Trend #2: 3D Text Effect Iron ons

Imagine transforming a plain T-shirt into a bold fashion statement—no sewing, no mess, just heat and press. Custom T-shirt iron-ons are having a major moment, and they’re not just for last-minute school projects anymore. From personalized gifts to limited-edition merch drops, this DIY favorite is evolving fast—especially with the rise of Print on Demand (POD) brands tapping into on-the-go customization. One trend leading the charge? Striking 3D text effects that pop off the fabric with depth, dimension, and serious style. As consumers crave unique, Instagram-worthy apparel they can’t find on every fast-fashion shelf, savvy creators are using iron-on transfers to deliver high-impact looks with low production overhead. Welcome to the new era of custom tees—where creativity meets convenience, one iron at a time.

Top 10 Best Custom T Shirt Iron Ons Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 Pro World Inc

Online Since 1997

Website: proworldinc.com

Free delivery over $99Tried, tested, and made for business. Our one-color screen printed transfers are built for bold, long-lasting designs that hold up under pressure — and in bulk.

#2 T-Shirt & Apparel Printing

Online Since 2001

Website: undergroundshirts.com

Design custom t-shirts and apparel with Underground Printing. Offering screen printing, embroidery, and fast delivery on all orders.

#3 DTFSheet

Online Since 2023

Website: dtfsheet.com

Custom Full Apparel Print & Press by DTFSheet™. We will press your designs on t-shirts for you. Samples. Try the top quality DTF Transfers yourself. Supplies.

#4 FM Expressions

Online Since 1997

Website: fmexpressions.com

We create custom screen print & DTF heat transfers. Get one-color heat transfers for just $0.15! Just add heat & pressure to start!

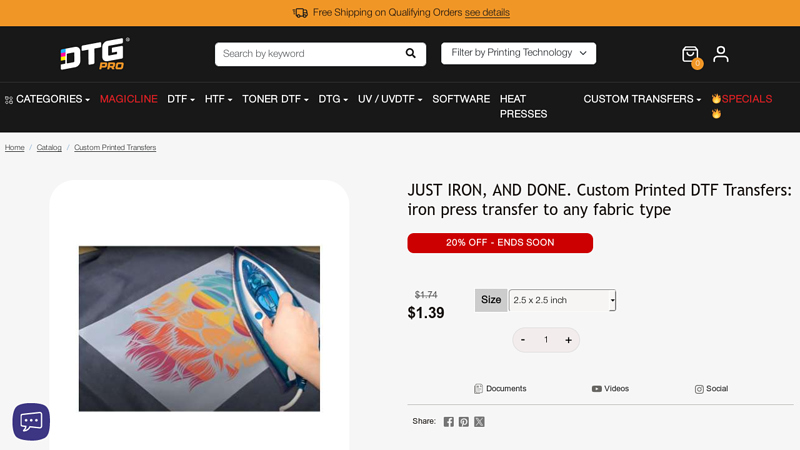

#5 JUST IRON, AND DONE. Custom Printed DTF Transfers

Online Since 2017

Website: dtgpro.com

In stock Rating 5.0 (1) Custom Printed DTF Transfers are now available for delivery right to your door! Printed with YOUR logo, photo or image and ready for transfer onto your own …

#6 Custom Heat Transfers from 613 Originals

Online Since 2018

Website: 613originals.com

Free delivery over $199Ditch the heat press! Our UV DTF transfers are super easy to apply on just about any hard surface. Simply stick, smooth, & peel. Ideal for tumblers, phone …

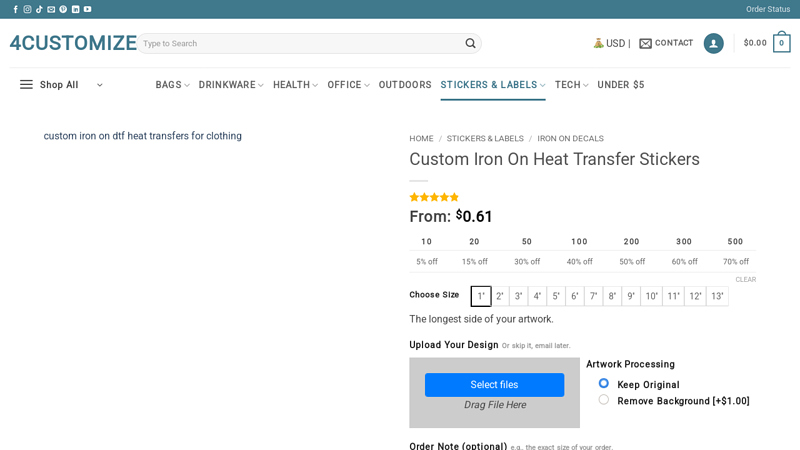

#7 Custom Iron On Heat Transfer Stickers

Online Since 2020

Website: 4customize.com

In stock Rating 4.8 (10) · Free delivery over $49Personalize your own artwork t-shirts, canvas bags, shoes, face masks with iron on heat transfer decals. Any Size, Any Shape, MOQ 10pcs.

