The global market for DC 24V power supply solutions has seen steady expansion, driven by increasing demand across industrial automation, telecommunications, and renewable energy sectors. According to a 2023 report by Mordor Intelligence, the global DC power supply market is projected to grow at a CAGR of 5.8% from 2023 to 2028, with 24V DC systems representing a dominant segment due to their efficiency, safety, and compatibility with low-voltage electronics. Similarly, Grand View Research estimates that the broader industrial power supply market will expand at a CAGR of 6.2% through 2030, fueled by advancements in IoT-enabled devices and the shift toward energy-efficient infrastructure. As industries prioritize stable and scalable power solutions, 24V DC manufacturers are at the forefront of innovation—delivering reliable performance in everything from factory automation to smart buildings. In this data-driven landscape, identifying the top performers becomes critical for engineers, procurement teams, and system integrators seeking quality and long-term reliability.

Top 10 Dc 24V Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

#2 Power conversion

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton has over 55 years of program heritage providing AC/DC, DC/DC and DC/AC power-conversion solutions for critical industrial applications….

#3 Cincon

Domain Est. 1998

Website: cincon.com

Key Highlights: Cincon Electronics is a leading manufacturer of DC/DC converters and AC/DC power supplies offering the high-quality and reliable power module solutions….

#4 Power Supply Manufacturer

Domain Est. 1998

Website: synqor.com

Key Highlights: SynQor designs and manufactures high-efficiency, high-reliability DC-DC power converters, AC-DC power converters, EMI filters and power systems….

#5 DC

Domain Est. 2000

Website: xppower.com

Key Highlights: Choose from our extensive range of DC – DC Converters. High quality, in-house design. Approved for industrial, medical, defense & railway applications….

#6 Murata Power Solutions Regulated DC

Domain Est. 1994

Website: murata.com

Key Highlights: High power efficiency and reliability · Offering a range of footprint sizes: 1/32 bricks up to 1/2 bricks in some models · Small footprint package · From 1 to 1000 ……

#7 Newmar

Domain Est. 1996

Website: newmarpower.com

Key Highlights: Newmar is committed to being the most responsive supplier of reliable DC Power Products for the Marine, Telecommunications, Network, Land Mobile and ……

#8 NetPower

Domain Est. 2000

Website: netpowercorp.com

Key Highlights: NetPower offers high performance DC-DC converters and AC-DC power supplies, offering market leading efficiency, reliability and power density….

#9 DC-DC Converters

Domain Est. 2001

Website: vicorpower.com

Key Highlights: Today’s most innovative companies trust Vicor to power their world-changing products. Explore DC-DC converter products, solutions and accessories….

#10 Newmar DC Power Onboard

Domain Est. 2016

Website: dcpoweronboard.com

Key Highlights: DC Power Solutions · Battery Chargers · DC Converters · Power Supplies · DC UPS & Power Control · Power Distribution Panels · Meters & Instruments · Accessories….

Expert Sourcing Insights for Dc 24V

H2: 2026 Market Trends for DC 24V Systems

The global market for 24V DC power systems is poised for significant transformation by 2026, driven by advancements in industrial automation, renewable energy integration, electric mobility, and energy efficiency regulations. As industries shift toward smart, modular, and sustainable solutions, 24V DC is emerging as a preferred standard for low-voltage power distribution, control systems, and IoT-enabled devices.

