T-shirts have evolved from simple wardrobe staples to powerful canvases for self-expression, brand messaging, and creative entrepreneurship — and the demand for custom designs has never been hotter. With the rise of print-on-demand (POD) services, launching your own apparel line is no longer reserved for big brands with deep pockets. From indie artists to side-hustle enthusiasts, anyone can design, sell, and ship custom tees without holding inventory. But as the barrier to entry lowers, a critical question remains: What does it really cost to create a custom t-shirt in today’s POD landscape?

As on-demand printing technology improves and platforms multiply, understanding the true cost — from base prices and print methods to hidden fees and profit margins — is key to making smart decisions. Let’s dive into what shapes custom t-shirt pricing in 2024 and how the booming POD trend is reshaping the game for creators and businesses alike.

Top 9 Best Custom T Shirt Cost Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 Custom No Minimum T-Shirts

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsUnderground Printing is your source for custom t shirts, custom sweatshirts and more. We specialize in screen printing and embroidery orders of all sizes.

#2 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#3 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#4 Custom Print Shop

Online Since 1995

Website: bonfire.com

Order custom shirts and apparel with ease on Bonfire. ✓Premium products. ✓No minimums. ✓Bulk discounts. ✓No upcharge for plus sizes. Start your order today!

#5 Premium

Online Since 2002

Website: gotprint.com

4.5 4.8K Design your own premium custom t-shirts for your company or event. Choose from a variety of styles and sizes – No minimum quantity order!

#6 Custom Printed T-Shirts in 24 Hrs

Online Since 2013

Website: 24hrtees.net

Upload your art and buy rush custom printed t-shirts & more in minutes! Fast custom t-shirt printing ships in as few as 24 hours. No minimums!

#7 How Much Should a Custom T-Shirt Cost

Online Since 1998

Website: 4imprint.com

Wondering how much a custom T-shirt costs? Explore 4imprint and let us take the guesswork out of it for you. We offer free art help, …

#8 T-Shirt Printing

Online Since 2001

Website: brokenarrowwear.com

We offer multiple print locations including front, back, and sleeves. Get instant pricing online on all our shirt options. Enter your quantity to receive …

#9 ooShirts: Cheap Custom T

Online Since 2007

Website: ooshirts.com

Custom t-shirts for less! ooShirts is the leader in affordable t-shirt printing. Free shipping & setup. Design your own t-shirts at awesomely low prices!

Expert Guide: Ordering custom t shirt cost

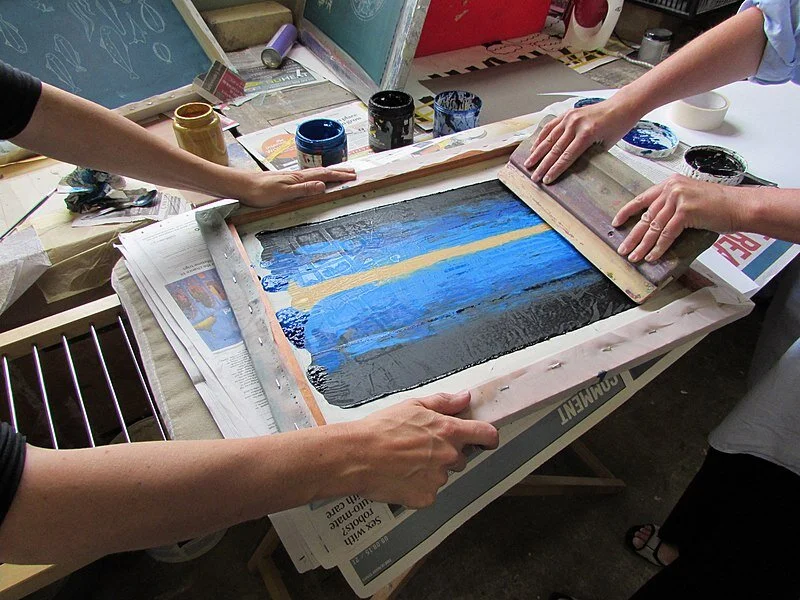

Comparison of Custom T-Shirt Printing Methods: Cost, Durability, and Best Use Cases

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs, bold colors | High – lasts many washes | Low per unit (bulk orders); higher setup fee |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, photos | Medium – may fade after 30–50 washes | Medium – higher per-unit cost, no setup fee |

| Heat Transfer | Small batches, quick turnaround, complex designs | Low to Medium – may crack or peel over time | Low setup cost; higher per-unit cost, especially for vinyl |

Guide to Choosing Fabrics for Custom T-Shirt Cost: 100% Cotton vs. 50/50 Blend vs. Tri-Blends

When ordering custom t-shirts, one of the most important decisions you’ll make is choosing the right fabric. Your fabric choice affects not only the comfort and appearance of the shirts but also the overall cost. Here’s a breakdown of the three most common fabric types—100% Cotton, 50/50 Blend, and Tri-blends—to help you decide based on quality, durability, and budget.

100% Cotton: Classic Comfort and Natural Feel

Cost Level: Mid to High

Best For: Softness, breathability, and a traditional feel

100% cotton t-shirts are the most classic choice and are known for their soft, natural texture and excellent breathability. They’re ideal for warm weather and everyday wear. Cotton absorbs ink well, making it a popular choice for detailed screen printing.

- Pros:

- Extremely soft and comfortable, especially after washing

- Breathable and great for warm climates

- Excellent print surface for vibrant designs

-

Biodegradable and natural fiber

-

Cons:

- More prone to shrinking if not pre-shrunk

- Can wrinkle easily

- Less durable than blended fabrics; may wear out faster with frequent washing

- Typically more expensive than blends due to material and processing costs

Cost Insight: Expect to pay a bit more for high-quality 100% cotton, especially if it’s ring-spun or combed cotton. Prices vary by weight (e.g., 5.3 oz vs. 6.1 oz), with heavier cotton generally costing more.

