The global custom plastic manufacturing industry is experiencing robust growth, driven by increasing demand across automotive, healthcare, electronics, and consumer goods sectors. According to Grand View Research, the global plastic molding market size was valued at USD 325.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.4% from 2023 to 2030. This upward trajectory is fueled by advancements in injection molding technologies, rising adoption of lightweight materials in automotive manufacturing, and growing emphasis on precision-engineered plastic components in medical devices. Additionally, Mordor Intelligence projects steady expansion in the custom plastics sector, citing rising outsourcing of manufacturing to specialized providers and increased demand for sustainable and biodegradable plastic solutions. As industries prioritize customization, scalability, and material innovation, the role of leading custom plastic manufacturers becomes increasingly critical. In this evolving landscape, the top 10 custom plastic manufacturers stand out for their technological capabilities, quality certifications, vertical integration, and capacity to meet complex, high-volume production demands.

Top 10 Custom Plastic Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Emco Industrial Plastics

Domain Est. 1997

Website: emcoplastics.com

Key Highlights: EMCO Plastics offers expert fabrication and machining of plastic and rubber components for diverse industries. Get high-quality, custom solutions now….

#2 Custom Plastics Inc

Domain Est. 2003

Website: customplasticsinc.com

Key Highlights: Custom Plastics, Inc. – Your one-stop shop for plastic injection molding, complex plastic extrusion, engineering and design, and in-line manufacturing ……

#3 Cooper Plastics: Custom Plastics Fabrication

Domain Est. 2011

Website: cooperplastics.com

Key Highlights: Cooper Plastics is a custom plastic manufacturer that offers numerous custom plastic fabrication methods to meet the unique needs of our clients….

#4 Custom Plastic Part Manufacturing Services

Domain Est. 2016

Website: norck.com

Key Highlights: At Norck, we manufacture custom plastic parts for a wide range of industries including: Medical: orthosis and prosthesis devices. Industrial: jigs and fixtures….

#5 Teel Plastics

Domain Est. 1995

Website: teel.com

Key Highlights: Teel Plastics extrudes high-quality, close-tolerance plastic tubing, piping, and profiles for many applications and offers injection molding as well….

#6 Omega Plastics

Domain Est. 1997 | Founded: 1978

Website: omegaplastics.com

Key Highlights: Since 1978, Omega Plastics has been providing custom extruded profile solutions to a wide range of markets, including construction, office furniture, ……

#7 Pexco

Domain Est. 1997

Website: pexco.com

Key Highlights: We offer industry-leading custom plastic solutions with a diverse, high-performance product range tailored to meet the unique needs of various industries….

#8 Plastic Ingenuity

Domain Est. 1997

Website: plasticingenuity.com

Key Highlights: Discover our thermoformed custom packaging solutions. We provide packaging for the food, healthcare, and consumer goods industries….

#9 Welch Plastics

Domain Est. 2002

Website: welchplastics.com

Key Highlights: We offer a range of services to include: custom plastic fabrication, product prototyping and design, high volume injection molding, custom plastic fabrication, ……

