The global hydraulic press market is experiencing robust growth, driven by increasing demand from industries such as automotive, aerospace, and heavy manufacturing. According to Grand View Research, the global hydraulic presses market size was valued at USD 2.1 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This upward trajectory is fueled by advancements in industrial automation and the need for high-force pressing solutions that offer precision and reliability. As a key player in this competitive landscape, Dake Corporation has solidified its position among the top manufacturers, delivering innovative, cost-effective hydraulic press solutions for over 90 years. With a broad product portfolio and a strong global distribution network, Dake continues to meet the evolving needs of modern manufacturing—a factor reflected in its consistent performance alongside market leaders in an industry poised for sustained expansion.

Top 4 Dake Corporation Hydraulic Press Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metal Machinery

Domain Est. 1996

Website: lagunatools.com

Key Highlights: Looking For Industrial Strength Metal Machines? From Arbor Presses to Cold Saws, Dake will work with you to determine the best solution for your application….

#2 Dake Corp.

Domain Est. 2015

Website: hydraulicpressmanufacturers.org

Key Highlights: Dake Corp., headquartered in Grand Haven, Michigan, is a well-established manufacturer and provider of hydraulic press products and services….

#3 [PDF] INVITATION FOR BID (IFB) #046

Domain Est. 2003

Website: springfieldmo.gov

Key Highlights: 1.0 SCOPE: The City of Springfield is seeking qualified firms or persons to provide DAKE HAND-OPERATED HYDRAULIC PRESS. MODEL 75H – NO SUBSTITUTIONS. A one-time ……

