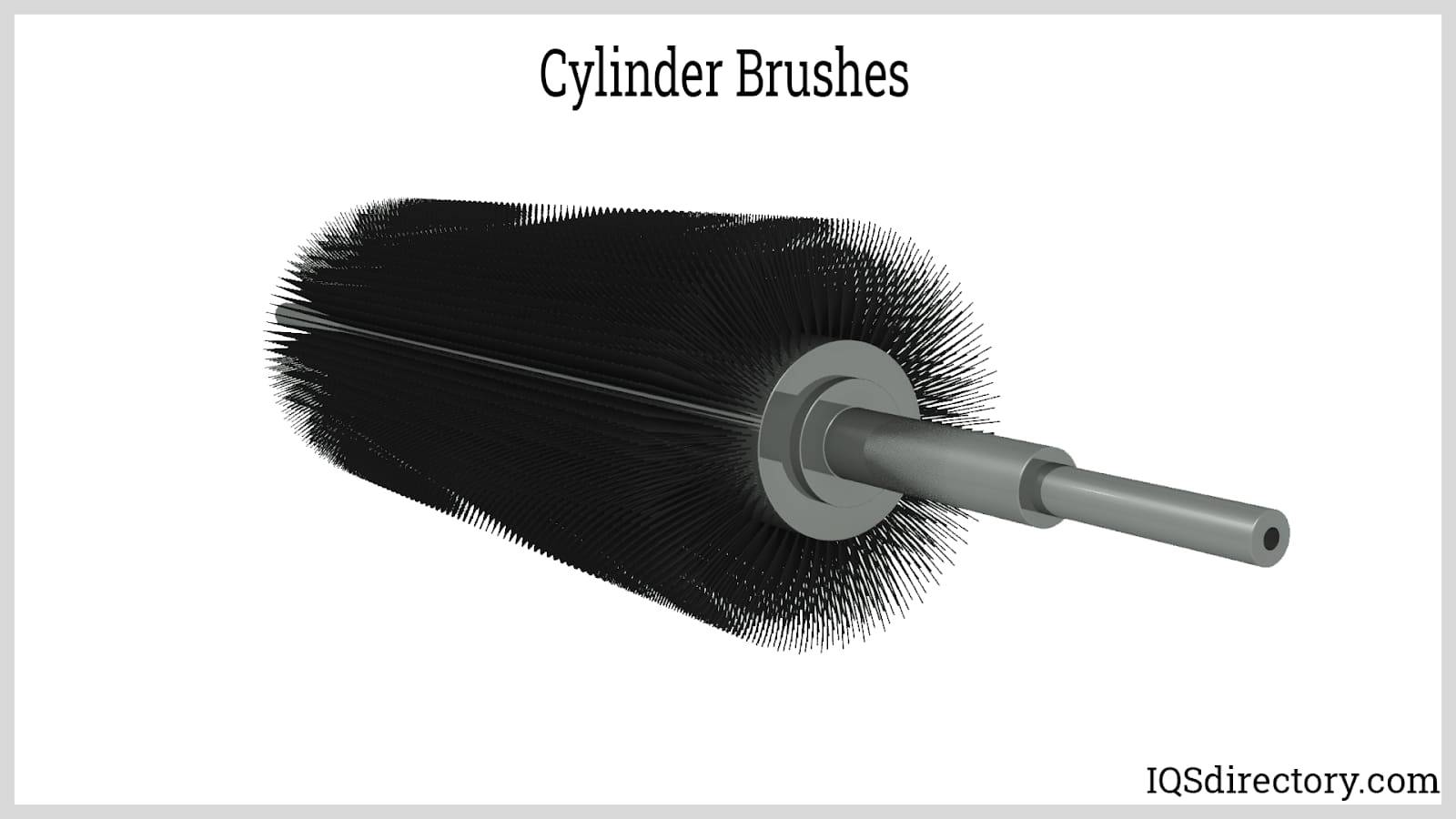

The global cylinder brush manufacturing market is experiencing steady expansion, driven by increasing demand across industries such as cleaning, printing, textiles, and industrial automation. According to Grand View Research, the global industrial brushes market size was valued at USD 1.32 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by rising automation in manufacturing processes and the need for precision cleaning in high-contamination environments. Cylinder brushes, in particular, are gaining traction due to their versatility and effectiveness in surface preparation, deburring, and maintenance applications. As industries prioritize efficiency and reliability, the demand for high-quality cylinder brushes continues to rise—making it essential to identify manufacturers that combine innovation, durability, and scalability. Based on production capacity, global reach, technological advancement, and customer reviews, here are the top 8 cylinder brush manufacturers leading the market today.

Top 8 Cylinder Brush Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Spiral Brushes

Domain Est. 1998

Website: spiralbrushes.com

Key Highlights: Spiral Brushes Inc. offers an extensive line of stock and custom configurable industrial power brushes and maintenance brushes….

#2 Industrial & Abrasive Brush Manufacturer

Domain Est. 2006

Website: tanisbrush.com

Key Highlights: Tanis is a leading industrial and abrasive brush manufacturer. We help businesses solve production needs and improve efficiency with quality brush products….

