The global piston market is experiencing steady growth, driven by increasing demand from the automotive, aerospace, and industrial engine sectors. According to Grand View Research, the global piston market size was valued at USD 9.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. This growth is fueled by advancements in internal combustion engine efficiency, rising vehicle production—particularly in emerging economies—and the need for high-performance components in heavy-duty and performance applications. As original equipment manufacturers (OEMs) and aftermarket players push for improved fuel economy, reduced emissions, and enhanced durability, the demand for custom pistons tailored to specific engine requirements has surged. In this competitive landscape, a select group of manufacturers have distinguished themselves through engineering innovation, advanced materials, and precision manufacturing capabilities. Below is a data-informed overview of the top 9 custom piston manufacturers shaping the industry’s future.

Top 9 Custom Pistons Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wiseco – Forged Pistons

Domain Est. 1996

Website: wiseco.com

Key Highlights: Shop forged pistons online at Wiseco. Explore our extensive range of powersport and automotive pistons to maximize your engine’s potential….

#2 Custom Pistons

Domain Est. 1996

Website: jepistons.com

Key Highlights: JE Piston’s in-house engineering and manufacturing centers can produce a custom piston for almost any 4-stroke engine….

#3 MAHLE Motorsport In The Pole Position

Domain Est. 1997 | Founded: 2000

Website: us.mahle.com

Key Highlights: MAHLE Motorsport North America was established in 2000 and has positioned itself as a leading supplier of forged pistons and rings in motorsport….

#4 DSS Racing Forged Pistons

Domain Est. 1998

Website: dssracing.com

Key Highlights: Hundreds of combinations available. Custom piston options. Select exactly what you want. Select from the Stroker Kits dropdown menu above….

#5 Diamond Pistons

Domain Est. 2000

Website: diamondracing.net

Key Highlights: Our custom coating options are designed to push performance beyond what raw aluminum can handle, especially in extreme heat and high cylinder pressure ……

#6 Vertex

Domain Est. 2000

Website: vertexpistons.com

Key Highlights: Find your product. Discover the full range of high-performance pistons and components. Find the right product for your engine now….

#7 Wossner Pistons USA

Domain Est. 2007

Website: wossnerpistons.com

Key Highlights: When it Comes to Pistons and Connecting Rods, champions choose Wossner. Our Forged Pistons are the high-performance choice for racing enthusiasts worldwide….

#8 UEM Pistons

Domain Est. 2008

#9 Gibtec Pistons

Domain Est. 2013

Website: gibtecpistons.com

Key Highlights: Our manufacturing operation is located in the heart of Denver, Colorado and we take pride in every piston we hand craft and custom build….

Expert Sourcing Insights for Custom Pistons

2026 Market Trends for Custom Pistons

As the automotive, motorsports, and industrial engine sectors evolve, the custom pistons market is poised for notable transformation by 2026. Driven by performance demands, material innovation, and sustainability pressures, several key trends are shaping the future of this specialized industry.

Rising Demand in High-Performance and Motorsports Segments

The high-performance automotive and motorsports industries remain primary drivers for custom pistons. Enthusiasts and professional racing teams continue to seek engine components that maximize power, efficiency, and reliability. By 2026, increasing participation in grassroots motorsports and the growing popularity of track days are expected to fuel demand for custom-forged aluminum and billet pistons. Additionally, the expansion of electric-hybrid racing series (such as Extreme E and Formula E’s performance variants) may create niche needs for hybrid internal combustion systems, further supporting custom piston applications.

