The demand for dark brown asphalt shingles has surged in recent years, driven by their aesthetic versatility, ability to blend with natural surroundings, and growing preference for rich, earth-toned roofing in both residential and commercial construction. According to a 2023 report by Grand View Research, the global asphalt roofing shingles market was valued at USD 13.8 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increased housing starts, roof renovation activities, and rising infrastructure investments—particularly in North America, which remains the largest regional market. Within this segment, dark brown shingles have emerged as a top choice due to their heat-absorbing properties in cooler climates and their compatibility with diverse architectural styles, from traditional to modern farmhouse designs. As consumer preferences shift toward durable, energy-efficient, and visually appealing roofing solutions, manufacturers are innovating with advanced granule technology, algae resistance, and extended warranties. In this evolving landscape, seven manufacturers stand out for their market presence, product quality, and technological advancement in producing top-performing dark brown shingle options.

Top 7 Dark Brown Shingles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 IKO North America

Domain Est. 1994

Website: iko.com

Key Highlights: IKO is a global leader in roof shingle manufacturing & supply of residential roofing products including asphalt roofing shingles, insulation & roof ……

#2 Choose Your Shingles

Domain Est. 1996

Website: atlasroofing.com

Key Highlights: Choose Your Shingles ; Color Blends. Black. Brown ; Features. HP 42 Technology. Core4 Technology ; Wind Performance. 150 MPH Wind Warranty. 130 MPH Wind Warranty….

#3 Landmark Pro Premium Roofing Shingles

Domain Est. 1995

Website: certainteed.com

Key Highlights: These shingles are engineered with a multi-layer design, featuring a fiberglass base and protective outer layer, providing superior impact resistance….

#4 Duration®

Domain Est. 1996

Website: owenscorning.com

Key Highlights: Duration® COOL Shingles feature deep, rich colors which are unexpected for solar-reflecting shingles that are typically very light in color. View Duration ……

#5 Residential Roofing Shingles

Domain Est. 1996

Website: tamko.com

Key Highlights: TAMKO roof is built with products and components designed to seamlessly work together. For superior protection and long-lasting reliability, choose a TAMKO ……

#6 Asphalt Roofing Shingles

Domain Est. 1996

Website: gaf.com

Key Highlights: Considering a new asphalt roof? GAF offers a range of residential roofing shingles with a 25-year StainGuard Plus™ Limited Warranty….

#7 Shingles Overview

Domain Est. 1999

Website: malarkeyroofing.com

Key Highlights: Malarkey offers shingles in the industry’s most popular styles, made with our industry-leading NEX® Polymer Modified (Rubberized) Asphalt….

Expert Sourcing Insights for Dark Brown Shingles

2026 Market Trends for Dark Brown Shingles

As the residential roofing industry evolves, dark brown shingles are poised to maintain a strong presence in the market through 2026. Driven by shifts in architectural preferences, sustainability concerns, and advancements in material technology, dark brown shingles are adapting to meet consumer demands. This analysis explores key market trends influencing the demand, production, and innovation surrounding dark brown asphalt and composite shingles leading into 2026.

Rising Popularity in Modern and Transitional Home Designs

Dark brown shingles have gained favor among homeowners and architects embracing modern, farmhouse, and transitional architectural styles. These designs often feature natural wood accents, stone veneers, and neutral color palettes—elements that pair well with the rich, earthy tones of dark brown roofing. In 2026, this aesthetic alignment is expected to sustain demand, particularly in suburban and mid-density developments where curb appeal significantly impacts property value.

Energy Efficiency Improvements and Cool Roof Technology

Historically, dark-colored shingles have been associated with higher heat absorption, leading to increased cooling costs. However, by 2026, manufacturers are responding with advanced “cool dark” shingle technologies. These products incorporate reflective granules and infrared-reflective pigments that allow dark brown shingles to absorb less heat while maintaining their visual appeal. As energy codes tighten across the U.S. and Canada, especially in sun-intensive regions like the Southwest and Southeast, the adoption of energy-efficient dark brown shingles is projected to grow.

