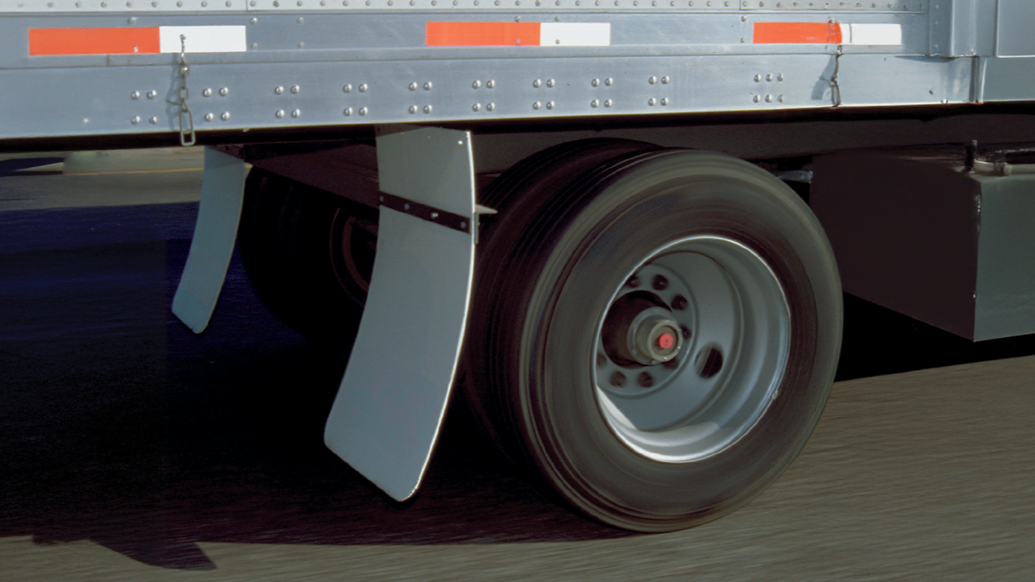

The global commercial vehicle accessories market, which includes critical components like custom tractor trailer mud flaps, is experiencing steady growth due to rising freight transport demand, stringent road safety regulations, and increased focus on vehicle aesthetics and branding. According to Grand View Research, the global commercial vehicle market size was valued at USD 1.7 trillion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion directly fuels demand for aftermarket and OEM-grade mud flaps designed to reduce road spray, comply with safety standards, and enhance fleet branding through customization.

Mud flaps—once simple protective components—are now becoming strategic elements in fleet identity and regulatory compliance, prompting specialized manufacturers to innovate in materials, durability, and custom design capabilities. With North America and Europe maintaining strict splash and spray regulations (e.g., FMVSS and UNECE standards), custom mud flap adoption is on the rise among long-haul trucking and logistics operators. As of 2024, Mordor Intelligence projects the commercial vehicle parts and accessories market will grow at a CAGR of over 5% through 2028, driven by fleet modernization and a growing emphasis on safety and sustainability.

Against this backdrop, a select group of manufacturers have emerged as leaders in the custom tractor trailer mud flap space—combining advanced manufacturing techniques, scalable customization, and compliance expertise to meet evolving industry needs. Here are the top nine companies shaping the market today.

Top 9 Custom Tractor Trailer Mud Flaps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mud Flap Manufacturer

Domain Est. 1996

Website: corporate.lippert.com

Key Highlights: We are a mud flap manufacturer supplying a complete line of custom-fit, vehicle-specific mud flaps for most truck makes and models, including hitch-mounted ……

#2 Truck Hardware

Domain Est. 2006

Website: truckhardware.ca

Key Highlights: Truck Hardware designs and produces aftermarket pickup truck accessories, including the Gatorback Mud Flap….

#3 Mud Flaps

Domain Est. 1997

Website: minimizer.com

Key Highlights: Minimizer offers both poly and rubber mud flaps in a variety of sizes. Our hot-stamping process creates the most durable mud flaps on the market….

