The global natural stone market, fueled by rising demand in construction and interior design, continues to expand at a steady pace. According to Mordor Intelligence, the marble market was valued at USD 33.5 billion in 2023 and is projected to grow at a CAGR of over 6.4% through 2029, driven by increased urbanization and luxury infrastructure development, particularly in Asia-Pacific and the Middle East. Dark grey marble, prized for its elegance, durability, and versatility in both residential and commercial spaces, has emerged as a top choice among architects and designers. As demand for premium, consistent-quality stone grows, specialized manufacturers are scaling production, enhancing extraction techniques, and investing in sustainable practices to meet evolving global standards. In this competitive landscape, eight manufacturers have distinguished themselves through innovation, reliability, and a strong presence in the dark grey marble segment.

Top 8 Dark Grey Marble Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

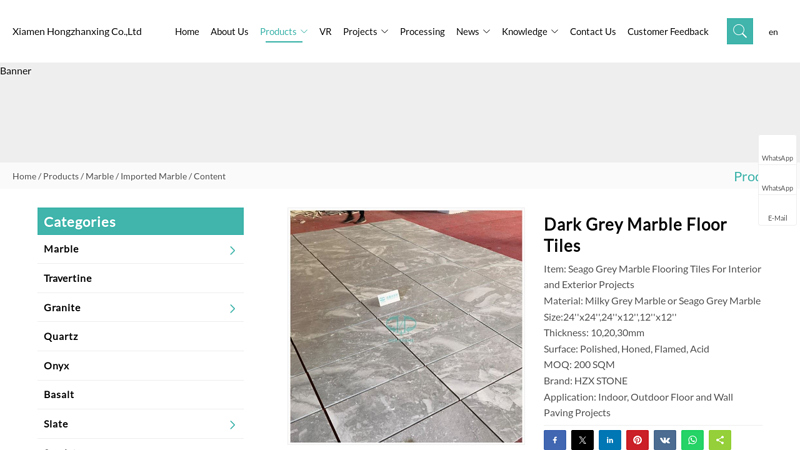

#1 Dark Grey Marble Floor Tiles Manufacturers, Suppliers, Factory

Domain Est. 2012

Website: hzxstone.com

Key Highlights: The Seago dark grey marble floor tiles are polished or honed, and incredibly strong meant to be used in all types of residential as well as commercial projects….

#2 Cumar Marble & Granite

Domain Est. 1999

Website: cumar.com

Key Highlights: Cumar is New England’s preeminent source and fabricator of marble, granite, limestone, and exotic stones for luxury kitchens, baths, and custom projects….

#3 Gray marble – Architecture & Design

Domain Est. 2002

Website: tinostone.com

Key Highlights: Find here quality gray marble for your project. Choose between different shades of gray and varieties of veins, textures, and finishes….

#4 Roman Grey – Dark Selection

Domain Est. 2003

Website: rkmarble.com

Key Highlights: Hail and snow pour over an inky midnight in the Roman Grey Dark Selection marble. With bold black and white veins, it flaunts a unique personality….

#5 StoneContact.com: Stone, Marble, Granite

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Stone portal website(StoneContact.com) is the world leading B2B stone website.We offer abundant stone products, prices, pictures, suppliers, such as marble, ……

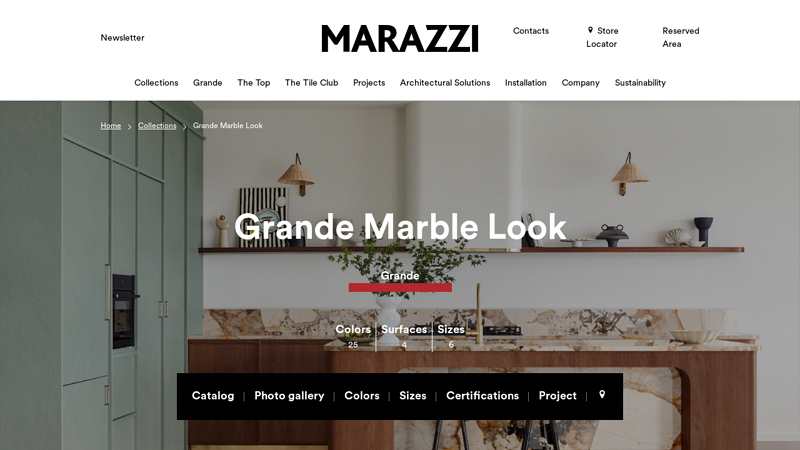

#6 Collection Grande Marble Look

Domain Est. 2004

Website: marazzigroup.com

Key Highlights: Discover the Grande Marble Look collection by Marazzi. Find unique solutions for floors and walls with modern design and excellent performance….

