The global customized furniture market, driven by rising consumer demand for personalized home solutions, is experiencing robust growth—particularly within the bedroom segment. According to Grand View Research, the global custom furniture market was valued at USD 108.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key driver of this expansion is the increasing preference for made-to-order bedroom furniture, including customized beds that align with individual space constraints, design aesthetics, and functional needs. Mordor Intelligence further supports this trend, projecting the custom furniture market to grow at a CAGR of over 5.5% during the forecast period 2023–2028, fueled by digital transformation in e-commerce platforms and advanced manufacturing technologies like CNC machining and 3D modeling. As consumers prioritize comfort, style, and space optimization, particularly in urban environments, manufacturers are responding with scalable customization options—setting the stage for the emergence of top players who combine craftsmanship, innovation, and data-driven design to lead the customized bed market.

Top 10 Customized Bed Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sherrill Furniture

Domain Est. 1997

Website: sherrillfurniture.com

Key Highlights: Sherrill Furniture manufactures handcrafting high-quality, customized furniture made in the USA. Learn more about our custom upholstery options….

#2 Charles H. Beckley, Inc.

Domain Est. 2000

Website: chbeckley.com

Key Highlights: ENJOY the long-lasting quality and comfort of traditionally constructed, hand-made, custom bedding; driven and designed by over 90 years of experience….

#3 Adjustable Beds

Domain Est. 1995

Website: reverie.com

Key Highlights: Our entire design philosophy allows you to keep customizing your mattress and adjustable base as your sleep needs evolve. See How It Works….

#4 Taylor King

Domain Est. 1998

Website: taylorking.com

Key Highlights: Taylor King manufactures handcrafted, custom upholstered furniture using the finest designer fabrics and leathers sourced from around the world….

#5 Custom Upholstered Beds – 100+ Fabrics for Custom Beds

Domain Est. 2002

Website: theinside.com

Key Highlights: 30-day returnsShop custom upholstered beds in 100+ fabrics at The Inside. Made-to-order from scratch with 30-day returns. Customize your bed to fit your style today….

#6 Helix

Domain Est. 2014

Website: helixsleep.com

Key Highlights: Free delivery · Free 100-day returnsShop Helix Sleep mattresses. Outrageous comfort designed for every body. Take our 30-second sleep quiz to find out which mattress is right for …

#7 Custom Metal Bed Frames

Domain Est. 2016

#8 The Ace Collection

Domain Est. 2017

Website: acesize.com

Key Highlights: CHOOSE THE SIZE THAT’S RIGHT FOR YOU THEN BUILD YOUR custom DREAM BED. Our mattresses are built to pass through a US standard door height of 80″….

#9 Evrbed: Modular Mattress Canada

Domain Est. 2021

Website: evrbed.com

Key Highlights: Discover the Evrbed Modular Mattress — customizable comfort for couples, personalized for every sleeper, and built to last a lifetime….

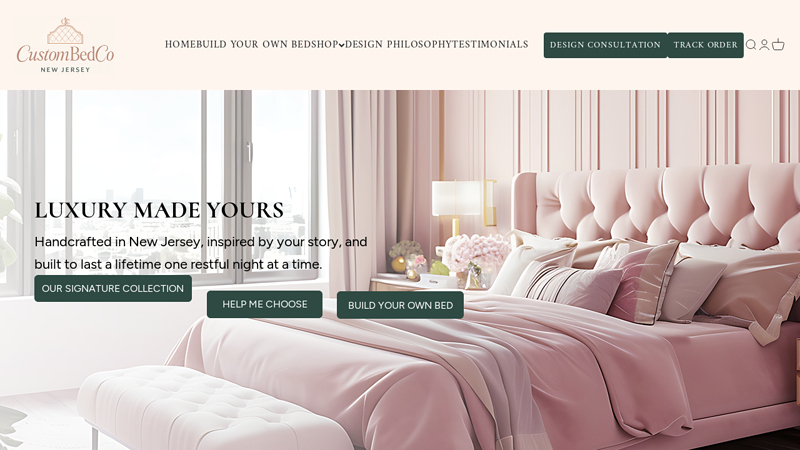

#10 The Custom Bed Company

Domain Est. 2023

Website: custombedco.com

Key Highlights: Bespoke USA Based upholstered beds and wall panels, crafted for luxury interiors. Custom designs, premium materials, and expert craftsmanship….