50/50 Blend: The Balanced Budget-Friendly Option

Cost Level: Low to Mid

Best For: Affordability, durability, and everyday use

A 50/50 blend combines equal parts cotton and polyester. This mix offers a compromise between comfort and performance, making it a popular choice for promotional shirts, events, and workwear.

- Pros:

- Resists shrinking and wrinkling better than 100% cotton

- More durable and long-lasting

- Lightweight and affordable

-

Good for simple prints and large orders

-

Cons:

- Slightly less breathable than 100% cotton

- Can feel less soft, especially with lower-quality blends

- May retain odors more than cotton

- Not as eco-friendly due to polyester content

Cost Insight: 50/50 blends are typically the most budget-friendly option. The use of synthetic polyester reduces material costs and increases production efficiency, making them ideal for bulk orders.

Tri-Blends: Soft, Stylish, and Premium Feel

Cost Level: High

Best For: Fashion-forward apparel, retail, and premium gifts

Tri-blend fabrics usually consist of cotton, polyester, and rayon (often in a 50/25/25 or similar ratio). These shirts are known for their ultra-soft, lightweight feel and vintage aesthetic. They drape beautifully and are popular in boutique and lifestyle brands.

- Pros:

- Exceptionally soft with a silky, vintage texture

- Great drape and reduced shrinkage

- Offers a more modern, stylish look

-

Breathable and comfortable for layering

-

Cons:

- Most expensive fabric option

- May pill over time with friction

- Not as durable as 100% cotton or 50/50 blends under heavy use

- Requires careful washing to maintain quality

Cost Insight: Tri-blend shirts command a premium price due to the complexity of blending three fibers and their popularity in fashion markets. Ideal for smaller, high-end runs rather than large promotional batches.

Summary: Choosing Based on Cost and Use

| Fabric Type | Cost Range | Best Use Case |

|---|---|---|

| 100% Cotton | $$ | Everyday wear, screen printing, eco-conscious buyers |

| 50/50 Blend | $ | Budget orders, events, workwear, large runs |

| Tri-Blend | $$$ | Fashion wear, retail, gifts, boutique branding |

Final Tip: Always request fabric samples before placing a large order. This helps you evaluate the hand feel, weight, and print quality—ensuring you get the best value for your custom t-shirt project.

How to Get the Best Price for Custom T-Shirt Orders (Bulk Quantity Breaks & Artwork Tips)

Ordering custom t-shirts in bulk can be a cost-effective way to promote your brand, event, or team—but getting the best price requires smart planning. Here’s how to save money using bulk quantity breaks and artwork optimization.

Leverage Bulk Quantity Breaks

Most screen printing and embroidery companies offer tiered pricing, where the per-unit cost drops as your order size increases. Here’s how to take full advantage:

-

Understand Quantity Tiers: Common breaks include 25, 50, 100, 250, and 500+ units. For example, the price per shirt at 50 pieces might be $10, but at 100 it drops to $7. Always ask for a pricing sheet.

-

Consolidate Orders: If you anticipate future needs, combine them into one larger order to hit a higher discount tier.

-

Match Sizes to Demand: Avoid over-ordering less popular sizes to stay within a lower quantity tier. Use past data or surveys to forecast size distribution accurately.

-

Choose Standard Colors: Basic colors like black, white, navy, and heather gray are usually cheaper than specialty dyes and may come with better bulk pricing.

Optimize Your Artwork for Lower Printing Costs

The design complexity directly affects printing costs. Simplify your artwork to save money:

-

Limit Print Colors: Each additional color in screen printing increases setup time and cost. Stick to 1–3 colors whenever possible. For example, a one-color print is significantly cheaper than a five-color design.

-

Use Vector Art: Provide high-quality vector files (AI, EPS, or SVG) to avoid extra fees for artwork cleanup or redrawing.

-

Minimize Print Areas: Smaller or single-location prints (e.g., left chest or center back) cost less than full front/back designs.

-

Avoid Halftones and Gradients: These require specialized screens and can increase production time. Opt for solid colors or flat designs.

-

Stick to One Design Per Order: Mixing multiple designs increases setup charges. If possible, standardize the design across all shirts.

Additional Cost-Saving Tips

-

Choose the Right Printing Method: Screen printing is cheaper for large runs with simple designs. DTG (Direct-to-Garment) is better for complex, full-color designs but costs more per unit in bulk.

-

Compare Multiple Vendors: Get quotes from at least 3–5 suppliers. Look beyond price—consider quality, turnaround time, and customer service.

-

Order Off-Peak: Avoid holiday seasons or back-to-school periods when demand (and prices) are high.

-

Negotiate Free Setup Fees: Some vendors waive screen setup fees for large orders—always ask!

By combining strategic bulk ordering with simplified, print-ready artwork, you can significantly reduce your custom t-shirt costs without sacrificing quality.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, reliability, and value. Start by evaluating the provider’s print quality and fabric options—opt for companies that offer durable materials and a variety of printing techniques (such as screen printing, DTG, or sublimation) to match your design needs. Consider customization flexibility, including sizing, color choices, and design placement. Read customer reviews and check for samples or mockups to gauge consistency and professionalism.

Pricing transparency is essential—look for clear cost breakdowns without hidden fees, and compare bulk order discounts if applicable. Reliable customer service, turnaround time, and shipping options also play a crucial role, especially for time-sensitive projects. Finally, assess sustainability practices if eco-friendliness is a priority. By balancing quality, cost, service, and customization capabilities, you can select a custom t-shirt provider that meets your specific goals and delivers impressive, long-lasting results.