-

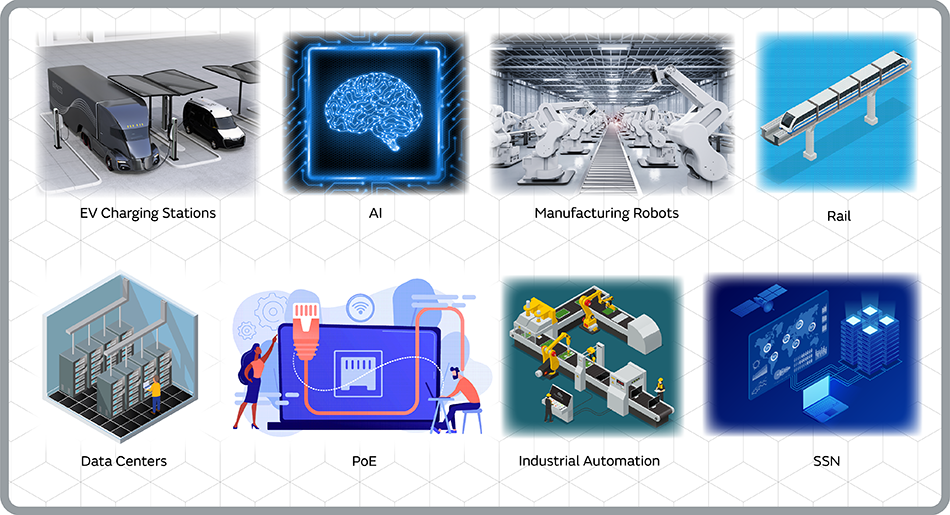

Growth in Industrial Automation and Industry 4.0

By 2026, the proliferation of smart factories and Industry 4.0 initiatives will continue to fuel demand for 24V DC power systems. These systems serve as the backbone for programmable logic controllers (PLCs), sensors, actuators, and human-machine interfaces (HMIs). The stability, safety, and compatibility of 24V DC with digital control systems make it ideal for automated manufacturing environments. Increased adoption of modular machine designs and decentralized control architectures will further expand the use of 24V DC across production lines. -

Expansion in Building Automation and Smart Infrastructure

The integration of Building Management Systems (BMS) and smart lighting, HVAC, and security systems is accelerating the deployment of 24V DC power solutions. With growing emphasis on energy efficiency and sustainability, commercial and residential buildings are adopting 24V DC for low-voltage control circuits. In addition, Power over Ethernet (PoE) applications, which often deliver 24V DC to power IP cameras, access controls, and wireless access points, are expected to see robust growth, supporting broader market penetration. -

Rise of Renewable Energy and Energy Storage

The transition to renewable energy sources such as solar and wind power is boosting demand for DC-based systems. By 2026, hybrid solar inverters and DC-coupled battery storage systems will increasingly utilize 24V DC as an intermediate voltage level, especially in off-grid and residential applications. The compatibility of 24V DC with small-scale solar charge controllers and portable power stations makes it a key enabler in decentralized energy systems. -

Electrification of Transportation and Mobility

While high-voltage systems dominate electric vehicles (EVs), 24V DC remains essential in auxiliary systems for commercial vehicles, buses, and off-road machinery. In particular, heavy-duty trucks and construction equipment in Europe and North America are standardizing on 24V DC for lighting, telematics, and control units. Moreover, innovations in e-mobility infrastructure, such as EV charging stations and automated guided vehicles (AGVs), will rely on 24V DC for safe and reliable control signaling. -

Advancements in Power Supply Technology

The 2026 market will witness advancements in DC-DC converters, uninterruptible power supplies (UPS), and efficient rectifiers tailored for 24V DC systems. High-efficiency switching power supplies with improved thermal management and digital monitoring capabilities will become standard. Integration with IoT platforms allowing remote diagnostics and predictive maintenance will enhance system reliability and reduce downtime. -

Regional Market Dynamics

Europe and North America will remain key markets due to stringent energy regulations and high industrial automation rates. Meanwhile, Asia-Pacific—especially China, India, and South Korea—will experience rapid growth driven by smart city projects, manufacturing expansion, and government incentives for green technologies. Standardization efforts by organizations such as IEC and UL will support global interoperability and safety compliance for 24V DC components. -

Sustainability and Circular Economy Trends

Environmental regulations and corporate sustainability goals will influence material selection and lifecycle management of 24V DC components. By 2026, manufacturers will increasingly adopt recyclable materials, energy-efficient designs, and modular architectures to support circular economy principles, further boosting market appeal.