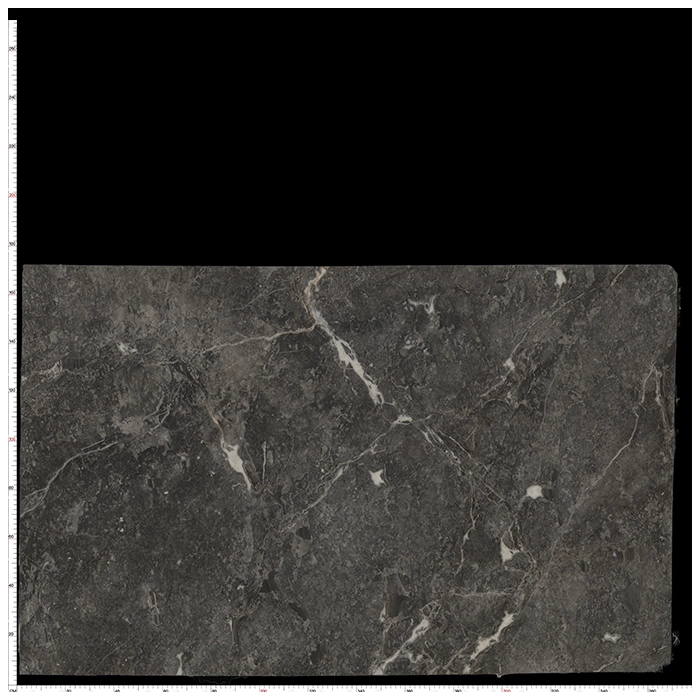

#7 Dark Grey Marble

Domain Est. 2020

#8 Grey marble. Portuguese grey marble. Grey marble supply …

Domain Est. 2021

Website: grey-marble.com

Key Highlights: Grey-marble.com is a complete informative website exclusively dedicated to grey colored marble from Portugal….

Expert Sourcing Insights for Dark Grey Marble

2026 Market Trends for Dark Grey Marble

The global demand for dark grey marble is poised for notable evolution by 2026, driven by shifting architectural preferences, sustainability concerns, and advancements in extraction and finishing technologies. As a premium natural stone, dark grey marble continues to occupy a prominent place in high-end residential, commercial, and hospitality projects. This analysis explores key market trends shaping the dark grey marble industry in 2026.

Rising Demand in Luxury Interior Design

In 2026, dark grey marble remains a favored material among luxury interior designers for its sophisticated aesthetic and timeless appeal. Its neutral yet dramatic tone complements modern minimalist, industrial, and Scandinavian design styles. High-net-worth homeowners and boutique developers are increasingly specifying dark grey marble for kitchen countertops, flooring, feature walls, and bathroom vanities. The trend is particularly strong in urban centers across North America, Western Europe, and the Middle East, where premium real estate projects emphasize elegance and durability.

Sustainability and Ethical Sourcing Influence

Environmental consciousness is reshaping the natural stone market. By 2026, consumers and architects are demanding greater transparency in the sourcing of marble. Leading suppliers of dark grey marble are responding by adopting certified sustainable quarrying practices, reducing carbon footprints, and investing in water recycling systems. Marble from regions like Italy and Greece, known for stricter environmental regulations, is gaining market share over less-regulated sources. Eco-labels and digital traceability platforms are becoming standard, allowing buyers to verify the ethical origin of their stone.

Technological Advancements in Processing

Innovations in cutting, polishing, and sealing technologies are enhancing the performance and versatility of dark grey marble. By 2026, waterjet cutting and CNC machining enable intricate designs and custom installations with minimal waste. Nanotechnology-based sealants are improving stain resistance and durability, making marble more practical for high-traffic areas. These advancements lower lifecycle costs and expand applications into commercial environments such as retail spaces and corporate lobbies.