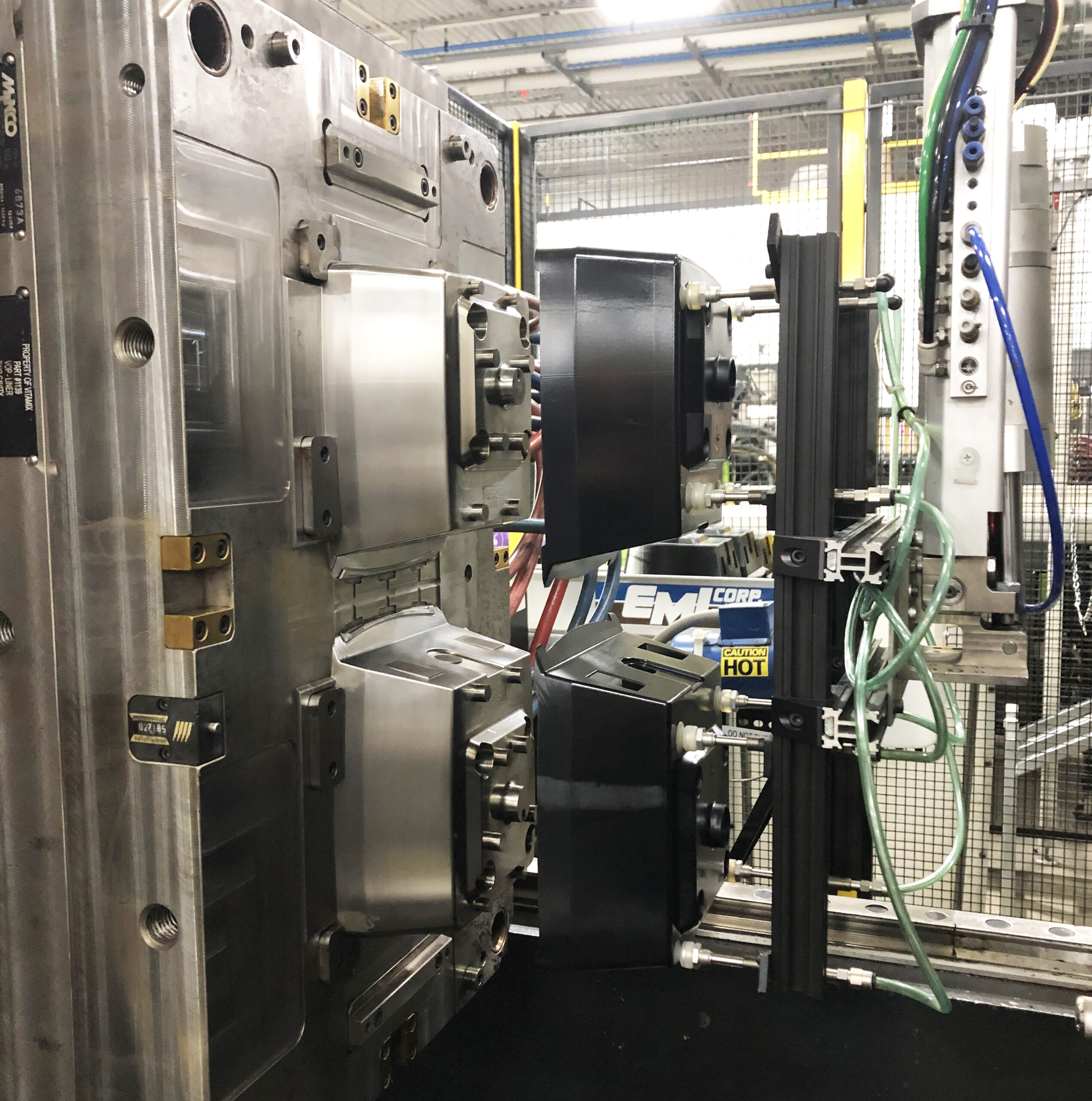

#10 Aprios

Domain Est. 2009

Website: aprios.com

Key Highlights: Aprios delivers innovative manufacturing solutions, specializing in prototyping or production at-scale for injection molding and additive manufacturing….

Expert Sourcing Insights for Custom Plastic

H2: 2026 Market Trends for Custom Plastic

The custom plastic manufacturing sector is poised for significant evolution by 2026, driven by technological innovation, shifting regulatory landscapes, and changing consumer demands. Here’s a strategic analysis of key trends shaping the market:

1. Accelerated Demand for Sustainable & Bio-Based Plastics

By 2026, sustainability will no longer be a niche preference but a core market requirement. Governments worldwide are enforcing stricter plastic regulations (e.g., EU Single-Use Plastics Directive, U.S. state-level bans), pushing manufacturers toward:

– Increased adoption of bioplastics (e.g., PLA, PHA) and compostable polymers.

– Growth in recycled content usage, especially post-consumer recycled (PCR) resins.

– Design for recyclability, with custom molders integrating material traceability and end-of-life planning into product development.

Impact: Custom plastic producers investing in green certifications (e.g., ISCC, TÜV) and closed-loop recycling systems will gain competitive advantage.

