The global personalized footwear market has seen robust growth, driven by rising consumer demand for customized products and comfort-oriented lifestyles. According to a report by Mordor Intelligence, the global slippers market was valued at USD 43.3 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029, with customization emerging as a key differentiator among manufacturers. Increasing e-commerce penetration, coupled with advancements in digital printing and on-demand production technologies, has enabled brands to offer tailored designs, monogramming, and size-specific fits. As competition intensifies, a new wave of manufacturers is excelling in offering scalable customization without compromising on quality or lead times. Below, we highlight the top 8 customized slippers manufacturers leveraging innovation, sustainability, and customer-centric manufacturing to capture growing market opportunities.

Top 8 Customized Slippers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 One

Website: mappershoe.com

Key Highlights: Mingyi is a PVC/EVA slippers manufacturer providing personalized custom slippers service, supporting OEM/ODM, which is very suitable for brand cooperation!…

#2 Customized Slippers Wholesale

Domain Est. 2019

Website: mychonly.com

Key Highlights: MYCHONLY is one of the most professional slippers manufacturers in China, specialized in providing the best customized service….

#3 Genuine Handmade Slippers for Men Women and Child

Domain Est. 1997

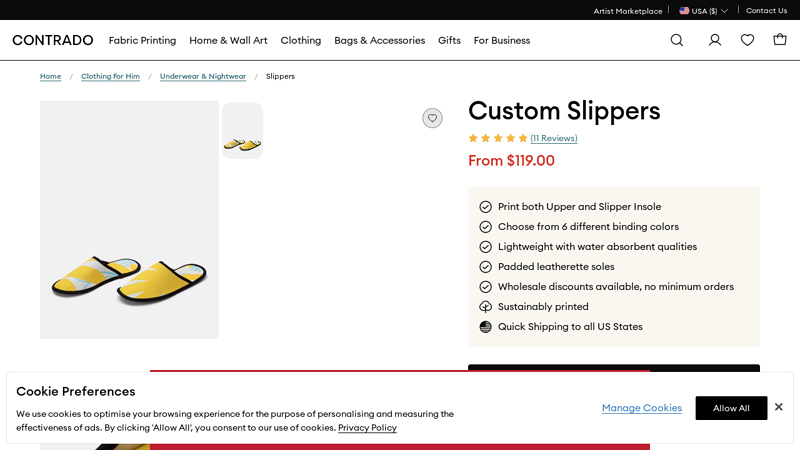

#4 Custom Slippers

Domain Est. 2004

Website: contrado.com

Key Highlights: In stock Rating 4.9 (11) Make your own slippers with your own artwork or logo, and choose from 6 different trim colors to highlight your design, creating a soft, comfortable slip…

#5 No. 1 in bio

Domain Est. 2010

Website: biofootwearcompany.com

Key Highlights: Hotel slippers customizable. Discover our range of personalised hotel slippers and all our white label hospitality products (minimum to personalise: 500 pairs ……

#6 Shop Custom Slippers Printed With Your Logo

Domain Est. 2010

#7 Custom Velvet Loafers & Embroidered Slippers

Domain Est. 2010

Website: fgfootwear.com

Key Highlights: FG offers premium custom-made velvet loafers and embroidered slippers with luxury packaging. Explore handcrafted men’s velvet shoes and exclusive bespoke ……

#8 Slippers

Domain Est. 2024

Website: evaslippers.com

Key Highlights: Discover high-quality, eco-friendly slippers by Ningbo Cotton Slipper, perfect for B2B needs. Designed for durability and comfort, our lightweight slippers ……

Expert Sourcing Insights for Customized Slippers

H2: 2026 Market Trends for Customized Slippers

By 2026, the customized slippers market is poised for significant transformation, driven by evolving consumer preferences, technological advancements, and heightened sustainability awareness. Key trends shaping the landscape include:

1. Hyper-Personalization via Advanced Technology:

Consumers will increasingly demand beyond basic monograms. Expect widespread adoption of AI-driven design platforms allowing intricate, user-generated artwork, 3D foot scanning for perfect ergonomic fit, and augmented reality (AR) try-ons. Brands leveraging machine learning to suggest designs based on user behavior or integrate biometric data (e.g., pressure points) will gain a competitive edge.

2. Sustainability as a Core Customization Pillar:

Eco-consciousness will be non-negotiable. Customization will extend to material choices, with transparent options like recycled ocean plastics, organic cotton, plant-based dyes, and biodegradable soles. Brands offering carbon footprint calculators for each design choice and take-back recycling programs will resonate strongly with environmentally aware buyers.