Conclusion

The 2026 outlook for 24V DC systems is highly positive, underpinned by long-term technological and environmental trends. As industries prioritize efficiency, safety, and digital integration, 24V DC will remain a critical enabler across diverse sectors. Companies investing in innovation, standardization, and sustainability within the 24V DC ecosystem are well-positioned to capture growing market opportunities.

Common Pitfalls When Sourcing 24V DC Power Supplies (Quality & IP Rating)

Sourcing reliable 24V DC power supplies requires careful attention to both quality and ingress protection (IP) ratings. Overlooking key factors can lead to system failures, safety hazards, and increased lifecycle costs. Below are common pitfalls to avoid:

Poor Build Quality and Component Selection

Low-cost power supplies often use substandard components such as electrolytic capacitors with short lifespans, undersized transformers, and inadequate PCB layouts. These compromises lead to premature failure, thermal instability, and output voltage fluctuations. Always verify manufacturer reputation, review datasheet details (e.g., capacitor brand or temperature rating), and consider third-party certifications (e.g., UL, CE, TÜV) as quality indicators.

Misunderstanding or Misrepresenting IP Ratings

Many suppliers advertise high IP ratings (e.g., IP67) without full compliance. A common pitfall is assuming the rating applies under all conditions. For example, an IP67 rating requires the unit to withstand temporary submersion—but only if connectors are properly sealed. Using incompatible or unmated connectors can void the protection. Always confirm the IP rating applies to the complete assembled unit, including terminal areas and mounting points.

Inadequate Thermal Management

Even with a suitable IP rating, sealed power supplies (especially IP65/IP67) can overheat in high ambient temperatures or enclosed spaces. Poor thermal design leads to derating or shutdown. Ensure the unit’s thermal performance is documented across the full operating temperature range, and consider active cooling or derating curves in your design.

Lack of Surge and Overload Protection

Low-quality units may omit essential protections such as overvoltage, overcurrent, and surge suppression. In industrial environments, voltage spikes and load variations are common. Without robust protection, downstream equipment is at risk. Verify that the power supply includes adequate transient protection (e.g.,符合 IEC 61000-4-5) and automatic recovery features.

Inconsistent Output Voltage and Ripple

Cheap 24V supplies may exhibit high output ripple or poor load regulation, which can disrupt sensitive electronics like PLCs, sensors, or communication modules. Check datasheet specifications for ripple & noise (typically <150mVp-p for industrial use) and load regulation (<1–3%). Independent testing or reviews can help validate real-world performance.

Shortened Lifespan Due to Low MTBF

Mean Time Between Failures (MTBF) is often inflated in marketing materials. Real-world longevity depends on operating conditions and component quality. Look for units with conservative MTBF estimates (e.g., 100,000+ hours at 40°C) backed by recognized calculation standards (e.g., Telcordia SR-332).

Counterfeit or Non-Compliant Products

Especially when sourcing online or from unknown suppliers, there’s a risk of counterfeit products that mimic branding but lack safety certifications or performance. Always purchase from authorized distributors and validate certification marks with the issuing body.

Avoiding these pitfalls ensures reliable, safe, and long-lasting operation of your 24V DC systems—particularly in demanding industrial, outdoor, or harsh environments.

Logistics & Compliance Guide for DC 24V Systems

This guide outlines key logistics and compliance considerations when shipping, handling, and deploying equipment powered by or operating at DC 24V. While DC 24V is generally considered low voltage and inherently safer than higher voltage systems, adherence to international standards, transportation regulations, and installation codes remains essential.

Regulatory Framework and Safety Standards

International Electrotechnical Commission (IEC) Standards

IEC 60204-1 (Safety of machinery – Electrical equipment of machines) defines safety requirements for electrical systems, including DC circuits. DC 24V falls under the “Safety Extra-Low Voltage” (SELV) category when properly isolated, typically not exceeding 60V DC. Compliance ensures protection against electric shock and fire hazards.