Expert Sourcing Insights for Customized Bed

2026 Market Trends for Customized Beds

Rising Consumer Demand for Personalization

The customized bed market is poised for significant growth by 2026, driven primarily by increasing consumer demand for personalized home furnishings. Modern buyers are prioritizing comfort, aesthetic alignment with interior design, and individual health needs. This shift has led mattress and bed frame manufacturers to offer modular designs, adjustable firmness, customizable dimensions, and fabric choices. Personalization extends beyond physical features—consumers now expect beds that integrate with smart home ecosystems and adapt to sleep patterns through AI-driven technology.

Integration of Smart Technology

By 2026, smart beds are expected to dominate the customized bed segment. Features such as biometric monitoring, temperature regulation, motion adjustment, and sleep analytics will become standard in premium models. Companies like Sleep Number and Eight Sleep are leading innovation, but traditional furniture brands are catching up with IoT-enabled solutions. These smart features not only enhance user experience but also collect valuable wellness data, creating new business models around health and sleep optimization services.

Focus on Health and Wellness

The global emphasis on health and wellness is a key driver shaping the customized bed market. Consumers are increasingly aware of the link between sleep quality and overall well-being. As a result, customized beds featuring orthopedic support, pressure relief zones, allergy-resistant materials, and posture alignment technologies are gaining traction. The rise in remote work and sedentary lifestyles has heightened the need for supportive sleep solutions, further boosting demand for beds tailored to individual body types and medical conditions.

Sustainable and Eco-Friendly Materials

Sustainability will play a crucial role in 2026’s market trends. Environmentally conscious consumers are demanding beds made from organic cotton, natural latex, reclaimed wood, and non-toxic adhesives. Brands that emphasize transparency in sourcing and carbon-neutral manufacturing will have a competitive advantage. Modular and repairable designs are also gaining popularity, reducing waste and supporting circular economy principles. Certifications like OEKO-TEX and GREENGUARD will be essential for market credibility.

Growth of Direct-to-Consumer (DTC) Models

The DTC model will continue to expand in the customized bed space by 2026. Online platforms allow consumers to configure beds to their exact preferences, receive home trials, and benefit from streamlined delivery via flat-pack or bed-in-a-box formats. This model reduces overhead costs and enables competitive pricing while offering high levels of customization. Augmented reality (AR) tools will enhance the online shopping experience, letting users visualize customized beds in their bedrooms before purchasing.

Regional Market Expansion

While North America and Europe lead in adoption, the Asia-Pacific region is expected to witness the fastest growth by 2026. Rising urbanization, increasing disposable income, and growing awareness of sleep health are fueling demand in countries like China, India, and South Korea. Localized customization—such as beds suited for smaller living spaces or cultural sleeping preferences—will be key to success in these emerging markets.

Conclusion

By 2026, the customized bed market will be defined by personalization, technology integration, health focus, sustainability, and digital innovation. Companies that combine advanced customization options with wellness benefits and eco-conscious practices will lead the industry. As consumer expectations evolve, the bed will transition from a simple piece of furniture to a personalized health and lifestyle solution.

Common Pitfalls in Sourcing Customized Beds (Quality and Intellectual Property)

Sourcing customized beds—whether for hospitality, healthcare, or residential projects—presents unique challenges, particularly concerning product quality and intellectual property (IP) protection. Overlooking these aspects can lead to costly setbacks, legal disputes, and brand damage. Below are key pitfalls to avoid.

Overlooking Material and Craftsmanship Standards

One of the most frequent issues in sourcing customized beds is assuming that all manufacturers adhere to the same quality benchmarks. Variations in wood sourcing, fabric durability, metal framing, and joinery techniques can significantly impact longevity and safety. Without clear specifications and third-party quality audits, buyers risk receiving substandard products that fail prematurely or do not meet regulatory standards.

Inadequate Communication of Design Specifications

Customization demands precision. Ambiguous sketches, incomplete technical drawings, or missing tolerances can result in misinterpretations during production. Misalignment between the intended design and the final product not only affects aesthetics but can also compromise functionality and user comfort. Establishing detailed design documentation and using 3D prototypes can mitigate this risk.

Failing to Protect Intellectual Property

When developing a unique bed design, especially for branded or luxury markets, protecting IP is critical. Many buyers fail to secure design patents, trademarks, or copyrights before sharing concepts with manufacturers—particularly in offshore markets. Without proper agreements, manufacturers may replicate and sell your design to competitors. Always use non-disclosure agreements (NDAs) and clearly define IP ownership in sourcing contracts.

Relying on Unverified Suppliers

Choosing a supplier based solely on cost or fast turnaround times can backfire. Unverified manufacturers may lack the technical expertise or ethical standards to deliver quality custom beds. Conduct thorough due diligence: review certifications (e.g., ISO, FSC), request client references, and perform factory audits to ensure compliance with labor and environmental regulations.