#3 Metlkor Industrial Cylinder brushes

Domain Est. 1996

Website: jenkinsbrush.com

Key Highlights: These cylinder brushes give you the strength of epoxy-set brushes, the brushing ability of tufted brushes and the strength and deflection and rotation speed of ……

#4 Tufted Industrial Cylinder Cleaning Brushes

Domain Est. 1998

Website: gordonbrush.com

Key Highlights: 2–7 day deliveryThese industrial tufted cylinder brushes are made using nylon, polypropylene, or Tampico fill material with a choice of either an ABS, HDPE, or PVC core….

#5 Leading Cylinder Brush Manufacturers

Domain Est. 2002

Website: industrialbrushes.net

Key Highlights: Contact the top cylinder brush manufacturers and suppliers with the help of this site. These companies offer fast shipping, in stock items ….

#6 Cylinder Brushes

Domain Est. 1997

Website: brush.com

Key Highlights: 3–8 day delivery 30-day returnsFrom conveyors to pan cleaners, metal finishing and flour dusting, cylinder brushes fill an endless need in industry. Click on any of the categories …

#7 Brushtec

Domain Est. 1997

Website: brushtec.com

Key Highlights: Brushtec is one of the world’s leaders in the design, and manufacturing of brushes. Our expertise ranges as wide from road sweeper brushes to food production ……

#8 Complete List of Cylinder Brush Manufacturers & Suppliers

Domain Est. 2012

Website: brushmanufacturers.org

Key Highlights: Get a comprehensive list of cylinder brush manufacturers and suppliers and review and compare their products and capabilities to find a great cylinder ……