2. Digitalization & Industry 4.0 Integration

Smart manufacturing will become standard in custom plastic operations:

– AI-driven process optimization for injection molding and extrusion, reducing waste and energy use.

– Digital twins enabling rapid prototyping and predictive maintenance.

– IoT-enabled machines providing real-time monitoring of quality, cycle times, and machine health.

Impact: Companies leveraging data analytics will achieve higher precision, lower costs, and faster time-to-market, attracting high-value clients in medical, automotive, and electronics sectors.

3. Rise of Onshoring & Regional Supply Chains

Geopolitical instability and supply chain disruptions (post-pandemic, trade tensions) are accelerating a shift toward regionalization:

– U.S. and EU manufacturers are reshoring production to reduce dependency on Asia.

– Nearshoring in Mexico, Eastern Europe, and Southeast Asia is gaining momentum.

Impact: Custom plastic suppliers with localized facilities and agile logistics will benefit from shorter lead times and reduced carbon footprints.

4. Advanced Materials & Functional Polymers

Demand for high-performance plastics will grow in:

– Medical devices: Biocompatible, sterilizable polymers (e.g., PEEK, PPSU).

– Electric vehicles (EVs): Lightweight, heat-resistant materials for batteries and charging systems.

– Electronics: Conductive and EMI-shielding plastics for 5G and IoT devices.

Impact: Custom molders offering material science expertise and co-development services will capture premium segments.

5. Regulatory Pressure & Compliance Complexity

By 2026, compliance will be a major differentiator:

– Tighter restrictions on additives (e.g., phthalates, BPA).

– Extended Producer Responsibility (EPR) schemes requiring financial and operational accountability for plastic waste.

– Mandatory carbon footprint disclosures (e.g., EU Green Deal).

Impact: Custom plastic firms must invest in regulatory intelligence and sustainable compliance frameworks to avoid penalties and maintain market access.