Sustainable and Recyclable Material Innovations

Environmental sustainability continues to influence consumer choices in roofing materials. By 2026, several leading manufacturers are expected to introduce dark brown shingles made with recycled content and improved recyclability at end-of-life. Additionally, bio-based asphalt alternatives and longer product lifespans (up to 50 years) are enhancing the environmental profile of dark brown options, making them more attractive to eco-conscious homeowners.

Regional Market Variations

Demand for dark brown shingles in 2026 will vary significantly by region:

– Northeast and Midwest: Steady demand due to compatibility with traditional brick and wood-sided homes.

– South and Southwest: Growth supported by new construction booms and improved heat-reflective technologies.

– West Coast: Moderate adoption, influenced by stricter energy codes and a preference for cooler tones, though hybrid designs are creating niche opportunities.

Integration with Solar Roofing Systems

As solar adoption accelerates, roofing aesthetics are becoming increasingly important. Dark brown shingles provide a cohesive backdrop for black solar panels, offering a sleek, integrated look that appeals to design-focused homeowners. In 2026, bundled roofing and solar solutions featuring dark brown shingles are expected to gain market share, particularly in states with strong solar incentives like California, Texas, and Florida.

Competitive Pricing and Market Accessibility

Compared to premium roofing materials like slate or metal, dark brown asphalt shingles remain cost-effective, with prices projected to stabilize in 2026 following recent supply chain corrections. Mass production efficiencies and competition among major brands (e.g., GAF, Owens Corning, CertainTeed) are keeping dark brown shingles accessible for mid-tier housing markets, where affordability and durability are key decision factors.

Conclusion

By 2026, dark brown shingles are expected to remain a dominant choice in the residential roofing market, supported by aesthetic versatility, technological advancements, and growing sustainability efforts. With innovations in energy efficiency and design integration—especially with solar systems—dark brown shingles are evolving beyond traditional applications to meet the demands of modern homeowners. As long as manufacturers continue to address thermal performance and environmental impact, dark brown shingles will likely hold a significant share of the roofing market in the coming years.

Common Pitfalls When Sourcing Dark Brown Shingles (Quality and Intellectual Property)

Sourcing dark brown asphalt shingles for roofing projects can present several challenges, particularly concerning product quality and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure long-term performance, compliance, and value.

