The global aftermarket automotive parts market, which includes custom pickup tool boxes, is experiencing robust growth driven by increasing demand for utility-focused vehicle modifications among tradespeople, outdoor enthusiasts, and fleet operators. According to Grand View Research, the global automotive aftermarket parts market was valued at USD 563.5 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. A key contributor to this trend is the rising popularity of light-duty trucks in North America, where customization for enhanced functionality is a priority. Mordor Intelligence further highlights that the North American automotive aftermarket is expected to grow at over 6% CAGR, fueled by strong consumer preference for durable, specialized accessories like custom tool boxes. As demand for secure, weather-resistant, and ergonomic storage solutions grows, manufacturers are innovating with advanced materials, modular designs, and tailored fits. In this competitive landscape, a select group of top-tier custom pickup tool box manufacturers are leading the way through quality, customization, and performance—shaping the future of mobile worksite efficiency.

Top 10 Custom Pickup Tool Boxes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 UWS: Truck Tool Boxes

Domain Est. 1997

Website: uwsta.com

Key Highlights: UWS is a leading US manufacturer of truck tool boxes, utility storage chests and truck accessories. Our products are engineered to be tough and reliable….

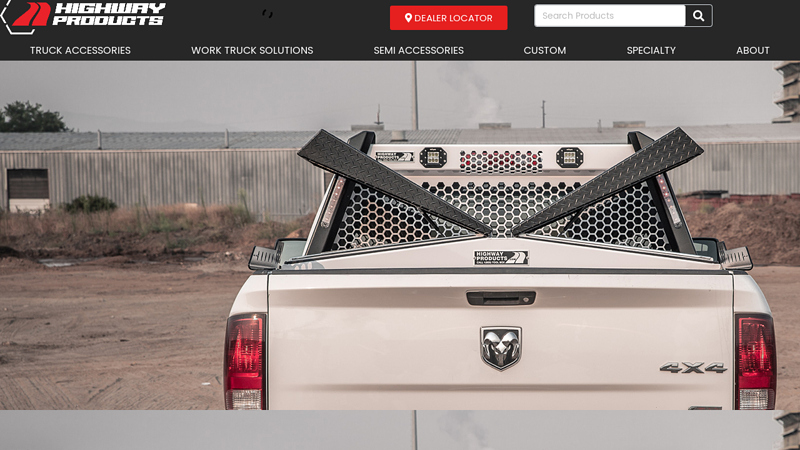

#2 Custom Truck Tool Boxes

Domain Est. 1996

Website: highwayproducts.com

Key Highlights: Highway Products has been customizing toolboxes for over 40 years. Whether you are looking for specialty powder coats to dimensional changes we have you covered ……

#3 Truck Boxes

Domain Est. 1996

Website: weatherguard.com

Key Highlights: Offering the best in security, nothing is getting into a WEATHER GUARD® truck tool box….

#4 Truck Tool Boxes

Domain Est. 1997

Website: buyersproducts.com

Key Highlights: Durable truck tool boxes made in the USA. Find underbody, crossover, gullwing, backpack, trailer tongue boxes, and more….

#5 DECKED Truck Bed Storage, Tool Boxes & Truck Accessories

Domain Est. 1998

Website: decked.com

Key Highlights: Free delivery · 30-day returnsDECKED truck bed tool boxes and cargo van storage systems revolutionize organization with a heavy-duty in-vehicle storage system featuring slide out …

#6 RC Industries

Domain Est. 1999

Website: rctoolbox.com

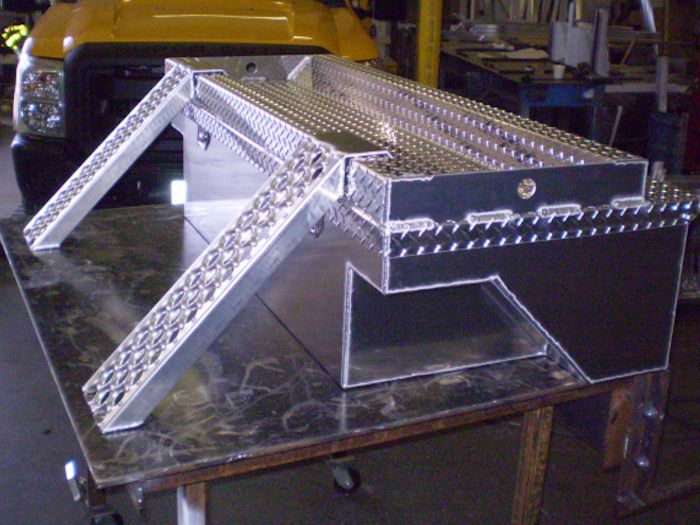

Key Highlights: American-made and highest quality custom toolboxes, truck tool boxes and advanced custom metal fabrication. Call (574) 295-6641….