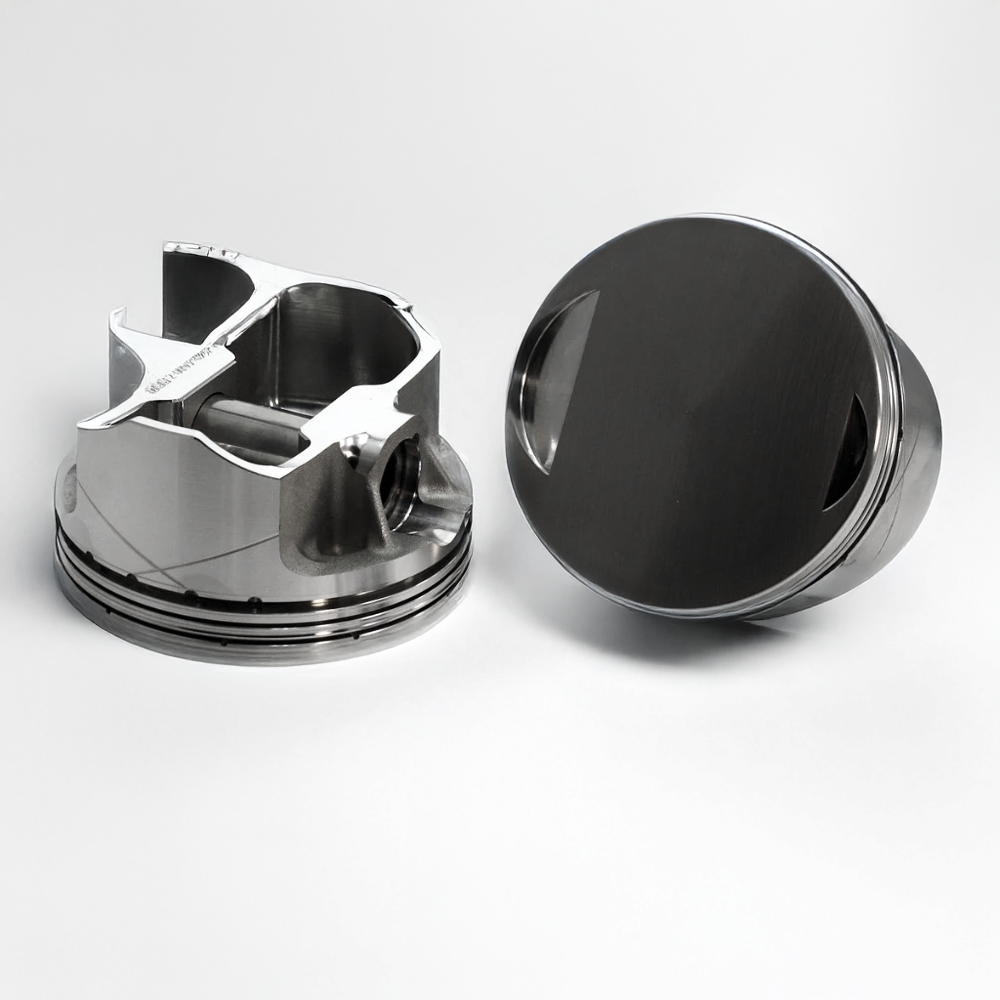

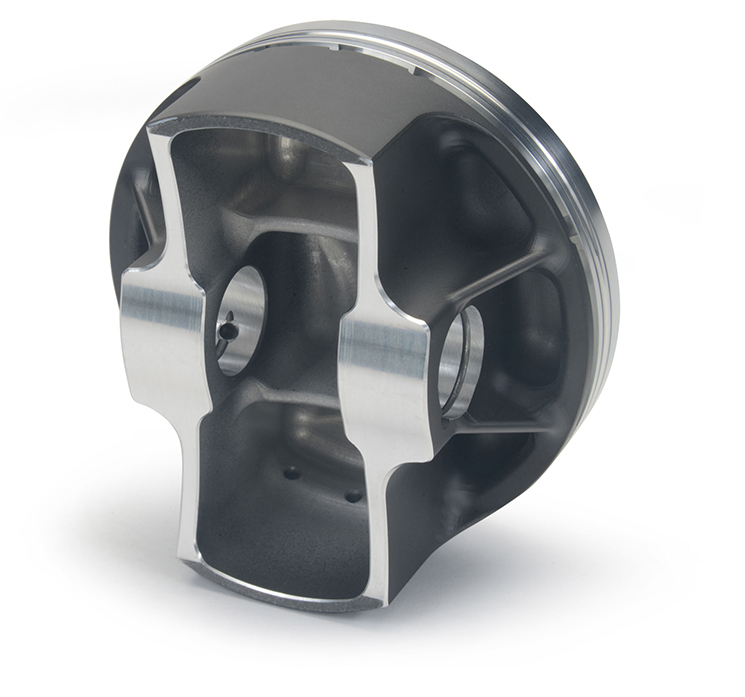

Adoption of Advanced Materials and Coatings

Material innovation is a cornerstone of 2026’s custom piston trends. High-strength, lightweight alloys such as 2618 and 4032 aluminum are becoming standard in performance builds, offering improved thermal stability and fatigue resistance. Furthermore, advancements in thermal barrier coatings (e.g., plasma-sprayed zirconia) and low-friction skirt coatings (like polymer-based anti-scuff layers) are enhancing piston longevity and engine efficiency. By 2026, manufacturers will increasingly integrate these technologies to meet the demands of forced-induction and high-compression engines.