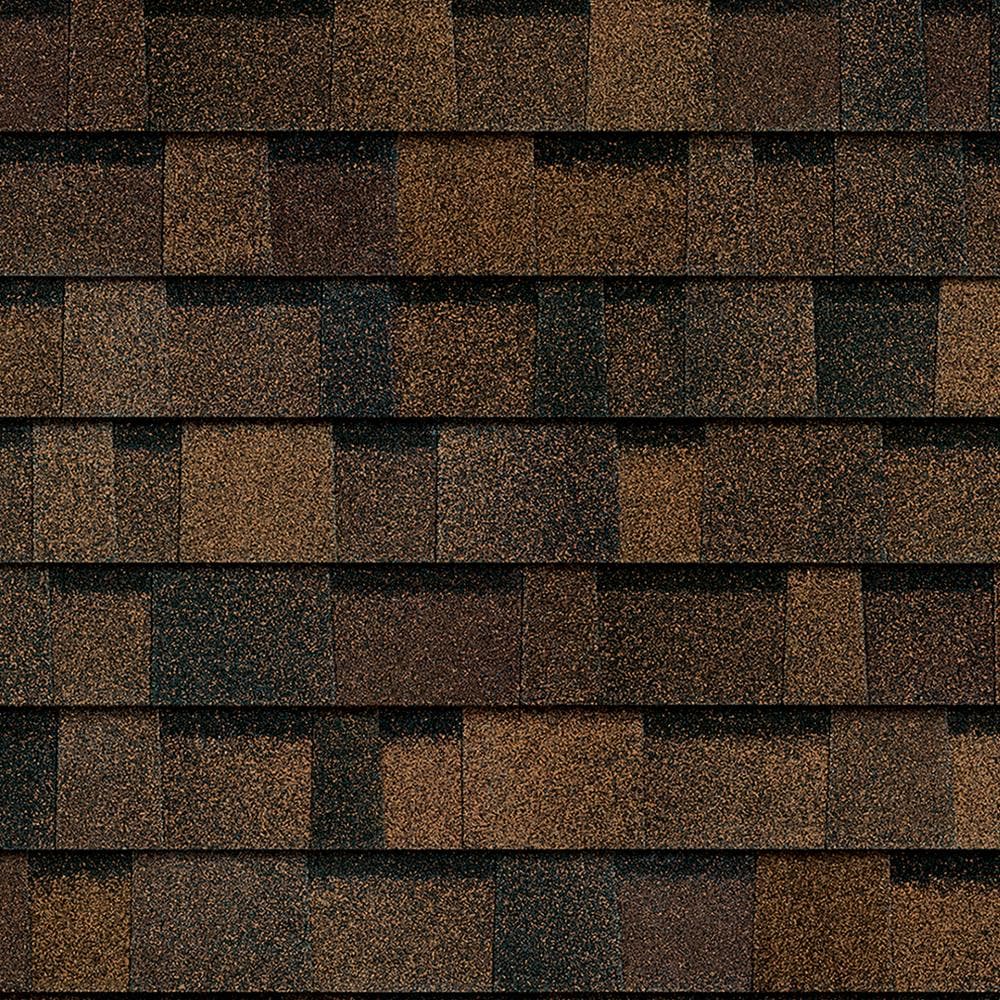

Inconsistent Color and Fading Over Time

Dark brown shingles are prone to color variation between batches and may fade unevenly due to UV exposure. Lower-quality pigments or inconsistent manufacturing processes can lead to a mottled appearance, reducing curb appeal. Always request color samples and verify the manufacturer’s UV resistance ratings and warranty coverage for color retention.

Poor Weather and Impact Resistance

Not all dark shingles are created equal in terms of durability. Inferior products may lack proper granule adhesion, leading to premature wear, especially in harsh climates. Look for shingles with UL 2218 Class 4 impact resistance and ASTM compliance. Avoid off-brand or unverified suppliers that may exaggerate performance claims.

Misrepresentation of Product Origin and Branding

Counterfeit or imitation shingles are a growing concern, particularly in regions with lax IP enforcement. Some suppliers may falsely claim their dark brown shingles are from reputable brands (e.g., GAF, CertainTeed, Owens Corning) without authorization. This not only breaches IP laws but also risks voiding warranties and compromising installation standards.

Lack of Warranty and Traceability

Genuine branded shingles come with transferable warranties and lot traceability. Sourcing from unauthorized distributors or gray market channels may result in untraceable products that lack valid warranty coverage. Always verify the supplier’s authorization and request documentation linking the shingles to the original manufacturer.

Intellectual Property Infringement Risks

Using or sourcing shingles that copy patented design elements (such as specific granule patterns, underlayment technology, or branding) can expose contractors and builders to legal liability. Ensure that the products adhere to IP regulations and avoid suppliers offering “compatible” or “look-alike” versions of branded dark brown shingles.

Inadequate Certification and Testing Documentation

Reputable shingles undergo rigorous third-party testing for fire resistance, wind uplift, and algae resistance. Low-quality or IP-infringing products often lack proper certification (e.g., FM, UL, ICC-ES). Demand up-to-date test reports and ensure compliance with local building codes.

By prioritizing authorized suppliers, verifying product authenticity, and insisting on comprehensive quality documentation, stakeholders can avoid these common pitfalls and ensure reliable, long-lasting roofing performance.

Logistics & Compliance Guide for Dark Brown Shingles

Product Overview

Dark brown shingles are asphalt roofing materials designed for durability, aesthetic appeal, and weather resistance. They are commonly used in residential and light commercial construction. This guide outlines logistical handling, transportation, storage, and regulatory compliance considerations specific to dark brown shingles.