Expert Sourcing Insights for Cylinder Brush

H2: 2026 Market Trends for Cylinder Brushes

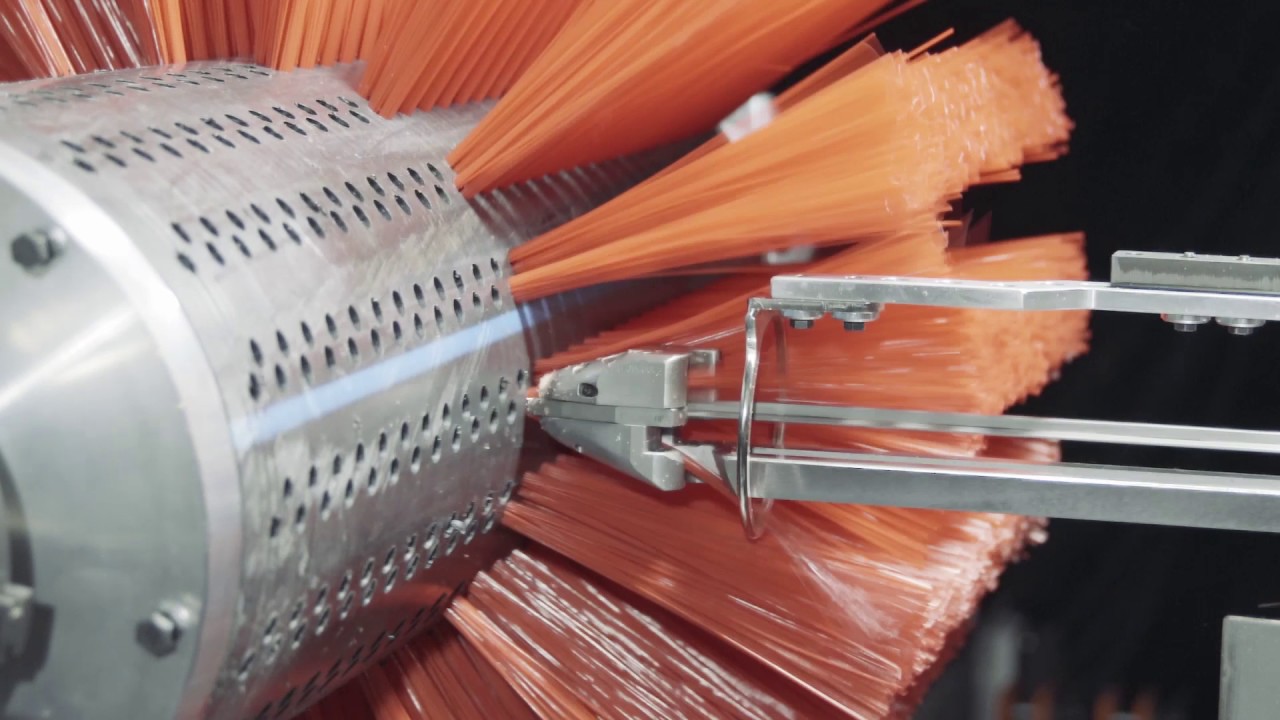

The global cylinder brush market is poised for significant transformation and growth by 2026, driven by evolving industrial demands, technological advancements, and sustainability initiatives. As automation and precision manufacturing continue to expand across key end-use sectors, cylinder brushes are increasingly being integrated into advanced cleaning, surface finishing, and material handling systems. The following trends are expected to shape the cylinder brush market in 2026:

-

Rising Demand from Industrial Automation

The surge in automated manufacturing processes across automotive, electronics, and pharmaceutical industries is fueling demand for high-performance cylinder brushes. These brushes are essential for conveyor belt cleaning, deburring, and surface preparation. As industries adopt Industry 4.0 technologies, smart cylinder brushes equipped with sensors for real-time wear monitoring are expected to gain traction. -

Growth in the Food and Beverage Sector

Stringent hygiene regulations are prompting food processing facilities to invest in sanitary-grade cylinder brushes made from FDA-compliant materials such as nylon and polypropylene. The emphasis on contamination prevention will drive innovation in antimicrobial coatings and easy-to-clean brush designs. -

Sustainability and Eco-Friendly Materials

Environmental concerns are influencing material choices in brush manufacturing. By 2026, a growing number of manufacturers are expected to shift toward biodegradable bristle materials and recyclable cores. This trend aligns with global sustainability goals and corporate ESG (Environmental, Social, and Governance) commitments. -

Customization and Application-Specific Designs

End-users are increasingly seeking tailored cylinder brush solutions to meet unique operational requirements. This includes customized diameters, bristle stiffness, and mounting configurations. Advances in CNC manufacturing and 3D printing are enabling faster prototyping and production of bespoke brushes. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific, Latin America, and Africa is creating new opportunities for cylinder brush suppliers. Countries like India, Vietnam, and Brazil are investing in infrastructure and manufacturing, which will boost demand for industrial cleaning tools, including cylinder brushes. -

Technological Integration and Smart Brushes

Integration with IoT-enabled systems allows for predictive maintenance and performance tracking. By 2026, smart cylinder brushes with embedded sensors may become standard in high-precision applications, reducing downtime and improving operational efficiency. -

Consolidation in the Supply Chain

Market consolidation is expected as larger manufacturers acquire niche players to expand their product portfolios and geographic reach. This will likely lead to improved R&D capabilities and broader distribution networks.