#4 #1 Source For Custom Mud Flaps

Domain Est. 1999

Website: usaflap.com

Key Highlights: We make mudflaps for Semi Trucks & Commercial Vehicles that can be ordered plain (as “Blanks”) or customized with graphics and/or text. Our in-house graphic ……

#5 Viking Mud Flaps

Domain Est. 2000

Website: vikingmudflaps.com

Key Highlights: Discover Viking Mud Flaps, a leading supplier of custom imprinted poly, rubber, and quarter fender truck and trailer mud flaps. Get a personalized quote today!…

#6 Mud Flaps

Domain Est. 2008

Website: eagleplasticsmudflaps.com

Key Highlights: Our Primary specialty at Eagle Plastics & Rubber is manufacturing a wide selection of custom heavy duty mud flaps for the truck & trailer industry….

#7 Custom Semi

Domain Est. 2017

Website: usdecalsandvinyls.com

Key Highlights: Free delivery Free 30-day returns…

#8 Mud Flaps

Domain Est. 2020

#9 FWmudflaps

Domain Est. 2020

Website: fwmudflaps.com

Key Highlights: Premium custom-printed mud flaps. Brand your company logo with FleetWide and be recognized! Complete graphic services for your design, typesetting, and proofing ……

Expert Sourcing Insights for Custom Tractor Trailer Mud Flaps

H2: 2026 Market Trends for Custom Tractor Trailer Mud Flaps

The market for custom tractor trailer mud flaps is poised for significant transformation by 2026, driven by advancements in materials, evolving regulatory standards, growing emphasis on branding, and increasing demand for aerodynamic efficiency in commercial transportation. As the logistics and freight industries continue to modernize, custom mud flaps are transitioning from purely functional components to integrated solutions that enhance safety, fuel economy, and brand visibility.

-

Material Innovation and Durability

By 2026, the demand for high-performance materials such as reinforced thermoplastics, polyurethane composites, and UV-resistant rubber will dominate the custom mud flap market. These materials offer superior resistance to abrasion, cracking, and extreme weather conditions—critical for long-haul trucking. Additionally, eco-friendly and recyclable materials are expected to gain traction due to increasing environmental regulations and corporate sustainability goals. -

Customization for Branding and Aesthetics

Fleets are increasingly leveraging mud flaps as mobile advertising platforms. Custom printing with logos, slogans, and vibrant graphics allows companies to enhance brand recognition across highways. By 2026, digital printing technologies will enable more intricate designs and faster turnaround times, making personalized mud flaps a cost-effective marketing tool for logistics firms and owner-operators alike. -

Regulatory Compliance and Safety Standards

Stringent regulations in North America and Europe regarding road safety and debris control will continue to shape product design. Custom mud flaps will need to meet updated standards for size, coverage, and attachment mechanisms to reduce splash and spray, especially in wet conditions. Manufacturers will focus on compliance-ready designs that can be easily customized without sacrificing regulatory adherence. -

Aerodynamic and Fuel-Efficient Designs

As fuel costs remain a top concern for carriers, the integration of aerodynamic features into mud flaps will become more prevalent. By 2026, expect to see custom mud flaps engineered with contoured edges, reduced drag profiles, and compatibility with full aerodynamic trailer skirts. These designs will help fleets improve fuel efficiency by reducing wind resistance, supporting ESG (Environmental, Social, and Governance) initiatives. -

Growth in E-Commerce and Last-Mile Delivery Fleets

The expansion of e-commerce is fueling demand for medium- and heavy-duty delivery vehicles, many of which require mud flaps. Customization options tailored to urban delivery fleets—including compact, rugged designs with high-visibility branding—will see increased demand. Regional distribution centers will prioritize durable, branded components that reflect corporate image. -

Digital Integration and Smart Features

Though still in early stages, some forward-looking manufacturers are exploring smart mud flaps embedded with sensors to monitor wear, alignment, or detachment. While not yet mainstream, by 2026, early-adopter fleets may begin integrating these features as part of broader IoT (Internet of Things) fleet management systems. -

Expansion of Online Customization Platforms

E-commerce platforms offering real-time design tools for custom mud flaps will become more sophisticated. By 2026, customers will be able to upload logos, preview 3D mockups, select materials, and receive instant quotes—all online. This shift will streamline procurement and open new markets to small fleets and independent operators.