Growth in Aftermarket and DIY Engine Building

The aftermarket performance sector is expanding, supported by a growing community of DIY engine builders and tuners. Online platforms, social media, and accessible tuning software have empowered consumers to customize their vehicles more than ever. This trend is driving demand for modular, application-specific custom pistons that support various engine displacements, compression ratios, and fuel types. By 2026, expect to see more customization options offered directly through e-commerce platforms, including AI-driven piston selection tools and virtual engine simulation integration.

Sustainability and Emissions Compliance Influence

Environmental regulations are indirectly shaping the custom piston market. While emissions standards primarily affect OEMs, the need for cleaner-burning, efficient internal combustion engines is trickling into the aftermarket. Custom piston designers are responding by optimizing piston crown geometry for better combustion efficiency and compatibility with alternative fuels like E85 and methanol. In regions with strict emissions testing, low-emission performance builds will favor custom pistons designed to work seamlessly with modern engine management systems.

Regional Market Dynamics

North America and Europe are expected to dominate the custom pistons market in 2026, driven by strong motorsports cultures and mature aftermarket ecosystems. Meanwhile, the Asia-Pacific region—particularly China, Japan, and India—is witnessing rapid growth in performance vehicle ownership and tuning communities. Local manufacturers are beginning to offer high-quality custom pistons at competitive prices, increasing global market competition and spurring innovation.

Integration with Digital Design and Manufacturing

By 2026, digital transformation will play a critical role in custom piston production. Computer-aided design (CAD), finite element analysis (FEA), and rapid prototyping via 3D printing are streamlining development cycles. CNC machining and automated forging lines enable faster turnaround for low-volume, high-precision orders. Additionally, blockchain-enabled supply chains and digital twins may enhance traceability and quality assurance, appealing to high-end clients in motorsports and aviation sectors.

Conclusion

The 2026 custom pistons market will be defined by technological advancement, performance optimization, and increasing accessibility. As engine builders demand greater precision, durability, and compatibility with evolving fuel and emissions standards, custom piston manufacturers must innovate continuously. Those who embrace digital manufacturing, sustainable practices, and customer-centric design will lead the next wave of growth in this dynamic niche.

Common Pitfalls Sourcing Custom Pistons: Quality and Intellectual Property Risks

Sourcing custom pistons—especially for high-performance, industrial, or specialized applications—introduces unique challenges. Two critical areas where companies often encounter pitfalls are quality control and intellectual property (IP) protection. Overlooking these can lead to operational failures, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inadequate Material Specifications

A frequent issue is failing to define precise material grades, tolerances, and surface finishes in technical documentation. Suppliers may use lower-grade alloys or substandard heat treatments if specifications are vague, resulting in premature wear, cracking, or engine failure under stress.

Lack of Rigorous Quality Assurance Processes

Not all manufacturers adhere to consistent quality standards. Sourcing from suppliers without certified quality management systems (e.g., ISO 9001) or without in-house testing capabilities (e.g., non-destructive testing, dimensional inspection) increases the risk of receiving defective or non-compliant pistons.

Insufficient Prototype and Validation Testing

Bypassing thorough performance testing—such as thermal cycling, fatigue analysis, or fit checks—can lead to undetected design flaws. Relying solely on design specs without real-world validation often results in field failures once the pistons are deployed.

Poor Communication on Manufacturing Tolerances

Custom pistons require tight tolerances for optimal performance. Miscommunication or lack of clarity on critical dimensions, crown geometry, or ring groove specs can lead to parts that don’t function as intended, causing inefficiencies or mechanical damage.

Intellectual Property-Related Pitfalls

Unprotected Design Documentation

Sharing detailed CAD models, blueprints, or engineering specifications without a signed Non-Disclosure Agreement (NDA) exposes your proprietary designs. Suppliers may replicate or resell your designs to competitors, especially in regions with weaker IP enforcement.

Ambiguous Ownership Clauses in Contracts

Failing to explicitly define IP ownership in sourcing agreements can result in disputes. Some suppliers may claim partial ownership of custom tooling or design iterations developed during production, limiting your ability to switch manufacturers or modify the design.