In summary, the 2026 cylinder brush market will be characterized by innovation, customization, and sustainability. Companies that invest in advanced materials, smart technologies, and eco-conscious manufacturing practices are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Cylinder Brushes (Quality and IP)

Sourcing cylinder brushes, especially for industrial or specialized applications, involves several potential pitfalls that can impact performance, compliance, and long-term costs. Two critical areas where issues commonly arise are quality assurance and intellectual property (IP) concerns. Being aware of these pitfalls can help buyers make informed decisions and avoid costly mistakes.

Quality-Related Pitfalls

Inconsistent Material Standards

One of the most frequent quality issues is the use of substandard or inconsistent materials in brush construction. Some suppliers may use lower-grade bristles, cores, or adhesives to cut costs. This can lead to premature wear, reduced cleaning efficiency, or failure under operational stress. Always verify material specifications and request test reports or certifications (e.g., FDA, RoHS, or REACH compliance) when relevant.

Poor Manufacturing Tolerances

Cylinder brushes must meet precise dimensional and alignment specifications to function correctly in machinery. Poorly manufactured brushes may have uneven bristle distribution, out-of-round cores, or imbalance—leading to vibration, machine damage, or inconsistent performance. It’s essential to confirm that the supplier adheres to tight tolerance standards and performs quality control checks.

Lack of Performance Testing

Some suppliers do not conduct real-world performance testing under conditions that simulate actual use (e.g., high speed, temperature, or specific media contact). Without this, the brush may not perform as expected once installed. Ask for test data or request sample trials before committing to large orders.

Inadequate Customization Documentation

Custom brushes require detailed specifications. Ambiguities in drawings, bristle patterns, or mounting configurations can result in incorrect products. Ensure that technical documentation is clear, signed off by both parties, and includes revision tracking.

Intellectual Property (IP) Concerns

Unauthorized Replication of Proprietary Designs

A major IP risk arises when suppliers copy patented or proprietary brush designs without permission. Sourcing from manufacturers that reverse-engineer OEM parts—especially for replacement brushes—can expose the buyer to legal liability. Always confirm that the supplier has the right to produce the design or that the IP has expired.

Lack of IP Ownership Clarity in Custom Projects

When developing a custom brush, the ownership of the resulting design may not be clearly defined in the contract. This can lead to disputes if the supplier uses the design for other clients or refuses to allow production by third parties. Ensure contracts explicitly state that IP rights transfer to the buyer or are licensed appropriately.

Use of Counterfeit or Branded Components

Some suppliers may use counterfeit or unlicensed branded components (e.g., brush filaments with registered trademarks) in their assemblies. This not only affects quality but can also result in trademark infringement claims. Require suppliers to disclose all component sources and provide authenticity documentation.

Insufficient Confidentiality Protections

Sharing detailed technical requirements with suppliers can expose sensitive operational information. If non-disclosure agreements (NDAs) are absent or weak, there’s a risk of design leaks or competitive misuse. Always establish strong confidentiality terms before disclosing proprietary information.

By carefully addressing these quality and IP pitfalls during the sourcing process, companies can ensure reliable performance, maintain compliance, and protect their innovation and brand integrity.

Logistics & Compliance Guide for Cylinder Brushes

Overview

Cylinder brushes are widely used in industrial, commercial, and consumer applications for cleaning, deburring, polishing, and surface preparation. Due to their varied materials and construction, proper logistics handling and regulatory compliance are essential to ensure safety, efficiency, and adherence to international standards.

Classification & Packaging

Product Identification

Cylinder brushes typically consist of a core (plastic, metal, or wood) and bristles made from nylon, natural fibers, wire, or abrasive materials. Accurate product classification is critical for shipping and customs.