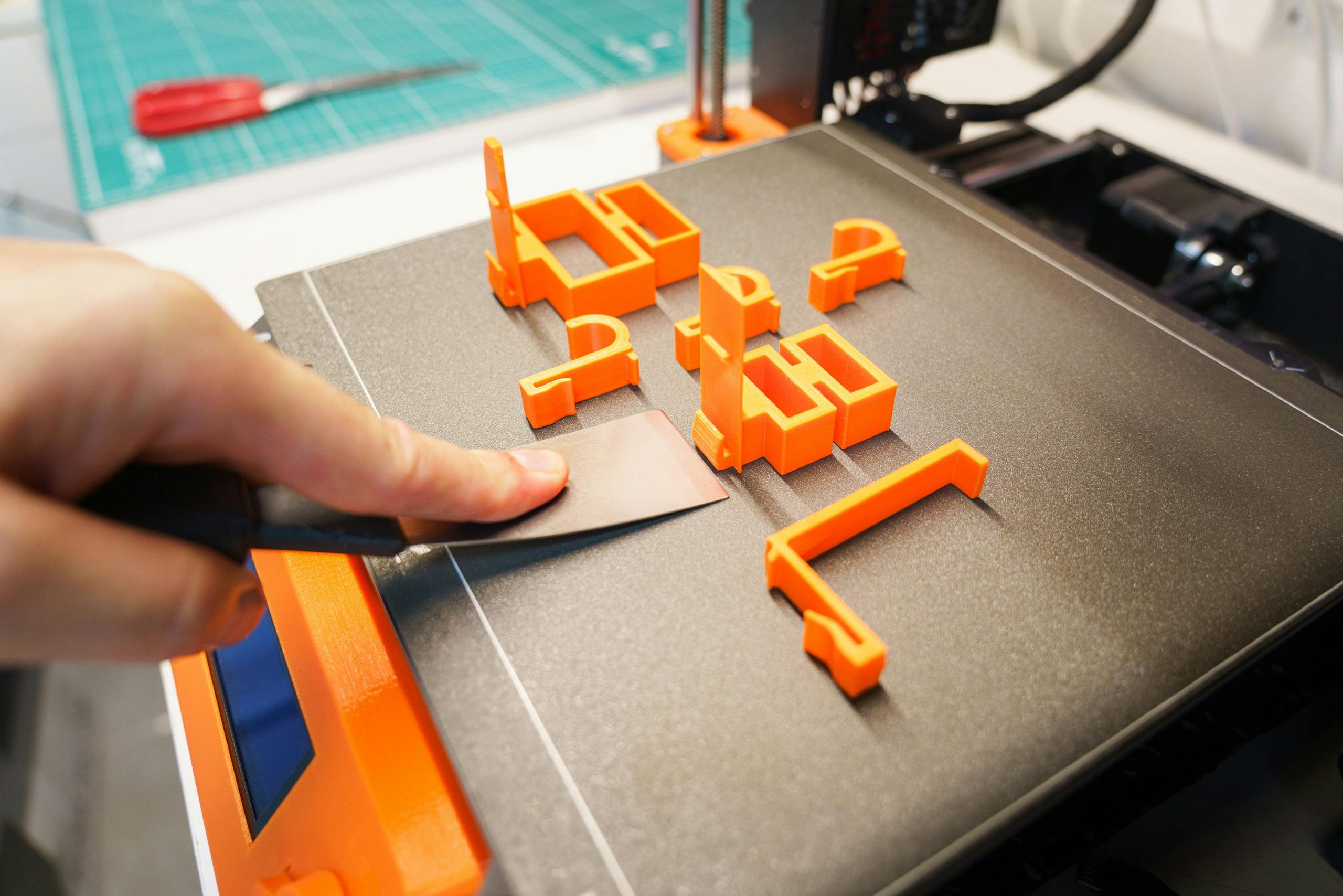

6. Customization at Scale via Automation

Advancements in automation and modular tooling enable mass customization:

– Quick-change molds and robotic cells allow efficient low-volume, high-mix production.

– 3D printing for rapid tooling and small-batch custom parts.

Impact: Niche and personalized products (e.g., bespoke medical implants, consumer electronics casings) will become more cost-effective, expanding market opportunities.

Strategic Outlook for 2026:

The custom plastic industry will transition from a commodity-focused model to a value-driven, technology-enabled sector. Success will depend on agility in sustainability, digital transformation, and strategic positioning within resilient supply chains. Early adopters of circular economy principles and smart manufacturing will lead the market, while laggards risk obsolescence.

Common Pitfalls in Sourcing Custom Plastic Components

Quality Inconsistencies

One of the most frequent challenges when sourcing custom plastic parts is inconsistent quality across production batches. Variations in material composition, injection molding parameters, or post-processing can lead to dimensional inaccuracies, surface defects (such as warping or sink marks), or compromised mechanical properties. Without strict quality control protocols and clear specifications, these inconsistencies can result in part failure, assembly issues, or costly rework. It’s crucial to establish detailed quality benchmarks, conduct regular inspections, and work with suppliers who adhere to recognized standards (e.g., ISO 9001).

Intellectual Property (IP) Risks

Sourcing custom plastic components—especially overseas—poses significant intellectual property concerns. Design files, molds, and proprietary tooling can be vulnerable to unauthorized replication or reverse engineering. Suppliers may inadvertently (or intentionally) use your designs for competing clients or sell duplicate parts in unregulated markets. To mitigate these risks, enforce robust legal protections such as non-disclosure agreements (NDAs), clearly define IP ownership in contracts, and consider patent or design registration in relevant jurisdictions. Additionally, limiting access to sensitive information and using trusted manufacturing partners can help safeguard your innovations.

Logistics & Compliance Guide for Custom Plastic Products

Overview of Custom Plastic Logistics

Managing the logistics of custom plastic products involves coordinating the manufacturing, packaging, transportation, and delivery of plastic components tailored to specific client requirements. Due to the variability in material composition, size, weight, and application, a structured approach to logistics is essential to ensure timely delivery, cost efficiency, and regulatory compliance.

Regulatory Compliance Requirements

Custom plastic products are subject to various international, national, and industry-specific regulations. Key compliance areas include:

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) – Applies to plastics exported to or used within the European Union. Manufacturers must register chemical substances and ensure restricted substances are not used above permitted levels.