#8 Custom T-Shirt Printing

Online Since 1997

Website: instantimprints.com

We can create the perfect custom t shirt of your design – or let one of our Image Experts design it for you! We have a variety of printing methods to suit your …

#9 All

Online Since 2004

Website: contrado.com

In stock Rating 4.8 (112) Made to measure t-shirts featuring your designs and artwork. Handmade to order from soft Jersey fabric. All-over custom t-shirt printing.

#10 Custom Iron-On Transfers

Online Since 2008

Website: stickeryou.com

Starting from $14.99 Rating 4.9 (2,862) Make custom high quality, washer safe, iron-ons in any shape and size. Our custom design tool makes it a seamless experience. Click here to learn more!

Expert Guide: Ordering custom t shirt iron ons

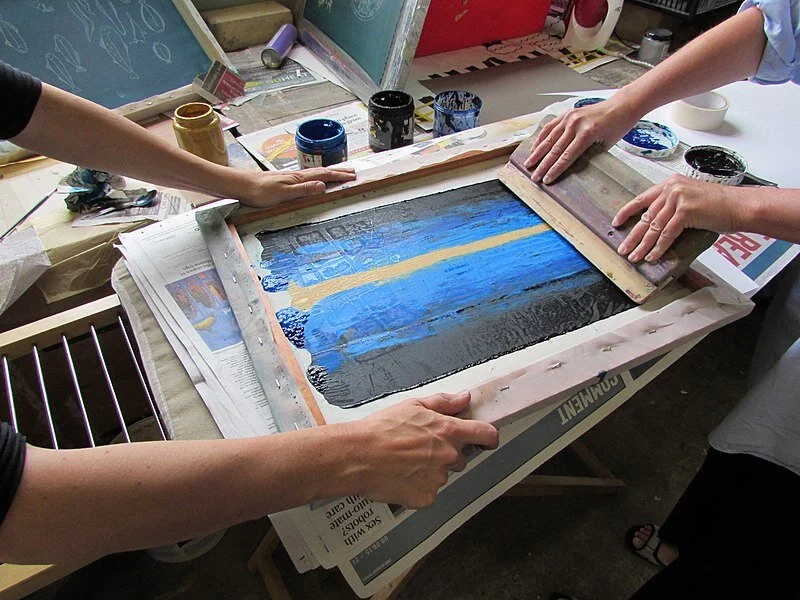

Comparison of Custom T-Shirt Printing Methods: Screen Printing, DTG, and Heat Transfer

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, bold designs, vibrant colors, cotton fabrics | High – lasts many washes if cured properly | Low per unit for bulk; high setup cost |

| DTG (Direct to Garment) | Detailed/full-color designs, small batches, soft hand feel, cotton blends | Moderate to High – may fade over time with frequent washing | Higher per unit; low setup cost, ideal for small runs |

| Heat Transfer | Quick turnaround, one-offs, complex designs, polyester or mixed fabrics | Low to Moderate – can crack or peel over time | Low setup; higher per unit, especially for quality transfers |

Guide to Choosing Fabrics for Custom T-Shirt Iron-Ons: 100% Cotton vs. 50/50 Blend vs. Tri-Blends

When applying custom iron-on designs to T-shirts, the fabric composition plays a crucial role in the final result—impacting adhesion, durability, softness, and appearance. Choosing the right shirt material ensures your design looks professional and lasts through washes. Here’s a breakdown of the three most common fabric types: 100% cotton, 50/50 blends, and tri-blends.

100% Cotton

Pros:

– Excellent Heat Resistance: Cotton can withstand high temperatures, making it ideal for heat pressing. This ensures strong adhesion of iron-on vinyl or transfers.

– Superior Adhesion: Provides a stable, flat surface for iron-ons, resulting in crisp, long-lasting designs.

– Absorbent and Breathable: Offers comfort and a classic T-shirt feel, ideal for everyday wear.

Cons:

– Prone to Shrinkage: May shrink significantly (up to 5–10%) after washing, especially if not pre-shrunk.

– Less Durable Over Time: More susceptible to pilling and wear with repeated washing.

– Can Wrinkle Easily: Requires more careful ironing and storage.

Best For: Traditional, heavyweight T-shirts where durability and professional results are top priorities. Ideal for bold, detailed designs using HTV (Heat Transfer Vinyl).

50/50 Cotton-Polyester Blend

Pros:

– Reduced Shrinkage: Blending cotton with polyester helps minimize shrinkage during washing.

– Increased Durability: Polyester adds strength, helping the shirt maintain shape and resist pilling.

– Good Heat Tolerance: Withstands standard heat press temperatures well, though care should be taken not to overheat (polyester can scorch above 320°F).

– Balanced Feel: Offers a soft hand feel with improved resilience.

Cons:

– Slightly Lower Adhesion: Polyester content can reduce the surface area available for vinyl bonding, potentially leading to less durability than on 100% cotton.

– Risk of Scorching: Requires lower pressing temperatures and shorter durations to avoid melting or shiny marks on polyester fibers.

Best For: Budget-friendly, everyday wear shirts. Great for casual designs and environments where shrinkage is a concern. Use medium heat (around 270–290°F) and a protective parchment sheet.