3. Smart Slippers Integration:

The convergence of comfort and technology will accelerate. Customized smart slippers featuring embedded sensors for health monitoring (gait analysis, step count, temperature), temperature regulation, or seamless home automation controls (e.g., turning on lights) will emerge as a premium niche, blending personalization with wellness and convenience.

4. Direct-to-Consumer (DTC) & On-Demand Manufacturing Dominance:

The supply chain will shift decisively towards agile, localized micro-factories using digital knitting and 3D printing. This enables true on-demand production, minimizing waste and inventory, while allowing rapid delivery of unique designs. DTC brands will thrive by offering immersive online configurators and strong community engagement.

5. Emotional Connection & Niche Targeting:

Customization will focus on storytelling and emotional value. Expect growth in slippers personalized with meaningful photos, pet prints, or cultural motifs. Brands will target specific niches—e.g., post-surgery recovery, pet owners, or fandom communities—with tailored designs, reinforcing brand loyalty through deep personal relevance.

6. Luxury & Gifting Market Expansion:

Customized slippers will solidify their position as premium lifestyle and gifting items. High-end materials (cashmere, silk linings) and collaborations with artists/designers will cater to the luxury segment. Subscription boxes offering seasonal custom designs and corporate gifting with branded slippers will see substantial growth.

In essence, by 2026, customized slippers will transcend footwear, becoming personalized, sustainable, and technologically enhanced extensions of individual identity and well-being, delivered through efficient, consumer-centric models.

Common Pitfalls When Sourcing Customized Slippers: Quality and Intellectual Property Risks

Sourcing customized slippers can be a lucrative venture, but it comes with significant risks—particularly concerning product quality and intellectual property (IP) protection. Falling into these common pitfalls can result in customer dissatisfaction, legal disputes, and reputational damage. Being aware of these challenges is essential for mitigating risks and ensuring a successful partnership with suppliers.

Quality-Related Pitfalls

Inconsistent Material Standards

One of the most frequent issues is inconsistency in material quality. Suppliers may use substandard fabrics, foam, or soles to reduce costs, especially once initial samples have been approved. Without clearly defined material specifications and third-party inspections, brands risk receiving bulk orders that differ significantly from prototypes.

Poor Craftsmanship and Construction

Customized slippers require precision in stitching, adhesion, and assembly. Low-cost manufacturers may cut corners, leading to issues such as peeling soles, misaligned logos, or weak seams. These defects often become apparent only after extended use, damaging customer trust and increasing return rates.

Inadequate Size and Fit Consistency

Slippers must fit comfortably across various foot shapes and sizes. Poorly calibrated molds or inconsistent manufacturing processes can lead to size inaccuracies. Without proper fit testing across production batches, brands may face widespread complaints and sizing-related returns.

Lack of Quality Control Processes

Many overseas manufacturers, particularly smaller workshops, lack rigorous quality assurance systems. Without defined inspection checkpoints and standardized operating procedures, defects can go unnoticed until the product reaches the end consumer.

Intellectual Property-Related Pitfalls

Unprotected Designs and Branding Elements

Custom slippers often feature unique designs, logos, or patented technologies. If a supplier is not bound by a clear IP agreement, they may replicate or resell your designs to competitors. This is especially risky in regions with weak IP enforcement.

Unauthorized Production and Gray Market Sales

Suppliers may produce excess units beyond the agreed quantity and sell them independently—either domestically or through online marketplaces. This not only dilutes your brand but can also lead to price undercutting and counterfeit products flooding the market.

Lack of Legal Recourse Due to Jurisdictional Challenges

Enforcing IP rights across borders can be difficult and costly. If a supplier in another country violates your IP, legal action may be slow or ineffective, particularly if the contract lacks enforceable jurisdiction clauses or if local laws offer limited protection.

Inadequate Contractual Safeguards

Many sourcing agreements fail to explicitly address IP ownership, usage rights, and confidentiality. Without detailed clauses stating that all designs, molds, and branding belong to the buyer, suppliers may claim partial ownership or reuse assets for other clients.

Mitigation Strategies

To avoid these pitfalls, businesses should:

– Conduct thorough supplier audits and factory visits.

– Require detailed material and construction specifications.

– Implement third-party quality inspections during and post-production.

– Establish comprehensive contracts that clearly define IP ownership and usage rights.

– Register trademarks and designs in key markets.

– Use non-disclosure agreements (NDAs) and restrict access to sensitive design files.