#7 Truck toolboxes and Accessories

Domain Est. 2001

Website: customtoolboxes.com

Key Highlights: Truck toolboxes and Accessories – K&W carries a full line of standard toolboxes and accessories; we also build custom items to your specifications….

#8 Trebor Manufacturing: Semi

Domain Est. 2002

Website: trebormanufacturing.com

Key Highlights: All our semi-truck tool boxes have multiple custom options and come in any custom sizes. You can even draw the truck box you have in mind and we will build it ……

#9 Service Truck Toolbox Systems

Domain Est. 2003

Website: stellarindustries.com

Key Highlights: Stellar’s full line of custom-made service truck tool storage systems (formerly American Eagle branded) are the most rugged and dependable products available….

#10 BoxoUSA Professional Tool Solutions

Domain Est. 2017

Expert Sourcing Insights for Custom Pickup Tool Boxes

H2: 2026 Market Trends for Custom Pickup Tool Boxes

The custom pickup tool box market is poised for notable transformation and growth by 2026, driven by evolving consumer demands, technological advancements, and shifting industry priorities. Below is an analysis of key trends expected to shape the market during this period.

-

Increased Demand for Customization and Personalization

By 2026, consumers and commercial users alike will increasingly seek highly customized tool storage solutions. Custom pickup tool boxes will move beyond basic sizes and colors to include personalized compartments, branding options, smart integration, and modular designs. This trend is fueled by the growing preference for utility vehicles in both professional trades (e.g., construction, electrical, plumbing) and lifestyle use (e.g., off-roading, camping). -

Growth in Lightweight, Durable Materials

Manufacturers are shifting toward advanced materials such as high-strength composites, aluminum alloys, and reinforced polymers. These materials offer superior durability while reducing overall vehicle weight—improving fuel efficiency and payload capacity. By 2026, tool boxes made from sustainable and corrosion-resistant materials will dominate the premium segment. -

Integration of Smart Technology

Smart features are expected to become a differentiating factor. By 2026, custom tool boxes may include GPS tracking, Bluetooth-enabled locks, inventory management sensors, and integration with mobile apps. These technologies enhance security, improve job site efficiency, and appeal to tech-savvy professionals. -

Expansion of E-Commerce and Direct-to-Consumer Sales

Online platforms will play a pivotal role in the distribution of custom tool boxes. Consumers will increasingly use digital configurators to design and order personalized tool boxes, with manufacturers leveraging 3D modeling and AI-driven recommendations. This shift enables faster delivery, lower costs, and broader geographic reach. -

Focus on Aesthetic Integration and Vehicle Styling

Custom tool boxes will increasingly be designed to complement the aesthetics of modern pickup trucks. OEM-like finishes, color-matched exteriors, and aerodynamic designs will appeal to lifestyle buyers who value both form and function. This trend is amplified by the rise of lifestyle-focused truck models (e.g., Ford Raptor, Chevrolet Silverado ZR2). -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns will push manufacturers to adopt greener production methods. Recyclable materials, low-VOC coatings, and energy-efficient manufacturing processes will become standard by 2026. Brands emphasizing sustainability will gain competitive advantage, especially among younger and environmentally conscious buyers. -

Rising Influence of Commercial Fleets and Government Contracts

Fleet operators and government agencies will drive demand for standardized yet customizable tool storage solutions. These sectors prioritize durability, security, and compliance with safety regulations. Custom tool box providers that offer volume pricing, modular configurations, and certification support will capture significant market share. -

Geographic Market Expansion

While North America remains the largest market, growth is expected in Latin America, the Middle East, and parts of Asia-Pacific due to rising construction activity and infrastructure development. Localized designs that cater to regional climates and usage patterns will be key to success.

