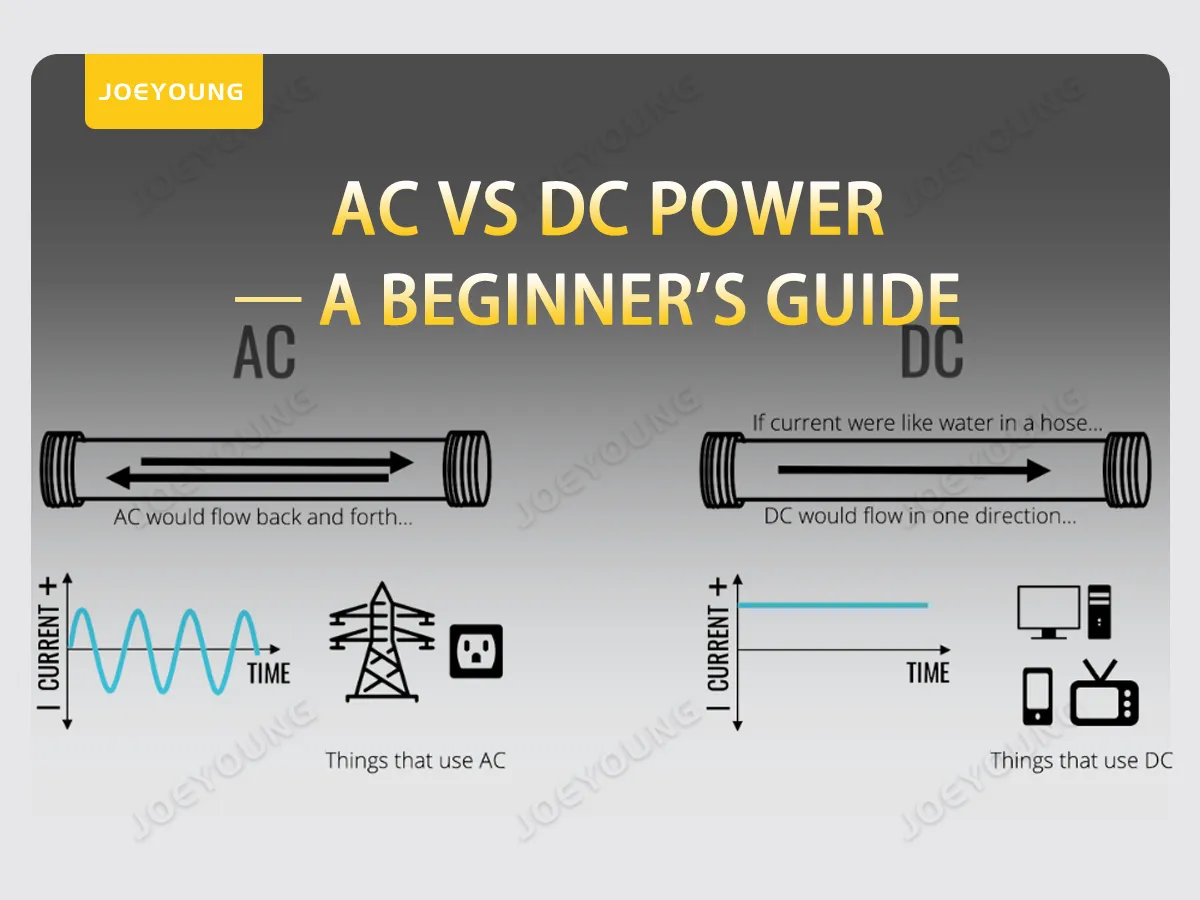

In summary, the choice between sourcing DC (Direct Current) and AC (Alternating Current) power depends on the specific application, infrastructure, and efficiency requirements. AC power remains the standard for most utility grids and household applications due to its ease of voltage transformation and long-distance transmission with minimal losses. It is widely accessible and well-suited for powering motors, lighting, and most commercial and residential equipment.

On the other hand, DC power is increasingly vital in modern electronic devices, renewable energy systems (such as solar panels), battery storage, and data centers, where efficiency and direct compatibility with electronics are critical. Advances in power electronics have made DC more practical, enabling efficient conversion between AC and DC and supporting the growth of DC microgrids and off-grid systems.

Ultimately, a hybrid approach that intelligently integrates both AC and DC power sources—leveraging the strengths of each—is often the most effective strategy. This ensures reliable, efficient, and sustainable energy use across diverse applications, from industrial processes to consumer electronics. As technology evolves, the ability to source and manage both types of power efficiently will be key to building resilient and future-ready energy systems.