Growth in Prefabricated and Large-Format Slabs

The trend toward prefabricated marble elements—such as ready-to-install countertops, vanity tops, and cladding panels—is accelerating. In 2026, large-format slabs (up to 3200 x 1600 mm) are in high demand, reducing seams and enabling seamless, monolithic appearances. This shift is supported by improved logistics and handling systems, making it easier to transport and install oversized pieces with precision.

Competitive Pressure from Engineered Alternatives

Despite its popularity, dark grey marble faces growing competition from engineered quartz and porcelain slabs that mimic its appearance at lower cost and maintenance. However, in the premium segment, natural marble retains a distinct advantage due to its authenticity, unique veining, and status symbol appeal. Market differentiation is achieved through storytelling, origin branding (e.g., “Statuario Dark” or “India Black”), and collaborations with renowned designers.

Regional Market Dynamics

Asia-Pacific, particularly India and China, remains a dominant force in both production and consumption. Indian quarries continue to supply cost-competitive dark grey marble to global markets, while domestic demand grows with rising urbanization and luxury construction. In Europe, Italy maintains its reputation for high-quality finishes and design innovation. Meanwhile, the Middle East is emerging as a key growth market, driven by large-scale infrastructure and tourism development projects.

Conclusion

By 2026, the dark grey marble market will be characterized by a balance between tradition and innovation. While enduring aesthetic appeal sustains demand, the industry’s future success hinges on sustainability, technological integration, and strategic branding. Suppliers who adapt to these evolving trends will be well-positioned to thrive in an increasingly competitive and conscious marketplace.

Common Pitfalls When Sourcing Dark Grey Marble (Quality, IP)

Sourcing high-quality dark grey marble requires careful attention to detail, especially when considering both aesthetic consistency and material integrity. Overlooking key factors can lead to costly mistakes, project delays, or dissatisfaction. Below are the most common pitfalls to avoid:

Inconsistent Color and Veining Patterns

Dark grey marble often varies significantly between quarries and even within the same block. Buyers may receive slabs that differ drastically from the sample, leading to mismatched installations. Always request full slabs for approval and verify batch consistency before production.

Poor Slab Quality and Structural Defects

Low-grade marble may contain fissures, pits, or weak spots that compromise durability. These flaws can become more apparent after polishing or during installation. Inspect each slab under proper lighting and avoid materials with excessive resin filling or repairs unless clearly disclosed.

Inadequate IP (Intended Purpose) Matching

Using marble not suited for its intended application—such as selecting a soft, porous variety for high-traffic flooring or wet areas—can lead to rapid wear, staining, or etching. Ensure the marble’s density, hardness, and finish are appropriate for the environment (e.g., honed for slip resistance in bathrooms).

Overlooking Finish and Polish Quality

A poorly executed polish can dull the stone’s natural depth and luster. Some suppliers apply temporary surface coatings that wear off quickly. Verify the finish type (polished, honed, brushed) and test for consistency and longevity before final selection.

Insufficient Certifications and Traceability

Lack of documentation on origin, processing, and quality control increases the risk of receiving substandard or misrepresented material. Always request quarry certificates, material test reports, and proof of ethical sourcing to ensure authenticity and compliance.

Hidden Costs Due to Slab Yield and Waste

Dark grey marble with dense veining or irregular patterns may require more slabs to achieve a coherent layout, increasing waste and overall cost. Work with a fabricator early to optimize slab layout and account for potential overage.

Inadequate Sealing and Maintenance Guidance

Many dark grey marbles are prone to staining and require regular sealing. Suppliers may fail to provide proper care instructions, leading to premature deterioration. Confirm maintenance requirements and ensure end-users are educated on proper upkeep.

Logistics & Compliance Guide for Dark Grey Marble

Overview of Dark Grey Marble

Dark Grey Marble is a natural stone widely used in construction, interior design, and architecture due to its elegant appearance and durability. Common types include Nero Marquina, Absolute Black, and Silver Grey. As a globally traded commodity, its transport and import/export are subject to logistical and regulatory considerations to ensure quality, safety, and legal compliance.

Sourcing & Quarrying Regulations

- Environmental Permits: Quarrying operations must comply with local environmental regulations, including land use, water discharge, and dust control.

- Sustainable Sourcing: Suppliers should adhere to sustainability certifications such as ISO 14001 or LEED-compliant practices where applicable.