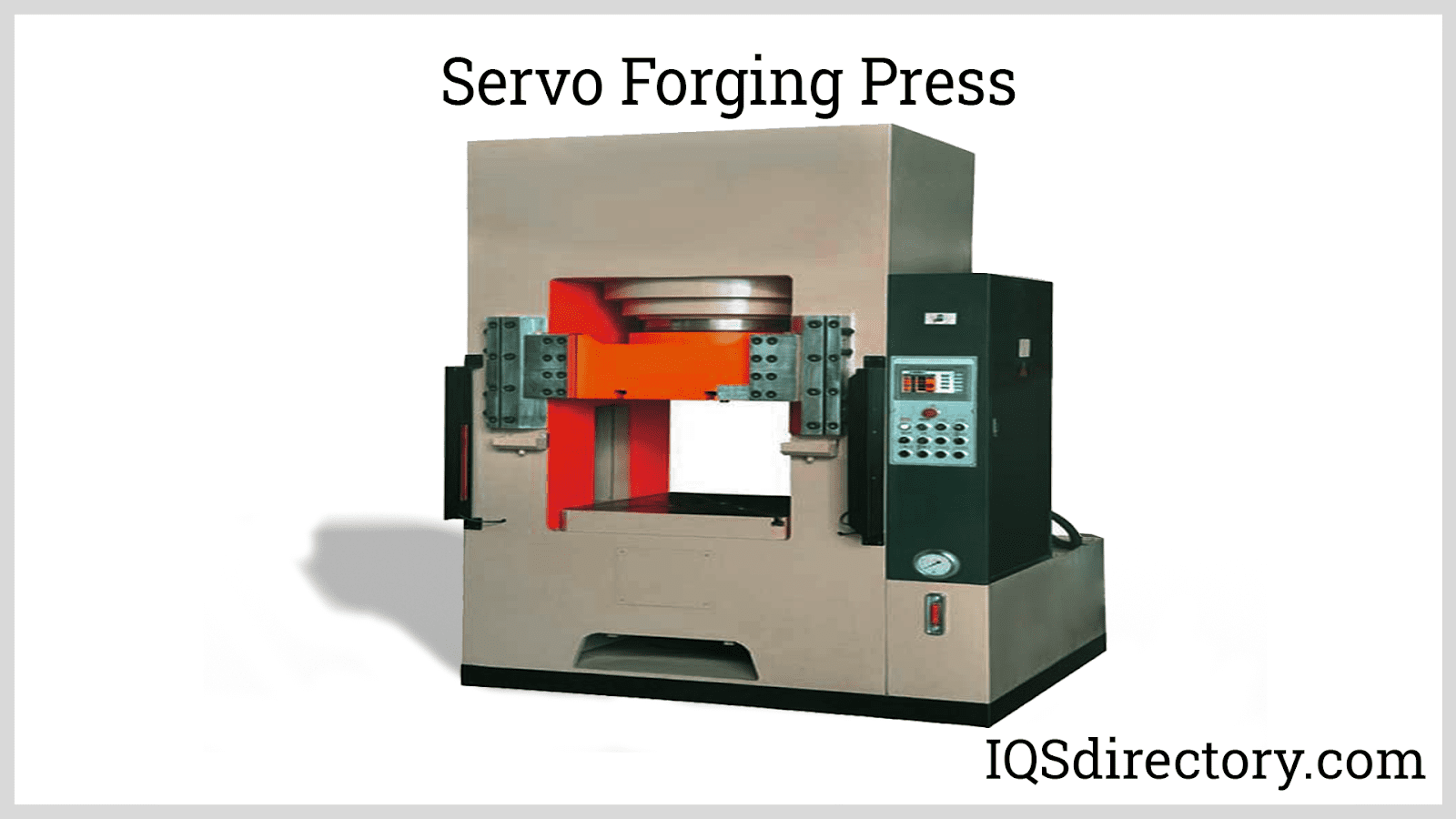

#4 The Handy Guide to Dake Hydraulic Presses

Domain Est. 2000

Website: blog.dakecorp.com

Key Highlights: Dake offers nine different types of hydraulic presses for all metalworking needs. That’s why we created this handy guide to help you select the right fit….

Expert Sourcing Insights for Dake Corporation Hydraulic Press

H2: Projected 2026 Market Trends for Dake Corporation Hydraulic Press

In 2026, the market for hydraulic presses, including those manufactured by Dake Corporation, is expected to experience notable shifts driven by technological advancements, evolving industrial demands, and global manufacturing trends. As a long-standing U.S.-based manufacturer known for affordable and reliable hydraulic press solutions, Dake is poised to benefit from several key market dynamics.

First, the continued growth of advanced manufacturing sectors—such as electric vehicle (EV) production, renewable energy infrastructure, and precision fabrication—will increase demand for versatile and cost-effective hydraulic pressing equipment. Dake’s focus on entry-level to mid-range presses aligns well with small and medium-sized enterprises (SMEs) expanding their production capabilities, particularly in North America and emerging markets.

Second, automation and Industry 4.0 integration will influence hydraulic press design and functionality. While Dake currently emphasizes mechanical simplicity and user-friendliness, the 2026 market may require enhanced compatibility with smart manufacturing systems. Dake could see growing demand if it incorporates basic digital controls, IoT connectivity, or data monitoring features into select models to meet evolving customer expectations.

Third, sustainability and energy efficiency are becoming critical factors in industrial equipment purchasing decisions. Hydraulic press buyers are increasingly prioritizing energy-efficient models and low-maintenance designs. Dake’s reputation for durable, straightforward machines positions it favorably, especially if the company advances its focus on eco-friendly hydraulic systems or energy recovery technologies.

Lastly, supply chain resilience and domestic manufacturing incentives in the U.S. may boost demand for American-made equipment. With Dake Corporation headquartered in Michigan and a history of domestic production, it stands to benefit from “onshoring” trends and government policies supporting local manufacturing, such as those under the CHIPS and Science Act or infrastructure investment initiatives.

In summary, the 2026 market for Dake Corporation hydraulic presses will likely be shaped by rising industrial automation, demand from growing sectors like EVs, sustainability concerns, and support for domestic manufacturing. To maintain competitiveness, Dake may need to balance its traditional value-driven approach with incremental technological enhancements tailored to modern production environments.

Common Pitfalls Sourcing Dake Corporation Hydraulic Presses (Quality, IP)

Sourcing industrial equipment like Dake Corporation hydraulic presses requires careful due diligence, particularly concerning quality assurance and intellectual property (IP) rights. Falling into common traps can lead to significant operational, financial, and legal consequences.

Quality-Related Pitfalls

Purchasing Counterfeit or Inferior Replicas

Dake Corporation manufactures high-quality, durable hydraulic presses used widely in industrial applications. A major risk when sourcing outside authorized channels is encountering counterfeit units or unauthorized replicas. These copies often use substandard materials, inferior hydraulic components, and lack proper engineering tolerances, resulting in premature failure, safety hazards, and inconsistent performance. Always verify authenticity through authorized dealers and inspect build quality, weld integrity, and component branding.

Lack of Certification and Safety Compliance

Genuine Dake presses comply with relevant safety and industry standards (e.g., ANSI, OSHA, CE). Unauthorized or gray-market units may not meet these requirements, especially if modified or assembled overseas. Sourcing without proper documentation increases liability risks and may violate workplace safety regulations. Ensure all equipment includes certification paperwork and has undergone required safety testing.

Absence of Warranty and After-Sales Support

Non-authorized resellers or third-party suppliers often cannot provide the manufacturer’s warranty or access to genuine spare parts and technical support. This leads to extended downtime and higher maintenance costs. Always confirm warranty coverage directly with Dake or an authorized distributor before purchase.

Intellectual Property (IP) Pitfalls

Infringement Through Unauthorized Replicas

Dake Corporation holds intellectual property rights, including patents, trademarks, and design rights, on their hydraulic press designs and branding. Sourcing counterfeit or cloned machines constitutes IP infringement. Purchasers—even unknowingly—can face legal exposure, seizure of equipment by customs, or cease-and-desist orders. Conduct due diligence to confirm the legitimacy of the supplier and product lineage.