In conclusion, the 2026 market for custom tractor trailer mud flaps will be defined by innovation, personalization, and performance. Manufacturers who invest in advanced materials, digital customization, and regulatory compliance will lead the industry, while fleets will increasingly view mud flaps not just as protective gear, but as strategic assets for branding, efficiency, and safety.

Common Pitfalls Sourcing Custom Tractor Trailer Mud Flaps (Quality, IP)

Sourcing custom tractor trailer mud flaps involves more than just finding a low price. Overlooking key quality and intellectual property (IP) concerns can lead to significant operational, legal, and reputational risks. Here are the most common pitfalls to avoid:

Poor Material Quality and Durability

Many suppliers offer mud flaps made from substandard rubber or composite materials that degrade quickly under real-world conditions. Low-quality flaps may crack, tear, or become brittle due to UV exposure, extreme temperatures, or road chemicals. This leads to frequent replacements, increased downtime, and potential safety hazards from flying debris.

Inadequate Customization Tolerances

Custom mud flaps require precise measurements and adherence to vehicle specifications. Suppliers with poor manufacturing controls may deliver products with inconsistent dimensions, incorrect mounting holes, or improper flex characteristics. These inconsistencies can result in improper fitment, reduced effectiveness, and potential damage to trailer components.

Lack of Compliance with Industry Standards

Reputable mud flaps must meet safety and environmental regulations such as FMVSS (Federal Motor Vehicle Safety Standards) or regional equivalents. Sourcing from vendors who do not certify compliance risks fines, failed inspections, or liability in the event of an accident caused by flap failure.

Insufficient Testing and Validation

Some manufacturers skip rigorous testing for abrasion resistance, tensile strength, and weatherability. Without proof of performance through standardized testing (e.g., ASTM or SAE protocols), there’s no assurance the custom flaps will hold up over time, especially under heavy-duty use.

Intellectual Property Infringement Risks

When designing custom logos, patterns, or proprietary shapes, there’s a risk the supplier may reuse your designs for other clients or fail to protect your IP. Without a clear contractual agreement, your unique branding or functional innovations could be copied, diluting your competitive advantage.

Ambiguous Ownership of Design Files

Suppliers may retain ownership of CAD files, molds, or tooling created for your custom order. This creates dependency, limits your ability to switch manufacturers, and may result in additional costs to retrieve or reproduce your designs later.

Failure to Secure IP Rights in Contracts

Generic procurement agreements often omit clauses addressing IP ownership, confidentiality, and usage rights. Without explicit terms stating that all custom designs are your sole property, you may face legal challenges if the supplier claims partial rights or shares your designs without consent.

Counterfeit or Knock-off Components

Some overseas or low-cost suppliers may produce flaps that mimic patented designs from established brands. Using such products—even unknowingly—can expose your company to intellectual property litigation, recalls, and damage to your brand reputation.

By proactively addressing these quality and IP-related pitfalls during the sourcing process—through due diligence, clear contracts, and verification of compliance—you can ensure reliable performance and protect your business interests.

Logistics & Compliance Guide for Custom Tractor Trailer Mud Flaps

Overview

Custom tractor trailer mud flaps are essential safety and branding components for commercial fleets. Proper logistics planning and adherence to compliance standards ensure durability, legal operation, and brand consistency across your fleet. This guide covers key aspects of sourcing, shipping, installing, and complying with regulations for custom mud flaps.