- Origin Documentation: Certificates of Origin and quarry source documentation are often required for import/export compliance.

Packaging & Handling Requirements

- Crating: Marble slabs and tiles should be packed in sturdy wooden crates with internal supports to prevent shifting.

- Moisture Protection: Use moisture-resistant wrapping (e.g., plastic film) to avoid staining or water damage during transit.

- Edge Protection: Apply corner guards to protect slab edges from chipping.

- Weight Distribution: Ensure even distribution of weight within containers to prevent slab breakage.

Transportation Logistics

- Mode of Transport:

- Sea Freight: Most common for bulk shipments; use of 20’ or 40’ dry containers. Slabs should be vertically stored using dunnage systems.

- Air Freight: Reserved for urgent, high-value samples; limited by cost and weight.

- Land Transport: Use shock-absorbing suspensions and secure load fastening for trucking.

- Temperature & Humidity: Avoid extreme temperature fluctuations; control humidity to prevent condensation inside containers.

Import/Export Compliance

- HS Code Classification:

- Typical HS Code: 2515.11 (Unworked marble) or 6802.91 (Worked marble, simply cut).

- Confirm with local customs authority for precise classification.

- Import Duties & Taxes: Vary by country; check bilateral trade agreements and tariff schedules (e.g., US Harmonized Tariff Schedule, EU TARIC).

- Phytosanitary & Fumigation: Not typically required for stone, but wooden packaging must comply with ISPM 15 (heat-treated or fumigated wood packaging).

- Customs Documentation: Include commercial invoice, packing list, bill of lading, certificate of origin, and import license (if required).

Quality Inspection & Standards

- Pre-Shipment Inspection: Conduct quality checks for color consistency, cracks, and surface finish. Third-party inspectors may be used.

- Dimensional Tolerance: Ensure compliance with buyer specifications (e.g., ASTM C503 for marble physical properties).

- Certifications: Provide test reports for density, water absorption, and flexural strength if requested.

Safety & Handling Compliance

- Workplace Safety: Comply with OSHA (USA), HSE (UK), or local regulations during handling and installation.

- Material Safety Data Sheets (MSDS): Required if sealants or resins are applied; natural marble itself is inert but cutting produces silica dust.

- Personal Protective Equipment (PPE): Mandate use of gloves, eye protection, and dust masks during processing.

Environmental & Ethical Compliance

- Conflict Minerals: Not applicable to marble, but ethical sourcing policies should confirm no forced labor or human rights violations in supply chain.

- Carbon Footprint: Consider emissions from transport; some buyers prefer low-carbon logistics or offset programs.

Special Considerations by Region

- USA: Comply with Lacey Act (if wood packaging is used) and EPA guidelines for silica dust.

- EU: Follow REACH and Construction Products Regulation (CPR) for treated stones. CE marking may be required for engineered products.

- Middle East & Asia: Some countries require halal certification for labor practices or specific import permits for natural stone.

Risk Management & Insurance

- Cargo Insurance: Cover for breakage, water damage, and total loss during transit.

- Incoterms: Clearly define responsibilities (e.g., FOB, CIF, DDP) in contracts to allocate risk.

- Contingency Planning: Prepare for port delays, customs holds, or quality disputes with clear escalation protocols.

Conclusion

A successful logistics and compliance strategy for Dark Grey Marble involves careful coordination between quarries, freight forwarders, customs brokers, and end buyers. Adherence to international standards, accurate documentation, and proactive risk management are essential to ensure timely delivery and regulatory compliance across global markets.

In conclusion, sourcing dark grey marble requires careful consideration of quality, origin, supplier reliability, and cost-effectiveness. This elegant and versatile natural stone offers a sophisticated aesthetic suitable for both residential and commercial applications. By evaluating key factors such as vein patterns, durability, consistency of color, and certification standards, buyers can ensure they select a premium product that meets design and performance requirements. Establishing relationships with reputable quarries and suppliers—particularly those in established marble-producing regions such as Italy, Turkey, or India—can enhance supply chain transparency and product traceability. Additionally, requesting samples, verifying material testing reports, and considering sustainability practices contribute to a responsible and successful sourcing process. Ultimately, investing time in thorough due diligence will result in a high-quality dark grey marble selection that delivers long-term value and aesthetic appeal.