Misuse of Trademarks and Branding

Some suppliers falsely advertise non-genuine presses as “Dake-style” or use Dake’s branding without authorization. This misrepresentation not only deceives buyers but also exposes them to IP liability if used in commercial operations. Verify that product listings and documentation accurately reflect the manufacturer and avoid vague or misleading branding.

Gray Market Imports with Altered IP Elements

Gray market units—originally intended for other regions—may be imported without Dake’s authorization. These machines might have modified labels, removed serial numbers, or altered components that void warranties and raise IP concerns. Such modifications can also impact compliance and traceability, complicating service and parts replacement.

Mitigation Strategies

To avoid these pitfalls, always purchase Dake hydraulic presses through authorized distributors, verify product authenticity using serial numbers with Dake Corporation, request full compliance documentation, and conduct supplier background checks. Engaging directly with Dake’s sales team ensures compliance with IP standards and guarantees quality and support.

Logistics & Compliance Guide for Dake Corporation Hydraulic Press

This guide outlines the essential logistics and compliance considerations for the safe and legal handling, transportation, installation, and operation of Dake Corporation Hydraulic Presses. Adherence to these guidelines ensures regulatory compliance, protects personnel, and maintains equipment integrity.

Shipping and Receiving Procedures

All Dake hydraulic presses are shipped securely via freight carrier. Upon delivery, inspect the packaging and unit immediately for any visible damage caused during transit. Document and photograph any discrepancies, then notify both the freight carrier and Dake Corporation customer service within 24 hours. Retain all packaging materials until the unit has been fully inspected and tested. Coordinate delivery access in advance, ensuring adequate space, floor load capacity, and maneuvering room for offloading with appropriate equipment such as forklifts or a crane.

Handling and Installation Requirements

Use proper lifting equipment rated for the press’s weight during uncrating and movement. Refer to the unit’s nameplate or manual for exact specifications. Maintain the press in an upright position at all times to avoid internal damage. Installation must be performed on a level, structurally sound foundation capable of supporting dynamic loads. Mount the press using anchor bolts as specified in the installation manual. Ensure electrical connections are made by a qualified electrician in compliance with local and national codes (e.g., NEC in the U.S.) and the press’s voltage and phase requirements.

Regulatory Compliance Standards

Dake hydraulic presses are designed and manufactured in accordance with applicable industry safety standards, including ANSI B11.1 (Safety of Mechanical Power Presses) and OSHA 29 CFR 1910 Subpart O (Machinery and Machine Guarding). The equipment complies with CE marking directives when configured for European markets, including the Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU. Units may also meet CSA standards for the Canadian market. Always verify compliance documentation included with your press or request certification from Dake Corporation as needed for regulatory audits.

Safety and Operational Compliance

Prior to operation, ensure all safety guards, emergency stop devices, and light curtains (if equipped) are fully functional. Train all operators in accordance with OSHA’s lockout/tagout (LOTO) procedures (29 CFR 1910.147) and machine-specific operation protocols. Conduct regular inspections and maintenance as per Dake’s recommended schedule to maintain compliance and operational safety. Keep a copy of the operator’s manual, maintenance log, and safety certifications readily available at the worksite.

Import/Export and Documentation

For international shipments, ensure all export documentation is completed accurately, including commercial invoices, packing lists, and certificates of origin. Verify that the hydraulic press meets destination country regulations for electrical systems, noise emissions, and machinery safety. Importers are responsible for customs clearance, duties, and adherence to local regulatory requirements. Dake Corporation can provide technical specifications and compliance statements to support import compliance upon request.

Conclusion for Sourcing Dake Corporation Hydraulic Press:

After thorough evaluation of the Dake Corporation as a supplier for hydraulic presses, it is evident that Dake offers reliable, high-quality, and durable equipment suitable for a wide range of industrial applications. With decades of experience in manufacturing, strong customer support, and a comprehensive product lineup, Dake presents a competitive option for businesses seeking cost-effective yet robust hydraulic press solutions.

Sourcing from Dake Corporation provides several advantages, including accessible pricing, availability of replacement parts, extensive technical documentation, and responsive service support. Additionally, their presses meet industry safety standards and are widely used in automotive, manufacturing, and maintenance environments, reflecting their proven performance and dependability.

While lead times and customization options may vary compared to some premium brands, Dake strikes a favorable balance between affordability and functionality. For organizations prioritizing value, proven reliability, and ease of maintenance, sourcing a hydraulic press from Dake Corporation is a sound and strategic decision. It is recommended to establish clear specifications, confirm delivery timelines, and explore warranty and service options to ensure a successful procurement outcome.

![[PDF] INVITATION FOR BID (IFB) #046](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-invitation-for-bid-ifb-046-327.jpg)