Packaging Requirements

- Use sturdy, moisture-resistant packaging to prevent deformation or damage during transit.

- Individual brushes should be wrapped or separated to avoid bristle damage.

- For bulk shipments, use corrugated cardboard boxes with internal dividers or palletized loads secured with stretch wrap.

- Clearly label packages with product name, size, bristle type, and handling instructions (e.g., “Fragile,” “This Side Up”).

Transportation & Handling

Domestic & International Shipping

- Cylinder brushes are generally non-hazardous and can be shipped via standard freight (air, sea, or ground).

- Confirm bristle material: Brushes with metal or wire bristles may be subject to additional screening or declaration due to potential security concerns.

- When shipping internationally, ensure compliance with carrier-specific regulations (e.g., IATA for air freight, IMDG for sea transport).

Storage Conditions

- Store in a dry, temperature-controlled environment to prevent warping or bristle degradation.

- Avoid direct sunlight and high humidity, especially for natural fiber or wooden-core brushes.

- Keep away from solvents or corrosive substances that could damage bristles or core materials.

Regulatory Compliance

Import/Export Documentation

- Provide accurate Harmonized System (HS) codes. Common codes include:

- 9603.50 – Brushes for cleaning or polishing (non-mechanical).

- 8466.30 – Machine tool brushes (if used as industrial components).

- Include commercial invoices, packing lists, and certificates of origin where required.

- Verify destination country regulations—some may require product conformity assessments or labeling in local language.

Safety & Environmental Standards

- Comply with REACH (EU) and RoHS directives if applicable, particularly for brushes containing certain metals or plastics.

- For brushes with abrasive or chemical coatings, provide Safety Data Sheets (SDS) as required under GHS.

- Ensure compliance with OSHA or equivalent workplace safety guidelines if intended for industrial use.

Labeling & Product Information

Mandatory Labels

- Product specifications (diameter, length, bristle material, core type).

- Manufacturer/importer name and contact information.

- Country of origin.

- Batch or lot number for traceability.

Additional Considerations

- Include usage instructions and safety warnings if applicable (e.g., “Use with protective eyewear”).

- Eco-labeling (e.g., recyclable packaging) may enhance market acceptance in environmentally regulated regions.

Special Handling for Specific Types

Wire or Metal Bristle Brushes

- May be classified as tools with potential for misuse; subject to heightened scrutiny in certain countries.

- Use tamper-evident packaging and declare clearly on shipping documents.

- Comply with regulations such as the UK’s Offensive Weapons Act if applicable.

Food-Grade Brushes

- Must meet FDA (US) or EC 1935/2004 (EU) standards for food contact materials.

- Use only approved bristle and core materials (e.g., FDA-compliant nylon).

- Include certification documentation with shipments.

Conclusion

Proper logistics and compliance for cylinder brushes involve accurate classification, secure packaging, adherence to transportation regulations, and fulfillment of regional legal requirements. Staying informed about changes in international trade policies and material safety standards ensures smooth distribution and minimizes supply chain disruptions.

Conclusion for Sourcing Cylinder Brushes

In conclusion, sourcing cylinder brushes requires a strategic approach that balances quality, cost, and reliability. By clearly defining the application requirements—such as brush dimensions, filament material, stiffness, and core specifications—buyers can narrow down potential suppliers effectively. Evaluating suppliers based on their manufacturing capabilities, quality control processes, certifications, and track record ensures consistent product performance and longevity.

Sourcing from reputable manufacturers, whether domestic or international, involves comparing lead times, minimum order quantities, and overall value rather than focusing solely on price. Establishing strong supplier relationships, conducting sample testing, and performing periodic audits further contribute to a successful procurement strategy.

Ultimately, an informed and diligent sourcing process will result in cylinder brushes that enhance operational efficiency, reduce maintenance downtime, and deliver long-term cost savings across various industrial applications.