Tri-Blend (Typically 50% Polyester, 25% Cotton, 25% Rayon)

Pros:

– Ultra-Soft Feel: Known for its luxurious, lightweight, and slightly drapey texture—popular in fashion-forward tees.

– Minimal Shrinkage: Very stable after washing due to high synthetic content.

– Great Drape and Aesthetic: Offers a vintage, lived-in look that appeals to many consumers.

Cons:

– Heat Sensitivity: Rayon and polyester are prone to melting or scorching at high temperatures. Requires careful, low-heat application.

– Reduced Adhesion: The smooth, soft surface can make it harder for vinyl to bond securely, especially on high-movement areas.

– Faster Wear on Design: The fabric’s softness can lead to faster cracking or peeling of vinyl with repeated use and washing.

Best For: Fashion tees, lightweight garments, and designs where comfort and drape are more important than extreme durability. Use low heat (around 265–275°F), shorter press times, and consider softer vinyl types like stretch or flocked HTV.

Final Tips for Success

- Always Pre-Press: Remove moisture and wrinkles before applying the design.

- Use a Protective Layer: Place a Teflon sheet or parchment paper over the design to prevent scorching, especially on blends.

- Follow Vinyl Manufacturer Guidelines: Adjust time, temperature, and pressure based on both the fabric and the vinyl type.

- Test First: Do a sample application on a scrap or inconspicuous area to fine-tune settings.

By matching your iron-on method to the fabric type, you’ll achieve professional, durable results every time.

How to Get the Best Price on Custom T-Shirt Iron-Ons (Bulk & Artwork Tips)

Getting custom iron-ons for t-shirts in bulk can be a cost-effective way to create branded apparel, team uniforms, or event merchandise. To maximize your savings and ensure top-quality results, focus on smart ordering strategies and proper artwork preparation.

Leverage Bulk Quantity Breaks

The most effective way to lower the unit cost of custom iron-ons is by ordering in larger quantities. Most suppliers offer tiered pricing, meaning the price per piece decreases as your order size increases.

- Understand Tiered Pricing: Suppliers typically set quantity brackets (e.g., 50–99, 100–249, 250–499, 500+). Jumping to the next tier often results in significant per-unit savings. For example, ordering 250 instead of 99 might cut the cost per iron-on by 30–50%.

- Plan for Future Needs: If you anticipate needing more iron-ons later, consider ordering a larger batch now to lock in lower pricing. Most iron-ons have a long shelf life when stored properly.

- Combine Orders: If you’re part of a group, team, or organization, combine orders to reach higher quantity tiers and share the savings.

- Negotiate with Suppliers: For very large orders (500+ units), don’t hesitate to ask for a custom quote. Many suppliers are willing to offer additional discounts for bulk commitments.

Optimize Artwork for Cost and Quality

High-quality artwork not only ensures a professional final product but also helps avoid costly reprints or delays. Follow these tips to streamline production and reduce costs.

- Use Vector Files (AI, EPS, SVG): Vector graphics scale infinitely without losing quality and are preferred by most print shops. They ensure crisp edges and precise colors, minimizing errors during production.

- Provide High-Resolution Raster Files (300 DPI): If using PNG or JPEG, ensure your design is at least 300 DPI at the final print size. Low-resolution images may require redrawing or upscaling, adding to costs.

- Simplify Your Design: Fewer colors and simpler designs often reduce production complexity and cost. Some suppliers charge extra for designs with many color layers or intricate details.

- Follow Color Guidelines: Use Pantone (PMS) colors if color accuracy is critical, or confirm with your supplier which color mode (CMYK or RGB) they prefer. Unnecessary color corrections can lead to added fees.

- Include Proper Bleed and Safe Zones: Add a 1/8-inch bleed around your design and keep critical text and elements within a safe margin to avoid trimming issues.

- Submit Print-Ready Files: Double-check that your file includes all fonts (or is outlined), is in the correct color mode, and matches the requested dimensions. This reduces back-and-forth and potential rush fees.

By strategically using bulk quantity breaks and submitting optimized artwork, you can significantly reduce your cost per iron-on while ensuring a high-quality, professional result. Always request a digital proof before production to confirm design accuracy and avoid costly mistakes.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, value, and customer satisfaction. Start by evaluating the provider’s product quality—look for durable fabrics, consistent stitching, and accurate color reproduction. Assess customization options such as printing techniques (e.g., screen printing, DTG, sublimation), design flexibility, and the ability to handle complex artwork.

Pricing and minimum order requirements are also crucial; compare costs across providers while watching for hidden fees, and ensure the minimums align with your needs. Reliable customer service, clear communication, and turnaround times are essential—choose a provider with responsive support and on-time delivery history.

Additionally, read customer reviews and examine portfolio samples to gauge reputation and consistency. If sustainability matters to you, consider eco-friendly materials and ethical production practices.

In conclusion, the ideal custom t-shirt provider balances quality, affordability, customization options, and excellent service. Take time to research and request samples when possible, ensuring your final choice aligns with your brand’s standards and project goals.