In conclusion, the 2026 custom pickup tool box market will be characterized by innovation, personalization, and technological integration. Companies that invest in smart design, sustainable practices, and digital customer engagement will lead the industry in meeting the diverse needs of both professional and recreational users.

Common Pitfalls When Sourcing Custom Pickup Tool Boxes (Quality, IP)

Sourcing custom pickup tool boxes offers significant benefits in terms of functionality and branding, but it also comes with critical risks—particularly around quality and intellectual property (IP). Failing to address these pitfalls can lead to costly delays, legal issues, and damaged reputations.

Quality Inconsistencies and Defects

One of the most frequent challenges is receiving tool boxes that do not meet specified quality standards. This often stems from poor material selection, subpar welding, or inadequate finishing. Suppliers, especially overseas manufacturers, may use lower-grade steel or aluminum to cut costs, leading to reduced durability and corrosion resistance. Inconsistent craftsmanship can result in misaligned lids, faulty latches, or weak structural integrity—issues that compromise both safety and performance in rugged environments.

To mitigate this, it’s essential to define detailed quality specifications upfront, conduct pre-production samples, and perform third-party inspections during or after manufacturing. Skipping these steps increases the risk of receiving a high-volume shipment of defective units.

Lack of Intellectual Property Protection

Custom tool boxes often incorporate unique designs, proprietary configurations, or branded elements that represent significant investment in R&D and branding. When sourcing from third-party manufacturers—particularly in regions with weaker IP enforcement—there is a real risk that your design could be copied or sold to competitors. Without proper legal safeguards, the supplier may replicate your design for other customers or even market it as their own.

To protect your IP, always execute a comprehensive Non-Disclosure Agreement (NDA) and include clear IP ownership clauses in the manufacturing contract. Consider filing for design patents or trademarks where applicable, and avoid sharing full design files until legal protections are in place. Additionally, work with suppliers who have a proven track record of respecting IP rights.

Inadequate Communication and Specification Misalignment

Misunderstandings during the design and production process can lead to final products that deviate from expectations. This includes dimensional inaccuracies, incorrect mounting configurations, or finishes that don’t match samples. Poor communication often results from vague technical drawings, language barriers, or lack of engineering oversight.

Ensure that all specifications—including CAD drawings, material grades, weld types, and surface treatments—are documented and confirmed in writing. Regular communication and milestone reviews with the supplier can catch discrepancies early.

Supply Chain and Lead Time Risks

Custom tool boxes typically involve longer lead times due to the need for tooling, fabrication, and finishing. Delays can occur if the supplier lacks capacity, encounters material shortages, or fails to manage sub-tier suppliers effectively. Unplanned delays can disrupt inventory planning and customer delivery schedules.

To reduce risk, vet suppliers for production capacity and supply chain reliability. Build buffer time into your schedule and consider dual sourcing for critical components.

Hidden Costs and Pricing Transparency

While initial quotes may appear competitive, additional costs can emerge from tooling charges, shipping, import duties, or minimum order quantity (MOQ) requirements. Some suppliers may also charge extra for design revisions or quality checks not clearly outlined in the contract.

Request a detailed breakdown of all costs upfront and confirm pricing terms in writing. Be wary of quotes that seem too good to be true—they may signal cost-cutting that compromises quality or IP safety.

By proactively addressing these pitfalls, businesses can successfully source high-quality, IP-protected custom pickup tool boxes that meet both performance and compliance standards.

Logistics & Compliance Guide for Custom Pickup Tool Boxes

Overview

Custom pickup tool boxes are specialized cargo storage solutions designed for pickup trucks. They serve industries such as construction, utilities, emergency services, and landscaping. Due to their customized nature and use in transportation, proper logistics planning and compliance with regulatory standards are essential. This guide outlines key logistics considerations and regulatory compliance requirements for manufacturing, shipping, and using custom pickup tool boxes.

Manufacturing & Design Compliance

Ensure all custom tool boxes are designed and built in accordance with applicable standards:

– Material Standards: Use corrosion-resistant materials (e.g., aluminum, steel with powder coating) compliant with ASTM or SAE standards.

– Structural Integrity: Design must meet load-bearing and vibration resistance standards per OEM truck specifications.