Regulatory Compliance Requirements

Federal Motor Carrier Safety Administration (FMCSA) Standards

Mud flaps must comply with FMCSA regulations under 49 CFR Part 393, which govern commercial motor vehicle safety. Key requirements include:

– Coverage Area: Mud flaps must extend from no more than 8 inches above the roadway to within 2 inches of the ground.

– Width: Must cover the full width of the tire tread.

– Material: Must be made of durable, flexible material (e.g., rubber or high-density polyethylene) capable of withstanding road debris and weather conditions.

State-Specific Regulations

Some states have additional rules regarding mud flap dimensions, reflectivity, or branding:

– California (CHP): Requires mud flaps on all axles and may enforce stricter material standards.

– New York and Texas: May have specific reflector or visibility requirements.

Always verify with local Department of Transportation (DOT) offices before deployment.

Reflective and Visibility Standards

To enhance nighttime visibility:

– Use retro-reflective strips or logos compliant with DOT FMVSS No. 108.

– Ensure at least 50% of the flap surface includes reflective material if used for visibility.

Customization and Branding Compliance

Logo and Text Sizing

- Ensure branding does not obstruct required visibility or coverage.

- Text height should be legible but not exceed 30% of the mud flap’s vertical dimension.

- Avoid using red or blue colors that may be confused with emergency vehicles.

Material and Durability

- Choose UV-resistant, abrasion-proof materials to maintain appearance and compliance over time.

- Confirm supplier provides test certifications for material longevity and flexibility.

Logistics and Supply Chain Management

Sourcing and Supplier Selection

- Partner with ISO 9001-certified manufacturers experienced in DOT-compliant mud flaps.

- Request samples and compliance documentation (e.g., material specs, test reports).

- Confirm lead times, especially for large or custom orders.

Packaging and Shipping

- Use protective packaging to prevent warping or damage during transit.

- Clearly label shipments with fleet ID, trailer number, or installation location.

- Optimize shipping method (LTL vs. FTL) based on order size and delivery urgency.

Inventory and Distribution

- Maintain a spare inventory (10–15% extra) to account for wear, damage, or fleet expansion.

- Use a centralized warehouse with regional distribution points to reduce downtime.

- Implement a tracking system for lot numbers, compliance certificates, and installation dates.

Installation and Maintenance

Proper Installation Procedures

- Install using stainless steel or rust-resistant hardware to prevent corrosion.

- Ensure mud flaps hang vertically and do not contact tires or suspension components.

- Follow manufacturer torque specifications for mounting brackets.

Inspection and Replacement

- Include mud flaps in routine pre-trip and post-trip inspections.

- Replace flaps showing cracks, tears, or detachment risks.

- Document replacements to maintain compliance records during DOT audits.

Documentation and Recordkeeping

Required Documentation

- Retain supplier compliance certificates and material safety data sheets (MSDS).

- Keep records of installation dates, vehicle assignments, and replacement history.

- Store proof of customization approvals (e.g., logo design compliance).

Audit Preparedness

- Be ready to present mud flap compliance documentation during DOT inspections.

- Train drivers and maintenance staff on recognition of non-compliant flaps.

Conclusion

Custom tractor trailer mud flaps serve both functional and marketing purposes. By adhering to federal and state regulations, managing the supply chain efficiently, and maintaining proper installation and records, fleets can ensure safety, avoid fines, and project a professional brand image on the road. Regular review of compliance standards and logistics processes is recommended to adapt to evolving regulations and operational needs.

In conclusion, sourcing custom tractor trailer mud flaps requires careful consideration of material quality, durability, customization options, compliance with safety regulations, and supplier reliability. Investing in high-performing, custom-fit mud flaps not only enhances vehicle protection and road safety but can also improve fleet aesthetics and branding. By partnering with reputable manufacturers who offer tailored solutions, competitive pricing, and strong customer support, fleet operators and truck owners can ensure long-term value, reduce maintenance costs, and maintain compliance across diverse operating conditions. Ultimately, a strategic sourcing approach leads to optimized performance and greater return on investment in the heavy-duty transportation sector.