By proactively addressing both quality and IP concerns, companies can protect their brand integrity and deliver a premium customized product to their customers.

Logistics & Compliance Guide for Customized Slippers

Customized slippers—ranging from personalized embroidery to unique sizing and materials—pose specific challenges in logistics and regulatory compliance. Successfully navigating these aspects is essential for timely delivery, customer satisfaction, and legal adherence across domestic and international markets.

Product Classification and Tariff Codes

Correctly classifying customized slippers is the foundation of compliant global trade. Most slippers fall under HTS Code 6404.11 or 6404.19 (for rubber/plastic uppers) or 6403.91–6403.99 (for leather/other materials). Customization may affect classification if it significantly alters the product’s nature. Always verify with customs authorities in the destination country, especially if the customization includes electronic components (e.g., heated insoles), which may require separate classification.

Labeling and Marking Requirements

Customized slippers must meet labeling standards in the target market. Key requirements include:

- Country of Origin: Must be clearly marked (e.g., “Made in Vietnam”) on the product or packaging.

- Material Composition: List all primary materials (e.g., “Upper: 100% Cotton; Sole: EVA Foam”).

- Care Instructions: Provide washing and maintenance guidance, particularly for personalized fabric items.

- Size and Branding: Include size (in local standards, e.g., US, EU, UK) and brand name.

- Customization Details: If personalization includes names or images, ensure no trademarked or offensive content is used.

Safety and Product Compliance Standards

Compliance with safety regulations varies by region:

- United States: Comply with CPSIA (Consumer Product Safety Improvement Act), including lead and phthalate limits. Slippers intended for children under 12 require tracking labels and third-party testing.

- European Union: Must meet REACH (chemical restrictions), EN 13402 (size labeling), and potentially CE marking if considered personal protective equipment (e.g., anti-slip work slippers).

- Canada: Follow Health Canada’s requirements under the Canada Consumer Product Safety Act (CCPSA).

- Australia/New Zealand: Comply with AS/NZS 2207 for slip resistance and general safety.

Conduct regular audits and maintain test reports from accredited labs for all materials and finished products.

Packaging and Shipping Considerations

Customized items often require individual handling:

- Protective Packaging: Use polybags, tissue paper, or rigid boxes to prevent damage to embroidered or printed designs.

- Dimensional Weight: Optimize packaging size to reduce shipping costs, especially for lightweight slippers.

- Labeling: Include scannable barcodes, return addresses, and customs forms for international shipments.

- Batch Management: Track customization batches (e.g., by order ID) to streamline fulfillment and returns.

Import and Export Documentation

Ensure accurate documentation to avoid customs delays:

- Commercial invoice (with detailed description of customization)

- Packing list

- Bill of lading or air waybill

- Certificate of Origin (if claiming preferential tariffs)

- Test reports or compliance certificates (upon request)

For high-value or frequent shipments, consider obtaining an Importer Security Filing (ISF) or Authorized Economic Operator (AEO) status to expedite clearance.

Intellectual Property and Customization Rights

When offering personalized designs:

- Obtain customer consent for use of names, logos, or images.

- Avoid reproducing copyrighted or trademarked content unless licensed.

- Include disclaimers in your terms of service regarding user-generated content.

Returns and Reverse Logistics

Customized products are often non-returnable due to personalization. Clearly communicate this policy at checkout. For defective items, establish a repair, replacement, or refund process, and consider local service centers to reduce return shipping costs.

Sustainability and Environmental Compliance

- Use recyclable or biodegradable packaging where possible.

- Comply with Extended Producer Responsibility (EPR) regulations in regions like the EU.

- Disclose use of sustainable materials (e.g., organic cotton, recycled foam) in marketing and labeling.

Conclusion

Shipping customized slippers globally requires careful attention to classification, safety, labeling, and documentation. By building compliance into your supply chain and staying updated on regional regulations, you can minimize delays, avoid penalties, and deliver a high-quality, personalized experience to customers worldwide.

In conclusion, sourcing customized slippers requires a strategic approach that balances quality, cost, customization options, and reliable supply chain management. By identifying clear product specifications, evaluating suppliers based on their experience and capabilities, and ensuring compliance with quality and ethical standards, businesses can successfully procure slippers that meet brand requirements and customer expectations. Additionally, fostering strong supplier relationships, conducting sample testing, and planning for scalability and lead times are critical for long-term success. With careful planning and due diligence, customized slipper sourcing can enhance brand identity, support marketing initiatives, and deliver added value to end consumers.