– Electrical Components (if applicable): Any installed lighting or power systems must comply with SAE J560 (for trailers) or FMVSS No. 108 (lighting).

– Customization Documentation: Maintain records of design specifications, material sourcing, and customization details for traceability.

Packaging & Handling

Proper packaging ensures safe transit and prevents damage:

– Use wooden crating or heavy-duty pallets with corner protectors for large or custom units.

– Secure hinges, latches, and drawers with temporary fasteners to prevent movement during shipping.

– Label packages with “Fragile,” “This Side Up,” and handling instructions.

– Include protective film on painted or polished surfaces to prevent scratches.

Domestic & International Shipping

Follow best practices for transporting custom tool boxes:

– Domestic (U.S.):

– Comply with Department of Transportation (DOT) regulations for freight classification (typically NMFC 157000 for tool boxes).

– Use freight carriers experienced in handling oversized or heavy cargo.

– Ensure accurate weight and dimensions are provided to avoid reclassification fees.

– International:

– Adhere to International Safe Transit Association (ISTA) standards for packaging.

– Provide commercial invoice, packing list, and bill of lading.

– Comply with ISPM 15 regulations if using wooden packaging (heat-treated and stamped).

– Verify customs classification (HS Code: typically 7326.90 for metal tool storage).

Import/Export Compliance

For cross-border movement:

– Confirm eligibility under trade agreements (e.g., USMCA for North America).

– Ensure product does not contain restricted substances (e.g., lead, cadmium) per RoHS or REACH, if applicable.

– Declare country of origin accurately on all shipping documents.

– Register with the Automated Commercial Environment (ACE) if shipping into the U.S.

Installation & Vehicle Integration

Proper installation is critical for safety and compliance:

– Follow OEM truck manufacturer guidelines for mounting systems (e.g., bed rail compatibility).

– Ensure tool boxes do not obstruct driver visibility or interfere with tailgate operation.

– Use certified hardware (grade 5 or higher bolts) and torque to specified values.

– If drilling into the truck bed, follow corrosion protection protocols (e.g., sealant application).

Safety & Regulatory Standards

Adhere to relevant safety regulations:

– DOT & FMVSS: Tool boxes must not interfere with required vehicle safety systems or obstruct lights.

– Occupational Safety (OSHA): In workplace settings, ensure boxes are secured to prevent shifting during transport, minimizing risk of injury.

– Fire Safety: Store flammable materials (e.g., solvents, fuels) only in approved, ventilated, and labeled containers within fire-rated compartments, if applicable.

Environmental & Sustainability Compliance

- Recycle scrap metal and packaging materials in accordance with local environmental regulations.

- Offer end-of-life take-back or recycling programs where feasible.

- Comply with EPA guidelines for finishes and coatings (e.g., low-VOC paints).

Documentation & Recordkeeping

Maintain comprehensive records for compliance and traceability:

– Product specifications and compliance certifications (e.g., material test reports).

– Shipping and customs documentation for 5+ years.

– Customer installation instructions and safety warnings.

– Warranty and service records.

Conclusion

Successful logistics and compliance for custom pickup tool boxes require attention to design standards, safe handling, regulatory requirements, and documentation. By following this guide, manufacturers, distributors, and users can ensure product integrity, legal compliance, and operational safety across the supply chain.

Conclusion: Sourcing Custom Pickup Tool Boxes

Sourcing custom pickup tool boxes requires a strategic approach that balances quality, cost, customization capabilities, and long-term reliability. After evaluating various suppliers, materials, manufacturing methods, and customization options, it is evident that selecting the right vendor involves more than just pricing—it encompasses durability, design flexibility, lead times, and after-sales support.

Custom tool boxes tailored to specific vehicle models and user requirements enhance organization, security, and job-site efficiency for professionals across industries such as construction, utilities, and field services. Investing in high-quality, custom-fit solutions from reputable manufacturers ensures longevity, improves brand image, and meets specific functional needs.

Ultimately, the ideal sourcing decision integrates comprehensive supplier vetting, clear communication of customization needs, and consideration of total cost of ownership. By prioritizing partnerships with experienced and responsive manufacturers, businesses can secure durable, purpose-built tool storage solutions that deliver lasting value and operational advantages.