- RoHS (Restriction of Hazardous Substances) – Required for plastics used in electrical and electronic equipment, limiting substances like lead, cadmium, and phthalates.

- FDA Regulations – For food-contact plastics, compliance with FDA 21 CFR is mandatory in the United States to ensure safety and non-toxicity.

- Proposition 65 (California) – Requires warning labels on products containing chemicals known to cause cancer or reproductive harm.

- REACH SVHC (Substances of Very High Concern) – Ensure disclosure if any SVHCs are present above 0.1% weight by weight.

Packaging and Labeling Standards

Proper packaging ensures product integrity during transit and supports compliance:

- Use anti-static, moisture-resistant, or cushioned packaging as appropriate for plastic type and component sensitivity.

- Label packages with:

- Product name and part number

- Material type (e.g., ABS, PVC, HDPE)

- Recyclability codes (e.g., SPI resin identification codes)

- Hazard symbols if applicable (e.g., flammable plastics)

- Country of origin

- Handling instructions (e.g., “Fragile,” “Do Not Stack”)

International Shipping Considerations

When exporting custom plastic products:

- Classify products using the correct HS (Harmonized System) code for customs clearance (e.g., 3926.90 for other plastic articles).

- Prepare accurate commercial invoices, packing lists, and certificates of origin.

- Be aware of import restrictions or tariffs in destination countries (e.g., single-use plastic bans in the EU and India).

- Use Incoterms (e.g., FOB, EXW, DDP) clearly defined in contracts to allocate responsibilities.

Environmental and Sustainability Compliance

Environmental regulations are increasingly affecting plastic logistics:

- Comply with Extended Producer Responsibility (EPR) laws in regions like the EU, which require producers to manage end-of-life product recycling.

- Provide documentation for recyclability or biodegradability claims to avoid greenwashing penalties.

- Track and report plastic waste under local environmental regulations (e.g., Plastic Packaging Tax in the UK for products with less than 30% recycled content).

Quality Control and Documentation

Maintain thorough documentation throughout the logistics chain:

- Certificates of Conformance (CoC) for each batch

- Material Test Reports (MTRs) verifying resin composition and properties

- Traceability logs linking production batches to shipments

- Non-conformance reports and corrective actions

Storage and Handling Protocols

- Store plastic components in a dry, temperature-controlled environment to prevent warping, moisture absorption, or degradation.

- Separate incompatible materials (e.g., PVC near flammable goods).

- Rotate stock using FIFO (First In, First Out) to prevent aging or obsolescence.

Risk Mitigation and Contingency Planning

- Diversify shipping methods (air, sea, ground) based on lead time and cost.

- Insure high-value or sensitive shipments against damage, delay, or loss.

- Establish backup suppliers or logistics partners to address disruptions.

Conclusion

Effective logistics and compliance management for custom plastic products require proactive planning, strict adherence to regulations, and transparent documentation. By integrating compliance into every stage—from design to delivery—companies can minimize risks, avoid penalties, and ensure customer satisfaction in global markets.

Conclusion for Sourcing Custom Plastic Components:

Sourcing custom plastic components requires a strategic approach that balances quality, cost, lead time, and long-term reliability. By clearly defining your specifications—such as material type, tolerances, volume requirements, and application environment—you can identify suppliers capable of meeting your exact needs. Evaluating manufacturers based on their expertise, production capabilities (e.g., injection molding, extrusion, 3D printing), quality control processes, and certifications ensures consistent and compliant output.

Engaging with suppliers early in the design phase can lead to valuable design for manufacturability (DFM) feedback, reducing costs and avoiding delays. Additionally, considering factors like tooling investment, minimum order quantities, and geographic location helps optimize both initial and recurring costs.

Ultimately, successful sourcing of custom plastic parts hinges on building strong partnerships with reliable suppliers who demonstrate technical proficiency, responsiveness, and scalability. With thorough due diligence and ongoing communication, businesses can secure high-performance plastic components that meet technical requirements and support product success in the market.