Risk of Reverse Engineering

Once a supplier manufactures your custom piston, they possess the physical part and potentially the know-how to reproduce it. Without contractual safeguards, they could reverse engineer and supply similar components to other clients, undermining your competitive advantage.

Inadequate Protection in Offshore Sourcing

Sourcing from low-cost regions may expose IP to higher risk, particularly where legal protections are less robust. Even with contracts, enforcement can be difficult and costly, making it essential to vet suppliers carefully and consider local IP laws.

Mitigation Strategies

- Require detailed technical specifications and material certifications.

- Audit suppliers’ quality systems and request sample test reports.

- Conduct third-party validation of prototypes before mass production.

- Use legally reviewed NDAs and clearly define IP ownership in contracts.

- Limit design data shared to only what’s necessary for manufacturing.

- Consider patenting unique piston designs or features where applicable.

By proactively addressing these quality and IP pitfalls, companies can safeguard performance, protect innovation, and build reliable supply chains for custom piston solutions.

Logistics & Compliance Guide for Custom Pistons

This guide outlines essential logistics and compliance considerations when manufacturing, shipping, and receiving custom pistons. Adhering to these standards ensures operational efficiency, regulatory adherence, and customer satisfaction.

Product Classification & Specifications

Custom pistons are typically classified under HS Code 8409.91 (Parts suitable for use solely or principally with internal combustion piston engines). Accurate classification ensures correct tariff application and avoids customs delays. Detailed specifications—including material (e.g., forged aluminum, cast iron), dimensions, weight, compression ratio, and OEM compatibility—must be documented and shared with logistics partners and customs authorities.

International Shipping Requirements

When shipping custom pistons internationally, proper packaging is critical to prevent damage during transit. Use anti-corrosion wrapping, rigid containers, and cushioning materials. All shipments require a commercial invoice, packing list, and bill of lading or air waybill. For exports from the U.S., compliance with the Export Administration Regulations (EAR) may apply; verify if pistons require an export license based on destination and end-use.

Import Compliance

Importers must verify country-specific regulations. In the EU, REACH and RoHS compliance may be required if hazardous substances are present in coatings or materials. In Canada, adherence to the Customs Act and accurate reporting via the CBSA’s electronic data interchange (EDI) system is mandatory. Always include a certificate of origin to qualify for preferential tariffs under trade agreements such as USMCA or CETA.

Documentation & Recordkeeping

Maintain comprehensive records for a minimum of five years, including:

– Technical drawings and material certifications

– Test reports (e.g., pressure, fatigue)

– Certificates of conformity

– Shipping and customs documentation

These records support audit readiness and demonstrate due diligence in compliance.

Environmental & Safety Regulations

Properly label and handle pistons treated with lubricants or coatings that may be subject to hazardous material regulations (e.g., IATA for air freight, IMDG for sea). Waste generated during manufacturing must be managed in compliance with local environmental laws (e.g., EPA regulations in the U.S.).

Quality Standards & Certifications

Adhere to industry standards such as ISO 9001 for quality management and ISO/TS 16949 for automotive components. Provide customers with certification upon request to validate manufacturing consistency and reliability.

Returns & Reverse Logistics

Establish a clear process for handling returns due to defects or incorrect specifications. Include return authorization (RMA) procedures, inspection protocols, and disposition options (repair, replace, scrap). Ensure compliance with import rules when receiving returned international shipments.

Regulatory Monitoring

Stay informed about changes in trade policies, sanctions, and customs procedures. Subscribe to updates from relevant agencies (e.g., U.S. CBP, EU Commission, Transport Canada) and participate in trusted trader programs (e.g., C-TPAT, AEO) to streamline cross-border movements.

By following this guide, businesses involved in the custom piston supply chain can ensure smooth operations, minimize risks, and maintain compliance across global markets.

In conclusion, sourcing custom pistons requires careful consideration of performance requirements, material selection, manufacturing precision, and supplier reliability. Whether for high-performance engines, racing applications, or specialized industrial machinery, custom pistons must be engineered to exact specifications to ensure optimal efficiency, durability, and compatibility with the existing system. Engaging with experienced manufacturers, validating design through simulation or prototyping, and confirming quality control processes are essential steps in the procurement process. Ultimately, investing time and resources into selecting the right custom piston solution leads to improved engine performance, longevity, and overall system reliability.