Neglecting Long-Term Support and Spare Parts

Custom beds often require specialized maintenance or replacement components. Sourcing from suppliers who don’t offer long-term support or spare parts can render the product obsolete after minor damage. Ensure service agreements include access to replacement parts and technical support, especially for institutional or commercial buyers.

Ignoring Compliance and Certification Requirements

Custom beds, particularly in healthcare or contract settings, must meet safety and fire resistance standards (e.g., BS 7177, CAL 117). Failing to verify compliance during sourcing can lead to rejected shipments, legal liability, or safety hazards. Confirm that the manufacturer can provide certified test reports and labels as part of the delivery.

Assuming Price Equals Value

The lowest bid may not offer the best long-term value. Hidden costs—such as rework, shipping delays, or product failure—can outweigh initial savings. Evaluate suppliers based on total cost of ownership, including quality consistency, warranty terms, and responsiveness, not just unit price.

By proactively addressing these pitfalls, businesses can ensure that their customized bed sourcing process delivers high-quality, original products that meet both functional needs and legal standards.

Logistics & Compliance Guide for Customized Beds

Product Classification and HS Code

Customized beds typically fall under HS Code 9403.50 (Furniture of wood, for bedrooms), though the exact code may vary by material (e.g., metal frames under 9403.20). Accurate classification is essential for import/export duties, customs clearance, and regulatory compliance. Confirm the appropriate HS code with your freight forwarder or customs broker based on materials and design specifications.

Regulatory Compliance Requirements

Customized beds must comply with safety and labeling regulations in the destination market. In the U.S., this includes meeting standards set by the Consumer Product Safety Commission (CPSC), particularly for structural integrity and lead content in paint or finishes. In the EU, beds must conform to EN 1725 (furniture safety standards for beds) and carry CE marking. Ensure all custom components meet local flammability, chemical (e.g., REACH), and labeling requirements.

Packaging and Labeling Standards

Use robust packaging to protect custom components during transit, especially for unique or delicate designs. Clearly label each package with product identifiers, handling instructions (e.g., “This Side Up”), and destination details. Include compliance labels (e.g., country of origin, safety certifications, care instructions) as required by local laws. For international shipments, labels must be in the official language of the destination country.

Shipping and Freight Considerations

Due to size and weight, customized beds are typically shipped via Less-Than-Container Load (LCL) or Full Container Load (FCL) for international logistics. Disassembled packaging optimizes space and reduces freight costs. Coordinate with freight partners to manage oversized or non-standard shipments. Include precise dimensions, weight, and freight class in shipping documentation to avoid delays or reclassification fees.

Import Duties and Documentation

Prepare a complete set of shipping documents: commercial invoice, packing list, bill of lading/airway bill, and certificate of origin. The commercial invoice must detail customization specifics, materials used, and total value for accurate duty assessment. Be aware of preferential trade agreements (e.g., USMCA, EU trade deals) that may reduce or eliminate tariffs based on manufacturing origin.

Quality Control and Inspection Protocols

Conduct pre-shipment inspections to verify that each customized bed matches the customer’s specifications and complies with safety standards. Implement a quality control checklist covering structural assembly, finish quality, hardware integrity, and packaging security. Retain inspection reports for compliance audits and customer service records.

Reverse Logistics and Warranty Support

Establish a clear process for handling returns, damages, or defects. Due to customization, most beds are non-returnable unless defective. Provide warranty support per local consumer protection laws (e.g., 1-year warranty in many jurisdictions). Offer spare parts logistics and repair guidance to minimize replacements and enhance customer satisfaction.

Environmental and Sustainability Compliance

Ensure materials (e.g., wood, foam, textiles) comply with environmental regulations such as FSC certification for wood, Proposition 65 in California, or EU Ecolabel standards. Implement waste reduction and recycling practices in manufacturing and packaging. Disclose sustainability credentials where applicable to meet market expectations and compliance requirements.

In conclusion, sourcing a customized bed requires careful consideration of individual needs, budget, design preferences, and long-term comfort. By working with reputable manufacturers or skilled local craftsmen, buyers can ensure high-quality craftsmanship and materials tailored to their specific requirements. Evaluating factors such as dimensions, mattress compatibility, storage options, and aesthetic style is essential to achieving a perfect fit for the space and lifestyle. Additionally, clear communication with suppliers, detailed specifications, and thorough research help minimize delays and ensure satisfaction. Ultimately, a well-sourced customized bed not only enhances the bedroom’s functionality and appearance but also contributes significantly to better sleep and overall well-being.