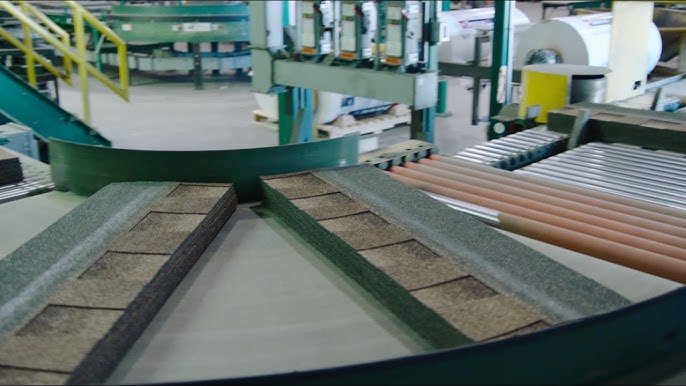

Packaging & Unit Load Configuration

Dark brown shingles are typically packaged in sealed bundles or stacks, shrink-wrapped on standard 48” x 40” pallets. Each bundle contains a set number of shingles (e.g., 21 or 27 per bundle for standard three-tab shingles). Pallet configurations must comply with manufacturer specifications to prevent shifting during transit. Use edge protectors and corner boards to minimize damage.

Transportation Requirements

Transport shingles on flatbed or dry van trailers with secure tie-downs to prevent movement. Protect loads from moisture using waterproof tarps; prolonged exposure to rain or snow can compromise packaging and material integrity. Avoid extreme temperature fluctuations during transit, as high heat may soften asphalt, increasing the risk of deformation.

Storage Guidelines

Store shingles in a dry, well-ventilated area, preferably indoors. If outdoor storage is necessary, elevate pallets off the ground and cover completely with UV-resistant, waterproof tarps—ensuring air circulation to reduce condensation. Limit stack height per manufacturer recommendations (typically 8–10 pallets) to avoid bottom-layer compression.

Handling & Safety Precautions

Use forklifts or pallet jacks to move full pallets; never drag or drop shingle bundles. Workers should wear cut-resistant gloves and safety footwear. Asphalt shingles may contain small amounts of bitumen and mineral granules, so minimize dust generation during handling. Provide adequate ventilation when working in enclosed spaces.

Regulatory Compliance

Ensure shingles meet relevant building and environmental standards:

– ASTM D3462 – Standard Specification for Asphalt Shingles.

– ICC-ES Evaluation Reports – Confirm code compliance for specific product lines.

– VOC Emissions – Comply with regional regulations (e.g., SCAQMD Rule 1113 in California) regarding volatile organic compounds.

– Recycling & Disposal – Follow local regulations for disposal of damaged or excess shingles. Some jurisdictions classify asphalt shingles as recyclable construction debris.

Labeling & Documentation

Each pallet must display: product name, color (dark brown), batch/lot number, manufacturing date, weight, and fire rating (e.g., Class A, B, or C). Include Safety Data Sheets (SDS) and product warranty information with shipments. Maintain traceability for quality control and recall preparedness.

Import & Customs Considerations (if applicable)

For international shipments, ensure Harmonized System (HS) code 6807.10 (asphalt floor, wall, or roofing tiles) is correctly applied. Provide certificates of origin, conformity, and any required phytosanitary documentation for wood pallets (ISPM 15). Verify tariff classifications and duty rates per destination country.

Environmental & Sustainability Practices

Encourage the use of shingles with recycled content where available. Promote proper job-site waste segregation to support recycling programs. Partner with certified recyclers to process post-consumer or rejected shingle materials into road paving or composite products.

Emergency Response

In case of fire, use foam, dry chemical, or carbon dioxide extinguishers. Avoid water jets, which may spread burning material. For spills or damaged packaging, collect loose granules and dispose of per local hazardous waste regulations. Refer to SDS for first aid and environmental impact procedures.

In conclusion, sourcing dark brown shingles requires careful consideration of quality, durability, cost, availability, and aesthetic compatibility with the overall design of the structure. It is essential to evaluate reputable suppliers and manufacturers known for consistent color retention, weather resistance, and warranty support. Additionally, factors such as regional climate, roofing underlayment, and energy efficiency—particularly heat absorption associated with darker hues—should inform the final selection. By balancing performance requirements with aesthetic goals and working with trusted contractors or distributors, sourcing dark brown shingles can result in a visually appealing, long-lasting roofing solution that enhances curb appeal and property value.