National Electrical Code (NEC) – United States

Article 725 of the NEC covers Class 2 and Class 3 remote-control, signaling, and power-limited circuits. DC 24V systems often qualify as Class 2, allowing reduced wiring protection requirements but still mandating proper wire gauge, overcurrent protection, and installation methods.

European Union – Low Voltage Directive (LVD) 2014/35/EU

Applies to electrical equipment designed for use within specified voltage limits, including DC 75–1500V. However, DC 24V equipment is generally exempt from LVD if below 75V DC, but may still fall under the scope of the Electromagnetic Compatibility (EMC) Directive 2014/30/EU and the RoHS Directive 2011/65/EU.

Transportation and Logistics Considerations

Packaging and Labeling

- Clearly label DC 24V equipment with voltage rating, polarity (+/-), and any relevant safety certifications (e.g., CE, UL, CCC).

- Use anti-static packaging where applicable, especially for sensitive control units or PCBs.

- Include handling instructions if components are sensitive to shock, moisture, or temperature extremes.

Battery-Powered Devices

If the DC 24V system includes lithium batteries (e.g., backup or portable units), compliance with IATA Dangerous Goods Regulations (DGR) is required for air transport. Proper UN38.3 testing certification, packaging, and labeling (e.g., UN3481 for lithium-ion batteries) must be followed.

Import and Customs Compliance

- Verify country-specific conformity marks (e.g., UKCA for the UK, KC for South Korea, PSE for Japan).

- Prepare technical documentation including Declaration of Conformity (DoC), circuit diagrams, and test reports.

- Ensure compliance with local energy efficiency standards (e.g., ERP Directive in the EU) if applicable.

Installation and Operational Compliance

Wiring and Protection

- Use conductors rated for the expected current and environmental conditions (e.g., temperature, moisture).

- Implement overcurrent protection (e.g., fuses or circuit breakers) sized appropriately for the load and wire gauge.

- Maintain proper polarity in DC systems to prevent equipment damage.

Grounding and Isolation

- Ensure SELV circuits are properly isolated from higher voltage systems to prevent accidental energization.

- Follow manufacturer guidelines for grounding metal enclosures, even in low-voltage systems, to prevent electromagnetic interference (EMI) and ensure safety.

Environmental and Electromagnetic Compatibility

- Verify EMC compliance per standards such as EN 61000-6-2 (industrial environments) or EN 61000-6-3 (residential environments).

- Shield cables in high-noise environments to prevent signal interference in control circuits.

Documentation and Traceability

Maintain comprehensive records including:

– Bill of Materials (BOM) with component certifications

– Compliance test reports (safety, EMC, environmental)

– User manuals with safety instructions and wiring diagrams

– Serial number tracking for field devices, if required by warranty or regulation

Summary

While DC 24V systems benefit from simplified safety requirements due to their low voltage, rigorous attention to compliance, proper logistics handling, and adherence to regional regulations is crucial for safe deployment and market access. Always consult local authorities and standards bodies to ensure full regulatory alignment.

Conclusion for Sourcing DC 24V:

Sourcing a reliable and efficient 24V DC power supply is critical for the stable operation of industrial control systems, automation equipment, lighting, telecommunications, and various electronic applications. When selecting a 24V DC power source, key considerations include input voltage compatibility, output current capacity, efficiency, thermal management, protection features (such as overload, overvoltage, and short-circuit protection), and compliance with relevant safety and regulatory standards (e.g., CE, UL, RoHS).

Options for sourcing 24V DC include AC/DC power supplies, DC/DC converters, switch-mode power supplies (SMPS), linear regulators, and renewable sources like solar panels with appropriate charge controllers. Among these, switch-mode power supplies are often preferred due to their high efficiency, compact size, and ability to handle varying loads.

Ultimately, the choice depends on the application’s specific requirements, environmental conditions, budget constraints, and scalability needs. Proper selection ensures long-term reliability, minimizes downtime, and supports optimal performance across the system. Conducting a thorough assessment of technical specifications and supplier quality is essential to making a cost-effective and future-proof decision in sourcing 24V DC power.